Abstract

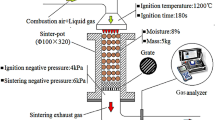

Process control is an effective approach to reduce the NOx emission from sintering flue gas. The effects of different materials adhered on coke breeze on NOx emission characteristics and sintering performance were studied. Results showed that the coke breeze adhered with the mixture of CaO and Fe2O3 or calcium ferrite significantly lowers the NOx emission concentration and conversion ratio of fuel-N to NOx. Pretreating the coke with the mixture of lime slurry and iron ore fines helped to improve the granulation effect, and optimize the carbon distribution in granules. When the mass ratio of coke breeze, quick lime, water and iron ore fines was 2:1:1:1, the average NOx emission concentration was decreased from 220 mg/m3 to 166 mg/m3, and the conversion ratio of fuel-N was reduced from 54.2% to 40.9%.

摘要

过程控制是降低烧结烟气NOx 排放的有效途径。研究了焦粉粘附不同物质时对NOx 排放和烧结 指标的影响。结果表明,当焦粉粘附CaO 和Fe2O3 的混合物或者铁酸钙时能减少燃料氮向NOx 的转化 从而降低NOx 排放浓度。用石灰浆和铁矿粉的混合物对焦粉进行预处理,有助于改善制粒效果,优化 制粒小球中的碳分布。当焦粉、生石灰、水、铁矿粉以质量比2:1:1:1 进行混合预处理后参与烧 结,NOx 平均排放浓度可由220 mg/m3 降至166 mg/m3, 燃料氮转化率可由54.2%降至40.9%。

Similar content being viewed by others

References

ZHAO Jia-pei, LOO Chin-eng, YUANG Jin-liang, WANG Fu, WANG Jia-tang, ZHANG Hou-cheng, MIAO He. A fundamental study of the co-combustion of coke and charcoal during iron ore sintering [J]. Energy & Fuels, 2018, 32(8): 8743–8759.

ZHU Ting-yu. Technology of sintering flue gas purification [M]. Beijing: Chemical Industry Press, 2009: 1–10. (in Chinese)

The Ministry of Ecology and Environment of the People’s Republic of China. Bulletin of “Emission standard of air pollutants during sintering and pelletizing of iron and steel industry”[EB/OL]. http://www.mee.gov.cn/xxgk2018/xxgk/xxgk03/201904/t20190429_701463.html. (in Chinese)

GAN Min, FAN Xiao-hui, JIANG Tao, CHEN Xu-ling, YU Zhi-yuan, JI Zhi-yun. Fundamental study on iron ore sintering new process of flue gas recirculation together with using biochar as fuel [J]. Journal of Central South University, 2014, 21(11): 4109–4114.

ZANDI M, MARTINEZ-PACHECO M, FRAY T. Biomass for iron ore sintering [J]. Minerals Engineering, 2010, 23(14): 1139–1145.

GAN Min, FAN Xiao-hui, CHEN Xu-ling, JI Zhi-yun, LV Wei, WANG Yi, YU Zhi-yuan, JIANG Tao. Reduction of pollutant emission in iron ore sintering process by applying biomass fuels [J]. Isij International, 2012, 52(9): 1580–1584.

LI Jun-jie, WEI Jin-chao, LIU Chang-qi. Combined desulfurization, denitrification and reduction of air toxics using activated coke [J]. Sintering and Pelletizing, 2017, 40(3): 79–85. (in Chinese)

YU Zhi-yuan, FAN Xiao-hui, GAN Min, CHEN Xu-ling. Effect of Ca-Fe oxides additives on NOx reduction in iron ore sintering [J]. Journal of Iron and Steel Research International, 2017, 24(12): 1184–1189.

GAN Min, LI Qiang, JI Zhi-yun, FAN Xiao-hui, LV Wei, CHEN Xu-ling, TIAN Ye, JIANG Tao. Influence of surface modification on combustion characteristics of charcoal and its performance on emissions reduction in iron ore sintering [J]. Isij International, 2017, 57(3): 420–428.

PEI Yuan-dong, ZHANG Si-bin, WU Sheng-li, SHI Jiang-shan, FAN Zheng-yun, ZHAO Zhi-xing, YIN You-hao. Sintering surface spraying steam to reduce NOx and dioxin emissions in Shougang [M]// Minerals, Metals and Materials Series. 2018: 53–58.

MO C L, TEO C S, HAMILTON I, MORRISON J. Adding hydrocarbons in raw mix to reduce emission ground to iron ore sintering process [J]. ISIJ, 1997, 37(4): 350–357.

IWAMI Y, YAMAMOTO T, OYAMA N, MATSUNO H, SAITO N, NAKASHIMA K. Improvement of sinter productivity by control of magnetite ore segregation in sintering bed [J]. Isij International, 2018, 58(12): 2200–2209.

KATAYAMA, K, KASAMA S. Influence of lime coating coke on NOx concentration in sintering process [J]. Isij International, 2016, 56(9): 1563–1569.

GAN Min, FAN Xiao-hui, LV Wei, CHEN Xu-ling, JI Zhi-yun, ZHOU Yang. Fuel pre-granulation for reducing NOx emissions from the iron ore sintering process [J]. Powder Technology, 2016, 301: 478–485.

MAO Xiao-ming, YOU Zhi-xiong, ZHANG Yuan-bo, FAN Zhen-yu, LI Guang-hui, JIANG Tao. Calcium ferrite formation characteristic during iron ore sintering with different oxygen atmospheres [J]. Journal of Central South University, 2014, 21(8): 3043–3048.

QIE Jun-mao, ZHANG Chun-xia, WANG Hai-feng, GUO Yu-hua, WU Sheng-li. Investigation of a granule structure that focused on reducing NOx emissions in sintering process [J]. Metallurgical Research & Technology, 2019, 116(3): 315–322.

WONG Guo-jing, FAN Xiao-hui, GAN Min, JI Zhi-yun, CHEN Xu-ling, TIAN Zhi-yuan, WANG Zhuang-zhuang. Improvement on the thermal cracking performance of pellets prepared from ultrafine iron ore [J]. Powder Technology, 2019, 342: 873–879.

LI Song, CHEN Zhi-chao, HE Erdemtu, JIANG Bing-kun, LI Zheng-qi, WANG Qing-xiang. Combustion characteristics and NOx formation of a retrofitted low-volatile coal-fired 330 Mw utility boilers under various loads with deep-air-staging [J]. Applied Thermal Engineering, 2017, 110: 223–233.

LV Wei, FAN Xiao-hui, GAN Min, CHEN Xu-ling, JI Zhi-yun. Formation of nitrogen mono oxide (NO) during iron ore sintering process [J]. Isij International, 2018, 58: 236–243.

KENJI T. NOx emission profile determined by in-situ gas monitoring of iron ore sintering during packed-bed coke combustion [J]. Fuel, 2019, 236: 244–250.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2017YFC0210302) supported by the National Key R&D Program of China; Projects(U1660206, U1760107) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Wang, Zc., Zhou, Za., Gan, M. et al. Process control technology of low NOx sintering based on coke pretreatment. J. Cent. South Univ. 27, 469–477 (2020). https://doi.org/10.1007/s11771-020-4309-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4309-y