A Fuzzy Logic Model for the Analysis of Ultrasonic Vibration Assisted Turning and Conventional Turning of Ti-Based Alloy

Abstract

:1. Introduction

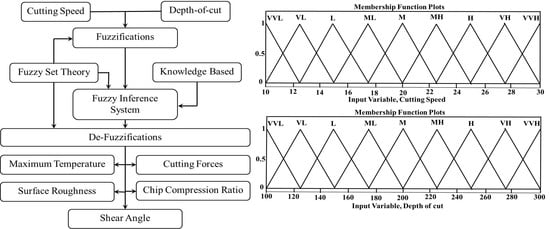

2. Proposed Fuzzy Logic Algorithm

2.1. Fuzzy-Based Algorithms for UVAT and CT

2.1.1. Fuzzy Membership Functions

2.1.2. Fuzzy Sets Used in Simulation

2.1.3. Proposed Rules

3. Experimental Work

4. Results and Discussion

4.1. Simulations Results

4.2. Experimental Results

4.3. Comparison of Simulated and Experimental Results

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Leyens, C.; Peters, M.; Hovsepian, P.; Lewis, D.; Luo, Q.; Münz, W.-D. Novel coating systems produced by the combined cathodic arc/unbalanced magnetron sputtering for environmental protection of titanium alloys. Surf. Coat. Technol. 2002, 155, 103–111. [Google Scholar] [CrossRef]

- Arrazola, P.-J.; Garay, A.; Iriarte, L.-M.; Armendia, M.; Marya, S.; Le Maître, F. Machinability of titanium alloys (Ti6Al4V and Ti555. 3). J. Mater. Process. Technol. 2009, 209, 2223–2230. [Google Scholar] [CrossRef] [Green Version]

- Maurotto, A.; Muhammad, R.; Roy, A.; Silberschmidt, V.V. Enhanced ultrasonically assisted turning of a β-titanium alloy. Ultrasonics 2013, 53, 1242–1250. [Google Scholar] [CrossRef] [Green Version]

- Celaya, A.; de Lacalle, L.N.L.; Campa, F.J.; Lamikiz, A. Ultrasonic Assisted Turning of mild steels. Int. J. Mater. Prod. Technol. 2010, 37, 60. [Google Scholar] [CrossRef]

- Celaya, A.; López de Lacalle, L.N.; Campa, F.J.; Lamikiz, A. Application of ultrasonics as assistance in machining operations. In Ultrasonics: Theory, Techniques and Practical Applications; Ayabito, H., Katsukawa, M., Eds.; Nova Science Publishers: New York, NY, USA, 2013; pp. 159–172. [Google Scholar]

- Airao, J.; Nirala, C.; Lacalle, L.; Khanna, N. Tool Wear Analysis during Ultrasonic Assisted Turning of Nimonic-90 under Dry and Wet Conditions. Metals 2021, 11, 1253. [Google Scholar] [CrossRef]

- Muhammad, R.; Ahmed, N.; Ullah, H.; Roy, A.; Silberschmidt, V.V. Hybrid machining process: Experimental and numerical analysis of hot ultrasonically assisted turning. Int. J. Adv. Manuf. Technol. 2018, 97, 2173–2192. [Google Scholar] [CrossRef] [Green Version]

- Agrawal, C.; Wadhwa, J.; Pitroda, A.; Pruncu, C.I.; Sarikaya, M.; Khanna, N. Comprehensive analysis of tool wear, tool life, surface roughness, costing and carbon emissions in turning Ti–6Al–4V titanium alloy: Cryogenic versus wet machining. Tribol. Int. 2021, 153, 106597. [Google Scholar] [CrossRef]

- Osman, K.A.; Yılmaz, V.; Ünver, H.Ö.; Şeker, U.; Kılıç, S.E. Slot milling of titanium alloy with hexagonal boron nitride and minimum quantity lubrication and multi-objective process optimization for energy efficiency. J. Clean. Prod. 2020, 258, 120739. [Google Scholar] [CrossRef]

- Muhammad, R.; Hussain, M.S.; Maurotto, A.; Siemers, C.; Roy, A.; Silberschmidt, V.V. Analysis of a free machining α+β titanium alloy using conventional and ultrasonically assisted turning. J. Mater. Process. Technol. 2014, 214, 906–915. [Google Scholar] [CrossRef] [Green Version]

- Suárez, A.; Veiga, F.; de Lacalle, L.N.L.; Polvorosa, R.; Lutze, S.; Wretland, A. Effects of Ultrasonics-Assisted Face Milling on Surface Integrity and Fatigue Life of Ni-Alloy 718. J. Mater. Eng. Perform. 2016, 25, 5076–5086. [Google Scholar] [CrossRef]

- Parandoush, P.; Fernando, P.; Zhang, H.; Ye, C.; Xiao, J.; Zhang, M.; Lin, D. A finishing process via ultrasonic drilling for additively manufactured carbon fiber composites. Rapid Prototyp. J. 2021, 27, 754–768. [Google Scholar] [CrossRef]

- Pujana, J.; Rivero, A.; Celaya, A.; de Lacalle, L.L. Analysis of ultrasonic-assisted drilling of Ti6Al4V. Int. J. Mach. Tools Manuf. 2009, 49, 500–508. [Google Scholar] [CrossRef]

- Lotfi, M.; Akbari, J. Finite element simulation of ultrasonic-assisted machining: A review. Int. J. Adv. Manuf. Technol. 2021, 1–20. [Google Scholar] [CrossRef]

- Lotfi, M.; Amini, S.; Akbari, J. Surface integrity and microstructure changes in 3D elliptical ultrasonic assisted turning of Ti–6Al–4V: FEM and experimental examination. Tribol. Int. 2020, 151, 106492. [Google Scholar] [CrossRef]

- Pei, L.; Shu, X. Investigation of the turning process of the TC21 titanium alloy: Experimental analysis and 3D simulation. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2020, 0954408920967777. [Google Scholar] [CrossRef]

- Muhammad, R.; Roy, A.; Silberschmidt, V.V. Finite Element Modelling of Conventional and Hybrid Oblique Turning Processes of Titanium Alloy. Procedia CIRP 2013, 8, 510–515. [Google Scholar] [CrossRef] [Green Version]

- Muhammad, R. Hot Ultrasonically Assisted Turning of Ti-15V3Al3Cr3Sn: Experimental and Numerical Analysis; Loughborough University: Loughborough, UK, 2013. [Google Scholar]

- Muhammad, R.; Ahmed, N.; Demiral, M.; Roy, A.; Silberschmidt, V.V. Computational Study of Ultrasonically-Assisted Turning of Ti Alloys. Adv. Mater. Res. 2011, 223, 30–36. [Google Scholar] [CrossRef] [Green Version]

- Aamir, M.; Tu, S.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Optimization and Modeling of Process Parameters in Multi-Hole Simultaneous Drilling Using Taguchi Method and Fuzzy Logic Approach. Materials 2020, 13, 680. [Google Scholar] [CrossRef] [Green Version]

- Aamir, M.; Waqas, M.; Iqbal, M.; Hanif, M.I.; Muhammad, R. Fuzzy logic approach for investigation of microstructure and mechanical properties of Sn96.5-Ag3.0-Cu0.5 lead free solder alloy. Solder. Surf. Mt. Technol. 2017, 29, 191–198. [Google Scholar] [CrossRef]

- Ubaid, A.M.; Dweiri, F.T.; Aghdeab, S.H.; Al-Juboori, L.A. Optimization of Electro Discharge Machining Process Parameters With Fuzzy Logic for Stainless Steel 304 (ASTM A240). J. Manuf. Sci. Eng. 2017, 140, 011013. [Google Scholar] [CrossRef]

- Hossain, A.; Hossain, A.; Nukman, Y.; Hassan, M.; Harizam, M.; Sifullah, A.; Parandoush, P.J.M. A fuzzy logic-based pre-diction model for kerf width in laser beam machining. Mater. Manuf. Process. 2016, 31, 679–684. [Google Scholar] [CrossRef]

- Tseng, T.-L.; Konada, U.; Kwon, Y. A novel approach to predict surface roughness in machining operations using fuzzy set theory. J. Comput. Des. Eng. 2016, 3, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Senthilkumar, N.; Sudha, J.; Muthukumar, V. A grey-fuzzy approach for optimizing machining parameters and the approach angle in turning AISI 1045 steel. Adv. Prod. Eng. Manag. 2015, 10, 195–208. [Google Scholar] [CrossRef]

- Ooi, M.E.; Sayuti, M.; Sarhan, A.A. Fuzzy logic-based approach to investigate the novel uses of nano suspended lubrication in precise machining of aerospace AL tempered grade 6061. J. Clean. Prod. 2015, 89, 286–295. [Google Scholar] [CrossRef] [Green Version]

- Barzani, M.M.; Zalnezhad, E.; Sarhan, A.A.; Farahany, S.; Ramesh, S. Fuzzy logic based model for predicting surface roughness of machined Al–Si–Cu–Fe die casting alloy using different additives-turning. Measurement 2015, 61, 150–161. [Google Scholar] [CrossRef]

- Vundavilli, P.R.; Parappagoudar, M.; Kodali, S.; Benguluri, S. Fuzzy logic-based expert system for prediction of depth of cut in abrasive water jet machining process. Knowl.-Based Syst. 2012, 27, 456–464. [Google Scholar] [CrossRef]

- Ramesh, S.; Karunamoorthy, L.; Palanikumar, K. Fuzzy Modeling and Analysis of Machining Parameters in Machining Titanium Alloy. Mater. Manuf. Process. 2008, 23, 439–447. [Google Scholar] [CrossRef]

- Kao, C.-C.; Shih, A.J.; Miller, S.F. Fuzzy Logic Control of Microhole Electrical Discharge Machining. J. Manuf. Sci. Eng. 2008, 130, 064502. [Google Scholar] [CrossRef]

- Lin, C.-T.; Chung, I.-F.; Huang, S.-Y. Improvement of machining accuracy by fuzzy logic at corner parts for wire-EDM. Fuzzy Sets Syst. 2001, 122, 499–511. [Google Scholar] [CrossRef]

- Lin, J.; Wang, K.; Yan, B.; Tarng, Y. Optimization of the electrical discharge machining process based on the Taguchi method with fuzzy logics. J. Mater. Process. Technol. 2000, 102, 48–55. [Google Scholar] [CrossRef]

- Tzeng, Y.-F.; Chen, F.-C. Multi-objective optimisation of high-speed electrical discharge machining process using a Taguchi fuzzy-based approach. Mater. Des. 2007, 28, 1159–1168. [Google Scholar] [CrossRef]

- Riaz, A.A.; Muhammad, R.; Ullah, N.; Hussain, G.; Alkahtani, M.; Akram, W. Fuzzy Logic-Based Prediction of Drill-ing-Induced Temperatures at Varying Cutting Conditions along with Analysis of Chips Morphology and Burrs Formation. Metals 2021, 11, 277. [Google Scholar] [CrossRef]

- Malik, A.; Sanghvi, N. Optimization of laser-assisted jet electrochemical machining parameters by grey relational analysis and fuzzy logic. World J. Eng. 2021. [Google Scholar] [CrossRef]

- Moganapriya, C.; Rajasekar, R.; Kumar, P.S.; Mohanraj, T.; Gobinath, V.; Saravanakumar, J. Achieving machining effec-tiveness for AISI 1015 structural steel through coated inserts and grey-fuzzy coupled Taguchi optimization approach. Struct. Multidiscip. Optim. 2021, 63, 1169–1186. [Google Scholar] [CrossRef]

- Vignesh, M.; Ramanujam, R.; Rajyalakshmi, G.; Bhattacharya, S. Application of Grey Theory and Fuzzy Logic to Optimize Machining Parameters of Zircon Sand Reinforced Aluminum Composites. In Lecture Notes in Mechanical Engineering; Gabler: Lakewood, CO, USA, 2020; pp. 653–662. [Google Scholar]

- Maurotto, A.; Siemers, C.; Muhammad, R.; Roy, A.; Silberschmidt, V.V. Ti Alloy with Enhanced Machinability in UAT Turning. Met. Mater. Trans. A 2014, 45, 2768–2775. [Google Scholar] [CrossRef] [Green Version]

- Muhammad, R.; Maurotto, A.; Roy, A.; Silberschmidt, V.V. Ultrasonically assisted turning of Ti-6Al-2Sn-4Zr-6Mo. J. Phys. Conf. Ser. 2012, 382, 012016. [Google Scholar] [CrossRef] [Green Version]

- Muhammad, R.; Maurotto, A.; Roy, A.; Silberschmidt, V.V. Analysis of Forces in Vibro-Impact and Hot Vibro-Impact Turning of Advanced Alloys. Appl. Mech. Mater. 2011, 70, 315–320. [Google Scholar] [CrossRef] [Green Version]

- Pedrycz, W. Why triangular membership functions? Fuzzy Sets Syst. 1994, 64, 21–30. [Google Scholar] [CrossRef]

- Ahmed, N.; Mitrofanov, A.V.; Babitsky, V.I.; Silberschmidt, V.V. Enhanced finite element model of ultrasonically assisted turning. Int. J. Mach. Mach. Mater. 2009, 6, 159. [Google Scholar] [CrossRef]

- Ahmed, N.; Mitrofanov, A.; Babitsky, V.; Silberschmidt, V.V. 3D finite element analysis of ultrasonically assisted turning. Comput. Mater. Sci. 2007, 39, 149–154. [Google Scholar] [CrossRef]

- Silberschmidt, V.V.; Mahdy, S.M.; Gouda, M.A.; Naseer, A.; Maurotto, A.; Roy, A. Surface-Roughness Improvement in Ul-Trasonically Assisted Turning. Procedia CIRP 2014, 13, 49–54. [Google Scholar] [CrossRef] [Green Version]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Machinability investigation of Inconel 718 in high-speed turning. Int. J. Adv. Manuf. Technol. 2009, 45, 421–429. [Google Scholar] [CrossRef]

- Muhammad, R.; Ahmed, N.; Shariff, Y.M.; Silberschmidt, V.V. Effect of Cutting Conditions on Temperature Generated in Drilling Process: A FEA Approach. Adv. Mater. Res. 2011, 223, 240–246. [Google Scholar] [CrossRef] [Green Version]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

| Process | Workpiece | Machining Input Parameter | Investigation | Reference |

|---|---|---|---|---|

| DP | Al-5083 | V, FR | SQ, hole size | [20] |

| EDM | SS-304 | pulse-on/off times and current | MRR and EWR | [22] |

| LM | PMMA | V, power of laser, CO2 pressure, and stand-off distance | Width-kerf | [23] |

| MP | Al-6061 T6 | V, DoC, and FR | SQ | [24] |

| TP | AISI 1045 | V, DoC, and FR and approach angle | SQ, TW and, MRR | [25] |

| MP | Al-6061 T6 | Nozzle pressure, nozzle angle, and nanoparticle concentration | Cutting forces, cutting temperature, and SQ | [26] |

| TP | Al-Si-Cu-Fe and doped alloys | FR, V, and alloy type | SQ | [27] |

| AWJM | Brittle materials | Nozzle diameter, pressure of liquid, mass flow rate of abrasive jet traverse rate | DoC | [28] |

| TP | Ti64 | V, DoC, FR, | SQ, TW, and specific cutting pressure | [29] |

| EDM drilling | AISI-1010 Steel | Voltage gap, spark ratio deviation, and change in the deviation in spark-ratio | Current, voltage, and ignition delay time | [30] |

| Wire EDM | Die steel | Thickness, FR, and corner angle | Machining accuracy at corner parts | [31] |

| EDM | Die steel | Discharge current, the polarity of the workpiece, voltage at open discharge, pulse-on time, duty factor, | MRR and electrode wear ratio | [32] |

| EDM | Tool steel | Powder concentration, open-circuit voltage, duty cycle, pulsed duration, pulsed peak current, powder concentration, powder size | Dimensional accuracy and precision | [33] |

| DP | AISI-1018 steel | V and FR | Process zone temperature, burr formation, and chip morphology | [34] |

| LAJEM | WC-Co composite | Inter-electrode gap, supply voltage, electrolyte concentration, and duty cycle | Hole taper angle, MRR, and SQ | [35] |

| TP | AISI-1015 steel | V, DoC, FR, coolant flow rate | TW and SQ | [36] |

| TP | ZrSiO4-grade-LM25 matrix composites | Coolant, V, FR, DoC | Cutting forces, SQ, and TW | [37] |

| MF Type | Fuzzy Input Variables | Fuzzy Output Variables | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Variable | Speed (v) | Depth-of-Cut (DoC) | Variable | Tangential Cutting Forces (Ft) | Radial Force Component (Fr) | Temperature (T) | Surface Roughness (Ra) | Chip Compression ratio (CCR) | Shear Angle (SA) | |||||||||

| Parameter | Range | Parameter | Range | Parameter | Range | Parameter | Range | Parameters | Range | Parameter | Range | Parameter | Range | Parameter | Range | |||

| Triangular | VVL | [10 10 12.5] | [10 30] | [100 100 125] | [100 300] | EL | [33 33 38] | [33 103] | [23 23 25.71] | [23 61] | [195 195 207.5] | [195 370] | [0.297 0.297 0.3372] | [0.297 0.86] | [0.58 0.58 0.5933] | [0.58 0.766] | [48 48 50.57] | [48 84] |

| VL | [10 12.5 15] | [100 125 150] | VVVL | [33 38 43] | [23 25.71 28.43] | [195 207.5 220] | [0.297 0.3372 0.3774] | [0.58 0.5988 0.6066] | [48 50.57 53.14] | |||||||||

| L | [12.5 15 17.5] | [125 150 175] | VVL | [38 43 48] | [25.71 28.43 31.14] | [207.5 220 232.5] | [0.3372 0.3774 0.4176] | [0.5966 0.6066 0.6199] | [50.57 53.14 55.71] | |||||||||

| ML | [15 17.5 20] | [150 175 200] | VL | [43 48 53] | [28.43 31.14 33.86] | [220 232.5 245] | [0.3774 0.4176 0.4578] | [0.6066 0.6199 0.6332] | [53.14 55.71 58.28] | |||||||||

| M | [17.5 20 22.5] | [175 200 225] | L | [48 53 58] | [31.14 33.86 36.57] | [232.5 245 257.5] | [0.4176 0.4578 0.498] | [0.6199 0.6332 0.6465] | [55.71 58.28 60.85] | |||||||||

| MH | [20 22.5 25] | [200 225 250] | MLL | [53 58 63] | [33.86 36.57 39.28] | [245 257.5 270] | [0.4578 0.498 0.5382] | [0.6332 0.6465 0.6598] | [58.28 60.85 63.42] | |||||||||

| H | [22.5 25 27.5] | [225 250 275] | ML | [58 63 68] | [36.57 39.28 42] | [257.5 270 282.5] | [0.498 0.5382 0.5784] | [0.6465 0.6598 0.6731] | [60.85 63.42 66] | |||||||||

| VH | [25 27.5 30] | [250 275 300] | M | [63 68 73] | [39.28 42 44.71] | [270 282.5 295] | [0.5382 0.5784 0.6186] | [0.6598 0.6731 0.6864] | [63.42 66 68.57] | |||||||||

| VVH | [27.5 30 30] | [275 300 300] | MH | [68 73 78] | [42 44.71 47.43] | [282.5 295 307.5] | [0.5784 0.6186 0.6588] | [0.6731 0.6864 0.6997] | [66 68.57 71.13] | |||||||||

| MHH | [73 78 83] | [44.71 47.43 50.14] | [295 307.5 320] | [0.6186 0.6588 0.699] | [0.6864 0.6997 0.713] | [68.57 71.13 73.7] | ||||||||||||

| H | [78 83 88] | [47.43 50.14 52.85] | [307.5 320 332.5] | [0.6588 0.699 0.7392] | [0.6997 0.713 0.7263] | [71.13 73.7 76.27] | ||||||||||||

| VH | [83 88 93] | [50.14 52.85 55.57] | [320 332.5 345] | [0.699 0.7392 0.7794] | [0.713 0.7263 0.7396] | [73.7 76.27 78.84] | ||||||||||||

| VVH | [88 93 98] | [52.85 55.57 58.28] | [332.5 345 357.5] | [0.7392 0.7794 0.8196] | [0.7263 0.7396 0.7529] | [76.27 78.84 81.41] | ||||||||||||

| VVVH | [93 98 103] | [55.57 58.28 61] | [345 357.5 370] | [0.7794 0.8196 0.86] | [0.7396 0.7529 0.766] | [78.84 81.41 84] | ||||||||||||

| EH | [98 103 103] | [58.28 61 61] | [357.5 370 370] | [0.8196 0.86 0.86] | [0.7529 0.766 0.766] | [81.41 84 84] | ||||||||||||

| MF Type | Fuzzy Input Variables | Fuzzy Output Variables | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Variable | Speed (v) | Depth-of-Cut (DoC) | Variable | Tangential Cutting Forces (Ft) | Radial Force Component (Fr) | Temperature (T) | Surface Roughness (Ra) | Chip Compression ratio (CCR) | Shear Angle (SA) | |||||||||

| Parameter | Range | Parameter | Range | Parameter | Range | Parameter | Range | Parameters | Range | Parameter | Range | Parameter | Range | Parameter | Range | |||

| Triangular | VVL | [10 10 12.5] | [10 30] | [100 100 125] | [100 300] | EL | [12 12 15] | [12 54] | [5 5 7.65] | [5 42] | [224 224 237.2] | [224 408] | [0.121 0.121 0.143] | [0.121 0.429] | [0.71 0.71 0.7173] | [0.71 0.8122] | [64 64 65.57] | [64 86] |

| VL | [10 12.5 15] | [100 125 150] | VVVL | [12 15 18] | [5 7.65 10.3] | [224 237.2 250.4] | [0.121 0.143 0.165] | [0.70 0.7173 0.7246] | [64 65.57 67.14] | |||||||||

| L | [12.5 15 17.5] | [125 150 175] | VVL | 15 18 21] | [7.65 10.3 12.95] | [237.2 250.4 263.6] | [0.143 0. 165 0.187] | [0.7173 0.7246 0.7319] | [65.57 67.14 68.71] | |||||||||

| ML | [15 17.5 20] | [150 175 200] | VL | [18 21 24] | [10.3 12.95 15.6] | [250.4 263.6 276.8] | [0.165 0.187 0.209] | [0.7246 0.7319 0.7392] | [67.14 68.71 70.28] | |||||||||

| M | [17.5 20 22.5] | [175 200 225] | L | [21 24 27] | [12.95 15.6 18.25] | [263.6 276.8 290] | [0.187 0.209 0.231] | [0.7319 0.7392 0.7465] | [68.71 70.28 71.85] | |||||||||

| MH | [20 22.5 25] | [200 225 250] | MLL | [24 27 30] | [15.6 18.25 20.9] | [276.8 290 303.2] | [0.209 0.231 0.253] | [0.7392 0.7465 0.7538] | [70.28 71.85 73.42] | |||||||||

| H | [22.5 25 27.5] | [225 250 275] | ML | [27 30 33] | [18.25 20.9 23.55] | [290 303.2 316.4] | [0.231 0.253 0.275] | [0.7465 0.7538 0.7611] | [71.85 73.42 75] | |||||||||

| VH | [25 27.5 30] | [250 275 300] | M | [30 33 36] | [20.9 23.55 26.2] | [303.2 316.4 329.6] | [0.253 0.275 0.297] | [0.7538 0.7611 0.7684] | [73.42 75 76.57] | |||||||||

| VVH | [27.5 30 30] | [275 300 300] | MH | [33 36 39] | [23.55 26.2 28.85] | [316.4 329.6 342.8] | [0.275 0.297 0.319] | [0.7611 0.7684 0.7757] | [75 76.57 78.13] | |||||||||

| MHH | [36 39 42] | [26.2 28.85 31.5] | [329.6 342.8 356] | [0.297 0.319 0.341] | [0.7684 0.7757 0.783] | [76.57 78.13 79.7] | ||||||||||||

| H | [39 42 45] | [28.85 31.5 34.15] | [342.8 356 369.2] | [0.319 0.341 0.363] | [0.7757 0.783 0.7903] | [78.13 79.7 81.27] | ||||||||||||

| VH | [42 45 48] | [31.5 34.15 36.8] | [356 369.2 382.4] | [0.341 0.363 0.385] | [0.783 0.7903 0.7976] | [79.7 81.27 82.84] | ||||||||||||

| VVH | [45 48 51] | [34.15 36.8 39.45] | [369.2 382.4 395.6] | [0.363 0.385 0.407] | [0.7903 0.7976 0.8049] | [81.27 82.84 84.41] | ||||||||||||

| VVVH | [48 51 54] | [36.8 39.45 42] | [382.4 395.6 408] | [0.385 0.407 0.429] | [0.7976 0.8049 0.8122] | [82.84 84.41 86] | ||||||||||||

| EH | [51 54 54] | [39.45 42 42] | [395.6 408.8 408] | [0.407 0.429 0.429] | [0.8049 0.8122 0.8122] | [84.41 86 86] | ||||||||||||

| Input | Output | Input | Output | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rules No | Speed | Depth-of-Cut | Tangential Cutting Force | Radial Cutting Force | Temperature | Surface Roughness | Chip Compression Ratio (CCR) | Shear Angle (SA) | Rules No | Speed | Depth-of-Cut | Tangential Cutting Force | Radial Cutting Force | Temperature | Surface Roughness | Chip Compression Ratio (CCR) | Shear Angle (SA) |

| R1 | VVL | VVL | EL | EL | EL | ML | EL | MH | R2 | VVL | VL | VVVL | VVVL | VVVL | M | EL | MHH |

| R3 | VVL | L | VVL | VVL | VVVL | MHH | VVVL | H | R4 | VVL | ML | VL | VL | VVL | VH | VVVL | VVH |

| R5 | VVL | M | L | L | VL | VVH | VVL | VVVH | R6 | VVL | MH | MLL | MLL | L | VVVH | VVL | VVVH |

| R7 | VVL | H | ML | ML | MLL | VVVH | L | VVVH | R8 | VVL | VH | M | M | MLL | EH | MLL | EH |

| R9 | VVL | VVH | MH | MH | ML | EH | MLL | EH | R10 | VL | VVL | VVVL | VVVL | VVVL | MLL | VVVL | MHH |

| R11 | VL | VL | VVL | VVL | VVVL | M | VVL | H | R12 | VL | L | VL | VL | VVL | MHH | VVL | VH |

| R13 | VL | ML | L | L | VL | VH | VL | VVH | R14 | VL | M | MLL | MLL | L | VH | VL | VVVH |

| R15 | VL | MH | ML | ML | MLL | VVH | VL | VVVH | R16 | ML | H | M | M | MLL | VVH | L | EH |

| R17 | VL | VH | MH | MH | ML | VVVH | MLL | EH | R18 | VL | VVH | MHH | MHH | M | EH | MLL | EH |

| R19 | L | VVL | VVL | VVL | VVL | MLL | VVL | H | R20 | L | VL | VL | VL | VVL | ML | VL | H |

| R21 | L | L | L | L | VL | M | VL | VH | R22 | L | ML | MLL | MLL | L | H | L | VVVH |

| R23 | L | M | ML | ML | MLL | H | L | VVVH | R24 | L | MH | M | M | ML | VH | MLL | VVVH |

| R25 | L | H | MH | M | M | VH | MLL | EH | R26 | L | VH | MHH | M | MH | VVVH | ML | EH |

| R27 | L | VVH | H | MHH | MH | EH | ML | EH | R28 | ML | VVL | VVL | VVL | VVL | L | EL | L |

| R29 | ML | VL | VL | VL | VL | M | VVVL | MLL | R30 | ML | L | VL | VL | L | MH | VVL | ML |

| R31 | ML | ML | L | L | MLL | MHH | VL | M | R32 | ML | M | MLL | MLL | MLL | H | L | MH |

| R33 | ML | MH | ML | ML | ML | H | ML | MH | R34 | ML | H | M | M | M | H | MH | MHH |

| R35 | ML | VH | M | MH | MH | VVH | MHH | H | R36 | ML | VVH | MHH | MHH | MHH | VVVH | H | H |

| R37 | M | VVL | VL | VVL | L | VL | EL | MLL | R38 | M | VL | L | VL | L | L | VVL | ML |

| R39 | M | L | MLL | L | MLL | ML | VL | M | R40 | M | ML | ML | MLL | MLL | M | L | MH |

| R41 | M | M | M | ML | ML | MHH | ML | MHH | R42 | M | MH | MH | M | M | H | M | MHH |

| R43 | M | H | MHH | MH | MH | H | MHH | H | R44 | M | VH | H | MHH | MHH | VH | H | VH |

| R45 | M | VVH | VH | H | H | VVH | VH | VH | R46 | MH | VVL | L | VL | L | VL | VVVL | ML |

| R47 | MH | VL | L | VL | MLL | L | VVL | M | R48 | MH | L | MLL | L | ML | L | VL | MH |

| R49 | MH | ML | ML | MLL | ML | ML | MLL | MHH | R50 | MH | M | M | ML | M | M | ML | H |

| R51 | MH | MH | MH | MH | MH | MH | MH | H | R52 | MH | H | MHH | MHH | MHH | MHH | H | VH |

| R53 | MH | VH | H | MHH | H | H | VH | VVH | R54 | MH | VVH | VH | VH | VH | VVH | VH | VVH |

| R55 | H | VVL | L | VL | L | VVL | VVVL | EL | R56 | H | VL | MLL | VL | L | VVL | VVL | VVVL |

| R57 | H | L | ML | L | MLL | VL | VL | VL | R58 | H | ML | M | MLL | ML | L | L | MLL |

| R59 | H | M | M | ML | M | MLL | L | ML | R60 | H | MH | MH | M | MH | M | ML | ML |

| R61 | H | H | MHH | MH | H | MH | M | M | R62 | H | VH | H | MHH | VH | MH | H | MH |

| R63 | H | VVH | VH | VH | VVH | VH | VH | MH | R64 | VH | VVL | L | L | ML | VVVL | VVL | VVVL |

| R65 | VH | VL | L | L | ML | VVVL | VL | VVL | R66 | VH | L | MLL | MLL | M | VVVL | L | MLL |

| R67 | VH | ML | M | ML | MH | VVL | L | ML | R68 | VH | M | MH | MH | MH | VL | MLL | M |

| R69 | VH | MH | MHH | MH | H | ML | M | MH | R70 | VH | H | H | H | VH | M | MH | MH |

| R71 | VH | VH | VH | VH | VVH | MHH | H | MHH | R72 | VH | VVH | VVH | VVH | VVVH | H | VVVH | MHH |

| R73 | VVH | VVL | MLL | MLL | ML | EL | VVL | EL | R74 | VVH | VL | ML | ML | M | VVVL | VL | VL |

| R75 | VVH | L | MH | M | MH | VVL | MLL | MLL | R76 | VVH | ML | MHH | MHH | MH | VL | M | M |

| R77 | VVH | M | H | H | MHH | L | MHH | MH | R78 | VVH | MH | VH | VH | VH | MLL | H | MH |

| R79 | VVH | H | VVH | VVH | VVH | M | VH | MHH | R80 | VVH | VH | VVVH | VVVH | VVVH | MH | VVH | H |

| R81 | VVH | VVH | EH | EH | EH | MHH | EH | H | |||||||||

| Input | Output | Input | Output | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rules | Speed | Depth of Cut | Tangential Cutting Force | Radial Cutting Force | Temperature | Surface Roughness | Chip Compression Ratio | Shear Angle | Rules | Speed | Depth of Cut | Tangential Cutting Force | Radial Cutting Force | Temperature | Surface Roughness | Chip Compression Ratio | Shear Angle |

| R1 | VVL | VVL | VVVL | EL | EL | VL | EL | L | R2 | VVL | VL | VL | VVL | VVVL | MLL | VVL | ML |

| R3 | VVL | L | MLL | L | VVL | ML | L | MH | R4 | VVL | ML | M | ML | VVL | M | MLL | H |

| R5 | VVL | M | MH | M | VL | MH | ML | VH | R6 | VVL | MH | MHH | MHH | VL | H | MH | VH |

| R7 | VVL | H | VH | VH | L | VH | H | VVH | R8 | VVL | VH | VHHH | VVVH | MLL | VVVH | VH | VVVH |

| R9 | VVL | VVH | EH | EH | MLL | EH | VVH | EH | R10 | VL | VVL | EL | EL | VVVL | VVL | VVVL | MLL |

| R11 | VL | VL | VL | VVL | VVL | L | VVL | MH | R12 | VL | L | ML | L | VL | MLL | L | H |

| R13 | VL | ML | ML | ML | VL | ML | ML | VH | R14 | VL | M | MH | MH | L | M | M | VVH |

| R15 | VL | MH | MHH | MHH | L | MHH | MHH | VVH | R16 | ML | H | VH | VH | MLL | H | H | VVVH |

| R17 | VL | VH | VVVH | VVVH | ML | VVH | VH | VVVH | R18 | VL | VVH | EH | EH | ML | VVVH | VVH | EH |

| R19 | L | VVL | VVVL | VVVL | VVL | VVL | L | L | R20 | L | VL | VVL | VL | VL | VL | MLL | L |

| R21 | L | L | VL | MLL | VL | L | ML | MLL | R22 | L | ML | ML | M | L | ML | ML | ML |

| R23 | L | M | M | MH | MLL | M | M | M | R24 | L | MH | MHH | MHH | M | MH | MHH | MH |

| R25 | L | H | H | VH | MH | H | H | MHH | R26 | L | VH | VH | VVH | MHH | VH | VH | H |

| R27 | L | VVH | VVH | VVVH | H | VVH | VVH | VH | R28 | ML | VVL | VVVL | VVVL | VVL | VVL | ML | L |

| R29 | ML | VL | VVL | VL | VL | VL | ML | L | R30 | ML | L | VL | L | L | L | ML | MLL |

| R31 | ML | ML | ML | ML | MLL | ML | M | ML | R32 | ML | M | M | M | ML | M | M | M |

| R33 | ML | MH | MHH | MHH | M | MHH | MH | MH | R34 | ML | H | H | H | MH | H | MHH | MHH |

| R35 | ML | VH | VH | VHH | MHH | VVH | VH | H | R36 | ML | VVH | VVH | VVVH | H | VVVH | VVH | VH |

| R37 | M | VVL | VVVL | VVVL | VL | VL | M | VVL | R38 | M | VL | VL | VL | L | L | M | L |

| R39 | M | L | L | MLL | MLL | MLL | MH | ML | R40 | M | ML | ML | M | ML | ML | MH | M |

| R41 | M | M | M | MH | M | M | MH | MHH | R42 | M | MH | MHH | MH | MH | MH | MHH | MHH |

| R43 | M | H | VH | H | MHH | MHH | VH | H | R44 | M | VH | VVH | VVH | H | VH | VVH | VH |

| R45 | M | VVH | VVH | VVVH | VH | VVH | VVVH | VVH | R46 | MH | VVL | EL | EL | L | L | MH | VVVL |

| R47 | MH | VL | VVL | VVL | MLL | ML | MH | VL | R48 | MH | L | L | L | ML | M | MHH | MLL |

| R49 | MH | ML | ML | ML | M | MH | MHH | M | R50 | MH | M | M | M | MH | MHH | MHH | MH |

| R51 | MH | MH | MH | MH | MH | H | H | MHH | R52 | MH | H | VH | H | H | VH | VH | H |

| R53 | MH | VH | VVH | VVH | VH | VVH | VVH | H | R54 | MH | VVH | VVVH | VVVH | VH | VVVH | VVVH | VH |

| R55 | H | VVL | EL | EL | MLL | VVL | M | VVL | R56 | H | VL | VVVL | VL | ML | VL | M | L |

| R57 | H | L | L | L | M | L | MH | ML | R58 | H | ML | ML | ML | MHH | MLL | MH | M |

| R59 | H | M | M | M | MHH | ML | MH | MH | R60 | H | MH | MHH | MHH | H | ML | MHH | MHH |

| R61 | H | H | H | H | VH | M | H | H | R62 | H | VH | VVH | VVH | VVH | MH | VH | VH |

| R63 | H | VVH | VVVH | VVVH | VVH | MH | VVH | VVH | R64 | VH | VVL | VVVL | EL | MLL | VVVL | MH | VVVL |

| R65 | VH | VL | VL | VVL | M | VVL | MH | VL | R66 | VH | L | L | L | MH | VL | MH | L |

| R67 | VH | ML | ML | ML | MHH | L | MHH | ML | R68 | VH | M | M | ML | H | L | MHH | M |

| R69 | VH | MH | MHH | MH | VH | MLL | H | MH | R70 | VH | H | H | H | VVH | ML | VH | MHH |

| R71 | VH | VH | VH | VVH | VVH | M | VVH | H | R72 | VH | VVH | VVVH | EH | VVVH | M | VVVH | VH |

| R73 | VVH | VVL | EL | EL | ML | EL | MHH | EL | R74 | VVH | VL | VVL | VVL | M | VVVL | MHH | VVL |

| R75 | VVH | L | L | L | MHH | VVL | H | L | R76 | VVH | ML | MLL | ML | H | VL | H | MLL |

| R77 | VVH | M | ML | ML | VH | VL | H | ML | R78 | VVH | MH | MH | MH | VH | L | VH | M |

| R79 | VVH | H | H | H | VVH | MLL | VVH | MH | R80 | VVH | VH | VH | VVH | VVVH | M | VVVH | MHH |

| R81 | VVH | VVH | VVH | EH | EH | MH | EH | H | |||||||||

| Cutting Conditions | Simulation Results | Experimental Results | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed (m/min) | DOC (µm) | Ft (N) | Fr (N) | Tmax (°C) | Ra (µm) | CCR | SA (°) | Ft (N) | Fr (N) | Tmax (°C) | Ra (µm) | CCR | SA (°) |

| 10 | 100 | 38.00 | 23.78 | 198.00 | 0.419 | 0.5838 | 58.2 | 38 ± 5 | 23 ± 4 | 195 | 0.413 ± 0.036 | 0.58 ± 0.15 | 58.59 ± 10 |

| 10 | 200 | 68.00 | 39.32 | 220.14 | 0.583 | 0.6464 | 73.7 | 72 ± 7 | 43 ± 3 | 227 | 0.621 ± 0.038 | 0.65 ± 0.20 | 77.56 ± 08 |

| 10 | 300 | 101.55 | 60.25 | 257.74 | 0.851 | 0.7394 | 83.3 | 101 ± 6 | 61 ± 5 | 262 | 0.861 ± 0.050 | 0.735 ± 0.08 | 84.88 ± 07 |

| 20 | 100 | 38.00 | 25.72 | 232.66 | 0.419 | 0.6730 | 53.1 | 35 ± 4 | 24 ± 3 | 231 | 0.401 ± 0.050 | - | - |

| 20 | 200 | 63.00 | 42.00 | 270.34 | 0.542 | 0.6860 | 66.0 | 68 ± 5 | 45 ± 2 | 276 | 0.601 ± 0.040 | 0.68 ± 0.20 | 71.67 ± 09 |

| 20 | 300 | 93.00 | 58.38 | 333.00 | 0.787 | 0.7530 | 78.8 | 94 ± 6 | 58 ± 3 | 325 | 0.783 ± 0.050 | 0.75 ± 0.10 | 78.89 ± 06 |

| 30 | 100 | 34.44 | 23.78 | 270.34 | 0.308 | 0.6996 | 48.7 | 34 ± 3 | 23 ± 3 | 269 | 0.297 ± 0.060 | - | - |

| 30 | 200 | 63.00 | 39.32 | 333.00 | 0.419 | 0.7128 | 63.4 | 64 ± 3 | 40 ± 4 | 326 | 0.419 ± 0.047 | 0.71 ± 0.17 | 63.46 ± 12 |

| 30 | 300 | 93.00 | 60.25 | 366.60 | 0.624 | 0.7622 | 73.7 | 93 ± 5 | 59 ± 5 | 370 | 0.611 ± 0.046 | 0.77 ± 0.10 | 73.67 ± 05 |

| Cutting Conditions | Simulation Results | Experimental Results | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed (m/min) | DOC (µm) | Ft (N) | Fr (N) | Tmax (°C) | Ra (µm) | CCR | SA (°) | Ft (N) | Fr (N) | Tmax (°C) | Ra (µm) | CCR | SA (°) |

| 10 | 100 | 12.8 | 5.76 | 227.0 | 0.253 | 0.712 | 76.57 | 12 ± 3.7 | 05 ± 3.0 | 224 | 0.263 ± 0.02 | 0.65 ± 0.16 | 76.98 ± 8 |

| 10 | 200 | 24.0 | 15.60 | 263.5 | 0.385 | 0.724 | 84.42 | 23 ± 2.6 | 14 ± 4.0 | 261 | 0.381 ± 0.01 | 0.72 ± 0.15 | 85.46 ± 3 |

| 10 | 300 | 36.0 | 26.20 | 303.2 | 0.424 | 0.749 | 85.54 | 38 ± 2.4 | 26 ± 3.2 | 302 | 0.424 ± 0.02 | 0.74 ± 0.10 | 86.20 ± 4 |

| 20 | 100 | 21.0 | 10.30 | 263.6 | 0.188 | 0.712 | 71.85 | 20 ± 1.7 | 10 ± 3.0 | 261 | 0.195 ± 0.02 | - | - |

| 20 | 200 | 33.0 | 20.89 | 303.0 | 0.319 | 0.753 | 78.10 | 33 ± 2.2 | 21 ± 2.0 | 303 | 0.313 ± 0.01 | 0.68 ± 0.15 | 78.30 ± 6 |

| 20 | 300 | 45.0 | 31.40 | 355.9 | 0.385 | 0.796 | 81.28 | 46 ± 3.2 | 35 ± 4.0 | 355 | 0.392 ± 0.02 | 0.79 ± 0.14 | 81.20 ± 6 |

| 30 | 100 | 27.0 | 18.24 | 303.2 | 0.127 | 0.725 | 64.50 | 28 ± 4.2 | 18 ± 3.2 | 298 | 0.121 ± 0.02 | - | - |

| 30 | 200 | 42.0 | 31.50 | 342.8 | 0.209 | 0.774 | 76.60 | 41 ± 2.3 | 32 ± 2.0 | 340 | 0.219 ± 0.02 | 0.77 ± 0.12 | 76.70 ± 4 |

| 30 | 300 | 53.1 | 41.27 | 404.4 | 0.319 | 0.818 | 79.70 | 54 ± 3.1 | 42 ± 3.8 | 408 | 0.327 ± 0.02 | 0.82 ± 0.18 | 78.50 ± 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhammad, R. A Fuzzy Logic Model for the Analysis of Ultrasonic Vibration Assisted Turning and Conventional Turning of Ti-Based Alloy. Materials 2021, 14, 6572. https://doi.org/10.3390/ma14216572

Muhammad R. A Fuzzy Logic Model for the Analysis of Ultrasonic Vibration Assisted Turning and Conventional Turning of Ti-Based Alloy. Materials. 2021; 14(21):6572. https://doi.org/10.3390/ma14216572

Chicago/Turabian StyleMuhammad, Riaz. 2021. "A Fuzzy Logic Model for the Analysis of Ultrasonic Vibration Assisted Turning and Conventional Turning of Ti-Based Alloy" Materials 14, no. 21: 6572. https://doi.org/10.3390/ma14216572