Characterization and Biocompatibility Properties In Vitro of Gel Beads Based on the Pectin and κ-Carrageenan

Abstract

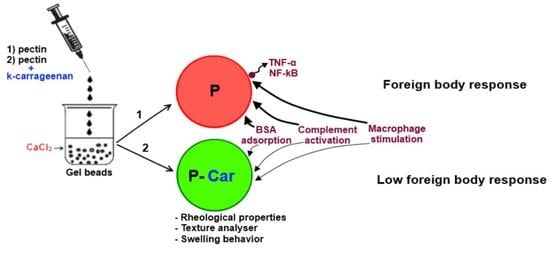

:1. Introduction

2. Results and Discussion

2.1. Rheological Properties of Pectin-Carrageenan Hydrogel

2.2. Preparation and Characterization of Gel Beads

2.3. Swelling Studies

2.4. Protein Adsorption

2.5. Complement Activation

2.6. Haemolysis Assay

2.7. Serosal Adhesion of Hydrogels

2.8. Peritoneal Macrophages Adhesion and Activation

3. Materials and Methods

3.1. Polysaccharides

3.2. Dynamic Oscillatory Measurements

3.3. Preparation of Gel Beads

3.4. Characterization of Gel Beads

3.5. Swelling Characterization of Gel Beads

3.6. BSA Adsorption of Gel Beads

3.7. Complement Activation Evaluation

3.8. Haemolysis Ratio Determination

3.9. Hydrogel Adhesion to Biological Tissue

3.10. Peritoneal Macrophages Adhesion and Activation

3.11. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cascone, S.; Lamberti, G. Hydrogel-based commercial products for biomedical applications: A review. Int. J. Pharm. 2020, 573, 118803. [Google Scholar] [CrossRef] [PubMed]

- Neves, S.C.; Moroni, L.; Barrias, C.C.; Granja, P.L. Leveling up hydrogels: Hybrid systems in tissue engineering. Trends Biotechnol. 2019, 38, 292–315. [Google Scholar] [CrossRef]

- Naahidi, S.; Jafari, M.; Logan, M.; Wang, M.; Yuan, M.; Bae, H.; Dixon, B.; Chena, P. Biocompatibility of hydrogel-based scaffolds for tissue engineering applications. Biotechnol. Adv. 2017, 35, 530–544. [Google Scholar] [CrossRef] [PubMed]

- Spicer, C.D. Hydrogel scaffolds for tissue engineering: The importance of polymer choice. Polym. Chem. 2020, 11, 184–219. [Google Scholar] [CrossRef]

- Heidarian, P.; Kouzani, A.Z.; Kaynak, A.; Paulino, M.; Nasri-Nasrabadi, B.; Zolfagharian, A.; Varley, R. Dynamic plant-derived polysaccharide-based hydrogels. Carbohydr. Polym. 2020, 231, 115743. [Google Scholar] [CrossRef] [PubMed]

- Mohammadinejad, R.; Maleki, H.; Larraneta, E.; Fajardo, A.R.; Nik, A.B.; Shavandi, A.; Sheikhi, A.; Ghorbanpour, M.; Farokhi, M.; Thakur, V.K. Status and future scope of plant-based green hydrogels in biomedical engineering. Appl. Mater. Today 2019, 16, 213–246. [Google Scholar] [CrossRef] [Green Version]

- Lara-Espinoza, C.; Carvajal-Millán, E.; Balandran-Quintana, R.; Lopez-Franco, Y.; Rascon-Chu, A. Pectin and pectin-based composite materials: Beyond food texture. Molecules 2018, 23, 942. [Google Scholar] [CrossRef] [Green Version]

- Minzanova, S.T.; Mironov, V.F.; Arkhipova, D.M.; Khabibullina, A.V.; Mironova, L.G.; Zakirova, Y.M.; Milyukov, V.A. Biological activity and pharmacological application of pectic polysaccharides: A review. Polymers 2018, 10, 1407. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Anderson, C.T. Biosynthesis, localisation, and function of pectins in plants. In Pectin: Technological and Physiological Properties; Kontogiorgos, V., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–15. [Google Scholar] [CrossRef]

- Chan, S.Y.; Choo, W.S.; Young, D.J.; Loh, X.J. Pectin as a rheology modifier: Origin, structure, commercial production and rheology. Carbohydr. Polym. 2017, 161, 118–139. [Google Scholar] [CrossRef]

- Zhang, B.; Hu, B.; Nakauma, M.; Funami, T.; Nishinari, K.; Draget, K.I.; Phillips, G.O.; Fang, Y. Modulation of calcium-induced gelation of pectin by oligoguluronate as compared to alginate. Food Res. Int. 2018, 116, 232–240. [Google Scholar] [CrossRef]

- Cao, L.; Lu, W.; Mata, A.; Nishinari, K.; Fang, Y. Egg-box model-based gelation of alginate and pectin: A review. Carbohydr. Polym. 2020, 242, 116389. [Google Scholar] [CrossRef]

- Pereira, R.F.; Barrias, C.C.; Bártolo, P.J.; Granja, P.L. Cell-instructive pectin hydrogels crosslinked via thiol-norbornene photo-click chemistry for skin tissue engineering. Acta Biomater. 2018, 66, 282–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moslemi, M. Reviewing the recent advances in application of pectin for technical and health promotion purposes: From laboratory to market. Carbohydrate Polymers 2021, 254, 117324. [Google Scholar] [CrossRef] [PubMed]

- Oh, G.-W.; Nam, S.Y.; Heo, S.-J.; Kang, D.-H.; Jung, W.-K. Characterization of ionic cross-linked composite foams with different blend ratios of alginate/pectin on the synergistic effects for wound dressing application. Int. J. Biol. Macromol. 2020, 156, 1565–1573. [Google Scholar] [CrossRef]

- Long, J.; Etxeberria, A.E.; Nand, A.V.; Bunt, C.R.; Ray, S.; Seyfoddin, A. A 3D printed chitosan-pectin hydrogel wound dressing for lidocaine hydrochloride delivery. Mater. Sci. Eng. C 2019, 104, 10987. [Google Scholar] [CrossRef] [PubMed]

- Ji, F.; Li, J.; Qin, Z.; Yang, B.; Zhang, E.; Dong, D.; Wang, J.; Wen, Y.; Tian, L.; Yao, F. Engineering pectin-based hollow nanocapsules for delivery of anticancer drug. Carbohydr. Polym. 2017, 177, 86–96. [Google Scholar] [CrossRef]

- Moreira, H.R.; Munarin, F.; Gentilini, R.; Visai, L.; Granja, P.L.; Tanzi, M.C.; Petrini, P. Injectable pectin hydrogels produced by internal gelation: pH dependence of gelling and rheological properties. Carbohydr. Polym. 2014, 103, 339–347. [Google Scholar] [CrossRef]

- Cui, S.; Yao, B.; Gao, M.; Sun, X.; Gou, D.; Hu, J.; Zhou, Y.; Liu, Y. Effects of pectin structure and crosslinking method on the properties of crosslinked pectin nanofibers. Carbohydr. Polym. 2017, 157, 766–774. [Google Scholar] [CrossRef]

- Augustine, R.; Augustine, A.; Kalarikkal, N.; Thomas, S. Fabrication and characterization of biosilver nanoparticles loaded calcium pectinate nano-micro dual-porous antibacterial wound dressings. Prog. Biomater. 2016, 5, 223–235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, N.; Xue, F.; Zhang, H.; Sanyour, H.J.; Rickel, A.P.; Uttecht, A.; Fanta, B.; Hu, J.; Hong, Z. Fabrication and characterization of pectin hydrogel nanofiber scaffolds for differentiation of mesenchymal stem cells into vascular cells. ACS Biomater. Sci. Eng. 2019, 5, 6511–6519. [Google Scholar] [CrossRef]

- Kulikouskaya, V.; Kraskouski, A.; Hileuskaya, K.; Zhura, A.; Tratsyak, S.; Agabekov, V. Fabrication and characterization of pectin-based three-dimensional porous scaffolds suitable for treatment of peritoneal adhesions. J. Biomed. Mater. Res. 2019, 107A, 1814–1823. [Google Scholar] [CrossRef] [PubMed]

- Silini, A.R.; Spoldi, V.; Munari, S.D.; Vertula, E.; Munarin, F.; Petrini, P.; Fare, S.; Parolini, O. Immunological and differentiation properties of amniotic cells are retained after immobilization in pectin gel. Cell Transplant. 2018, 27, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Markov, P.A.; Krachkovsky, N.S.; Durnev, E.A.; Martinson, E.A.; Litvinets, S.G.; Popov, S.V. Mechanical properties, structure, bioadhesion, and biocompatibility of pectin hydrogels. J. Biomed. Mater. Res. Part A 2017, 105A, 2572–2581. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.-F.; Fu, Y.-P.; Chen, X.-F.; Austarheim, I.; Inngjerdingen, K.T.; Huang, C.; Eticha, L.D.; Song, X.; Li, L.; Paulsen, B.S. Purification and partial structural characterization of a complement fixating polysaccharide from rhizomes of Ligusticum chuanxiong. Molecules 2017, 22, 287. [Google Scholar] [CrossRef] [Green Version]

- Georgiev, Y.N.; Paulsen, B.S.; Kiyohara, H.; Cize, M.; Ognyanov, M.H.; Vasicek, O.; Risef, F.; Denev, P.N.; Yamada, H.; Lojek, A.; et al. The common lavender (Lavandula angustifolia Mill.) pectic polysaccharides modulate phagocytic leukocytes and intestinal Peyer’s patch cells. Carbohydr. Polym. 2017, 174, 948–959. [Google Scholar] [CrossRef]

- Markov, P.A.; Khramova, D.S.; Shumikhin, K.V.; Nikitina, I.R.; Beloserov, V.S.; Martinson, E.A.; Litvinets, S.G.; Popov, S.V. Mechanical properties of the pectin hydrogels and inflammation response to their subcutaneous implantation. J. Biomed. Mater. Res. 2019, 107, 2088–2098. [Google Scholar] [CrossRef] [PubMed]

- Gupta, P.K.; Rajanc, M.G.R.; Kulkarni, S. Activation of murine macrophages by G1-4A, a polysaccharide from Tinospora cordifolia, in TLR4/MyD88 dependent manner. International Immunopharmacology 2017, 50, 168–177. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, R.; Wen, P.; Song, Y.; He, B.; Tan, J.; Hao, H.; Wang, H. Structural characterization and immunological activity of pectin polysaccharide from kiwano (Cucumis metuliferus) peels. Carbohydr. Polym. 2021, 254, 117371. [Google Scholar] [CrossRef]

- Lee, S.J.; In, G.; Han, S.T.; Lee, M.H.; Lee, J.W.; Shin, K.S. Structural characteristics of a red ginseng acidic polysaccharide rhamnogalacturonan I with immunostimulating activity from red ginseng. J. Ginseng Res. 2020, 44, 570–579. [Google Scholar] [CrossRef]

- Amorim, J.C.; Vriesmann, L.C.; Petkowicz, C.L.O.; Martinez, G.R.; Noleto, G.R. Modified pectin from Theobroma cacao induces potent pro-inflammatory activity in murine peritoneal macrophage. Int. J. Biol. Macromol. 2016, 92, 1040–1048. [Google Scholar] [CrossRef]

- Klopfleisch, R.; Jung, F. The pathology of the foreign body reaction against biomaterials. J. Biomed. Mater. Res. Part A 2017, 105A, 927–940. [Google Scholar] [CrossRef] [PubMed]

- Beaumont, M.; Tran, R.; Vera, G.; Niedrist, D.; Rousset, A.; Pierre, R.; Shastri, V.P.; Forget, A. Hydrogel-forming algae polysaccharides: From seaweed to biomedical applications. Biomacromolecules 2021, 22, 1027–1052. [Google Scholar] [CrossRef]

- Jiang, J.L.; Zhang, W.Z.; Ni, W.-X.; Shao, J.-W. Insight on structure-property relationships of carrageenan from marine red algal: A review. Carbohydr. Polym. 2021, 257, 117642. [Google Scholar] [CrossRef]

- Zhong, H.; Gao, X.; Cheng, C.; Liu, C.; Wang, Q.; Han, X. The structural characteristics of seaweed polysaccharides and their application in gel drug delivery systems. Mar. Drugs 2020, 18, 658. [Google Scholar] [CrossRef]

- Mokhtari, H.; Tavakoli, S.; Safarpour, F.; Kharaziha, M.; Bakhsheshi-Rad, H.R.; Ramakrishna, S.; Berto, F. Recent advances in chemically-modified and hybrid carrageenan-based platforms for drug delivery, wound healing, and tissue engineering. Polymers 2021, 13, 1744. [Google Scholar] [CrossRef]

- Shen, S.; Chen, X.; Shen, Z.; Chen, H. Marine polysaccharides for wound dressings application: An overview. Pharmaceutics 2021, 13, 1666. [Google Scholar] [CrossRef] [PubMed]

- Wahba, M.I. Carrageenan stabilized calcium pectinate beads and their utilization as immobilization matrices. Biocatal. Agric. Biotechnol. 2021, 35, 102078. [Google Scholar] [CrossRef]

- Günter, E.A.; Martynov, V.V.; Belozerov, V.S.; Martinson, E.A.; Litvinets, S.G. Characterization and swelling properties of composite gel microparticles based on the pectin and κ-carrageenan. Int. J. Biol. Macromol. 2020, 164, 2232–2239. [Google Scholar] [CrossRef] [PubMed]

- Özkahraman, B.; Özbaş, Z.; Yaşayan, G.; Akgüner, Z.P.; Yarımcan, F.; Alarçin, E.; Bal-Öztürk, A. Development of mucoadhesive modified kappa-carrageenan/pectin patches for controlled delivery of drug in the buccal cavity. J. Biomed. Mater. Res. 2021, 1–12. [Google Scholar] [CrossRef]

- Ross-Murphy, S.B.; Morris, V.J.; Morris, E.R. Molecular viscoelasticity of xanthan polysaccharide. Faraday Symp. Chem. Soc. 1983, 18, 115–129. [Google Scholar] [CrossRef]

- Rosalina, I.; Bhattacharya, M. Dynamic rheological measurements and analysis of starch gels. Carbohydr. Polym. 2002, 48, 191–202. [Google Scholar] [CrossRef]

- Clark, A.H.; Ross-Murphy, S.B. Structural and mechanical properties of biopolymers gels. Adv. Polym. Sci. 1987, 83, 57–192. [Google Scholar]

- Alonso-Mougan, M.; Meijide, F.; Jover, A.; Rodriguez-Nunez, E.; Vazquez-Tato, J. Rheological behaviour of an amide pectin. J. Food Eng. 2002, 55, 123–129. [Google Scholar] [CrossRef]

- Dobies, M.; Kozak, M.; Jurga, S. Studies of gelation process investigatedby fast field cycling relaxometry and dynamical rheology: The case of aqueouslow methoxyl pectin solution. Solid State Nucl. Magn. Reson. 2004, 25, 188–193. [Google Scholar] [CrossRef]

- Campo, V.L.; Kawano, D.F.; Braz da Silva, D., Jr.; Carvalho, I. Carrageenans: Biological properties, chemical modifications and structural analysis—A review. Carbohydr. Polym. 2009, 77, 167–180. [Google Scholar] [CrossRef]

- Roh, Y.H.; Shin, C.S. Preparation and characterization of alginate-carrageenan complex films. J. Appl. Polym. Sci. 2006, 99, 3483–3490. [Google Scholar] [CrossRef]

- Ninan, N.; Muthiah, M.; Park, I.K.; Elain, A.; Thomas, S.; Grohens, Y. Pectin/carboxymethyl cellulose/microfibrillated cellulose composite scaffolds for tissue engineering. Carbohydr. Polym. 2013, 98, 877–885. [Google Scholar] [CrossRef]

- Secchi, E.; Munarin, F.; Alaimo, M.D.; Bosisio, S.; Buzzaccaro, S.; Ciccarella, G.; Vergaro, V.; Petrini, P.; Piazza, R. External and internal gelation of pectin solutions: Microscopic dynamics versus macroscopic rheology. J. Phys. Condens. Matter 2014, 26, 464106. [Google Scholar] [CrossRef]

- Jaiswal, L.; Shankar, S.; Rhim, J.-W. Carrageenan-based functional hydrogel film reinforced with sulfur nanoparticles and grapefruit seed extract for wound healing application. Carbohydr. Polym. 2019, 224, 11519. [Google Scholar] [CrossRef]

- Alves, V.D.; Costa, N.; Coelhoso, I.M. Barrier properties of biodegradable composite films based on kappa-carrageenan/pectin blends and mica flakes. Carbohydr. Polym. 2010, 79, 269–276. [Google Scholar] [CrossRef]

- Brash, J.L.; Horbett, T.A.; Latour, R.A.; Tengvall, P. The blood compatibility challenge. Part 2: Protein adsorption phenomena governing blood reactivity. Acta Biomater. 2019, 94, 11–24. [Google Scholar] [CrossRef] [PubMed]

- Firkowska-Boden, I.; Zhang, X.; Jandt, K.D. Controlling protein adsorption through nanostructured polymeric surfaces. Adv. Healthc. Mater. 2018, 7, 1700995. [Google Scholar] [CrossRef]

- Lima, P.H.L.; Pereira, S.V.A.; Rabello, R.B.; Rodriguez-Castellon, E.; Beppu, M.M.; Chevallier, P.; Mantovani, D.; Vieira, R.S. Blood protein adsorption on sulfonated chitosan and kappa-carrageenan films. Colloids Surf. B Biointerfaces 2013, 111, 719–725. [Google Scholar] [CrossRef]

- Carneiro, T.N.; Navaes, D.S.; Rabelo, R.B.; Celebi, B.; Chevallier, P.; Mantovani, D.; Beppu, M.M.; Vieira, R.S. BSA and fibrinogen adsorption on chitosan/k-carrageenan polyelectrolyte complexes. Macromol. Biosci. 2013, 13, 1072–1083. [Google Scholar] [CrossRef]

- Song, X.; Wang, K.; Tang, C.-Q.; Yang, W.-W.; Zhao, W.-F.; Zhao, C.-S. Design of carrageenan-based heparin-mimetic gel beads as self-anticoagulant hemoperfusion adsorbents. Biomacromolecules 2018, 19, 1966–1978. [Google Scholar] [CrossRef]

- Lokhande, G.; Carrow, J.K.; Thakur, T.; Xavier, J.R.; Parani, M.; Bayless, K.J.; Gaharwar, A.K. Nanoengineered injectable hydrogels from kappa-carrageenan and two-dimensional nanosilicates for wound healing application. Acta Biomater. 2018, 70, 35–47. [Google Scholar] [CrossRef] [Green Version]

- Hedayati, M.; Neufeld, M.J.; Reynolds, M.M.; Kipper, M.J. The quest for blood-compatible materials: Recent advances and future technologies. Mater. Sci. Eng. R 2019, 138, 118–152. [Google Scholar] [CrossRef]

- Labarre, D. The interactions between blood and polymeric nanoparticles depend on the nature and structure of the hydrogel covering the surface. Polymers 2012, 4, 986–996. [Google Scholar] [CrossRef]

- Wang, S.; Shi, S.; Lian, H.; Zhu, C.; Wang, H.; Liu, R.; Bligh, S.W.A. Structural features and anti-complementary activity of an acidic polysaccharide from Forsythia suspensa. J. Glycom. Lipidom. 2016, 6, 138. [Google Scholar] [CrossRef]

- Michaelsen, T.E.; Gilje, A.; Samuelsen, A.B.; HùgaÊsen, K.; Paulsen, B.S. Interaction between human complement and a pectin type polysaccharide fraction, PMII, from the leaves of Plantago major L. Scand. J. Immunol. 2000, 52, 483–490. [Google Scholar] [CrossRef]

- Kiyohara, H.; Matsumoto, T.; Nagai, T.; Kim, S.-J.; Yamada, H. The presence of natural human antibodies reactive against pharmacologically active pectic polysaccharides from herbal medicines. Phytomedicine 2006, 13, 494–500. [Google Scholar] [CrossRef]

- Yao, R.; Huang, C.; Chen, X.; Yin, Z.; Fu, Y.; Li, L.; Feng, B.; Song, X.; He, C.; Yue, G.; et al. Two complement fixing pectic polysaccharides from pedicel of Lycium barbarum L. promote cellular antioxidant defense. Int. J. Biol. Macromol. 2018, 112, 356–363. [Google Scholar] [CrossRef]

- Ho, G.T.T.; Zou, Y.-F.; Wangensteen, H.; Barsett, H. RG-I regions from elderflower pectins substituted on GalA are strong immunomodulators. Int. J. Biol. Macromol. 2016, 92, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.-F.; Zhang, B.-Z.; Barsett, H.; Inngjerdingen, K.T.; Diallo, D.; Michaelsen, T.E.; Paulsen, B.S. Complement fixing polysaccharides from Terminalia macroptera root bark, stem bark and leaves. Molecules 2014, 19, 7440–7458. [Google Scholar] [CrossRef] [PubMed]

- Sokolova, E.V.; Kravchenko, A.O.; Sergeeva, N.V.; Kalinosky, A.I.; Glazunov, V.P.; Bogdanovich, L.N.; Yermak, I.M. Effect of red seaweed sulfated galactans on initial steps of complement activation in vitro. Carbohydr. Polym. 2021, 254, 117251. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Shi, Z.; Wang, Y.; Song, X.; Wang, L.; Han, M.; Du, H.; He, C.; Zhao, W.; et al. Anticoagulant chitosan-kappa-carrageenan composite hydrogel sorbent for simultaneous endotoxin and bacteria cleansing in septic blood. Carbohydr. Polym. 2020, 243, 116470. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Groth, T. Host Responses to Biomaterials and Anti-Inflammatory Design—A Brief Review. Macromol. Biosci. 2018, 18, 1800112. [Google Scholar] [CrossRef]

- Tamilselvi, S.; Kavitha, R.; Usharani, M.; Mumjitha, M.; Mohanapriya, S.; Mohanapriya, S. Mechanical characterization of bio composite films as a novel drug carrier platform for sustained release of 5-fluorouracil for colon cancer: Methodological investigation. J. Mech. Behav. Biomed. Mater. 2021, 115, 104266. [Google Scholar] [CrossRef] [PubMed]

- Bai, S.; Sun, Y.; Cheng, Y.; Ye, W.; Jiang, C.; Liu, M.; Ji, Q.; Zhang, B.; Mei, Q.; Liu, D.; et al. MCP mediated active targeting calcium phosphate hybrid nanoparticles for the treatment of orthotopic drug-resistant colon cancer. J. Nanobiotechnol. 2021, 19, 367. [Google Scholar] [CrossRef]

- Kodoth, A.K.; Ghate, V.M.; Lewis, S.A.; Prakash, B.; Badalamoole, V. Pectin-based silver nanocomposite film for transdermal delivery of Donepezil. Int. J. Biol. Macromol. 2019, 134, 269–279. [Google Scholar] [CrossRef]

- Arunagiri, V.; Tsai, H.-C.; Darge, H.F.; Chiang, H.W.; Thankachan, D.; Mei, C.J.; Lai, J.-Y. Preparation of physically crosslinked polyelectrolyte gelatin-tannic acid-κ-carrageenan (GTC) microparticles as hemostatic agents. Int. J. Biol. Macromol. 2021, 191, 324–334. [Google Scholar] [CrossRef]

- Madruga, L.Y.C.; Sabino, R.M.; Santos, E.C.G.; Popat, K.C.; Balaban, R.C.; Kipper, M.J. Carboxymethyl-kappa-carrageenan: A study of biocompatibility, antioxidant and antibacterial activities. Int. J. Biol. Macromol. 2020, 152, 483–491. [Google Scholar] [CrossRef]

- Konovalova, M.V.; Markov, P.A.; Durnev, E.A.; Kurek, D.V.; Popov, S.V.; Varlamov, V.P. Preparation and biocompatibility evaluation of pectin and chitosan cryogels for biomedical application. J. Biomed. Mater. Res. Part A 2017, 105A, 547–556. [Google Scholar] [CrossRef]

- Servais, A.B.; Kienzle, A.; Valenzuela, C.D.; Ysasi, A.B.; Wagner, W.; Tsuda, A.; Ackermann, M.; Mentzer, S.J. Structural heteropolysaccharide adhesion to the glycocalyx of visceral mesothelium. Tissue Eng. Part A 2018, 24, 199–206. [Google Scholar] [CrossRef]

- Zheng, Y.; Pierce, A.F.; Wagner, W.L.; Khalil, H.A.; Chen, Z.; Servais, A.B.; Ackermann, M.; Mentzer, S.J. Functional adhesion of pectin biopolymers to the lung visceral pleura. Polymers 2021, 13, 2976. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Pierce, A.F.; Wagner, W.L.; Khalil, H.A.; Chen, Z.; Funaya, C.; Ackermann, M.; Mentzer, S.J. Biomaterial-assisted anastomotic healing: Serosal adhesion of pectin films. Polymers 2021, 13, 2811. [Google Scholar] [CrossRef]

- Gorbet, M.; Sperling, C.; Maitz, M.F.; Siedlecki, C.A.; Werner, C.; Sefton, M.V. The blood compatibility challenge. Part 3: Material associated activation of blood cascades and cells. Acta Biomater. 2019, 94, 25–32. [Google Scholar] [CrossRef] [PubMed]

- Pettinelli, N.; Rodríguez-Llamazares, S.; Abellac, V.; Barrala, L.; Bouzaa, R.; Farraga, Y.; Lagoc, F. Entrapment of chitosan, pectin or κ-carrageenan within methacrylate based hydrogels: Effect on swelling and mechanical properties. Mater. Sci. Eng. C 2019, 96, 583–590. [Google Scholar] [CrossRef]

- Vijayakumar, S.; Saravanakumar, K.; Malaikozhundan, B.; Divya, M.; Vaseeharan, B.; Durán-Lara, E.-F.; Wang, M.-H. Biopolymer k-carrageenan wrapped ZnO nanoparticles as drug delivery vehicles for anti MRSA therapy. Int. J. Biol. Macromol. 2020, 144, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Patova, O.A.; Golovchenko, V.V.; Vityazev, F.V.; Burkov, A.A.; Belyi, V.A.; Kuznetsov, S.N.; Litvinets, S.G.; Martinson, E.A. Physicochemical and rheological properties of gelling pectin from Sosnowskyi’s hogweed (Heracleum sosnowskyi) obtained using different pretreatment conditions. Food Hydrocoll. 2017, 65, 77–86. [Google Scholar] [CrossRef]

- Dodgson, K.S.; Price, R.G. A note on the determination of the ester sulfato content of sulfated polysaccharides. Biochem. J. 1962, 84, 106–110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Holdsworth, S.D. Applicability of rheological models to the interpretation of flow and processing behavior of fluid food products. J. Texture Stud. 1971, 2, 393–418. [Google Scholar] [CrossRef]

- Ramkumar, D.H.S.; Bhattacharya, M. Relaxation behavior and the application of integral constitutive equations to wheat dough. J. Texture Stud. 1996, 27, 517–544. [Google Scholar] [CrossRef]

- Popov, S.V.; Markov, P.A.; Patova, O.A.; Vityazev, F.V.; Bakutova, L.A.; Borisenkov, M.F.; Martinson, E.A.; Ananchenko, B.A.; Durnev, E.A.; Burkov, A.A.; et al. In vitro gastrointestinal-resistant pectin hydrogel particles for β-glucuronidase adsorption. J. Biomater. Sci. Polym. Ed. 2017, 28, 293–311. [Google Scholar] [CrossRef]

- Mahdavinia, G.R.; Mousanezhad, S.; Hosseinzadeh, H.; Darvishi, F.; Sabzi, M. Magnetic hydrogel beads based on PVA/sodium alginate/laponite RD and studying their BSA adsorption. Carbohydr. Polym. 2016, 147, 379–391. [Google Scholar] [CrossRef] [PubMed]

- Paderin, N.M.; Popov, S.V. The effect of dietary pectins on object recognition memory, depression-like behaviour, and il-6 in mouse hippocampi. J. Funct. Foods 2018, 43, 131–138. [Google Scholar] [CrossRef]

| Gels | Storage Modulus | ||

|---|---|---|---|

| A (Pa) | B (Slope) | R2 | |

| P1 | 629.7 | −0.147 | 0.87 |

| P1-Car0.1 | 891.5 | −0.054 | 0.36 |

| P1-Car0.2 | 1066.9 | −0.027 | 0.05 |

| P1-Car0.5 | 1732.2 | −0.044 | 0.36 |

| P1.5 | 1222.3 | −0.151 | 0.82 |

| P1.5-Car0.1 | 1493.0 | −0.130 | 0.78 |

| P1.5-Car0.2 | 2135.9 | −0.100 | 0.75 |

| P1.5-Car0.5 | 804.5 | −0.042 | 0.15 |

| P 2.0 | 1335.7 | 0.055 | 0.07 |

| P2-Car0.1 | 1918.2 | −0.089 | 0.56 |

| P2-Car0.2 | 1805.8 | −0.024 | 0.06 |

| P2-Car0.5 | 1488.4 | −0.013 | 0.02 |

| Gel Bead | Weight *, mg | Diameter *, mm | Gel strength **, N |

|---|---|---|---|

| P2 | 0.27 ± 0.05 | 1.08 ± 0.12 | 0.47 ± 0.06 |

| P2-Car0.2 | 0.26 ± 0.04 | 1.13 ± 0.14 | 0.25 ± 0.04 a |

| P2-Car0.5 | 0.37 ± 0.06 a | 1.14 ± 0.14 | 0.18 ± 0.03 a |

| P1.5 | 0.19 ± 0.02 a | 1.44 ± 0.15 a | 0.28 ± 0.05 a |

| P1.5-Car0.5 | 0.32 ± 0.03 b | 1.43 ± 0.13 | 0.11 ± 0.02 b |

| Sample | OD (540 nm) | Haemolysis Rate (%) |

|---|---|---|

| Distilled Water (Positive control) | 2.634 ± 0.056 a | 100 ± 0 |

| 0.9% NaCl (Negative control) | 0.074 ± 0.013 | 0 ± 0 |

| P2 | 0.150 ± 0.037 a | 2.6 ± 0.96 a |

| P2-Car0.2 | 0.123 ± 0.036 a | 2.1 ± 1.06 a |

| P2-Car0.5 | 0.094 ± 0.040 ab | 0.8 ± 0.16 ab |

| P1.5-Car0.5 | 0.100 ± 0.089 ab | 1.0 ± 0.35 ab |

| Sample | Sulphate (-SO3−) a | UA a | Gal a | Xyl a | Glc a | Rha a | Ara a | OMe a | DM a | Mw, kDa | Mw/Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AU701 | 86.5 ± 0.7 | 2.3 ± 0.1 | 2.8 ± 0.1 | 1.5 ± 0.1 | 1.3 ± 0.1 | 0.6 ± 0.4 | 6.2 ± 0.4 | 43 | 401 | 5.2 | |

| κ-Car | 11.7 ± 0.7 | - | 29.3 ± 2.3 | 0.4 ± 0.2 | 9.4 ± 0.2 | - | 0.1 ± 0.0 | - | - | 1670 | 7.2 |

| Sample Code | P2 | P2-Car0.2 | P2-Car0.5 | P1.5 | P1.5-Car0.5 |

|---|---|---|---|---|---|

| Polysaccharide weight, mg | |||||

| Pectin | 200 | 200 | 200 | 150 | 150 |

| κ-carrageenan | - | 20 | 50 | - | 50 |

| Polysaccharide concentration, % w/v | |||||

| Pectin | 2 | 2 | 2 | 1.5 | 1.5 |

| κ-carrageenan | - | 0.2 | 0.5 | - | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popov, S.; Paderin, N.; Khramova, D.; Kvashninova, E.; Melekhin, A.; Vityazev, F. Characterization and Biocompatibility Properties In Vitro of Gel Beads Based on the Pectin and κ-Carrageenan. Mar. Drugs 2022, 20, 94. https://doi.org/10.3390/md20020094

Popov S, Paderin N, Khramova D, Kvashninova E, Melekhin A, Vityazev F. Characterization and Biocompatibility Properties In Vitro of Gel Beads Based on the Pectin and κ-Carrageenan. Marine Drugs. 2022; 20(2):94. https://doi.org/10.3390/md20020094

Chicago/Turabian StylePopov, Sergey, Nikita Paderin, Daria Khramova, Elizaveta Kvashninova, Anatoliy Melekhin, and Fedor Vityazev. 2022. "Characterization and Biocompatibility Properties In Vitro of Gel Beads Based on the Pectin and κ-Carrageenan" Marine Drugs 20, no. 2: 94. https://doi.org/10.3390/md20020094