Abstract

Speciation of complex mixtures of trace explosives presents a formidable challenge for sensors that rely on chemoselective interfaces due to the unspecific nature of weak intermolecular interactions. Nanomechanical infrared (IR) spectroscopy provides higher selectivity in molecular detection without using chemoselective interfaces by measuring the photothermal effect of adsorbed molecules on a thermally sensitive microcantilever. In addition, unlike conventional IR spectroscopy, the detection sensitivity is drastically enhanced by increasing the IR laser power, since the photothermal signal comes from the absorption of IR photons and nonradiative decay processes. By using a broadly tunable quantum cascade laser for the resonant excitation of molecules, we increased the detection sensitivity by one order of magnitude compared to the use of a conventional IR monochromator. Here, we demonstrate the successful speciation and quantification of picogram levels of ternary mixtures of similar explosives (trinitrotoluene (TNT), cyclotrimethylene trinitramine (RDX) and pentaerythritol tetranitrate (PETN)) using nanomechanical IR spectroscopy.

Similar content being viewed by others

Introduction

Detection, speciation and quantification of extremely small concentrations of explosive vapors with high selectivity and sensitivity have immediate applications in many areas such as national security, forensics and humanitarian demining1. Microfabricated chemical sensors are being actively investigated as potential sensor platforms capable of mass deployment. Despite having many advantages such as miniature size, high sensitivity, low-cost and low power consumption, the microfabricated sensors suffer from poor chemical selectivity. Miniature sensors rely on adsorption-induced changes in physical variables such as adsorbed mass, surface stress, refractive index, resistance, capacitance and temperature which are sensitive indicators of molecular binding. Since the changes in physical properties due to molecular adsorption are not chemically specific, sensors are usually modified with receptors (chemical interfaces) which can provide selectivity. Immobilized chemoselective interfaces, however, can only provide partial selectivity due to the unspecific nature of chemical binding; especially those based on weak intermolecular interactions such as hydrogen bonding. The interference from other chemical vapors which cause unacceptable levels of false positives is a major challenge for all sensors based on analyte interactions with immobilized chemical interfaces. Therefore, achieving chemical selectivity in a mixture of unknown chemical vapors is extremely difficult without resorting to molecular separation. Even approaches based on sensor arrays immobilized with unique chemical interfaces and subsequent analysis of array response using pattern recognition algorithms fail when it comes to ternary mixtures2,3,4,5,6.

Adding to the challenge is the low vapor pressure of explosives, which severely limits the number of molecules reaching the sensor surface in an acceptable detection time which requires extremely high sensitivity. In addition, explosive vapors can be present with a variety of vapors in the sensing environment and this can interfere with the selectivity of detection. Therefore, an urgent need exists for developing techniques which are selective, sensitive and quantitative for different mixtures of explosive vapors. In order to be effective, the sensor must have the ability to differentiate between the explosive molecules and other similar compounds. For surface adsorption-based sensors, interfering chemicals which have a high vapor pressure, such as volatile organic compounds, do not cause interference since they do not adsorb well on the surface at room temperature7. However other materials with very low vapor pressure, such as different types of explosives, can cause challenges in selective detection and quantification.

Unlike sensing paradigms based on immobilized chemoselective interfaces on sensor surfaces, spectroscopic techniques based on unique molecular vibrational transitions in the mid infrared (IR) “molecular fingerprint” regime, where many molecules display characteristic vibrational peaks free from overtone, are highly selective8. Spectroscopic signal from a mixture of molecules follows the superposition principle, unless there are intermolecular interactions. This is different from sensing based on partially selective chemoselective interfaces, which fails in mixtures due to the lack of orthogonality in sensor responses. Although mid-IR absorption spectroscopy based chemical sensing offers high selectivity, it lacks sensitivity when used for detection of surface adsorbed chemicals.

Photothermal cantilever deflection spectroscopy (PCDS), which combines the extreme thermal sensitivity of a bi-material microcantilever with the high selectivity of mid-IR spectroscopy, is capable of obtaining molecular signatures of trace amounts of adsorbed molecules on the cantilever surface9,10,11,12,13,14,15. In the PCDS technique, the target molecules are first allowed to adsorb on a bi-material cantilever. During resonant excitation of target molecules using IR light, the bi-material cantilever undergoes deflection, the amplitude of cantilever deflection as a function of IR wavelength resembles the infrared absorption spectra of the adsorbed molecules. Unlike conventional IR absorption spectroscopy, in which a small intensity change is collected by cryogenically cooled mid-IR detectors in a large background with inherent laser source noise, PCDS, an “action spectroscopy”, measures the photothermal effect of a small number of adsorbed molecules with a high photon flux taking full advantage of the high brightness of a quantum cascade laser (QCL) light source. Therefore, the PCDS signal strength scales with the intensity of incident photons while the noise in PCDS mainly comes from thermomechanical noise of a microcantilever. Using a high power tunable QCL, we have been able to increase the sensitivity of detection by one order of magnitude. This, therefore, lays the foundation for the enhancement of the sensitivity of detection by increasing the intensity of the excitation source.

In this report, we demonstrate the successful implementation of PCDS for selective detection and quantification of the ternary mixtures of similar explosive molecules (trinitrotoluene (TNT), cyclotrimethylene trinitramine (RDX) and pentaerythritol tetranitrate (PETN)), which represent the three most commonly found explosive classes (nitro-aromatics, nitramines and nitrate esters) with tens of picogram resolution in ambient condition. In addition, we improve the limit of recognition (LOR), the maximum recognizable mixture composition range, by an order of magnitude (<32:1) with a 100% recognition rate, by calibrating and analyzing PCDS spectra compared to the LOR of immobilized chemoselective interfaces-based multi-transducer array microsensors. In contrast to an immobilized chemoselective interfaces-based microsensor array, which has a relatively short operation-life due to the degradation of coating in ambient condition, resulting in the loss of selectivity and capability of the quantitative detection, the PCDS technique utilizes a very robust single microstructure without any chemoselective interfaces. Significant field applications potential is demonstrated by the selective detection and quantification of ternary mixtures of explosive molecules in ambient condition.

Results

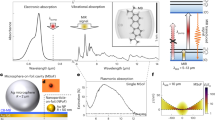

The PCDS setup used in this study is shown in Fig. 1a. Inherently, the PCDS provides two orthogonal signals in a single transducer platform. The nanomechanical IR spectrum, a differential plot of the amplitude of the cantilever deflection as a function of impinging IR wavelength with and without target molecules, represents molecular signatures of the target molecules adsorbed on the cantilever surface while the resonance frequency change of the microcantilever gives real time information of adsorbed mass (Fig. 1b). The bi-material microcantilever serves as an extremely sensitive thermal sensor as well as a microresonator for the detection, speciation and quantification of ternary mixtures of the explosive molecules. When IR photons are absorbed by the explosive molecules on the cantilever surface, the explosive molecules undergo transitions from the ν = 0 ground vibrational states to the ν = 1 excited states (Fig. 1c). The high frequency low density normal modes (represented on a sharp Morse potential) is coupled to the high ν excited states of other low frequency high density normal modes (one of which represented on a flat Morse potential) via intramolecular vibrational energy redistribution. Eventually, the energy is released to the phonon bath of the bi-material cantilever surface through multiple steps of vibrational energy relaxation. These nonradiative decay processes result in heating up the bi-material cantilever, generating the deflection of the cantilever.

Illustration of two orthogonal signals acquired by photothermal cantilever deflection spectroscopy (PCDS).

(a) Schematic drawing of the PCDS setup. (b) The nanomechanical IR spectrum represents molecular signatures of target molecules adsorbed on the cantilever surface and resonance frequency change of the microcantilever gives the real time information of adsorbed mass. (c) A bi-material microcantilever, which is a robust microstructure without any immobilized chemoselective interfaces, is employed as an extremely sensitive thermal sensor as well as a microresonator. During resonant excitation by IR photons, the molecules undergo transitions from ground vibrational states to excited vibrational states. Since the density of states is very high, there exist multiple paths for relaxation in a nonradiative fashion. The nonradiative decay process-induced phonons result in heating of the bi-material cantilever.

Within certain dynamic ranges, the normalized peak amplitudes of the nanomechanical IR spectrum can be utilized to estimate the relative mass ratio of each target molecule in a mixture since the IR spectrum of a mixture is a linear superposition of individual spectra. Fig. 2 shows the normalized nanomechanical IR absorption spectra of TNT (black), RDX (green), PETN (red), 1:1:1 mixture of these three explosives (blue), a weighted linear superposition of individual explosive spectra (sky blue) and the Fourier transform infrared (FTIR) spectrum of the ternary mixture (orange). The PCDS spectra of the individual explosives were taken separately as references and agreed quite well with our previous report15. These spectra were acquired with a monochromatic IR source and normalized by the adsorbed mass of explosive molecules for calibration purposes. The adsorbed mass of TNT, RDX, PETN and the ternary mixture on the cantilever was 6.78 ng, 6.44 ng, 6.99 ng and 9.8 ng respectively, as calculated using Eq. 2. The relative mass ratio of the ternary mixture (TNT:RDX:PETN) adsorbed on the cantilever surface was estimated to be 0.36:0.1:0.54 from the mathematical fitting of PCDS spectrum of the ternary mixture with normalized PCDS spectra of individual explosive molecules. Therefore, the actual mass of TNT, RDX and PETN on the cantilever surface was determined to be 3.53 ng, 0.98 ng and 5.29 ng respectively. Even though the same volume for each explosive solution with same concentration was mixed, the actual mass of each explosive adsorbed on the cantilever surface was quite different due to different molecular affinity to the silicon oxide surface. Since their vapor pressures are different, desorption rates from the surface are also different7.

Normalized PCDS spectra of TNT (black), RDX (green), PETN (red) and a 1:1:1 mixture (blue) by volume of each standard sample solution of TNT, RDX and PETN on the cantilever, a mathematically fitted IR spectrum of the mixture (sky blue) and FTIR spectrum of the ternary mixture (orange) on the cantilever chip.

The peaks at 6.49 and 7.46 μm are from TNT (black arrows), the peaks at 6.38 and 7.27 μm are from RDX (green arrows), while the peaks at 6.06 and 7.82 μm come from PETN (red arrows). Both PCDS and FTIR spectrum of the ternary mixture clearly show several characteristic peaks at the position indicated by the arrows.

Several distinct peaks and shoulders appeared in the ternary mixture spectrum since the mixture spectrum is a linear superposition of individual spectra (note that spectral resolution of our IR monochromator in this range is approximately 0.12 μm). The peaks at 6.06, 6.38 and 6.49 μm are due to the asymmetric stretching of the NO2 (nitro) group bonds while the peaks at 7.27, 7.46 and 7.82 μm are from the symmetric stretching of the same group bonds. Comparing these peaks with those of individual TNT, RDX and PETN spectra, it is apparent that the peaks at 6.49 and 7.46 μm are from TNT, the peaks at 6.38 and 7.27 μm are from RDX and the peaks at 6.06 and 7.82 μm are from PETN molecules16,17,18,19,20. It is interesting to note that the prominent RDX peak at 7.57 μm is not clear in the PCDS spectrum and the prominent PETN peak at 7.82 μm is missing in the FTIR spectrum due to the difference in the relative mass ratio between RDX and PETN. Other than these two differences, all of the characteristic peaks are separate and distinct, matching closely with each other. This demonstrates the capability of PCDS to distinguish between these closely related explosive molecular species. Since the peaks and shoulders are highly distinguishable, we can surmise that PCDS can detect differences between such closely related molecular species and anticipate that PCDS can distinguish between other interfering compounds and target molecules while sensing in “real world” environments.

We have improved the limit of detection (LOD) and explored the LOR of this PCDS setup by employing a tunable QCL as a powerful IR source. Fig. 3a presents the normalized peak amplitude of RDX at 7.57 μm (green squares) and the standard deviation of spectrum noise in a non-absorbing region (violet circles) as a function of the incident laser power. The inset shows the magnified view of the standard deviation of noise. The straight lines are the linear fit of the normalized peak amplitudes and the standard deviation of noise. Although the noise increased when increasing the incident laser power, the PCDS signal enhancement dominated and consequently signal-to-noise ratio (SNR) increased in our tested power range. Fig. 3b shows normalized PCDS spectra of TNT (black), RDX (green) and PETN (red) acquired with the same cantilever using the maximum power of QCL in our tested range with a 5 nm spectral resolution. The peaks between 7.1 and 8.0 μm are from the symmetric stretching vibration of the NO2 (nitro) group bonds with carbon (C–NO2) in TNT (7.46 μm); nitrogen (N–NO2) in RDX (7.57 μm); and oxygen (O–NO2) in PETN (7.82 μm), respectively. The peak amplitudes at 7.46, 7.57 and 7.82 μm for TNT (black squares), RDX (green triangles) and PETN (red circles) were plotted as a function of adsorbed mass of each explosive molecule in Fig. 3c to explore the LOD of the PCDS setup. The straight lines are the linear fit of the peak amplitudes for TNT (black), RDX (green) and PETN (red) respectively. It was estimated that the limit of detection for TNT, RDX and PETN is 39 pg, 28 pg and 79 pg, respectively with an SNR of 3.

Limit of detection (LOD) for the explosive molecules.

(a) Normalized peak amplitude of RDX at 7.57 μm (green squares) and the standard deviation of spectrum noise in a non-absorbing region (violet circles) as a function of the incident QCL power. The inset shows the magnified view of the standard deviation of noise. The straight lines are the linear fit of the normalized peak amplitudes of RDX (green) and the standard deviation of noise (violet). (b) Normalized PCDS spectra of TNT (black), RDX (green) and PETN (red) acquired with the same microcantilever with a spectral resolution of 5 nm. (c) The peak amplitudes at 7.46, 7.57 and 7.82 μm for TNT, RDX and PETN, respectively, are plotted as a function of adsorbed mass of each explosive molecule with the error bar corresponding to the standard deviation. The straight lines are the linear fit of the peak amplitudes for TNT (black), RDX (green) and PETN (red), respectively. The LOD for each explosive molecule is determined at the intersection of the straight line and the minimum peak amplitude for each explosive with a signal-to-noise ratio of 3.

The concept of a LOR was introduced more than a decade ago and is well established as an additional criterion for evaluating the performance of a vapor sensor array21. Originally, LOR was defined as the maximum recognizable mixture composition range which can be reliably determined from the response pattern of a sensor array. This is especially important in the speciation of vapor mixture components. To estimate the LOR of our PCDS setup, 15 ternary mixtures of standard explosives samples were prepared using varying volume ratios of each standard sample solution. Fig. 4a shows the normalized PCDS spectra of ternary mixtures (TNT:RDX:PETN) of explosives with the volume ratio of the TNT sample solution increasing from 1:1:1 to 15:1:1. The intensity of a peak is directly proportional to the adsorbed mass. The actual masses of TNT, RDX and PETN on the cantilever surface were determined with the total adsorbed mass from the resonance frequency shift measurements and the estimated relative mass ratios obtained from the mathematical fitting of the PCDS spectra of the ternary mixtures with linear superpositions of normalized PCDS spectra of individual explosive molecules. A representative fitting result is provided in Supplementary Information. In a similar manner, the normalized PCDS spectra of ternary mixtures of explosives with increasing RDX and PETN concentrations (Fig. 4b and 4c) were analyzed and the relative mass ratios were plotted with respect to the relative mass ratio of increasing explosives as shown in Fig. 4d. It was estimated that the LOR based on the LOD of our PCDS setup for TNT to RDX is 32:1 and RDX to TNT is 31:1 with an SNR of 3 which ensures there are no false positives or negatives. The LOR for TNT to PETN is 23:1 and PETN to TNT is 32:1; the LOR for RDX to PETN is 30:1 and PETN to RDX is 26:1 with the same SNR.

Limit of recognition (LOR) for the explosive molecules.

(a) Normalized PCDS spectra of ternary mixtures (TNT:RDX:PETN) of explosives showing an increased volume ratios of TNT sample solution from 1:1:1 to 15:1:1. (b) Normalized PCDS spectra of ternary mixtures (TNT:RDX:PETN) of explosives showing an increased volume ratios of RDX sample solution from 1:1:1 to 1:15:1. (c) Normalized PCDS spectra of ternary mixtures (TNT:RDX:PETN) of explosives showing an increased volume ratios of PETN sample solution from 1:1:1 to 1:1:15. (d) Relative mass ratios of two other explosive molecules with respect to the relative mass ratio of increasing explosive molecule. The straight lines are the linear fit of the relative mass ratios for TNT (black), RDX (green) and PETN (red), respectively. The LOR based on the LOD for each explosive molecule is determined at the intersection of the straight line and the minimum relative mass ratio divided by each LOD for the other explosives with a signal-to-noise ratio of 3.

The results demonstrate that the PCDS technique using a very robust single microcantilever transducer without any chemical interfaces overcomes the LOR of immobilized chemoselective interfaces-based multi-transducer array microsensors up to an order of magnitude6 and achieves room temperature reversibility without leading to unacceptable levels of false positives or negatives.

Discussion

The relationship between adsorbed mass and resonant frequency shift is given by22

where Δm is the mass of the adsorbate and m0 is the mass of the clean cantilever. E0, t0 and f0 are the initial values of the Young's modulus, thickness and resonance frequency of the cantilever, respectively. ΔE, Δt, and Δf are the changes in the Young's modulus, thickness and resonance frequency of the cantilever, respectively. In this study, if the changes in thickness and Young's modulus are negligible and explosive molecules are considered uniformly adsorbed on the surface, then Eq. 1 can be simplified to:

Using this equation, the adsorbed mass of explosives on the cantilever is determined.

In PCDS, the amplitude of cantilever deflection depends on the impinging power of IR, the IR absorption mode and the amount of adsorbed molecules as well as the thermal sensitivity of the cantilever15. Although the PCDS signal can be further increased by enhancing the thermal sensitivity of the microcantilever as well as by increasing the impinging power of IR, we should take thermomechanical noise, a dominant noise source for PCDS, into account in order to evaluate SNR which determines the limit of detection23,24. The root mean square amplitude of cantilever deflection from thermomechanical noise at well below the resonance frequency is given by25

where kB is the Boltzmann constant, T is the absolute temperature, B is the measurement bandwidth, Q is the quality factor, k is the spring constant and ω0 is the angular resonance frequency of the cantilever. Although the thermomechanical noise increases when increasing the incident IR laser power due to heating effect, the maximum temperature rise in the cantilever is linearly proportional to the incident laser power as detailed in Supplementary Information. Therefore, thermomechanical noise grows slower than the PCDS signal shown in Fig. 3a and consequently SNR increases.

The LOR for the PCDS setup also can be further extended by using broadly tunable QCLs ranging from 5.5 μm to 8.0 μm which covers the asymmetric and symmetric stretching vibrations of the NO2 (nitro) group bonds in explosive molecules. The more characteristic peaks of analytes we have, the wider the range of recognizable mixture composition we can expect to achieve. With the advent of miniature IR sources, it is possible to decrease the size of the device into a handheld one. Therefore, significant field application potential is anticipated by miniaturizing a broadly tunable IR source and readout electronics which are integrated into a microcantilever sensor system.

We have observed that, although the positions of the absorption peaks in the PCDS spectra agree closely with those in conventional IR spectra, the relative intensities of the observed PCDS peaks do not15. We reasoned that, unlike conventional IR absorption spectroscopy which measures the molecular IR absorption following the Beer-Lambert law, PCDS signals come from the nonradiative decay-induced thermal variation of the cantilever as a result of molecular IR absorption and multi-step coupling of the vibrational excited states of surface adsorbed molecules to the phonon bath of the cantilever through intramolecular vibrational energy redistribution and vibrational energy relaxation. Therefore, the differences between the relative peak intensities of PCDS and conventional IR spectra could be used for quantifying the vibrational dynamics of the adsorbed molecules and the energy transfer processes on the surface.

Methods

Chemicals

Three standard explosive samples (TNT, RDX and PETN) were purchased from AccuStandard, Inc. (New Haven, CT) and used without further purification. As indicated by the manufacturer, the standard concentration of each explosive is 1 mg/mL.

Preparation of a microcantilever

Rectangular silicon cantilevers (CSC12-E) were obtained from MikroMasch USA (San Jose, CA). The dimension of each cantilever was 350 μm in length, 35 μm in width and 1 μm in thickness. The microcantilevers were cleaned by rinsing with acetone, ethanol and a UV ozone treatment then coated with 10 nm of chromium (adhesion layer) followed by 200 nm of gold using an e-beam evaporator. The individual explosive and ternary mixtures (by volume of standard sample solution) of explosive molecules (TNT, RDX and PETN) were deposited on a microcantilever sequentially using micro glass capillaries and the cantilever was completely regenerated by UV ozone cleaning following each measurement.

The PCDS experimental setup

For the PCDS experiments, the explosives-deposited cantilever was mounted on a stainless steel cantilever holder which was attached to the head unit of MultiMode atomic force microscope (AFM) (Bruker, Santa Barbara, CA). The deflection and resonance frequency of the microcantilever were measured using the optical beam deflection method with a laser diode and a position sensitive detector. The IR radiation from the monochromator (Foxboro Miran 1A-CVF) was mechanically chopped at 80 Hz and focused on the cantilever. The IR wavelength was scanned from 2.5 μm to 14.5 μm (4000 cm−1 to 690 cm−1 in wavenumber) and has a resolution of 0.05 μm at 3 μm, 0.12 μm at 6 μm and 0.25 μm at 11 μm according to the manufacturer. The 200 kHz pulsed IR radiation with 10% duty cycle from the QCL (Daylight Solutions, UT-8) was electrically burst at 80 Hz using a function generator DS345 (Stanford Research Systems, Sunnyvale, CA) and directed to the cantilever. The laser power was measured with a FieldMax II laser power meter (Coherent Inc., Santa Clara, CA). The IR wavelength was scanned from 7.1 μm to 8.3 μm (1408 cm−1 to 1204 cm−1 in wavenumber) with a spectral resolution of 5 nm. The nanomechanical IR spectra were taken using a SR850 lock-in amplifier (Stanford Research Systems, Sunnyvale, CA) and the resonance frequencies of the microcantilever were measured with a SR760 spectrum analyzer (Stanford Research Systems, Sunnyvale, CA).

FTIR microscope

The ternary mixture of explosive molecules on the microcantilever chip was characterized using a standard FTIR technique as a reference. Two (2) microliters of 1:1:1 mixture solution was drop-cast onto the microcantilever chip and the FTIR spectra were obtained using an FTIR microscope (Nicolet Continuμm FTIR microscope) in reflection mode. The number of registered scans was 200 with resolution of 4 cm−1.

References

Yinon, J. Detection of Explosives by Electronic Noses. Anal. Chem. 75, 99A–105A (2003).

Hsieh, M.-D. & Zellers, E. T. Limits of Recognition for Simple Vapor Mixtures Determined with a Microsensor Array. Anal. Chem. 76, 1885–1895 (2004).

Then, D., Vidic, A. & Ziegler Ch. A highly sensitive self-oscillating cantilever array for the quantitative and qualitative analysis of organic vapor mixtures. Sens. Actuators B 117, 1–9 (2006).

Zhao, W., Pinnaduwage, L. A., Leis, J. W., Gehl, A. C., Allman, S. L., Shepp, A. & Mahmud, K. K. Identification and quantification of components in ternary vapor mixtures using a microelectromechanical-system-based electronic nose. J. Appl. Phys. 103, 104902-1–104902-11 (2008).

Jin, C., Kurzawski, P., Hierlemann, A. & Zellers, E. T. Evaluation of Multitransducer Arrays for the Determination of Organic Vapor Mixtures. Anal. Chem. 80, 227–236 (2008).

Jin, C. & Zellers, E. T. Limits of Recognition for Binary and Ternary Vapor Mixtures Determined with Multitransducer Arrays. Anal. Chem. 80, 7283–7293 (2008).

Pinnaduwage, L. A., Thundat, T., Gehl, A., Wilson, S. D., Hedden, D. L. & Lareau, R. T. Desorption characteristics of uncoated silicon microcantilever surfaces for explosive and common nonexplosive vapors. Ultramicroscopy 100, 211–216 (2004).

Wilson, E. B., Decius, J. C. & Cross, P. C. Molecular Vibrations (McGraw-Hill, USA, 1955).

Barnes, J. R., Stephenson, R. J., Welland, M. E., Gerber,. Ch. & Gimzewski, J. K. Photothermal spectroscopy with femtojoule sensitivity using a micromechanical device. Nature 372, 79–81 (1994).

Wachter, E. A., Thundat, T., Oden, P. I., Warmack, R. J., Datskos, P. G. & Sharp, S. L. Remote optical detection using microcantilevers. Rev. Sci. Instrum. 67, 3434–3439 (1996).

Li, G., Burggraf, L. W. & Baker, W. P. Photothermal spectroscopy using multilayer cantilever for chemical detection. Appl. Phys. Lett. 76, 1122–1124 (2000).

Datskos, P. G., Rajic, S., Sepaniak, M. J., Lavrik, N., Tipple, C. A., Senesac, L. R. & Datskou, I. Chemical detection based on adsorption-induced and photoinduced stresses in microelectromechanical systems devices. J. Vac. Sci.Technol. B 19, 1173–1179 (2001).

Arakawa, E. T., Lavrik, N. V., Rajic, S. & Datskos, P. G. Detection and differentiation of biological species using microcalorimetric spectroscopy. Ultramicroscopy 97, 459–465 (2003).

Wig, A., Arakawa, E. T., Passian, A., Ferrell, T. L. & Thundat, T. Photothermal spectroscopy of Bacillus anthracis and Bacillus cereus with microcantilevers. Sens. Actuators B 114, 206–211 (2006).

Krause, A. R., Van Neste, C., Senesac, L., Thundat, T. & Finot, E. Trace explosive detection using photothermal deflection spectroscopy. J. Appl. Phys. 103, 094906-1–094906-6 (2008).

Pristera, F., Halik, M., Castelli, A. & Fredericks, W. Analysis of Explosives Using Infrared Spectroscopy. Anal. Chem. 32, 495–508 (1960).

Lewis, I. R., Daniel Jr, N. W. & Griffiths, P. R. Interpretation of Raman Spectra of Nitro-Containing Explosive Materials. Part I: Group Frequency and Structural Class Membership. Appl. Spectrosc. 51, 1854–1867 (1997).

Makashir, P. S. & Kurian, E. M. Spectroscopic and thermal studies on 2,4,6-trinitro toluene (TNT). J. Therm. Anal. Cal. 55, 173–185 (1999).

Makashir, P. S. & Kurian, E. M. Spectroscopic and Thermal Studies on Pentaerythritol Tetranitrate (PETN). Propell. Explos. Pyrot. 24, 260–265 (1999).

Beal, R. W. & Brill, T. B. Vibrational Behavior of th–e –NO2 Group in Energetic Compounds. Appl. Spectrosc. 59, 1194–1202 (2005).

Zellers, E. T., Park, J., Hsu, T. & Groves, W. A. Establishing a Limit of Recognition for a Vapor Sensor Array. Anal. Chem. 70, 4191–4201 (1998).

Varshney, M., Waggoner, P. S., Tan, C. P., Aubin, K., Montagna, R. A. & Craighead, H. G. Prion Protein Detection Using Nanomechanical Resonator Arrays and Secondary Mass Labeling. Anal. Chem. 80, 2141–2148 (2008).

Kwon, B., Wang, C., Park, K., Bhargava, R. & King, W. P. Thermomechanical sensitivity of microcantilevers in the mid-infrared spectral region. Nanoscale Microscale Thermophys. Eng. 15, 16–28 (2011).

Kwon, B., Rosenberger, M., Bhargava, R., Cahill, D. G. & King, W. P. Dynamic thermomechanical response of bimaterial microcantilevers to periodic heating by infrared radiation. Rev. Sci. Instrum. 83, 015003-1–015003-7 (2012).

Sarid, D. Scanning Force Microscopy: With Applications to Electric, Magnetic and Atomic Forces (Oxford Univ. Press, USA, 1994).

Acknowledgements

This work was supported by the Canada Excellence Research Chairs (CERC) Program. D.L. also would like to acknowledge the partial support from Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2012R1A6A3A03040416).

Author information

Authors and Affiliations

Contributions

S.K. and D.L. designed, carried out the experiments, collected and analyzed the data and wrote the manuscript; X.L. helped with data analysis and wrote the manuscript; C.V.N. assisted with the experimental design; S.J. helped with data analysis; T.T. conceived the experiments, analyzed results and wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

PCDS supplementary

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Kim, S., Lee, D., Liu, X. et al. Molecular recognition using receptor-free nanomechanical infrared spectroscopy based on a quantum cascade laser. Sci Rep 3, 1111 (2013). https://doi.org/10.1038/srep01111

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01111

This article is cited by

-

Advances in explosives analysis—part I: animal, chemical, ion, and mechanical methods

Analytical and Bioanalytical Chemistry (2016)

-

Resonating Behaviour of Nanomachined Holed Microcantilevers

Scientific Reports (2015)

-

Piezotransistive transduction of femtoscale displacement for photoacoustic spectroscopy

Nature Communications (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.