1. Introduction

Information and Communication Technology (ICT) has been slow to adapt to the construction industry for several reasons, although they are mainly related to the sector’s own characteristics [

1], e.g., the temporality of the projects, the traditional character, the simultaneousness of works, the singularity of each construction project. However, a major transformation concerning the use of new technologies to support the management of construction projects has been observed in the last decade [

2].

The life cycle of construction projects includes several phases: (i) requirements identification, (ii) project planning, (iii) design (iv) execution, (v) maintenance and (vi) demolition. Among these phases, the two that take the longest period of time in the life cycle of a building project are the execution and the maintenance phases [

3]. From a management perspective, the objective in each one of these phases is different and it requires different tools. For example, in the early stages of the project, coordination and collaboration between the different involved parties is essential, while in the execution phase the main focus is on cost, schedule, quality and safety control [

4]. In the maintenance phase, it is essential to control various factors such as air quality, energy performance and building maintenance, among others. However, all these phases share the need for an adequate data acquisition process as well as techniques to manage such data properly [

5]. In recent decades, a revolutionary technology named Building Information Modeling (BIM) has provided an opportunity to move to the new digital era enabling automation capabilities for more integrated communication, data exchange and sharing between project actors. In this sense, architects, engineers, and construction experts can efficiently plan, design, build and manage buildings. Such a concept of BIM is commonly known as passive BIM. However, when the efficiency of building alternatives is required to be evaluated during the design or the construction phase, the passive BIM approach may not be sufficient. Dynamic systems, which connect BIM with analytical functions or solutions with optimisation techniques to improve the decision making process, are necessary [

6].

In this context, data capture can be facilitated by the diversity of existing sensors, as well as by communication among them, whereas efficient information extraction and processing are made possible by the application of different artificial intelligence techniques that can provide intelligent support in the life cycle of construction projects.

This vision has been enhanced by the paradigm known as the Internet of Things (IoT), which describes a system of interrelated and uniquely identified computing devices that have the ability to transfer data over a network, without requiring human interactions [

7]. Recently, this paradigm is being considered by researchers in the field of construction, especially in the execution and maintenance phase through the sensorization of physical spaces [

8] and wearable sensing devices (WSDs). Internet of Things brings, among other aspects, remarkable benefits in the construction life cycle, distinguishing among others the reduction of costs, smarter designs and knowledge about the environment in real-time, etc. [

9]. However, one of the aspects that has recently attracted most interest in the scientific community and that represents a great challenge is related to safety [

10,

11,

12,

13.

On the other hand, the use of computational intelligence techniques and intelligent systems, which are able to solve complex and multidisciplinary problems in an automatic way from the data provided by the Internet of Things paradigm, supporting the decisions of an expert, are also contributing to great benefits in the field of construction. In particular to provide intelligent support on the prevention of accidents at any of the construction phases. Nevertheless, the data provided by the IoT framework are usually affected by uncertainty and, in order to support any decision-making process, the human behavior or expert knowledge have to be modeled. To achieve this goal, Fuzzy Logic Systems (FLSs), which are rule-based expert systems based on fuzzy set theory to represent the semantics of rules and to process inference when input data are provided [

14], have been successfully used in a wide range of real-world problems in the construction sector. For example, for risk construction management [

15,

16,

17], for rehabilitation and maintenance tasks [

18,

19,

20], tracking materials and decision-making in construction management [

21,

22,

23], or sustainability [

24]. In addition, fuzzy systems have also been applied to modelling of uncertainties related to occupational risks in the construction sector [

25,

26,

27]. FLS can include a priori expert knowledge and represent systems for which it is not possible to obtain a mathematical model.

In this context, the IEEE Computational Intelligence Society (IEEE-CIS) has sponsored the publication of the new standard for FLS (IEEE Std 1855-2016) [

28]. This standard was established with the main objective of providing the fuzzy community with a unique and well-defined tool allowing a system to be designed completely independently from the specific hardware/software. The new standard defines a new W3C eXtensible Markup Language (XML) based language, named Fuzzy Markup Language (FML) [

29] aimed at providing a unified and well-defined representation of interoperable FLS [

30]. Additionally, in order to make the IEEE standard operative and useful for the fuzzy community, the library JFML [

31] has been developed to offer a complete implementation of the new IEEE standard. Some hardware/sensor developments based on JFML have also been successfully done [

32].

Therefore, the integration of data capture technologies in some phases of the life cycle of a construction project with both the Internet of Things paradigm and the use of Fuzzy Logic Systems poses an interesting challenge that can provide significant benefits for the prevention of accidents in the phases of a construction project in real-time. These aspects have motivated the present work by the idea of defining an IoT infrastructure as the core of ubiquitous computing and automatic data transfer from sensors with the use of JFML to monitoring the risk of falling objects accidents in some phases of the life cycle of a construction project. Specifically, we propose to use the MQTT protocol to send data from sensors over the defined IoT architecture and to integrate it with the JFML library to represent FLS in a human language to model expert knowledge in the prevention of falling objects accidents in the execution phase. To test our architecture, an expert FLS modeled according to the IEEE std 1855-2016 is used. The input variables of this FLS are associated with the most commonly used sensors in the execution phase to prevent accidents, whereas the output variable models the risk level of falling objects accident with four degrees: low, medium, high and very high. As shown in the experimental session, the results obtained by our proposal are assessed suitable by an expert panel.

The paper is structured as follows. In

Section 2, some preliminary concepts related to the most existing common tasks and risks in the execution phase of the life cycle of a construction project, the Internet of Things and the Fuzzy Markup Language are presented in a general way. In

Section 3, the potential technologies used in the execution phase are presented, from the point of view of the Internet of Things, while in

Section 4 an IOT-JFML-based system for the management of data collected by the sensors in the task of prevention the risk of falling object accidents is developed. An illustrative case study focused on a building project and the execution phase where expert knowledge in the falling object accidents prevention is detailed in

Section 5. Finally, the main conclusions and future works are reflected in

Section 6.

3. Main Technologies Used in the Execution Phase

This section details some of the technologies that have been involved in IoT systems and identified in the literature as relevant for data acquisition during the execution phase in the life cycle of a construction project.

The most commonly used technologies, within the elements of an IoT system, we mainly consider those based on wireless communication as well as different sensors such as altimeters, anemometers, gyroscopes, accelerometers, temperature and humidity, etc. In addition, radio frequency identification (RFID) or global positioning systems (GPS or GNNS) are also considered. Sensors can measure the physical conditions of the world, such as position, occupancy, acceleration, velocity, movement, temperature, etc. As will be detailed below, they have been widely applied to monitor parameters including environmental status, occupant behavior, and energy usage inside buildings [

54,

55,

56]. While Radio Frequency Identification (RFID) can, through electromagnetic fields, automatically identify and track tags attached to objects. Finally, the Global Positioning System (GPS) makes it possible to determine the position of people or objects with great precision.

Table 1 organizes several authors’ proposals as indicated above, firstly distinguishing the technologies (sensors, RFID and GPS) and secondly distinguishing whether the objective of the proposal is focused on health and safety aspects in the execution phase. As can be seen in the table, the most widely used technology is RFID, although the use of sensors has been winning greater acceptance in recent years. In relation to the phases of the work, most of the proposals focus on the execution phase and, specifically, to facilitate and improve safety management during the execution process. Within this task, which is very relevant in the construction sector due to the high accident rate, the proposals are mainly focused on identifying risks and alerting workers to avoid accidents [

9,

57,

58]. Similarly, the control of some important activities such as planning [

59] or the condition of concrete structures [

60] have attracted the attention of the research community. In the maintenance phase, the proposals focus on energy efficiency management [

61], planning in emergency situations [

62] and occupancy estimation to adapt climatic conditions [

63].

As can be seen in

Table 1, the proposals dedicated to safety management mainly use RFID technology and sensors. All proposals present trends in the use of these technologies in the phases of construction projects that, in conjunction with the deployment under IOT infrastructure, show promising results.

4. IoT-JFML Proposal for the Risk of Falling Object Accidents

In order to improve the management of data collected by the sensors in the task of prevention the risk of falling object accidents, an IOT-JFML-based system was developed. To do this, on the one hand, we analyze several sensors/actuators from the perspective of their main characteristics that can be used from safety tasks. On the other hand, we propose an infrastructure for the system based on an integration of the JFML library, an IoT infrastructure based on MQTT and the proposed sensors/actuators.

4.1. Sensors Description

The main objective of the designed system is to prevent risk of falling object accidents on construction sites by considering data collected by several sensors in workplace areas during the execution phase. Information provided by the sensors is related to relevant variables in the risk of falling object accidents. The objects that commonly fall range from large items such as roof trusses and steel beams to small items such as fasteners, small hand tools and small particles from the loading crane.

The most relevant factors in the risk of falling objects are identified and monitored in the current approach. Wireless capabilities are required in this context because wired connections are not suitable for it.

Use or non-use of a helmet. The adequate use of a helmet is a key factor in the risk of falling objects widely identified in the literature [

77].

Worker’s location. Identifying the exact location of the workers is one of the most important functions for accident prevention [

78].

Load crane location. Each crane has a load chart that, in short, specifies the crane’s capabilities. The location of the load in real-time is another factor to be considered for accident prevention [

79].

Worker’s altitude. Height is another important factor in the risk of falling object accidents. Many consequences of an accident depends on the altitude of the worker and fall and some authors identified the altitude as a good predictor of the overall outcome and chance of survival [

80].

Load crane altitude. In the same way, the altitude of the load is another key aspect of the severity of the accident [

81].

Safety barriers. Many accidents are explained by the lack of physical barrier elements. There is significant potential for accident prevention in the construction industry by systematic barrier management [

82].

Distance between workers and load crane. It is obvious that a worker placed near to the load crane is more likely to fall than another placed in away from that workplace. The distance from the load to the worker is another relevant variable monitored by the system [

83].

Wind velocity. Weather factors cannot be controlled in construction projects due to the outdoor nature of them [

84]. Wind velocity has an adverse effect on construction sites [

85]. Wind velocity was considered as a relevant variable too.

In order to measure, evaluate and control the described variables, the following sensors and devices, which are summarized in

Table 2, have been included within the proposed real-time monitoring system.

All sensors are connected on ESP32 devices, which are designed for IoT applications. The ESP32 features a Hybrid Wi-Fi and Bluetooth Chip with in-built antenna switches, RF components, and power management modules.

For the helmet, an optical pulse sensor is embedded in the helmet for wearing detection. The optical pulse sensor measures pulse waves which are changes in the volume of a blood vessel that occur when the heart pumps blood. A set of m safety barriers (, ,.... ), each one composed of a set of gyroscopes, (, ,... ) is also considered. In this case, the set of gyroscopes is distributed along the barrier and the orientation of axes and polarity of rotation can be used to determine if the barrier is fixed or not. On the other hand, an altimeter and a GNSS-antenna for GPS GLONASS 28dB are used to calculate the distance between workers and the load. An altimeter is also used for detecting when the worker or the load are placed in an elevated working place. In addition, an anemometer provides wind velocity at the workplace. A high velocity of wind could decrease the stability of the worker or load and then the risk of falling objects will be higher. Finally, a vibration sensor within a color LED is embedded into a wristband to advise the worker of the risk level of accident based on a color scale and the intensity of vibration. For instance, if the risk level is high, the color LED will be red and the vibration will be hard, if the risk level is medium, the color LED will be orange and the vibration will be medium or if the risk level is low, the color LED will be green and the vibration intensity will be soft.

On the basis of these sensors and their values, different working situations could be considered and the different risk levels can be estimated. For example, the BLE beacon attached to the headset, in combination with a BLE receiver detects if a worker is wearing a helmet or not. The receiver calculates the relative distance from the helmet to the worker based on a RSSI signal [

75]. For example, if the distance between the BLE beacon and the receiver is lower than a value, the headset is considered as being attached to the worker. Taking these situations into consideration, sensors are distributed through the workplace by considering expert knowledge from the safety in construction sector. This distribution provides valuable information about working conditions in real time that will be used as input data in the IOT-JFML architecture defined in the following subsection.

4.2. Proposed Architecture

The JFML library and the new IoT module offer a complete implementation of an IoT infrastructure to carry out intelligent IoT solutions under the IEEE std 1855-2016. These capabilities are extended to the design and implementation of the previous falling object accidents proposal.

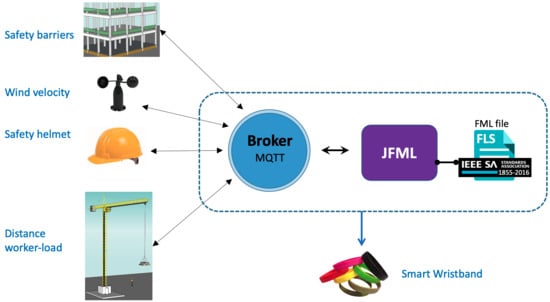

Figure 1 shows an overview of the proposed architecture.

The main elements included in this implementation are the sensors/actuators, the broker, the JFML instance and the FML file that represents expert knowledge according to the IEEE std 1855-2016 for the fall object accidents problem. In general, sensors/actuators provide data that pass through the broker which are used for the JFML to make the inference according to the expert knowledge represented in the FML file.

The broker, which implements the MQTT protocol, is a Mosquitto instance [

47] while the JFML library can be run on a remote computer or on the cloud. This architecture allows communication between all the elements due to the broker and the wireless capabilities. In the following section, we summarize the behaviour of this communication procedure:

Sensors provide data, which are published into “input” topics. In consequence, they must be associated with input variables. For example, the altimeter sensor for the worker () publishes data into the topic “input/Alt_worker”, the anemometer sensor publishes data into the topic “‘input/Anm_wind”, etc.

JFML is subscribed to all input topics to receive input data from the sensors and to assign them to the input variables. These input variables are defined in the FLS (represented in the FML file according to the IEEE std 1855-2016). For examxple, JFML is subscribed to the topics “‘input/Alt_worker”, “‘input/Anm’, etc. to receive data from the sensors and , respectively. These sensors are associated with the input variables worker altitude and wind velocity, respectively. Hence, all input variables receive data from sensors.

When all of the sensors have published their data and JFML has assigned these values to the input variables, the inference is carried out. Rules are fired according to the input values and the rule base defined in the FML file.

Once the inference process is finished, the output variables obtain values from the corresponding defuzzification method. Then, JFML publishes these values to “output” topics. For example, the value of the output variable smart wristband is published by JFML into the topic “output/wristband”.

Actuators receive data so they are subscribed to “output” topics. In consequence, they must be associated with output variables. For example, the LED indicator and the vibration sensor are subscribed to the topic “output/wristband” to receive data from the output variable smart wristband.

6. Conclusions

The life cycle of construction projects is a long process involving different stages with different objectives. Although the construction industry has always had a very traditional nature involving many small companies and where technology has not been very present, today new approaches such as the Internet of Things are playing a key role in improving the decision-making process.

This paper proposed an IoT infrastructure combined with the Fuzzy Markup Language on JFML for on-site construction safety—the IOT-JFML system for falling objects. This system enables detection and management of this mentioned risk during the construction process by means of several sensors, an actuator, a broker based on the MQTT protocol, an instance of JFML and an FML file.

In particular, we focus on the execution phase, as this is the phase where there are most risks and where most accidents occur. One of the most frequent risks due to the characteristics of the construction process is falling objects. A complete analysis has been carried out with the aim of identifying the relevant factors for this risk. Then, different sensors have been proposed to measure these factors (beacon, gyroscope, altimeter, anemometer, etc.). To model the risk situation and to evaluate the proposal a panel of experts comprising 10 persons (f9ve professionals from construction companies and five academic researchers) were consulted. Following a methodology for determining a Fuzzy Logic Systems where the panel of experts has been involved, four input and one output fuzzy variables and 15 fuzzy rules which have been considered to design a Fuzzy Logic System (FLS) for this risk problem.

The main elements included in this system implementation are the sensors/actuators, the broker, the JFML instance and the FML file that represents expert knowledge according to the IEEE std 1855-2016 for the fall object accidents problem. Sensors provide data that pass through the broker which are used for the JFML to make the inference according to the expert knowledge represented in the FML file. Then, a vibration sensor within a color LED are embedded into a wristband to advise the worker of the risk level of accident on the basis of a color scale and the intensity of vibration.

Finally, in order to illustrate the potential of this proposal, three habitual working scenarios are detailed as simulations of real situations in a construction workplace during the execution phase by using the IOT-JFML proposal for falling object risk. As an illustrative example, we consider a scenario for material loading tasks. The proposed architecture is flexible and scalable so, in future research, it could be extended to multiple workers in different situations. In the case of multiple tasks with multiple workers, the information obtained will help to coordinate construction safety practices.

The main advantage of the proposed system is the ability to assess risk levels for construction workers in real-time. In traditional risk assessment, risks are identified prior to the start of construction works. However, due to the dynamic nature of the construction industry, the risk of falling objects can constantly change. In this sense, our proposal allows for continuous monitoring of workers, offering the opportunity to update risk levels in real-time. Our proposal could be used as input data for the establishment of active BIM environments that are currently under development, but are expected to be used effectively as a decision-making tool for construction project management, by linking the two approaches to reduce the risk of falling objects during the construction process.

Finally, the proposed architecture could have an important implication also in other real world applications, not only for falling object risk in construction phases. For example, the proposed architecture based on an IoT infrastructure combined with the Fuzzy Markup Language on JFML could be equipped with a different set of sensors to address forensic science scenarios such as the analysis of crime scenes and the automatic reconstruction of crime dynamics [

94,

95].