Abstract

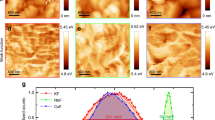

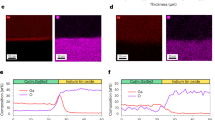

Thin-film photovoltaic devices based on chalcopyrite Cu(In,Ga)Se2 (CIGS) absorber layers show excellent light-to-power conversion efficiencies exceeding 20% (refs 1, 2). This high performance level requires a small amount of alkaline metals incorporated into the CIGS layer, naturally provided by soda lime glass substrates used for processing of champion devices3. The use of flexible substrates requires distinct incorporation of the alkaline metals, and so far mainly Na was believed to be the most favourable element, whereas other alkaline metals have resulted in significantly inferior device performance4,5. Here we present a new sequential post-deposition treatment of the CIGS layer with sodium and potassium fluoride that enables fabrication of flexible photovoltaic devices with a remarkable conversion efficiency due to modified interface properties and mitigation of optical losses in the CdS buffer layer. The described treatment leads to a significant depletion of Cu and Ga concentrations in the CIGS near-surface region and enables a significant thickness reduction of the CdS buffer layer without the commonly observed losses in photovoltaic parameters6. Ion exchange processes, well known in other research areas7,8,9,10,11,12,13, are proposed as underlying mechanisms responsible for the changes in chemical composition of the deposited CIGS layer and interface properties of the heterojunction.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Green, M. A., Emery, K., Hishikawa, Y., Warta, W. & Dunlop, E. D. Solar cell efficiency tables (version 41). Prog. Photovolt. 21, 1–11 (2013).

Jackson, P. et al. New world record efficiency for Cu(In,Ga) Se2 thin-film solar cells beyond 20%. Prog. Photovolt. 19, 894–897 (2011).

Hedstrom, J. et al. 23rd IEEE Phot. Spec. Conf. (PVSC) 364–371 (IEEE, 1993).

Contreras, M. A. et al. 26th IEEE Phot. Spec. Conf. (PVSC) 359–362 (IEEE, 1997).

Bodegård, M., Granath, K. & Stolt, L. Growth of Cu(In,Ga) Se2 thin films by coevaporation using alkaline precursors. Thin Solid Films 361, 9–16 (2000).

Contreras, M. A. et al. Optimization of CBD CdS process in high-efficiency Cu(In,Ga) Se2-based solar cells. Thin Solid Films 403–404, 204–211 (2002).

Jenny, H. Studies on the mechanism of ionic exchange in colloidal aluminium silicates. J. Phys. Chem. 36, 2217–2258 (1932).

Clearfield, A. Role of ion exchange in solid-state chemistry. Chem. Rev. 88, 125–148 (1988).

Rivest, J. B. & Jain, P. K. Cation exchange on the nanoscale: An emerging technique for new materials synthesis, device fabrication, and chemical sensing. Chem. Soc. Rev. 42, 89–96 (2013).

Nordberg, M. E. et al. Strengthening by ion exchange. J. Am. Ceram. Soc. 47, 215–219 (1964).

Zou, J. et al. Two-step K+–Na+ and Ag+–Na+ ion-exchanged glass waveguides for C-band applications. Appl. Opt. 41, 7620–7626 (2002).

Das, S. R. et al. The preparation of Cu2S films for solar cells. Thin Solid Films 51, 257–264 (1978).

Ramanathan, K. et al. Proc. 2nd World Conf. on Photovoltaic Solar Energy Conversion 477–481 (Joint Research Centre, European Commission, 1998).

Wolden, C. A. et al. Photovoltaic manufacturing: Present status, future prospects, and research needs. J. Vac. Sci. Technol. A 29, 030801 (2011).

Chopra, K. L., Paulson, P. D. & Dutta, V. Thin-film solar cells: An overview. Prog. Photovolt. 12, 69–92 (2004).

Grätzel, M. Photoelectrochemical cells. Nature 414, 338–344 (2001).

Bernede, J. C. Organic photovoltaic cells: History, principle and techniques. J. Chil. Chem. Soc. 53, 1549–1564 (2008).

Reinhard, P. et al. Review of progress toward 20% efficiency flexible CIGS solar cells and manufacturing issues of solar modules. IEEE J. Photovolt. 3, 572–580 (2013).

Kessler, F. & Rudmann, D. Technological aspects of flexible CIGS solar cells and modules. Sol. Energ. 77, 685–695 (2004).

Chirilă, A. et al. Highly efficient Cu(In,Ga) Se2 solar cells grown on flexible polymer films. Nature Mater. 10, 857–861 (2011).

Rudmann, D. et al. Sodium incorporation strategies for CIGS growth at different temperatures. Thin Solid Films 480, 55–60 (2005).

Jackson, P. et al. High quality baseline for high efficiency, Cu(In1−x,Gax)Se2 solar cells. Prog. Photovolt. 15, 507–519 (2007).

Ishizuka, S., Yamada, A., Fons, P. & Niki, S. Flexible Cu(In,Ga) Se2 solar cells fabricated using alkali-silicate glass thin layers as an alkali source material. J. Renew. Sustain. Energ. 1, 013102 (2009).

Cojocaru-Mirédin, O. et al. Characterisation of grain boundaries in Cu(In,Ga) Se2 films using atom-probe tomography. IEEE J. Photovolt. 1, 207–212 (2011).

Abou-Ras, D. et al. Confined and chemically flexible grain boundaries in polycrystalline compound semiconductors. Adv. Energy. Mater. 2, 992–998 (2012).

Wuerz, R. et al. CIGS thin-film solar cells and modules on enamelled steel substrates. Sol. Energ. Mater. Sol. Cells 100, 132–137 (2012).

Klein, A. et al. Fermi level-dependent defect formation at Cu(In,Ga) Se2 interfaces. Appl. Surf. Sci. 166, 508–512 (2000).

Rau, U. et al. Oxygenation and air-annealing effects on the electronic properties of Cu(In,Ga) Se2 films and devices. J. Appl. Phys. 86, 497–505 (1999).

Nakada, T. & Kunioka, A. Direct evidence of Cd diffusion into Cu(In,Ga) Se2 thin films during chemical-bath deposition process of CdS films. Appl. Phys. Lett. 74, 2444–2446 (1999).

Kiss, J. et al. Theoretical study on the structure and energetics of Cd insertion and Cu depletion of CuIn5Se8 . J. Phys Chem. C 117, 10892–10900 (2013).

Acknowledgements

This work was supported by the Swiss National Science Foundation and the Swiss Federal Office of Energy. The laboratory for Nanoscale Materials Science and the Laboratory for Electronics/Metrology/Reliability at Empa are acknowledged for SIMS and scanning and transmission electron microscopy measurements, respectively.

Author information

Authors and Affiliations

Contributions

A.C., P.R., F.P., P.B., S.B., S.N. and A.N.T. designed the research and experiments. A.C., P.R. and P.B. fabricated the solar cells. A.C., P.R., F.P., S.B., A.R.U., C.F., C.G., H.H., D.J., L.K., D.K., R.E. and A.N.T. performed the characterization and analysis. A.C., P.R., F.P., S.B. and A.N.T. wrote the paper. All authors contributed to discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 892 kb)

Rights and permissions

About this article

Cite this article

Chirilă, A., Reinhard, P., Pianezzi, F. et al. Potassium-induced surface modification of Cu(In,Ga)Se2 thin films for high-efficiency solar cells. Nature Mater 12, 1107–1111 (2013). https://doi.org/10.1038/nmat3789

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3789

This article is cited by

-

Charge-carrier-concentration inhomogeneities in alkali-treated Cu(In,Ga)Se2 revealed by conductive atomic force microscopy tomography

Nature Energy (2024)

-

High-concentration silver alloying and steep back-contact gallium grading enabling copper indium gallium selenide solar cell with 23.6% efficiency

Nature Energy (2024)

-

Influence of hybrid Fe/Cr parameters structures synthesised with laser radiation on their photosensitivity

Journal of Materials Science: Materials in Electronics (2023)

-

(NH4)2S-induced improvement of CdS buffer layer for 15.52% efficiency solution-processed CIGS solar cell

Journal of Materials Science: Materials in Electronics (2023)

-

Recent progress in defect engineering for kesterite solar cells

Science China Physics, Mechanics & Astronomy (2023)