Abstract

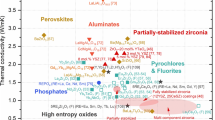

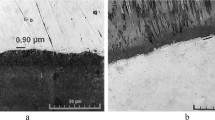

In application as a thermal barrier coating (TBC), partially stabilized zirconia (Zr) approaches some limits of performance. To further enhance the efficiency of gas turbines, higher temperature capability and a longer lifetime of the coating are needed for the next generation of TBCs. This paper presents the development of new materials and concepts for application as TBC. Materials whose compositions have the pyrochlore structure or doped Zr are presented in contrast with new concepts like nanolayers between the top and bond coat, metal-glass composites, and double-layer structures. In the last concept, the new compositions are used in a combination with Zr, as a double, multi, or graded layer coating. In this case, the benefits of Zr will be combined with the promising properties of the new top coating. In the case of metal-glass composites, the paper will be focused on the influences of different plasma spraying processes on the microstructure. The performance of all these different coating systems has been evaluated by burner rig tests. The results will be presented and discussed.

Similar content being viewed by others

References

W.A. Nelson and R.M. Orenstein: “TBC Experience in Land-Based Gas Turbines,” J. Therm. Spray Technol., 1997, 6(2), pp. 176–80.

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit: “Mechanisms Controlling the Durability of Thermal Barrier Coatings,” Prog. Mater. Sci., 2001, 46, pp. 505–53.

N.P. Padture, M. Gell, and E.H. Jordan: “Thermal Barrier Coatings for Gas-Turbine Engine Application,” Science, 2002, 296, pp. 280–84.

S. Stecura: “Two-Layer Thermal Barrier Coating for Turbine Airfoils—Furnace and Burner Rig Test Results,” NASA TM X-3425. National Aeronautics and Space Administration, Lewis Research Center, Cleveland, OH, 1976.

S. Stecura: “Two Layer Thermal Barrier Coating for High Temperature Components,” Am. Ceram. Soc. Bull., 1977, 56, pp. 1082–85.

R.A. Miller: “Current Status of Thermal Barrier Coatings—an Overview,” Surf. Coat Technol., 1987, 30, pp. 1–11.

R.J. Bratton and S.K. Lau: “Zirconia Thermal Barrier Coatings” in Advances in Ceramics, 3, Science and Technology of Zirconia, A.H. Heuer and L.W. Hobbs, ed., The American Ceramic Society, Westerville, OH, 1981, pp. 226–53.

R.L. Jones, R.F. Reidy, and D. Mess: “Scandia, Yttria Stabilized Zirconia for Thermal Barrier Coatings,” Surf. Technol., 1996, 82, pp. 70–76.

R.L. Jones and D. Mess: “Improved Tetragonal Phase Stability at 1400 °C With Scandia, Yttria-Stabilized Sirconia,” Surf. Technol., 1996, 86–87, pp. 94–101.

P.D. Harmsworth and R. Stevens: “Microstructure and Phase Composition of ZrO2-CeO2 Thermal Barrier Coatings,” J. Mater. Sci., 1991, 26, pp. 3991–95.

D-J. Kim: “Effect of Ta2O5, Nb2O5, and HfO2 Alloying on the Transformability of Y2O3-Stabilized Tetragonal ZrO2,” J. Am. Ceram. Soc., 1990, 73(1), pp. 115–20.

S. Raghavan, H. Wang, W.D. Porter, R.B. Dinwiddie, and M.J. Mayo: “Thermal Properties of Zirconia Co-Doped with Trivalent and Pentavalent Oxides,” Acta Mater., 2001, 49, pp. 169–79.

S. Raghavan, H. Wang, R.B. Dinwiddie, W.D. Porter, R. Vaßen, D. Stöver, and M. J. Mayo: “Ta2O5 / Nb2O5 and Y2O3 Co-Doped Zirconias for Thermal Barrier Coatings,” J. Amer. Ceram. Soc. (submitted).

R.A. Miller: “Thermal Barrier Coatings of Aircraft Engines: History and Directions,” J. Therm. Spray Technol., 1997, 6(1), pp. 35–42.

D. Zhu and R.A. Miller: “Sintering and Creep Behaviour of Plasma-Sprayed Zirconia and Hafnia-Based Thermal Barrier Coatings,” Surf Coatings Technol., 1998, 108–109, pp. 114–20.

R. Vaßen, N. Czech, W. Malléner, W. Stamm, and D. Stöver: “Influence of Impurity Content and Porosity of Plasma Sprayed Yttria Stabilised Zirconia Layers on the Sintering Behaviour,” Surf. Coat. Technol., 2001, 141, pp. 135–40.

R. Vassen, X. Cao, F. Tietz, D. Basu, and D. Stöver: “Zirconates as New Materials for Thermal Barrier Coatings,” J. Am. Ceram. Soc., 1999, 83(8), pp. 2023–28.

R. Vaßen, F. Tietz, G. Kerkhoff, R. Wilkenhöner, and D. Stöver: “New Materials for Advanced Thermal Barrier Coatings” in Proceedings of the 6th Liége Conference, Part III, Materials for Advanced Power Engineering, J. Lecomte-Beckers, F. Schubert, and P. J. Ennis, ed., Forschungszentrum Jülich GmbH, Jülich, Germany, 1998, pp. 1627–35.

U. Bast and E. Schumann: “Develoment of Novel Oxide Materials for TBCs” in Ceramic Engineering and Science Proceedings, 26th Annual Conference Cocoa Beach, H.-T. Lin and M. Singh, ed., The American Ceramic Society, Westerville, OH, 2002, 23(4), pp. 525–32.

J.E. Parrott and D. Stuckes, Thermal Conductivity of Solids, Pion Limited, London, UK, 1975.

R. Berman, Thermal Conduction in Solids, Clarendon Press, Oxford, UK, 1976.

P.G. Klemens: “Theory of the Thermal Conductivity of Solids,” in Thermal Conductivity, Vol. 1, R.P. Tye, ed., Academic Press, London and New York, 1969.

H. Lehmann, D. Pitzer, G. Pracht, R. Vaßen, and D. Stöver: “Thermal Conductivity and Thermal Expansion Coefficients of the Lanthanum-Rare-Earth-Element-Zirconate System,” J. Am. Ceramic Soc., 2003, 86(8), pp. 1338–44.

R. Vaßen and D. Stöver: “Conventional and New Materials for Thermal Barrier Coatings” in Functional Gradient Materials and Surface Layers Prepared by Fine Particle Technology, NATO Science Series II: Mathematics, Physics and Chemistry, M.-I. Baraton and I. Uvarova, ed., Kluwer Acadmic Publishers, Dordrecht, The Netherlands, 2001, Vol. 16, pp. 199–216.

M.J. Maloney: “Thermal Barrier Coating Systems and Materials,” US Patent No. US 6,177,200 B1, 1998.

G.W. Schäfer and R. Gadow: “Lanthane Aluminate Thermal Barrier Coating” in Proceedings of the Annual Cocoa Beach Conference, The American Ceramic Society, Westerville, OH, 1999, pp. 291–97.

C.J. Friedrich, R. Gadow, and T. Schirmer: “Lanthane Aluminate—A New Material for Atmospheric Plasma Spraying of Advanced Thermal Barrier Coatings” in Proceedings ITSC 2000, Thermal Spray: Surface Engineering via Applied Research, C.C. Berndt, ed., ASM International, Materials Park, OH, 2000, pp. 1219–26.

R. Vaßen, X. Cao, and D. Stöver, “Improvement of New Thermal Barrier Coating Systems Using a Layered or Graded Structure” in 25th Annual Conference Cocoa Beach, Ceramic Engineering and Science Proceedings, M. Singh and T. Jessen, ed., The American Ceramic Society, Westerville, OH, 2001, pp. 435–42.

R. Vaßen, G. Barbezat, and D. Stöver: “Comparison of Thermal Cycling Life of YSZ and La2Zr2O7-Based Thermal Barrier Coatings,” Materials for Advanced Power Engineering, Schriften Forschungszentrum Jülich-Reihe Energietechnik, 2002, 21(1), pp. 511–21.

M. Dietrich, V. Verlotski, R. Vaßen, and D. Stöver: “Metal-Glass Based Composites for Novel TBC-Systems,” Materialwissenschaften und Werkstofftechnik, 2001, 8, pp. 669–72.

M. Dietrich, V. Verlotski, R. Vaßen, and D. Stöver: “Microstructure and Performance of New Metal Glass Composite TBC” in 26th Annual Conference Cocoa Beach, Ceramic Engineering and Science Proceedings, H.-T. Lin and M. Singh, ed., The American Ceramic Society, Westerville, OH, 2002, 23(4), pp. 449–56.

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit: “Mechanisms Controlling the Durability of Thermal Barrier Coatings,” Prog. Mater. Sci., 2001, 46, pp. 505–53.

V. Teixeira, M. Andritschky, W. Fischer, H.P. Buchkremer, and D. Stöver: “Analysis of Residual Stresses in Thermal Barrier Multilayered Coatings at High Temperature,” Nato ASI Ser., Ser. 3, 1998, 43, pp. 415–30.

V. Teixeira, M. Andritschky, W. Fischer, D. Stöver, and H.P. Buchkremer: “Residual Stress Analysis of Plasma Sprayed Thermal Barrier Coatings” in Thermal Spray: A United Forum for Scientific and Technological Advances, C.C. Berndt, ed., ASM International, Materials Park, OH, 1997, pp. 839–45.

H-S. Yang, G-R. Bai, L.J. Thompson, and J.A. Eastman: “Interfacial Thermal Resistance in Nanocrystalline Yttria-Stabilized Zirconia,” Acta Mater., 2002, 50, pp. 2309–17.

G. Soyez, J.A. Eastman, L.J. Thompson, R.J. DiMelfi, G-R. Baj, and P.M. Baldo: “Grain Size Dependent Thermal Conductivity of Nanocrystalline Yttria-Stabilized Zirconia Films Grown by Metal-Organic Chemical Vapor Deposition,” Appl. Phys. Lett., 2000, 77(8), pp. 1155–57.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stöver, D., Pracht, G., Lehmann, H. et al. New material concepts for the next generation of plasma-sprayed thermal barrier coatings. J Therm Spray Tech 13, 76–83 (2004). https://doi.org/10.1007/s11666-004-0052-4

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11666-004-0052-4