Overview of the Current State of Gallium Arsenide-Based Solar Cells

Abstract

:1. Introduction

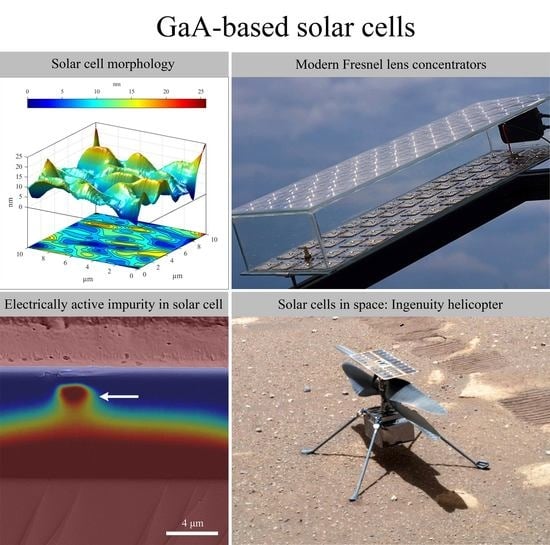

2. Structure and Composition of GaAs Solar Cells

- MOVPE is used to deliver faster growth rates for bulk layers and low breakdown at high temperatures and low vacuum. MOVPE does not require significant bake times and can recover more quickly from equipment failures than MBE.

- MBE is, unlike MOVPE, considered a method for superior quality and pure materials in ultra-high vacuum (UHV). It is easier to maintain and is able to grow thermodynamically forbidden materials [21].

- Lattice matched [22]

- Upright [23]

- Metamorphic [24]—use the localization of defects in a buffer layer located between layers with different lattice constants.

- Inverted [25]—this is an inverted growth of the structure, so materials with a higher bandgap grow here first. The structure is then rotated, and the substrate is removed. This leads to a better performance of the solar cell.

3. Applications of Solar Cells

3.1. Aerospace and Military

3.2. Solar Photovoltaic Concentrators

3.3. Probes, Satellites and Other Space Objects

Light Intensity Affecting Solar Cells in Space

4. Stability and Degradation of Structures

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Sample Availability

Abbreviations

| AFM | Atomic Force Microscope |

| AM0 | Air Mass at zero atmosphere |

| ARC | Anti-Reflection Coating |

| CPV | Concentrator Photovoltaics |

| CSOC | Concentrator Standard Operating Conditions |

| CSTC | Concentrator Standard Test Conditions |

| EBIC | Electron Beam-Induced Current |

| HALE | High Altitude Long Endurance |

| HCPV | High-Concentration Photovoltaics |

| HEMT | High Electron Mobility Transistor |

| LCPV | Low Concentration Photovoltaic |

| MBE | Molecular Beam Epitaxy |

| MOVPE | Metal Organic Vapor Phase Epitaxy |

| MPCV | Multipurpose Crew Vehicle |

| MPP | Maximum Power Point |

| NASA | National Aeronautics and Space Administration |

| NREL | National Renewable Energy Laboratory |

| PV | Photovoltaic |

| SEM | Scanning Electron Microscope |

| SOE | Secondary Optical Element |

| SoG | Silicone-on-Glass |

| IMM | Inverted Metamorphic |

| IUPAC | International Union of Pure and Applied Chemistry |

| IR | Infrared |

| ISE | Institute for Solar Energy Systems |

| UAV | Unmanned Aerial Vehicles |

| UHV | Ultra-High Vacuum |

| UV | Ultraviolet |

References

- Brozel, M.R.; Stillman, G.E. INSPEC (Information service). In Properties of Gallium Arsenide; IEE: London, UK, 1996; p. 981. [Google Scholar]

- Ghandhi, S.K. VLSI Fabrication Principles: Silicon and Gallium Arsenide; Wiley: Hoboken, NJ, USA, 1994; p. 834. [Google Scholar]

- Barron, A.R. Chemistry of Electronic Materials; Midas Green Innovations: Swansea, Wales, 2021; p. 214. [Google Scholar]

- Arickx, P.; Kurstjens, R.; Geens, W.; Dessein, K. The Next Generation of Germanium Substrates: ExpogerTM. E3S Web Conf. 2017, 16, 03010. [Google Scholar] [CrossRef] [Green Version]

- Alferov, Z.A. NobelPrize.org. Available online: https://www.nobelprize.org/prizes/physics/2000/alferov/facts/ (accessed on 3 May 2021).

- Papež, N. Degradation of GaAs Solar Cells. Ph.D. Thesis, Brno University of Technology, Brno, Czech Republic, 2021. [Google Scholar]

- Yamaguchi, M.; Takamoto, T.; Araki, K.; Kojima, N. Recent results for concentrator photovoltaics in Japan. Jpn. J. Appl. Phys. 2016, 55, 04EA05. [Google Scholar] [CrossRef]

- Geisz, J.F.; France, R.M.; Schulte, K.L.; Steiner, M.A.; Norman, A.G.; Guthrey, H.L.; Young, M.R.; Song, T.; Moriarty, T. Six-junction III–V solar cells with 47.1% conversion efficiency under 143 Suns concentration. Nat. Energy 2020, 5, 326–335. [Google Scholar] [CrossRef]

- Darbe, S.; Escarra, M.D.; Warmann, E.C.; Atwater, H.A. Simulation and partial prototyping of an eight-junction holographic spectrum-splitting photovoltaic module. Energy Sci. Eng. 2019, 7, 2572–2584. [Google Scholar] [CrossRef] [Green Version]

- Iles, P.A. Photovoltaic Conversion: Space Applications. In Encyclopedia of Energy; Elsevier: Amsterdam, The Netherlands, 2004; pp. 25–33. [Google Scholar] [CrossRef]

- King, R.R.; Fetzer, C.M.; Law, D.C.; Edmondson, K.M.; Yoon, H.; Kinsey, G.S.; Krut, D.D.; Ermer, J.H.; Hebert, P.; Cavicchi, B.T.; et al. Advanced III-V multijunction cells for space. In Proceedings of the Conference Record of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conversion, WCPEC-4, Waikoloa, HI, USA, 7–12 May 2006; Volume 2, pp. 1757–1762. [Google Scholar] [CrossRef]

- Li, J.; Aierken, A.; Zhuang, Y.; Xu, P.Q.; Wu, H.Q.; Zhang, Q.Y.; Wang, X.B.; Mo, J.H.; Yang, X.; Chen, Q.Y.; et al. 1 MeV electron and 10 MeV proton irradiation effects on inverted metamorphic GaInP/GaAs/InGaAs triple junction solar cell. Sol. Energy Mater. Sol. Cells 2021, 224, 111022. [Google Scholar] [CrossRef]

- Rodziewicz, T.; Zaremba, A.; Wacławek, M. Photovoltaics: Solar energy resources and the possibility of their use. Ecol. Chem. Eng. S 2016, 23, 9–32. [Google Scholar] [CrossRef] [Green Version]

- Ţălu, Ş.; Papež, N.; Sobola, D.; Tofel, P. Fractal Analysis of the 3-D surface Topography of GaAs Solar Cells. In DEStech Transactions on Environment, Energy and Earth Sciences; DEStech Publications Inc.: Lancaster, PA, USA, 2018. [Google Scholar] [CrossRef] [Green Version]

- Sobola, D.; Ţălu, Ş.; Tománek, P. Surface Condition of GaAs Solar Cells. Acta Tech. Corviniensis Bull. Eng. 2017, 27–32. [Google Scholar]

- Kittel, C. Introduction to Solid State Physics; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- NSM Archive—Physical Properties of Semiconductors. Available online: http://www.ioffe.ru/SVA/NSM/Semicond/ (accessed on 4 May 2021).

- Varshni, Y.P. Temperature dependence of the energy gap in semiconductors. Physica 1967, 34, 149–154. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Meyer, J.R.; Ram-Mohan, L.R. Band parameters for III-V compound semiconductors and their alloys. J. Appl. Phys. 2001, 89, 5815–5875. [Google Scholar] [CrossRef] [Green Version]

- Sharma, T.K. MOVPE and MBE growth of semiconductor thin films. AIP Conf. Proc. 2012, 1451, 18–23. [Google Scholar] [CrossRef]

- Pelzel, R. A Comparison of MOVPE and MBE Growth Technologies for III-V Epitaxial Structures. In Proceedings of the CS MANTECH Conference, New Orleans, LA, USA, 13–16 May 2013. [Google Scholar]

- Tu, C.W.; Beggy, J.C.; Baiocchi, F.A.; Abys, S.M.; Pearton, S.J.; Hsieh, S.J.; Kopf, R.F.; Caruso, R.; Jordan, A.S. Lattice-Matched Gaas/Ca 0.45 Sr 0.55 F 2/Ge(100) Heterostrucuures Grown By Molecular Beam Epitaxy. MRS Proc. 1987, 91, 359–364. [Google Scholar] [CrossRef]

- Eaglesham, D.J.; Devenish, R.; Fan, R.T.; Humphreys, C.J.; Morkoc, H.; Bradley, R.R.; Augustus, P.D. Defects in MBE and MOCVD-grown GaAs on Si. In Microscopy of Semiconducting Materials, 1987; CRC Press: Boca Raton, FL, USA, 2020; pp. 105–110. [Google Scholar] [CrossRef]

- Kim, Y.; Shin, H.B.; Lee, W.H.; Jung, S.H.; Kim, C.Z.; Kim, H.; Lee, Y.T.; Kang, H.K. 1080 nm InGaAs laser power converters grown by MOCVD using InAlGaAs metamorphic buffer layers. Sol. Energy Mater. Sol. Cells 2019, 200, 109984. [Google Scholar] [CrossRef]

- Huang, X.; Long, J.; Wu, D.; Ye, S.; Li, X.; Sun, Q.; Xing, Z.; Yang, W.; Song, M.; Guo, Y.; et al. Flexible four-junction inverted metamorphic AlGaInP/AlGaAs/ In0.17Ga0.83As/In0.47Ga0.53As solar cell. Sol. Energy Mater. Sol. Cells 2020, 208, 110398. [Google Scholar] [CrossRef]

- Hagar, B.; Sayed, I.; Colter, P.C.; Bedair, S.M. Multi-junction solar cells by Intermetallic Bonding and interconnect of Dissimilar Materials: GaAs/Si. Sol. Energy Mater. Sol. Cells 2020, 215, 110653. [Google Scholar] [CrossRef]

- Colozza, A.J.; Scheiman, D.A.; Brinker, D.J. GaAs/Ge Solar Powered Aircraft; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef] [Green Version]

- Scheiman, D.A.; Brinker, D.J.; Bents, D.J.; Colozza, A.J. Design of a GaAs/Ge solar array for unmanned aerial vehicles. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Waikoloa, HI, USA, 5–9 December 1994; Volume 2, pp. 2006–2009. [Google Scholar] [CrossRef] [Green Version]

- Wojtczuk, S.; Reinhardt, K. High-power density (1040 W/kg) GaAs cells for ultralight aircraft. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Washington, DC, USA, 13–17 May 1996; pp. 49–52. [Google Scholar] [CrossRef]

- Kayes, B.M.; Zhang, L.; Twist, R.; Ding, I.K.; Higashi, G.S. Flexible thin-film tandem solar cells with >30% efficiency. IEEE J. Photovolt. 2014, 4, 729–733. [Google Scholar] [CrossRef]

- Stender, C.L.; Adams, J.; Elarde, V.; Major, T.; Miyamoto, H.; Osowski, M.; Pan, N.; Tatavarti, R.; Tuminello, F.; Wibowo, A.; et al. Flexible and lightweight epitaxial lift-off GaAs multi-junction solar cells for portable power and UAV applications. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference, PVSC 2015, New Orleans, LA, USA, 14–19 June 2015. [Google Scholar] [CrossRef]

- Scheiman, D.; Hoheisel, R.; Edwards, D.J.; Paulsen, A.; Lorentzen, J.; Jenkins, P.; Caruthers, S.; Carter, S.; Walters, R. A path toward enhanced endurance of a UAV using IMM solar cells. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Portland, OR, USA, 5–10 June 2016; pp. 1095–1100. [Google Scholar] [CrossRef]

- D’Oliveira, F.A.; De Melo, F.C.L.; Devezas, T.C. High-altitude platforms—Present situation and technology trends. J. Aerosp. Technol. Manag. 2016, 8, 249–262. [Google Scholar] [CrossRef]

- Zephyr-UAV-Airbus. Available online: https://www.airbus.com/defence/uav/zephyr.html (accessed on 1 May 2021).

- Maguire, Y. Building Communications Networks in the Stratosphere—Facebook Engineering. 2015. Available online: https://engineering.fb.com/2015/07/30/connectivity/building-communications-networks-in-the-stratosphere/ (accessed on 3 May 2021).

- Maguire, Y. High Altitude Connectivity: The Next Chapter—Facebook Engineering. 2018. Available online: https://engineering.fb.com/2018/06/27/connectivity/high-altitude-connectivity-the-next-chapter/ (accessed on 3 May 2021).

- Weintraub, S. Alphabet Cuts Former Titan Drone Program from X Division, Employees Dispersing to Other Units—9to5Google. 2017. Available online: https://9to5google.com/2017/01/11/alphabet-titan-cut/ (accessed on 3 May 2021).

- Boyer, M. High-Altitude Pseudo-Satellite|Sunglider™ Platform Station|AeroVironment, Inc. 2019. Available online: https://www.avinc.com/resources/press-releases/view/hawk30-takes-flight-aerovironment-achieves-successful-first-test-flight-of (accessed on 3 May 2021).

- Boyuan, C. Rainbow Solar UAV to Make High-Altitude Flight Soon—China.org.cn. 2017. Available online: http://www.china.org.cn/china/2017-03/06/content_40418057.htm (accessed on 3 May 2021).

- PHASA-35 First Flight|Newsroom|BAE Systems|International. 2020. Available online: https://www.baesystems.com/en/article/ground-breaking-solar-powered-unmanned-aircraft-makes-first-flight (accessed on 3 May 2021).

- High Altitude, Ultra-Long Endurance, Pseudo-Satellite—HAPS—Odysseus —Aurora Flight Sciences. Available online: https://www.aurora.aero/odysseus-high-altitude-pseudo-satellite-haps/ (accessed on 3 May 2021).

- Smith, J.M. Alta Devices moves out of the lab and into the valley. MRS Bull. 2012, 37, 794–795. [Google Scholar] [CrossRef] [Green Version]

- Prismatic. Prismatic Completes First Two PHASA-35 HALE UAVs—Prismatic. 2019. Available online: https://www.prismaticltd.co.uk/news/prismatic-completes-first-two-phasa-35-hale-uavs/ (accessed on 1 May 2021).

- Kasaeian, A.; Tabasi, S.; Ghaderian, J.; Yousefi, H. A review on parabolic trough/Fresnel based photovoltaic thermal systems. Renew. Sustain. Energy Rev. 2018, 91, 193–204. [Google Scholar] [CrossRef]

- Sasaki, K.; Agui, T.; Nakaido, K.; Takahashi, N.; Onitsuka, R.; Takamoto, T. Development of InGaP/GaAs/InGaAs inverted triple junction concentrator solar cells. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2013; Volume 1556, pp. 22–25. [Google Scholar] [CrossRef] [Green Version]

- Hudec, C.L. Construction of Gallium Arsenide Solar Concentrator for Space Use. Calhoun: Monterey, CA, USA, 1988. [Google Scholar]

- O’neill, M.; Piszczor, M. Development of a dome Fresnel lens/gallium arsenide photovoltaic concentrator for space applications. In Proceedings of the 19th IEEE Photovoltaic Specialists Conference, New Orleans, LA, USA, 4–8 May 1987. [Google Scholar]

- Warmann, E.C.; Espinet-Gonzalez, P.; Vaidya, N.; Loke, S.; Naqavi, A.; Vinogradova, T.; Kelzenberg, M.; Leclerc, C.; Gdoutos, E.; Pellegrino, S.; et al. An ultralight concentrator photovoltaic system for space solar power harvesting. Acta Astronaut. 2020, 170, 443–451. [Google Scholar] [CrossRef]

- Hornung, T.; Hornung, T. Ein-und Mehrstufige Optische Konzentratoren für Photovoltaische Anwendungen. Ph.D. Thesis, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg, Germany, 2013. [Google Scholar]

- Papež, N.; Gajdoš, A.; Dallaev, R.; Sobola, D.; Sedlák, P.; Motúz, R.; Nebojsa, A.; Grmela, L. Performance analysis of GaAs based solar cells under gamma irradiation. Appl. Surf. Sci. 2020, 510, 145329. [Google Scholar] [CrossRef]

- Steiner, M.; Bösch, A.; Dilger, A.; Dimroth, F.; Dörsam, T.; Muller, M.; Hornung, T.; Siefer, G.; Wiesenfarth, M.; Bett, A.W. FLATCON® CPV module with 36.7% efficiency equipped with four-junction solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 1323–1329. [Google Scholar] [CrossRef]

- Wiesenfarth, M.; Steiner, M.; Dörsam, T.; Siefer, G.; Dimroth, F.; Nitz, P.; Bett, A.W. FLATCON® CPV module technology: A new design based on the evaluation of 10 years of outdoor measurement data. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2019; Volume 2149, p. 030007. [Google Scholar] [CrossRef]

- Awan, A.B.; Zubair, M.; Praveen, R.P.; Bhatti, A.R. Design and comparative analysis of photovoltaic and parabolic trough based CSP plants. Sol. Energy 2019, 183, 551–565. [Google Scholar] [CrossRef]

- Widyolar, B.K.; Abdelhamid, M.; Jiang, L.; Winston, R.; Yablonovitch, E.; Scranton, G.; Cygan, D.; Abbasi, H.; Kozlov, A. Design, simulation and experimental characterization of a novel parabolic trough hybrid solar photovoltaic/thermal (PV/T) collector. Renew. Energy 2017, 101, 1379–1389. [Google Scholar] [CrossRef] [Green Version]

- Habchi, A.; Hartiti, B.; Labrim, H.; Fadili, S.; Benyoussef, A.; Belouaggadia, N.; Faddouli, A.; Benaissa, M.; Ntsoenzok, E.; EZ-Zahraouy, H. Performance study of a new hybrid parabolic trough collector system integrated with hybrid tubular thermoelectric generator. Appl. Therm. Eng. 2021, 192, 116656. [Google Scholar] [CrossRef]

- Slooff, L.H.; Bende, E.E.; Burgers, A.R.; Budel, T.; Pravettoni, M.; Kenny, R.P.; Dunlop, E.D.; Büchtemann, A. A luminescent solar concentrator with 7.1% power conversion efficiency. Phys. Status Solidi RRL Rapid Res. Lett. 2008, 2, 257–259. [Google Scholar] [CrossRef] [Green Version]

- Andreev, V.M. GaAs and High-Efficiency Space Cells. In Practical Handbook of Photovoltaics: Fundamentals and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2003; pp. 417–433. [Google Scholar] [CrossRef]

- Leverington, D. New Cosmic Horizons: Space Astronomy from the V2 to the Hubble Space Telescope; Cambridge University Press: Cambridge, UK, 2000; p. 507. [Google Scholar]

- Garner, R. Observatory—Electrical Power. 2017. Available online: https://www.nasa.gov/content/goddard/hubble-space-telescope-electrical-power-system/ (accessed on 3 May 2021).

- EMCORE Corporation Awarded Solar Panel Manufacturing Contract From ATK Space Systems|EMCORE. Available online: https://investor.emcore.com/news-releases/news-release-details/emcore-corporation-awarded-solar-panel-manufacturing-contract (accessed on 2 May 2021).

- Toyota, H.; Ishii, N.; Nakamura, M.; Ooto, H.; Koide, K.; Sakamoto, T.; Abe, H.; Yoshino, H.; Takamura, H.; Ose, T.; et al. On-Orbit Operations of A Power System For Japan’s Venus Explorer Akatsuki. E3S Web Conf. 2017, 16, 18004. [Google Scholar] [CrossRef] [Green Version]

- Lauretta, D.S.; Balram-Knutson, S.S.; Beshore, E.; Boynton, W.V.; Drouet d’Aubigny, C.; DellaGiustina, D.N.; Enos, H.L.; Golish, D.R.; Hergenrother, C.W.; Howell, E.S.; et al. OSIRIS-REx: Sample Return from Asteroid (101955) Bennu. Space Sci. Rev. 2017, 212, 925–984. [Google Scholar] [CrossRef] [Green Version]

- Robinson-Avila, K. From New Mexico to Mars—SolAero Technologies, Inc. 2020. Available online: https://solaerotech.com/https-www-abqjournal-com-1518244-from-new-mexico-to-mars-ex-national-labs-local-businesses-contribute-brains-brawn-to-spacecraft-html/ (accessed on 3 May 2021).

- Images from the Mars Perseverance Rover—NASA Mars. 2021. Available online: https://mars.nasa.gov/mars2020/multimedia/raw-images/SI1/0046/0671022109/238ECM/N0031416SRLC07021/000085J (accessed on 1 May 2012).

- Cotal, H.; Fetzer, C.; Boisvert, J.; Kinsey, G.; King, R.; Hebert, P.; Yoon, H.; Karam, N. III-V multijunction solar cells for concentrating photovoltaics. Energy Environ. Sci. 2009, 2, 174–192. [Google Scholar] [CrossRef]

- Smil, V. The Earth’s Biosphere: Evolution, Dynamics, and Change; MIT Press: Cambridge, MA, USA, 2002; p. 346. [Google Scholar]

- Böhm-Vitense, E. Introduction to Stellar Astrophysics; Cambridge University Press: Cambridge, UK, 1989. [Google Scholar]

- Luminosity of Stars. Available online: https://www.atnf.csiro.au/outreach/education/senior/astrophysics/photometry_luminosity.html (accessed on 3 May 2021).

- Lissauer, J.J.; de Pater, I. Fundamental Planetary Science; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Papež, N.; Sobola, D.; Škvarenina, Ľ.; Škarvada, P.; Hemzal, D.; Tofel, P.; Grmela, L. Degradation analysis of GaAs solar cells at thermal stress. Appl. Surf. Sci. 2018, 461, 212–220. [Google Scholar] [CrossRef]

- Papež, N.; Škvarenina, Ľ.; Tofel, P.; Sobola, D. Thermal stability of gallium arsenide solar cells. In Proceedings of the SPIE, San Diego, CA, USA, 6–10 August 2017; p. 10603. [Google Scholar] [CrossRef]

- Papež, N.; Gajdoš, A.; Sobola, D.; Dallaev, R.; Macků, R.; Škarvada, P.; Grmela, L. Effect of gamma radiation on properties and performance of GaAs based solar cells. Appl. Surf. Sci. 2020, 527, 146766. [Google Scholar] [CrossRef]

- Papež, N.; Dallaev, R.; Kaspar, P.; Sobola, D.; Škarvada, P.; Ţălu, Ş.; Ramazanov, S.; Nebojsa, A. Characterization of GaAs Solar Cells under Supercontinuum Long-Time Illumination. Materials 2021, 14, 461. [Google Scholar] [CrossRef]

- Papež, N.; Dallaev, R.; Sobola, D.; Macku, R.; Škarvada, P. Microstructural investigation of defects in photovoltaic cells by the electron beam-induced current method. In Procedia Structural Integrity; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 23, pp. 595–600. [Google Scholar] [CrossRef]

- Ţălu, Ş. Micro and Nanoscale Characterization of Three Dimensional Surfaces: Basics and Applications; Napoca Star: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Ţălu, Ş.; Papež, N.; Sobola, D.; Achour, A.; Solaymani, S. Micromorphology investigation of GaAs solar cells: Case study on statistical surface roughness parameters. J. Mater. Sci. Mater. Electron. 2017, 28, 15370–15379. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Xue, Y.; Shi, C.; Ning, H.; Xu, R.; Jiao, Q.; Jia, T. Theoretical simulation of the degradation on GaAs sub-cell with different defects induced by 1MeV electron irradiation. Optik 2020, 223, 165532. [Google Scholar] [CrossRef]

- Hu, J.M.; Wu, Y.Y.; Zhang, Z.; Yang, D.Z.; He, S.Y. A study on the degradation of GaAs/Ge solar cells irradiated by <200 keV protons. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2008, 266, 267–270. [Google Scholar] [CrossRef]

- Gruginskie, N.; Cappelluti, F.; van Eerden, M.; Bauhuis, G.; Mulder, P.; Vlieg, E.; Schermer, J. Proton irradiation induced GaAs solar cell performance degradation simulations using a physics-based model. Sol. Energy Mater. Sol. Cells 2021, 223, 110971. [Google Scholar] [CrossRef]

- Yamaguchi, M. High-Efficiency GaAs-Based Solar Cells. In Post-Transition Metals; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

| Semiconductor | Chemical Formula | Bandgap/eV ( 0 ) | Bandgap/eV ( 300 ) | Gap | Lattice Constant/Å ( 300 ) |

|---|---|---|---|---|---|

| Gallium arsenide | GaAs | 1.52 | 1.42 | d | 5.653 |

| Indium phosphide | InP | 1.42 | 1.35 | d | 5.869 |

| Gallium antimonide | GaSb | 0.81 | 0.72 | d | 6.096 |

| Silicon | Si | 1.17 | 1.12 | i | 5.431 |

| Germanium | Ge | 0.74 | 0.66 | i | 5.658 |

| /mV | /mA | /mV | /mA | /mW | FF/– | |

|---|---|---|---|---|---|---|

| Before processing | 783.0 | 3.190 | 600.5 | 2.821 | 1.694 | 0.678 |

| After processing | 741.8 | 2.989 | 480.6 | 2.300 | 1.105 | 0.274 |

| Days | /mV | /mA | /mV | /mA | /mW | FF/– |

|---|---|---|---|---|---|---|

| 0 | 832.4 | 8.701 | 660.6 | 8.965 | 5.262 | 0.727 |

| 7 | 817.5 | 8.661 | 650.7 | 7.803 | 5.078 | 0.717 |

| 20 | 810.7 | 8.851 | 595.6 | 7.560 | 4.503 | 0.628 |

| 32 | 813.9 | 8.440 | 545.5 | 7.031 | 3.836 | 0.558 |

| 42 | 787.7 | 8.513 | 580.5 | 7.432 | 4.315 | 0.643 |

| 57 | 750.5 | 8.687 | 520.5 | 7.277 | 3.787 | 0.581 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papež, N.; Dallaev, R.; Ţălu, Ş.; Kaštyl, J. Overview of the Current State of Gallium Arsenide-Based Solar Cells. Materials 2021, 14, 3075. https://doi.org/10.3390/ma14113075

Papež N, Dallaev R, Ţălu Ş, Kaštyl J. Overview of the Current State of Gallium Arsenide-Based Solar Cells. Materials. 2021; 14(11):3075. https://doi.org/10.3390/ma14113075

Chicago/Turabian StylePapež, Nikola, Rashid Dallaev, Ştefan Ţălu, and Jaroslav Kaštyl. 2021. "Overview of the Current State of Gallium Arsenide-Based Solar Cells" Materials 14, no. 11: 3075. https://doi.org/10.3390/ma14113075