The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber Modifications

2.3. Characterizations of Untreated and Treated Kenaf Fibers

2.4. Fabrication of Epoxy Composites Reinforced with Kenaf Fibers Using Compression Moulding

2.5. Characterization of Epoxy Composite Reinforced with Untreated and Treated Kenaf Fibers

3. Results and Discussion

3.1. Thermal Stability Analysis

3.2. Tensile Properties of Kenaf Single Fibers

3.3. FTIR Spectroscopy Result

3.4. Morphological Analysis for Kenaf Fibers

3.5. Tensile Strength Properties of Untreated and Treated Kenaf/Epoxy Composites

3.6. Dynamic Mechanical Properties of Untreated and Treated Kenaf/Epoxy Composites

3.7. Morphological Analysis for Epoxy Composite Reinforced with Untreated and Treated Kenaf Fiber

4. Conclusions

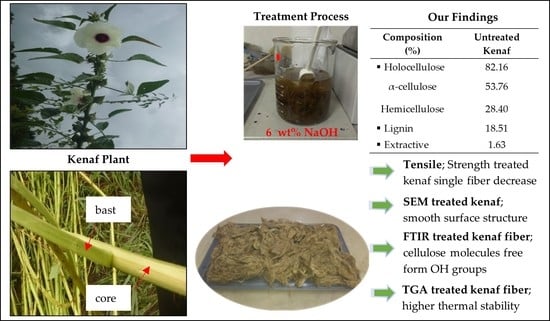

- Treated kenaf fiber exhibited higher thermal stability at higher temperatures compared to untreated kenaf fiber.

- As compared to treated kenaf fiber, untreated kenaf fiber showed high tensile properties and 6 wt% alkali treatment decreased the tensile strength by 34.65% while the Young’s modulus dropped 11.92%

- FTIR analysis show the disappearance of a peak due to the elimination of lignin and hemicellulose after the NaOH treatment.

- Immersion of kenaf fiber in 6 wt% NaOH for 24 h successfully cleans the fiber surface removing all the impurities.

- Alkali treatment has an influence regarding the increase of thermal stability of composites with increasing temperature during thermal degradation.

- Incorporated treated kenaf in the epoxy composite significantly decreases the mechanical properties of the epoxy composite.

- Epoxy composite reinforced with untreated kenaf fiber is sensitive to temperature whereby it shows a higher loss value (82%) between room temperature to 150 °C. Room temperature is the optimum temperature for the treated kenaf/epoxy composite where the tensile strength starts to become lower than a neat epoxy starting from a temperature of 50 °C onwards.

- The storage modulus was influenced by the chemical treatment and also temperature. Storage modulus values were minimum for the composite reinforced with treated kenaf fiber and decreased as the temperature increased.

- Alkali treatment leads to lower tan δ values and increases the loss modulus value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- El-Shekeil, Y.A.; Salit, M.S.; Abdan, K.; Zainudin, E.S. Development of a New Kenaf Bast Fiber-Reinforced Thermoplastic Polyurethane Composite. Bioresources 2011, 6, 4662–4672. [Google Scholar]

- Fulton, I.; Qatu, M.S.; Shi, S. Mechanical Properties of Kenaf-Based Natural Fiber Composites. In Proceedings of the 16th International Conference on Composite Structures, Porto, Portugal, 28–30 June 2011. [Google Scholar]

- Alamri, H.; Low, I.M. Mechanical Properties and Water Absorption Behaviour of Recycled Cellulose Fibre Reinforced Epoxy composites. Polym. Test. 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Saxena, M.; Pappu, A.; Haque, R.; Sharma, A. Cellulose Fibers: Bio and Nano-Polymer Composites; Kalia, S., Kaith, B.S., Kaur, I., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-17369-1. [Google Scholar]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A Review of Adequate Materials for Automotive Applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Ismail, N.F.; Sulong, A.B.; Muhamad, N.; Tholibon, D.; MdRadzi, M.K.F.; WanIbrahim, W.A.S. Review of the Compression Moulding of Natural Fiber-Reinforced Thermoset Composites: Material Processing and Characterisations. Pertanika J. Trop. Agric. Sci. 2015, 38, 533–547. [Google Scholar]

- Khalil, H.P.S.A.; Yusra, A.F.I.; Bhat, A.H.; Jawaid, M. Cell Wall Ultrastructure, Anatomy, Lignin Distribution, and Chemical Composition Of Malaysian Cultivated Kenaf Fiber. Ind. Crop. Prod. 2010, 31, 113–121. [Google Scholar] [CrossRef]

- Hashim, M.Y.; Roslan, M.N.; Amin, A.M.; Ahmad Zaidi, A.M.; Ariffin, S. Mercerization treatment parameter effect on natural fiber reinforced polymer matrix composite: A brief review. Int. J. Mater. Metall. Eng. 2012, 6, 778–784. [Google Scholar]

- Ghassemieh, E. Materials in Automotive Application, State of the Art and Prospects. In New Trends and Developments in Automotive Industry; IntechOpen: London, UK, 2011; pp. 365–394. [Google Scholar]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Jawaid, M.; Thariq, M.; Saba, N. Mechanical and Physical Testing of Biocomposites, Fibre Reinforced Composites And Hybrid Composites; Woodhead Publishing: Oxford, UK, 2019; ISBN 9780081022924. [Google Scholar]

- Andre, N.G.; Ishak, Z.A.M. Predicting the Tensile Modulus of Randomly Oriented Nonwoven Kenaf/Epoxy Composites. Porc. Chem. 2016, 19, 419–425. [Google Scholar] [CrossRef] [Green Version]

- Akil, H.M.; Omar, M.F.; Mazuki, A.a.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf Fiber Reinforced Composites: A Review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.S.; Kaur, I. Cellulose Fibers: Bio- and Nano-Polymer Composites. Green Chemistry and Technology; Springer: New York, NY, USA, 2011; ISBN 9783642173691. [Google Scholar]

- Reddy, M.I.; Reddy, V.S. Dynamic Mechanical Analysis of Hemp Fiber Reinforced Polymer Matrix Composites. Int. J. Eng. Res. Technol. 2014, 3, 410–415. [Google Scholar]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.S.; Margem, F.M. Thermogravimetric behavior of natural fibers reinforced polymer composites—An overview. Mater. Sci. Eng. A 2012, 557, 17–28. [Google Scholar] [CrossRef]

- Mutasher, S.A.; Poh, A.; Than, A.M.; Law, J. The Effect of Alkali Treatment Mechanical Properties of Kenaf Fiber Epoxy Composite. Key Eng. Mater. 2011, 471–472, 191–196. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B.F. Investigation on Interfacial Adhesion of Date Palm/Epoxy usingFragmentation Technique. J. Mater. 2014, 53, 928–937. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The Effect of Alkaline Treatment on Mechanical Properties of Kenaf Fibers and Their Epoxy Composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.R.M.; Raftari, M. Characteristics of continuous unidirectional kenaf fiber reinforced epoxy composites. Mater. Des. 2014, 64, 640–649. [Google Scholar] [CrossRef]

- Krishna, K.V.; Kanny, K. The Effect of Treatment on Kenaf Fi Ber Using Green Approach And Their Reinforced Epoxy Composites. Compos. Part B 2016, 104, 1–22. [Google Scholar] [CrossRef]

- Ismail, N.F.; Muhamad, N.; Sulong, A.B.; Haron, C.H.C.; Tholibon, D.; Tharazi, I.; MdRadzi, M.K.F.; Razak, Z. Mechanical Properties of Compression Molded Epoxy Polymer Composites Reinforced With Kenaf Fibers. J. Mech. Eng. 2017, 2, 1–12. [Google Scholar]

- Azwa, Z.N.; Yousif, B.F. Characteristics of Kenaf Fibre/Epoxy Composites Subjected to Thermal Degradation. Polym. Degrad. Stab. 2013, 98, 2752–2759. [Google Scholar] [CrossRef]

- Saliu, H.R.; Ishiaku, U.S.; Yakubu, M.K.; Kolawole, E.G.; Adefila, S.S. The Effect of Epoxy Concentration and Fibre Loading on the Mechanical Properties of ABS/Epoxy-Coated Kenaf Fibre Composites. Open J. Compos. Mater. 2015, 5, 41–48. [Google Scholar] [CrossRef] [Green Version]

- Ismail, N.F.; Muhammad, N.; Sulong, A.B.; Haron, C.H.C. Effects of Alkali Treatment on Mechanical Properties of Epoxy Composites Reinforced Kenaf Fibre using Compression Moulding Process. Int. J. Mech. Mechatron. Eng. 2018, 18, 86–95. [Google Scholar]

- Prakash, V.A.; Viswanthan, R. Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos. Part A Appl. Sci. Manuf. 2019, 118, 317–326. [Google Scholar] [CrossRef]

- Razak, S.I.A.; Rahman, W.A.W.A.; Sharif, N.F.A.; Nayan, N.H.M.; Saidi, M.A.A.; Yahya, M.Y. Polyaniline-coated kenaf core and its effect on the mechanical and electrical properties of epoxy resin. Compos. Interfaces 2013, 20, 611–622. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Suraya, N.L. Anhydride Modification of Cultivated Kenaf Bast Fibers:Morphological, Spcetroscopic and Thermal Studies. BioResources 2011, 6, 1122–1135. [Google Scholar]

- Ibrahim, N.A.; Hadithon, K.A.; Abdan, K. Effect of Fiber Treatment on Mechanical Properties of Kenaf Fiber-Ecoflex Composites. J. Reinf. Plast. Compos. 2009, 29, 2192–2198. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Sulong, A.B.; Radzi, M.K.F.; Ismail, N.F.; Raza, M.R.; Muhamad, N.; Khan, M.A. Influence of Alkaline Treatment and Fiber Loading onThe Physical And Mechanical Properties of Kenaf/Polypropylene Composites For Variety of Applications. Prog. Nat. Sci. Mater. Int. 2016, 26, 657–664. [Google Scholar] [CrossRef]

- Sulong, A.B.S.; Mohd Radzuan, N.A.; Mamat, M.R.; Tharazi, I.; Tholibon, D.; Dweiri, R.; Hammadi, M.S. Kenaf Reinforced PLA Composite Thermoforming: A Numerical Simulation. Int. J. Integr. Eng. 2019, 10, 15–20. [Google Scholar] [CrossRef]

- Aziz, S.H.; Ansell, M.P. The Effect of Alkalization and Fibre Alignment onThe Mechanical andThermal Properties ofKenaf and Hemp Bast Fibre Composites: Part 1—Polyester Resin Matrix. Compos. Sci. Technol. 2004, 64, 1219–1230. [Google Scholar] [CrossRef]

- Symington, M.C.; Banks, W.M.; West, O.D.; Pethrick, R.A. Tensile Testing of Cellulose Based Natural Fibers for Structural Composite Applications. J. Compos. Mater. 2009, 43, 1083–1108. [Google Scholar] [CrossRef] [Green Version]

- Mahjoub, R.; Mohamad, J.; Rahman, A.; Sam, M.; Hamid, S. Tensile Properties of Kenaf Fiber Due to Various Conditions Of Chemical Fiber Surface Modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- El-Shekeil, Y.; Sapuan, S.M.; Zainudin, E.S.; Khalina, A. Effect of Fiber Loading on the Mechanical Properties of Kenaf Fiber Reinforced Thermoplastic Polyurethane Composite. Key Eng. Mater. 2011, 471–472, 1058–1063. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterizationof Natural Fiber Surfaces and Natural Fiber Composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Kassim, M.A.; Taib, M.N.A.M.; Jamaludin, M.A.; Zakaria, N.; Nordin, K. Mechanical Properties of Treated Kenaf (Hibiscus Cannabinus) Polyester Composite At Different Alkaline Concentration. In Proceedings of the 2013 IEEE Business Engineering and Industrial Applications Colloquium (BEIAC), Langkawi, Malaysia, 7–9 April 2013; pp. 421–424. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A. Effect of Layering Pattern onThe Dynamic Mechanical Properties andThermal Degradation Of Oil Palm-Jute Fibers Reinforced Epoxy Hybrid Composite. BioResources 2011, 6, 2309–2322. [Google Scholar]

- Shanmugam, D.; Thiruchitrambalam, M. Static and Dynamic Mechanical Properties of Alkali Treated Unidirectional Continuous Palmyra Palm Leaf Stalk Fiber/Jute Fiber Reinforced Hybrid Polyester Composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Tholibon, D.; Sulong, A.B.; Muhammad, N.; Ismail, N.F.; Tharazi, I.; Md Radzi, M.K.F. Tensile Properties of Unidirectional Kenaf Fiber Polypropylene Composite. J. Teknol. 2016, 78, 101–106. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A Review on Dynamic Mechanical Properties of Natural Fibre Reinforced Polymer Composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization Behavior of Poly(Ε-Caprolactone)/Layered Double Hydroxide Nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Akil, H.; Akram, A.; Mazuki, M.; Safiee, S.; Arifin, Z.; Ishak, M.; Bakar, A.A. Study on Dynamic Mechanical Properties of Pultruded Kenaf Fiber Reinforced Composites. In Proceedings of the 7th Asian-Australian Conference on Composite Materials, Taipei, Taiwan, 15–18 November 2010. [Google Scholar]

| Properties | Epoxy | Hardener |

|---|---|---|

| Flexural strength [N/mm2] | 96 | - |

| Flexural modulus [kN/mm2] | 3.0 | - |

| Yield Compressive strength [N/mm2] | 112 | - |

| Tensile Strength [N/mm2] | 79 | - |

| Elongation at break [%] | 4.4 | - |

| Gel point time [min] 500 g | 25 | - |

| Density [g/cm3] | 1.16 | 1.07 ± 0.02 |

| Mixing ratio | 2 | 1 |

| Sample | Temperature Transition Range [°C] | Maximum Temperature Rate [°C] | Weight Loss [%] |

|---|---|---|---|

| Kenaf fiber with NaOH treatment | 26–200 | 89.93 | 10.94 |

| 200–300 | 258.63 | 20.71 | |

| 300–390 | 386.13 | 65.97 | |

| Kenaf fiber without NaOH treatment | 27–200 | 79.89 | 11.67 |

| 200–350 | 277.79 | 27.97 | |

| 350–390 | 377.39 | 79. 90 |

| Peak | Compound |

|---|---|

| Peak 1 | moisture content |

| Peak 2 | hemicellulose |

| Peak 3 | cellulose |

| Types of Fiber | Tensile Strength [MPa] | Young’s Modulus [MPa] |

|---|---|---|

| Kenaf fiber with NaOH treatment | 138.92 | 5767.53 |

| Kenaf fiber without NaOH treatment | 159.98 | 8201.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ismail, N.F.; Mohd Radzuan, N.A.; Sulong, A.B.; Muhamad, N.; Che Haron, C.H. The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites. Polymers 2021, 13, 2005. https://doi.org/10.3390/polym13122005

Ismail NF, Mohd Radzuan NA, Sulong AB, Muhamad N, Che Haron CH. The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites. Polymers. 2021; 13(12):2005. https://doi.org/10.3390/polym13122005

Chicago/Turabian StyleIsmail, Nur Farhani, Nabilah Afiqah Mohd Radzuan, Abu Bakar Sulong, Norhamidi Muhamad, and Che Hassan Che Haron. 2021. "The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites" Polymers 13, no. 12: 2005. https://doi.org/10.3390/polym13122005