Use of Opuntia ficus-indica Fruit Peel as a Novel Source of Mucilage with Coagulant Physicochemical/Molecular Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemical and Reagents

2.2. Plant Material

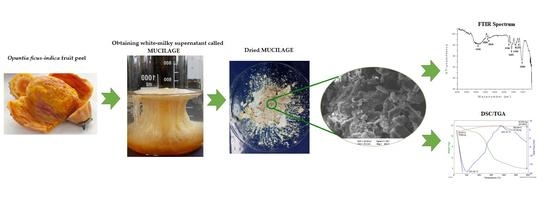

2.3. Mucilage Extraction

2.4. Mucilage Physicochemical/Molecular Characterization

2.4.1. UPLC-QTOF-MS

2.4.2. Fourier-Transform Infrared (FTIR) Spectroscopy

2.4.3. Raman Spectroscopy

2.4.4. Nuclear Magnetic Resonance (NMR)

2.4.5. X-ray Diffraction (XRD) Analysis

2.4.6. Zeta Potential

2.4.7. Scanning Electron Microscopy (SEM)

2.4.8. Thermal Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Mucilage in Solution

3.1.1. Polymer Molecular Weight Distribution in Water

3.1.2. NMR Spectra of Mucilage in DMSO-d6

3.2. Powdered Mucilage

3.2.1. Molecular Vibrations

3.2.2. X-ray Powder Diffraction (XRD)

3.2.3. Morphological and Thermal Characterizations

3.2.4. Zeta Potential

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aboulhassan, M.A.; Souabi, S.; Yaacoubi, A.; Baudu, M. Treatment of Paint manufacturing wastewater by the combination of chemical and biological processes. Int. J. Sci. Environ. Technol. 2014, 3, 1747–1758. [Google Scholar]

- Xu, H.; Li, J.; Fu, R.; Cheng, R.; Wang, S.; Zhang, J. Flocculation of coal washing wastewater using polysaccharide produced by Paenibacillus mucilaginosus WL412. Environ. Sci. Pollut. Res. 2017, 24, 28132–28141. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.Q. The role of coagulation in water treatment. Curr. Opin. Chem. Eng. 2015, 8, 36–44. [Google Scholar] [CrossRef]

- Saleem, M.; Bachmann, R.T. A contemporary review on plant-based coagulants for applications in water treatment. J. Ind. Eng. Chem. 2019, 72, 281–297. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, F.; Luo, Y.; Yang, H. A preliminary study on cactus as coagulant in water treatment. Process Biochem. 2006, 41, 730–733. [Google Scholar] [CrossRef]

- Pichler, T.; Young, K.; Alcantar, N. Eliminating turbidity in drinking water using the mucilage of a common cactus. Water Sci. Technol. Water Supply 2012, 12, 179–186. [Google Scholar] [CrossRef]

- Torres, L.G.; Carpinteyro-Urban, S.L.; Vaca, M. Use of Prosopis laevigata seed gum and Opuntia ficus-indica mucilage for the treatment of municipal wastewaters by coagulation-flocculation. Nat. Resour. 2012, 3, 35–41. [Google Scholar] [CrossRef]

- Bustillos, L.G.T.; Carpinteyro-urban, S.; Orozco, C. Production and characterization of Opuntia ficus-indica mucilage and its use as coagulant-flocculant aid for industrial wastewaters. Int. J. Biotechnol. Res. 2013, 1, 38–45. [Google Scholar]

- Bouatay, F.; Mhenni, F. Use of the cactus cladodes mucilage (Opuntia ficus-indica) as an eco-friendly flocculants: Process development and optimization using stastical analysis. Int. J. Environ. Res. 2014, 8, 1295–1308. [Google Scholar]

- Mounir, B.; Abdeljalil, Z.; Abdellah, A. Comparison of the efficacy of two bioflocculants in water treatment. Int. J. Sci. Eng. Technol. 2014, 737, 734–737. [Google Scholar]

- De Souza, M.T.F.; Ambrosio, E.; De Almeida, C.A.; De Souza Freitas, T.K.F.; Santos, L.B.; De Cinque Almeida, V.; Garcia, J.C. The use of a natural coagulant (Opuntia ficus-indica) in the removal for organic materials of textile effluents. Environ. Monit. Assess. 2014, 186, 5261–5271. [Google Scholar] [CrossRef] [PubMed]

- Melgar, B.; Inês, M.; Ciric, A.; Sokovic, M.; García-Castello, E.M.; Rodríguez-López, A.D.; Ferreira, I. By-product recovery of Opuntia spp. peels: Betalainic and phenolic profiles and bioactive properties. Ind. Crops Prod. 2017, 107, 353–359. [Google Scholar] [CrossRef]

- Amaya-CruzIz, D.M.; Pérez-Ramírez, I.F.; Delgado-García, J.; Mondragón-Jacobo, C.; Dector-Espinoza, A.; Reynoso-Camacho, R. An integral profile of bioactive compounds and functional properties of prickly pear (Opuntia ficus indica L.) peel with different tonalities. Food Chem. 2019, 278, 568–578. [Google Scholar] [CrossRef]

- Andreu-Coll, L.; Cano-Lamadrid, M.; Sendra, E.; Carbonell-Barrachina, A.; Legua, P.; Hernández, F. Fatty acid profile of fruits (pulp and peel) and cladodes (young and old) of prickly pear [Opuntia ficus-indica (L.) Mill.] from six Spanish cultivars. J. Food Compos. Anal. 2019, 84, 103294. [Google Scholar] [CrossRef]

- Gheribi, R.; Habibi, Y.; Khwaldia, K. Prickly pear peels as a valuable resource of added-value polysaccharide: Study of structural, functional and film forming properties. J. Biol. Macromol. 2019, 126, 238–245. [Google Scholar] [CrossRef] [PubMed]

- Matsuhiro, B.; Sáenz, C.; Sepúlveda, E. Opuntia spp. Mucilage’s: A Functional Component with Industrial Perspectives. J. Arid Environ. 2004, 57, 275–290. [Google Scholar]

- Nath, A.; Mishra, A.; Pande, P.P. A review natural polymeric coagulants in wastewater treatment. Mater. Today 2021, 46, 6113–6117. [Google Scholar] [CrossRef]

- Kumar, V. Partial replacement of alum by using natural coagulant aid to remove turbidity from institutional wastewater. Int. J. Integr. Eng. 2020, 12, 241–251. [Google Scholar]

- Okoro, B.U.; Sharifi, S.; Jesson, M.A.; Bridgeman, J. Natural organic matter (NOM) and turbidity removal by plant-based coagulants: A review. J. Environ. Chem. Eng. 2021, 9, 106588. [Google Scholar] [CrossRef]

- Feihrmann, A.N.C.; Baptista, A.T.A.; Lazari, J.P.; Silva, M.O.; Vieira, M.F.; Vieira, A.M.S. Evaluation of coagulation/floculation process for water treatment using defatted cake from Moringa oleifera. Chem. Eng. Trans. 2017, 57, 1543–1548. [Google Scholar]

- Isemura, H. Catechin in Human Health and Disease. Molecules 2019, 24, 528. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Gihar, S.; Shrivash, M.K.; Kumar, P.; Kundu, P.P. A review on the synthesis of graft copolymers of chitosan and their potential applications. Int. J. Biol. Macromol. 2020, 163, 2097–2112. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.-L.; Gao, J.; Yin, Y.-Y.; Jin, Z.-Y.; Xu, X.-M.; Chen, H.-Q. Extraction optimization by response surface methodology of mucilage polysaccharide from the peel of Opuntia dillenii haw. fruits and their physicochemical properties. Carbohydr. Polym. 2016, 151, 381–391. [Google Scholar] [CrossRef]

- Choudhary, M.; Madhumita, B.; RaySudarsan, N. Evaluation of the potential application of cactus (Opuntia ficus-indica) as a bio-coagulant for pre-treatment of oil sands process-affected wáter. Sep. Purif. Rev. 2019, 209, 714–724. [Google Scholar] [CrossRef]

- Fard, M.B.; Hamidi, D.; Yetilmezsoy, K.; Alavi, J.; Hosseinpour, F. Utilization of Alyssum mucilage as a natural coagulant in oily-saline wastewater treatment. J. Water Process. Eng. 2021, 40, 101763. [Google Scholar] [CrossRef]

- Mohd Asharuddin, S.; Othman, N.; Altowayti, W.A.H.; Abu Bakar, N.; Hassan, A. Recent advancement in starch modification and its application as water treatment agent. Environ. Technol. Innov. 2021, 23, 101637. [Google Scholar] [CrossRef]

- Salgado-Cruz, M.d.l.P.; Calderón-Domínguez, G.; Chanona-Pérez, J.; Farrera-Rebolloa, R.R.; Méndez-Méndez, J.V.; Díaz-Ramírez, M. Chia (Salvia hispanica L.) seed mucilage release characterisation. A microstructural and image analysis study. Ind. Crops Prod. 2013, 51, 453–462. [Google Scholar] [CrossRef]

- Nharingo, T.; Moyo, M. Application of Opuntia ficus-indica in bioremediation of wastewaters. A critical review. J. Environ. Manag. 2016, 166, 55–72. [Google Scholar] [CrossRef]

- Kumar, R.; Barakat, M.A. Decolourization of hazardous brilliant green from aqueous solution using binary oxidized cactus fruit peel. Chem. Eng. J. 2013, 226, 377–383. [Google Scholar] [CrossRef]

- Pelaez-Cid, A.A.; Tlalpa-Galan, M.A.; Herrera-Gonzalez, A.M. Carbonaceous material production from vegetable residue and their use in the removal of textile dyes present in wastewater. Mater. Sci. Eng. 2013, 45, 012023. [Google Scholar] [CrossRef]

- Mirbahoush, S.M.; Chaibakhsh, N.; Moradi-Shoeili, Z. Highly efficient removal of surfactant from industrial effluents using flaxseed mucilage in coagulation/photo-Fenton oxidation process. Chemosphere 2019, 231, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Sui Kim, I.T.; Sethu, V.; Arumugasamy, S.K.; Selvarajoo, A. Fenugreek seeds and okra for the treatment of palm oil mill effluent (POME)—Characterization studies and modeling with backpropagation feedforward neural network (BFNN). J. Water Process. Eng. 2020, 37, 101500. [Google Scholar] [CrossRef]

- Muniz, G.L.; Borges, A.C.; Fonseca da Silva, T.C. Performance of natural coagulants obtained from agro-industrial wastes in dairy wastewater treatment using dissolved air flotation. J. Water Process. Eng. 2020, 37, 101453. [Google Scholar] [CrossRef]

- Roy, A.; Patra, M.; Sarkhel, S.; Sengupta, S.; Saha, S.; Jha, S.; Sarkhel, G.; Shrivastava, S.L. Fucose-containing Abroma augusta mucilage hydrogel as a potential probiotic carrier with prebiotic function. Food Chem. 2022, 387, 132941. [Google Scholar] [CrossRef] [PubMed]

- Freitas, T.K.F.S.; Oliveira, V.M.; De Souza, M.T.F.; Geraldino, H.C.L.; Almeida, V.C.; Fávaro, S.L.; Garcia, J.C. Optimization of coagulation-flocculation process for treatment of industrial textile wastewater using okra (A. esculentus) mucilage as natural coagulant. Ind. Crops Prod. 2015, 76, 538–544. [Google Scholar] [CrossRef]

- Bouaouinea, O.; Bourven, I.; Khalil, F.; Bressollier, P.; Baudu, M. Identification and role of Opuntia ficus indica constituents in the flocculation mechanism of colloidal solutions. Sep. Purif. Rev. 2019, 209, 892–899. [Google Scholar] [CrossRef]

- Matsuhiro, B.; Lillo, L.E.; Saenz, C.; Urzúa, C.C.; Zarate, O. Chemical characterization of the mucilage from fruits of Opuntia ficus indica. Carbohydr. Polym. 2006, 63, 263–267. [Google Scholar] [CrossRef]

| Ni Max | Mn | Mw | Mz | Mz+1 | I |

|---|---|---|---|---|---|

| 15 | 438.80 | 536.80 | 613.95 | 671.78 | 1.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Otálora, M.C.; Wilches-Torres, A.; Lara, C.R.; Cifuentes, G.R.; Gómez Castaño, J.A. Use of Opuntia ficus-indica Fruit Peel as a Novel Source of Mucilage with Coagulant Physicochemical/Molecular Characteristics. Polymers 2022, 14, 3832. https://doi.org/10.3390/polym14183832

Otálora MC, Wilches-Torres A, Lara CR, Cifuentes GR, Gómez Castaño JA. Use of Opuntia ficus-indica Fruit Peel as a Novel Source of Mucilage with Coagulant Physicochemical/Molecular Characteristics. Polymers. 2022; 14(18):3832. https://doi.org/10.3390/polym14183832

Chicago/Turabian StyleOtálora, Maria Carolina, Andrea Wilches-Torres, Carlos Rafael Lara, Gabriel Ricardo Cifuentes, and Jovanny A. Gómez Castaño. 2022. "Use of Opuntia ficus-indica Fruit Peel as a Novel Source of Mucilage with Coagulant Physicochemical/Molecular Characteristics" Polymers 14, no. 18: 3832. https://doi.org/10.3390/polym14183832