An Innovative Treatment Based on Sodium Citrate for Improving the Mechanical Performances of Flax Fiber Reinforced Composites

Abstract

:1. Introduction

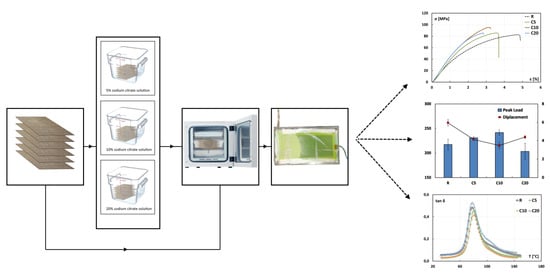

2. Experimental Section

2.1. Materials and Composites Manufacturing

2.2. Mechanical Characterization

2.3. Morphological Characterization

3. Results and Discussion

3.1. Mechanical Characterization

3.2. Morphological Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kalia, S.; Kaith, B.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites—A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Bozaci, E.; Sever, K.; Sarikanat, M.; Seki, Y.; Demir, A.; Ozdogan, E.; Tavman, I. Effects of the atmospheric plasma treatments on surface and mechanical properties of flax fiber and adhesion between fiber–matrix for composite materials. Compos. Part B Eng. 2013, 45, 565–572. [Google Scholar] [CrossRef]

- Scalici, T.; Fiore, V.; Valenza, A. Effect of plasma treatment on the properties of Arundo Donax L. leaf fibres and its bio-based epoxy composites: A preliminary study. Compos. Part B Eng. 2016, 94, 167–175. [Google Scholar] [CrossRef]

- Ragoubi, M.; Bienaimé, D.; Molina, S.; George, B.; Merlin, A. Impact of corona treated hemp fibres onto mechanical properties of polypropylene composites made thereof. Ind. Crop. Prod. 2010, 31, 344–349. [Google Scholar] [CrossRef]

- Kabir, M.; Wang, H.; Lau, K.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Le Troedec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Gloaguen, V.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A Appl. Sci. Manuf. 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 589–597. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Yuan, X. Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment. J. Reinf. Plast. Compos. 2012, 31, 425–437. [Google Scholar] [CrossRef]

- Gañan, P.; Garbizu, S.; Llano-Ponte, R.; Mondragon, I. Surface modification of sisal fibers: Effects on the mechanical and thermal properties of their epoxy composites. Polym. Compos. 2005, 26, 121–127. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Sisal fiber-reinforced green composites: Effect of ecofriendly fiber treatment. Polym. Compos. 2018, 39, 4310–4321. [Google Scholar] [CrossRef]

- Dos Santos, J.C.; Siqueira, R.L.; Vieira, L.M.G.; Freire, R.T.S.; Mano, V.; Panzera, T.H. Effects of sodium carbonate on the performance of epoxy and polyester coir-reinforced composites. Polym. Test. 2018, 67, 533–544. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Tensile properties of chemically treated hemp fibres as reinforcement for composites. Compos. Part B Eng. 2013, 53, 362–368. [Google Scholar] [CrossRef]

- AlSaeed, T.; Yousif, B.F.; Ku, H. The potential of using date palm fibres as reinforcement for polymeric composites. Mater. Des. 2013, 43, 177–184. [Google Scholar] [CrossRef]

- Bartos, A.; Anggono, J.; Farkas, Á.E.; Kun, D.; Soetaredjo, F.E.; Móczó, J.; Antoni; Purwaningsih, H.; Pukánszky, B. Alkali treatment of lignocellulosic fibers extracted from sugarcane bagasse: Composition, structure, properties. Polym. Test. 2020, 88, 106549. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Fiore, V.; Sanfilippo, C.; Calabrese, L. Influence of sodium bicarbonate treatment on the aging resistance of natural fiber reinforced polymer composites under marine environment. Polym. Test. 2019, 80, 106100. [Google Scholar] [CrossRef]

- Mukhtar, I.; Leman, Z.; Zainudin, E.S.; Ishak, M.R. Effectiveness of alkali and sodium bicarbonate treatments on sugar palm fiber: Mechanical, thermal, and chemical investigations. J. Nat. Fibers 2020, 17, 877–889. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L. Effect of stacking sequence and sodium bicarbonate treatment on quasi-static and dynamic mechanical properties of flax/jute epoxy-based composites. Materials 2019, 12, 1363. [Google Scholar] [CrossRef] [Green Version]

- Dos Santos, J.C.; de Oliveira, L.Á.; Vieira, L.M.G.; Mano, V.; Freire, R.T.; Panzera, T.H. Eco-friendly sodium bicarbonate treatment and its effect on epoxy and polyester coir fibre composites. Constr. Build. Mater. 2019, 211, 427–436. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Effect of sodium bicarbonate treatment on mechanical properties of flax-reinforced epoxy composite materials. J. Compos. Mater. 2017, 52, 1061–1072. [Google Scholar] [CrossRef]

- Belaadi, A.; Amroune, S.; Bourchak, M. Effect of eco-friendly chemical sodium bicarbonate treatment on the mechanical properties of flax fibres: Weibull statistics. Int. J. Adv. Manuf. Technol. 2020, 106, 1753–1774. [Google Scholar] [CrossRef]

- Azim, A.B.E.A.; Elsaid, T.W.; El Said, H.W.; Hemida, W.; Zaghlool, S.; Ramadan, A.; Gouda, Z.; El Masry, S.; Reda, W.; Ali, H.M. A randomized controlled clinical trial of 4% sodium citrate versus heparin as locking solution for temporary dialysis catheters among hemodialysis patients. Clin. Nephrol. 2018, 90, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Maca, J.V.; Miller, R.K.; Acuff, G.R. Microbiological, sensory and chemical characteristics of vacuum-packaged ground beef patties treated with salts of organic acids. J. Food Sci. 1997, 62, 591–596. [Google Scholar] [CrossRef]

- Sallam, K.I. Antimicrobial and antioxidant effects of sodium acetate, sodium lactate, and sodium citrate in refrigerated sliced salmon. Food Control 2007, 18, 566–575. [Google Scholar] [CrossRef] [Green Version]

- Mohan, C.O.; Ravishankar, C.N.; Kumar, K.A.; Gopal, T.S. Biogenic amines and nucleotide breakdown products of sodium acetate, sodium lactate, and sodium citrate treated seer fish (Scomberomorus commerson) during iced storage. J. Food Saf. 2019, 39, e12633. [Google Scholar] [CrossRef]

- Lee, Y.-L.; Cesario, T.; Owens, J.; Shanbrom, E.; Thrupp, L.D. Antibacterial activity of citrate and acetate. Nutrition 2002, 18, 665–666. [Google Scholar] [CrossRef]

- Zhang, W.; Li, H.-J.; Chen, L.; Sun, J.; Ma, X.; Li, Y.; Liu, C.; Han, X.; Pang, B.; Wu, Y.-C. Performance and mechanism of a composite scaling–corrosion inhibitor used in seawater: 10-methylacridinium iodide and sodium citrate. Desalination 2020, 486, 114482. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. A review on the characterisation of natural fibres and their composites after alkali treatment and water absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 234, 198–217. [Google Scholar] [CrossRef]

- Wang, H.; Memon, H.; Hassan, E.A.M.; Miah, S.; Ali, A. Effect of jute fiber modification on mechanical properties of jute fiber composite. Materials 2019, 12, 1226. [Google Scholar] [CrossRef] [Green Version]

- Ridzuan, M.J.M.; Majid, M.S.A.; Hafis, S.M.; Azduwin, K. The effects of alkali treatment on the mechanical and morphological properties of Pennisetum purpureum/glass-reinforced epoxy hybrid composites. Plast. Rubber Compos. 2017, 46, 421–430. [Google Scholar] [CrossRef]

- Reddy, K.O.; Maheswari, C.U.; Shukla, M.; Song, J.I.; Rajulu, A.V. Tensile and structural characterization of alkali treated Borassus fruit fine fibers. Compos. Part B Eng. 2013, 44, 433–438. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Bartos, A.; Utomo, B.P.; Kanyar, B.; Anggono, J.; Soetaredjo, F.E.; Móczó, J.; Pukánszky, B. Reinforcement of polypropylene with alkali-treated sugarcane bagasse fibers: Mechanism and consequences. Compos. Sci. Technol. 2020, 200, 108428. [Google Scholar] [CrossRef]

- Yan, L. Effect of alkali treatment on vibration characteristics and mechanical properties of natural fabric reinforced composites. J. Reinf. Plast. Compos. 2012, 31, 887–896. [Google Scholar] [CrossRef]

- Wu, C.; Yang, K.; Gu, Y.; Xu, J.; Ritchie, R.O.; Guan, J. Mechanical properties and impact performance of silk-epoxy resin composites modulated by flax fibres. Compos. Part A Appl. Sci. Manuf. 2019, 117, 357–368. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Fiore, V.; Sanfilippo, C.; Calabrese, L. Dynamic mechanical behavior analysis of flax/jute fiber-reinforced composites under salt-fog spray environment. Polymers 2020, 12, 716. [Google Scholar] [CrossRef] [Green Version]

- Jawaid, M.; Khalil, H.A.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part B Eng. 2013, 45, 619–624. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Vitale, G.; Valenza, A. Static and dynamic mechanical properties of Arundo Donax fillers-epoxy composites. Mater. Des. 2014, 57, 456–464. [Google Scholar] [CrossRef]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous Palmyra Palm Leaf Stalk Fiber/jute fiber reinforced hybrid polyester composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Nair, K.M.; Thomas, S.; Groeninckx, G. Thermal and dynamic mechanical analysis of polystyrene composites reinforced with short sisal fibres. Compos. Sci. Technol. 2001, 61, 2519–2529. [Google Scholar] [CrossRef]

- Nadlene, R.; Sapuan, S.; Jawaid, M.; Ishak, M.; Yusriah, L. The effects of chemical treatment on the structural and thermal, physical, and mechanical and morphological properties of roselle fiber-reinforced vinyl ester composites. Polym. Compos. 2016, 39, 274–287. [Google Scholar] [CrossRef]

- Simonassi, N.T.; Pereira, A.C.; Monteiro, S.N.; Margem, F.M.; Rodríguez, R.J.S.; De Deus, J.F.; Vieira, C.M.F.; Drelich, J. Reinforcement of polyester with renewable ramie fibers. Mater. Res. 2017, 20, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Yousif, B.F.; Shalwan, A.; Chin, C.W.; Ming, K.C. Flexural properties of treated and untreated kenaf/epoxy composites. Mater. Des. 2012, 40, 378–385. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Agarwal, B.D.; Broutman, L.J.; Bert, C.W. Analysis and performance of fiber composites. J. Appl. Mech. 1981, 48, 213. [Google Scholar] [CrossRef]

- Seki, Y.; Sarikanat, M.; Sever, K.; Durmuşkahya, C. Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos. Part B Eng. 2013, 44, 517–523. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- Liu, W.; Mohanty, A.K.; Drzal, L.T.; Askel, P.; Misra, M. Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 2004, 39, 1051–1054. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

| SQ | DF | MS | F | p-Value | ||

|---|---|---|---|---|---|---|

| Tensile Strength | Batch | 2281.83 | 3 | 760.6099 | 257.9597 | 9.37727 × 10−14 |

| Error | 47.17697 | 16 | 2.948561 | |||

| Total | 2329.007 | 19 | ||||

| Tensile Modulus | Batch | 13.87749 | 3 | 4.62582860 | 60.85088 | 5.71951 × 10−9 |

| Error | 1.216305 | 16 | 0.07601908 | |||

| Total | 15.09379 | 19 | ||||

| Flexural Strength | Batch | 414.2694 | 3 | 138.0898 | 8.629053 | 1.22916 × 10−3 |

| Error | 256.0463 | 16 | 16.00289 | |||

| Total | 670.3157 | 19 | ||||

| Flexural Modulus | Batch | 2.443777 | 3 | 0.814592295 | 11.70749 | 2.6105 × 10−4 |

| Error | 1.11326 | 16 | 0.069578719 | |||

| Total | 3.557036 | 19 |

| Sample | R | C5 | C10 | C20 |

|---|---|---|---|---|

| Thickness [mm] | 4.07 ± 0.02 | 4.44 ± 0.03 | 4.55 ± 0.07 | 4.71 ± 0.04 |

| Theoretical density [g/cm3] | 1.3183 | 1.3327 | 1.3334 | 1.3595 |

| Experimental density [g/cm3] | 1.2288 | 1.2941 | 1.3047 | 1.2610 |

| Fiber content [%] | 36.8 ± 0.2 | 36.5 ± 0.2 | 37.3 ± 0.5 | 36.2 ± 0.3 |

| Voids content [%] | 6.8 ± 0.1 | 2.9 ± 0.1 | 2.2 ± 0.1 | 7.2 ± 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiore, V.; Badagliacco, D.; Sanfilippo, C.; Miranda, R.; Valenza, A. An Innovative Treatment Based on Sodium Citrate for Improving the Mechanical Performances of Flax Fiber Reinforced Composites. Polymers 2021, 13, 559. https://doi.org/10.3390/polym13040559

Fiore V, Badagliacco D, Sanfilippo C, Miranda R, Valenza A. An Innovative Treatment Based on Sodium Citrate for Improving the Mechanical Performances of Flax Fiber Reinforced Composites. Polymers. 2021; 13(4):559. https://doi.org/10.3390/polym13040559

Chicago/Turabian StyleFiore, Vincenzo, Dionisio Badagliacco, Carmelo Sanfilippo, Riccardo Miranda, and Antonino Valenza. 2021. "An Innovative Treatment Based on Sodium Citrate for Improving the Mechanical Performances of Flax Fiber Reinforced Composites" Polymers 13, no. 4: 559. https://doi.org/10.3390/polym13040559