Evaluation of Functional Features of Lignocellulosic Particle Composites Containing Biopolymer Binders

Abstract

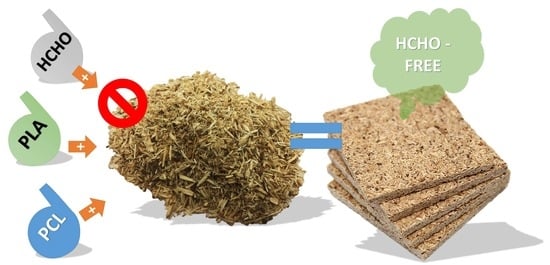

:1. Introduction

2. Materials and Methods

2.1. Preparation of the Adhesive

2.2. Materials Characterization

2.3. Particleboard Manufacturing

2.4. Physical and Mechanical Properties

2.5. Statistical Analysis

3. Results and Discussion

4. Conclusions

- The density profile of the composites produced using biopolymers is significantly different from this for composites made of commercial UF resin. Biopolymer bonded composites had a homogeneous (flat) density profile, irrespectively of binder amount.

- Both MOR and MOE significantly rise when the biopolymer binder content rises. The MOR values are about 3 times higher with the resination increase from 12% to 20%. In the case of MOE, it was 880% higher, while PCL content rose from 12% to 20%, and over 360% raise for PLA content increased from 12% to 20%.

- A specific density profile can influence the low IB of composites bonded with biopolymers. Further attempts to modify the density profiles by sanding can validate this remark.

- The increase of biopolymer binder significantly influences the TS, WA, and SWA of tested composites. However, the changes are most intensive when the resination raises from 12% to 15%.

- Regarding achieved results of MOR, MOE, IB, TS, WA, and SWA, it can be concluded that the increase of biopolymer binder content from 15% to 20% seems unjustifiable.

- The most promising biopolymer within the tested ones seems to be polycaprolactone (PCL).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeniocak, M.; Göktaş, O.; Erdil, Y.Z.; Özen, E.; Alma, M.H. Investigating the use of vine pruning stalks (Vitis vinifera L. CV sultani) as raw material for particleboard manufacturing. Wood Res. 2014, 59, 167–176. [Google Scholar]

- Sala, C.M.; Robles, E.; Kowaluk, G. Influence of adding offcuts and trims with a recycling approach on the properties of high-density fibrous composites. Polymers 2020, 12, 1327. [Google Scholar] [CrossRef]

- Prasetiyo, K.W.; Oktaviani, L.; Astari, L.; Syamani, F.A.; Subyakto, S.; Achmadi, S.S. Physical-Mechanical Properties and Bonding Mechanism of Corn Stalks Particleboard with Citric Acid Adhesive. Jurnal Ilmu dan Teknologi Kayu Tropis 2018, 16, 131–140. [Google Scholar]

- Mesquita, R.G.d.A.; Sanadi, A.R.; Marconcini, J.M.; Correa, A.C.; César, A.A.d.S.; Andrade, L.M.F.; Lopes, T.A.; Simão, J.A.; Mendes, L.M. The effect of cellulose nanocrystals in sugarcane bagasse particleboards of pith and fibers. Cerne 2019, 25, 203–213. [Google Scholar] [CrossRef]

- Baskaran, M.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Sato, M.; Sugimoto, T. Optimization of press temperature and time for binderless particleboard manufactured from oil palm trunk biomass at different thickness levels. Mater. Today Commun. 2015, 3, 87–95. [Google Scholar] [CrossRef]

- Borysiuk, P.; Jenczyk-Tolloczko, I.; Auriga, R.; Kordzikowski, M. Sugar beet pulp as raw material for particleboard production. Ind. Crops Prod. 2019, 141, 111829. [Google Scholar] [CrossRef]

- Taha, I.; Elkafafy, M.S.; El Mously, H. Potential of utilizing tomato stalk as raw material for particleboards. Ain Shams Eng. J. 2018, 9, 1457–1464. [Google Scholar] [CrossRef] [Green Version]

- Ciannamea, E.M.; Stefani, P.M.; Ruseckaite, R.A. Medium-density particleboards from modified rice husks and soybean protein concentrate-based adhesives. Bioresour. Technol. 2010, 101, 818–825. [Google Scholar] [CrossRef]

- Guler, C.; Sahin, H.I.; Sevcan, Y. The potential for using corn stalks as a raw material for production particleboard with industrial wood chips. Wood Res. 2016, 61, 299–306. [Google Scholar]

- Sekaluvu, L.; Tumutegyereize, P.; Kiggundu, N. Investigation of factors affecting the production and properties of maize cob-particleboards. Waste Biomass Valorization 2014, 5, 27–32. [Google Scholar] [CrossRef]

- Narciso, C.R.P.; Reis, A.H.S.; Mendes, J.F.; Nogueira, N.D.; Mendes, R.F. Potential for the Use of Coconut Husk in the Production of Medium Density Particleboard. Waste Biomass Valorization 2020, 12, 1647–1658. [Google Scholar] [CrossRef]

- Juliana, A.H.; Paridah, M.T.; Rahim, S.; Nor Azowa, I.; Anwar, U.M.K. Properties of particleboard made from kenaf (Hibiscus cannabinus L.) as function of particle geometry. Mater. Des. 2012, 34, 406–411. [Google Scholar] [CrossRef]

- Kowaluk, G.; Szymanowski, K.; Kozlowski, P.; Kukula, W.; Sala, C.; Robles, E.; Czarniak, P. Functional Assessment of Particleboards Made of Apple and Plum Orchard Pruning. Waste Biomass Valorization 2019, 11, 2877–2886. [Google Scholar] [CrossRef] [Green Version]

- Grigsby, W.J.; Thumm, A.; Carpenter, J.E.P.; Hati, N. Investigating the extent of urea formaldehyde resin cure in medium density fibreboard: Characterisation of extractable resin components. Int. J. Adhes. Adhes. 2014, 50, 50–56. [Google Scholar] [CrossRef]

- Salleh, K.M.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Nadhari, W.N.A.W.; Karim, N.A.; Jumhuri, N.; Ang, L.Z.P. Evaluation of properties of starch-based adhesives and particleboard manufactured from them. J. Adhes. Sci. Technol. 2015, 29, 319–336. [Google Scholar] [CrossRef]

- Yu, C.W.F.; Crump, D.R. Testing for formaldehyde emission from wood-based products—A review. Indoor Built Environ. 1999, 8, 280–286. [Google Scholar] [CrossRef]

- Zhao, X.F.; Peng, L.Q.; Wang, H.L.; Wang, Y.B.; Zhang, H. Environment-friendly urea-oxidized starch adhesive with zero formaldehyde-emission. Carbohydr. Polym. 2018, 181, 1112–1118. [Google Scholar] [CrossRef] [PubMed]

- Chotikhun, A.; Hiziroglu, S.; Kard, B.; Konemann, C.; Buser, M.; Frazier, S. Measurement of termite resistance of particleboard panels made from Eastern redcedar using nano particle added modified starch as binder. Meas. J. Int. Meas. Confed. 2018, 120, 169–174. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Starch-Based Adhesives for Wood/Wood Composite Bonding: Review. Open J. Polym. Chem. 2017, 7, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Liang, J.; Zhang, J.; Zhou, X.; Du, G. Performance of urea-formaldehyde adhesive with oxidized cassava starch. BioResources 2017, 12, 7590–7600. [Google Scholar] [CrossRef]

- Patel, A.K.; Michaud, P.; Petit, E.; De Baynast, H.; Grédiac, M.; Mathias, J.D. Development of a chitosan-based adhesive. Application to wood bonding. J. Appl. Polym. Sci. 2013, 127, 5014–5021. [Google Scholar] [CrossRef]

- Roffael, E.; Dix, B.; Okum, J. Use of spruce tannin as a binder in particleboards and medium density fiberboards (MDF). Holz als Roh Werkst. 2000, 58, 301–305. [Google Scholar] [CrossRef]

- Widyorini, R.; Umemura, K.; Kusumaningtyas, A.R.; Prayitno, T.A. Effect of starch addition on properties of citric acid-bonded particleboard made from bamboo. BioResources 2017, 12, 8068–8077. [Google Scholar] [CrossRef]

- Nakanishi, E.Y.; Cabral, M.R.; de Souza Gonçalves, P.; dos Santos, V.; Savastano Junior, H. Formaldehyde-free particleboards using natural latex as the polymeric binder. J. Clean. Prod. 2018, 195, 1259–1269. [Google Scholar] [CrossRef]

- Abuarra, A.; Hashim, R.; Bauk, S.; Kandaiya, S.; Tousi, E.T. Fabrication and characterization of gum Arabic bonded Rhizophora spp. particleboards. Mater. Des. 2014, 60, 108–115. [Google Scholar] [CrossRef]

- Kowaluk, G.; Wronka, A. Bonding of sawmill birch wood with selected biopolymer-based glues. Ann. WULS For. Wood Technol. 2020, 109, 32–36. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef] [Green Version]

- Owodunni, A.A.; Lamaming, J.; Hashim, R.; Abdulwahab Taiwo, O.F.; Hussin, M.H.; Mohamad Kassim, M.H.; Bustami, Y.; Sulaiman, O.; Mohamad Amini, M.H.; Hiziroglu, S. Properties of green particleboard manufactured from coconut fiber using a potato starch based adhesive. BioResources 2020, 15, 2279–2292. [Google Scholar] [CrossRef]

- Owodunni, A.A.; Lamaming, J.; Hashim, R.; Taiwo, O.F.A.; Hussin, M.H.; Mohamad Kassim, M.H.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Adhesive application on particleboard from natural fibers: A review. Polym. Compos. 2020, 41, 4448–4460. [Google Scholar] [CrossRef]

- Hashim, R.; Said, N.; Lamaming, J.; Baskaran, M.; Sulaiman, O.; Sato, M.; Hiziroglu, S.; Sugimoto, T. Influence of press temperature on the properties of binderless particleboard made from oil palm trunk. Mater. Des. 2011, 32, 2520–2525. [Google Scholar] [CrossRef]

- Nonaka, S.; Umemura, K.; Kawai, S. Characterization of bagasse binderless particleboard manufactured in high-temperature range. J. Wood Sci. 2013, 59, 50–56. [Google Scholar] [CrossRef]

- Baskaran, M.; Hashim, R.; Sulaiman, O.; Awalludin, M.F.; Sudesh, K.; Arai, T.; Kosugi, A. Properties of Particleboard Manufactured from Oil Palm Trunk Waste Using Polylactic Acid as a Natural Binder. Waste Biomass Valorization 2019, 10, 179–186. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Bonding of birch solid wood of sawmill surface roughness with use of selected thermoplastic biopolymers. Ann. WULS For. Wood Technol. 2019, 106, 9–15. [Google Scholar] [CrossRef]

- TAPPI UM 23 Bulk Density of Wood Chips. Useful Method. 2015. Available online: https://www.techstreet.com/standards/tappi-um-23?product_id=1894398 (accessed on 13 November 2021).

- EN 310 Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319 Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317 Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 382-2 Fibreboards—Determination of Surface Absorption—Part 2: Test Method for Hardboards; European Committee for Standardization: Brussels, Belgium, 1993.

- Chen, S.; Lu, X.; Pan, F.; Wang, T.; Zhang, Z. Preparation and characterization of urea-formaldehyde resin/reactive montmorillonite composites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2017, 32, 783–790. [Google Scholar] [CrossRef]

- Hachani, S.E.; Wis, A.A.; Necira, Z.; Nebbache, N.; Meghezzi, A.; Ozkoc, G. Effects of magnesia incorporation on properties of polystyrene/magnesia composites. Acta Chim. Slov. 2018, 65, 646–651. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between processing parameters and degradation of different polylactide grades during twin-screw extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef]

- Yang, S.L.; Wu, Z.H.; Yang, W.; Yang, M.B. Thermal and mechanical properties of chemical crosslinked polylactide (PLA). Polym. Test. 2008, 27, 957–963. [Google Scholar] [CrossRef]

- Leonés, A.; Mujica-Garcia, A.; Arrieta, M.P.; Salaris, V.; Lopez, D.; Kenny, J.M.; Peponi, L. Organic and inorganic PCL-based electrospun fibers. Polymers 2020, 12, 1325. [Google Scholar] [CrossRef]

- Wong, E.D.; Zhang, M.; Wang, Q.; Han, G.; Kawai, S. Formation of the density profile and its effects on the properties of fiberboard. J. Wood Sci. 2000, 46, 202–209. [Google Scholar] [CrossRef]

- Suzuki, S.; Miyamoto, K. Effect of manufacturing parameters on the linear expansion and density profile of particleboard. J. Wood Sci. 1998, 44, 444–450. [Google Scholar] [CrossRef] [Green Version]

- Wong, E.D.; Zhang, M.; Wang, Q.; Kawai, S. Formation of the density profile and its effects on the properties of particleboard. Wood Sci. Technol. 1999, 33, 327–340. [Google Scholar] [CrossRef]

- EN 312 Particleboards—Specifications; European Committee for Standardization: Brussels, Belgium, 2010.

| Tested Materials | Mass Loss | |

|---|---|---|

| 50% | 80% | |

| °C | ||

| PLA | 349.3 | 363.3 |

| PCL | 387.4 | 413.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gumowska, A.; Robles, E.; Kowaluk, G. Evaluation of Functional Features of Lignocellulosic Particle Composites Containing Biopolymer Binders. Materials 2021, 14, 7718. https://doi.org/10.3390/ma14247718

Gumowska A, Robles E, Kowaluk G. Evaluation of Functional Features of Lignocellulosic Particle Composites Containing Biopolymer Binders. Materials. 2021; 14(24):7718. https://doi.org/10.3390/ma14247718

Chicago/Turabian StyleGumowska, Aneta, Eduardo Robles, and Grzegorz Kowaluk. 2021. "Evaluation of Functional Features of Lignocellulosic Particle Composites Containing Biopolymer Binders" Materials 14, no. 24: 7718. https://doi.org/10.3390/ma14247718