Novel Polyvinyl Butyral/Monoacylglycerol Nanofibrous Membrane with Antifouling Activity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials, Chemicals and Microorganisms

2.2. Preparation of 1-Monocaprin

2.3. Preparation of Nanofibrous Membranes

2.4. Characterization of the Polymer Solutions

2.5. Characterization of the Nanofibrous Membranes

2.6. Antibacterial Activity

- (a)

- The agar disk diffusion method encompassed the following: circular samples (9 mm in diameter) of nanofibers from neat PVB or PVB enriched with MAG 10 (3 wt%) on nonwoven textile were placed on agar plates previously inoculated with 1 mL of 0.5 McF turbid bacterial suspension (Escherichia coli, Staphylococcus aureus) in sterile saline solution. The plates were incubated at 37 °C for 24 h and the whole experiment was repeated three times. The authors evaluated the inhibition zones as well as growth under the samples.

- (b)

- Samples of PVB or PVB/MAG 10 nanofibers on an aluminum foil substrate (disks of diameter 30 mm) were added into 100 mL flasks (Duran, DWK, Mainz, Germany) containing 25 mL Brain Heart Infusion (BHI) broth (Himedia Laboratories Pvt. Ltd., Mumbai, India) and bacteria (Escherichia coli, Staphylococcus aureus) at the concentration of 5 × 103–5 × 104 CFU/mL. The mixtures were shaken at 100 rpm on a shaking incubator at 37 °C. Then, the viable counts of bacteria present in the solution after the required contact time (60, 120, 300 and 1440 min) were determined via the spiral plate method on an Eddy Jet spiral plater (IUL, Barcelona, Spain). This experiment was performed in triplicate. The following Equation (1) was applied to calculate the rate of reduction in percent (% R):where A is the number of viable bacteria present in BHI with PVB nanofibers (control) after the given contact time, and B is the number of viable bacteria present in BHI with PVB/MAG 10 nanofibers (sample) after the same.

- (c)

- Antibacterial activity was determined with adherence to the procedure stipulated under ISO 22196:2011 for Escherichia coli and Staphylococcus aureus [43]. Bacterial suspensions were prepared at concentrations ranging from 2.5 × 105 to 1 × 106 cells/mL. Four hundred µL of the suspension was deposited on a specimen 50 mm × 50 mm in size (neat PVB—Control untreated sample; PVB/MAG 10), which was covered with a square piece of polyethylene film (40 mm × 40 mm). The specimens and the films were placed under UV-light for 60 min to sterilize them prior to the experiments. Immediately (neat PVB), and after the contact time of 24 h, the specimens (neat PVB, PVB/MAG 10), both on aluminum foil, were rinsed with SCDLP broth (10 mL; soybean casein digest broth with lecithin and polyoxyethylene sorbitan monooleate) and the value for CFU/mL was determined. Log reduction in the number of living and viable cells of tested bacteria (R) was calculated according to Equation (2):where U0 is the average value for the common logarithm of the number of viable bacteria, in cells/cm2, recovered from the control samples (neat PVB nanofibers) immediately after inoculation, Ut is the mean for the common logarithm of the number of viable bacteria, in cells/cm2, recovered from the control samples (neat PVB nanofibers) after 24 h and At is the mean for the common logarithm of the number of viable bacteria, in cells/cm2, recovered from the test samples (PVB/MAG 10 nanofibers) after 24 h [43]. Reduction in the quantity of cells capable of growth by two orders of magnitude (R ≥ 2) was interpreted as a bactericidal effect of the tested nanofibers [44].

2.7. Antifouling Activity

2.8. Statistical Analysis

3. Results

3.1. Characterizatin of the Polymer Solutions

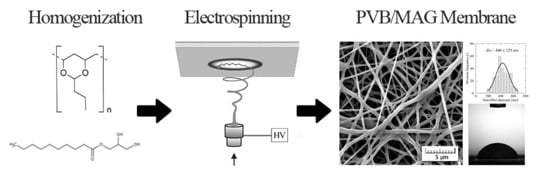

3.2. Characterization of Nanofibrous Membranes

3.3. Antibacterial Efficiency

3.3.1. Disk Diffusion Method

3.3.2. Dynamic Cultivation Method

3.3.3. Contact Method

3.4. Antifouling Activity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cai, N.; Li, C.; Han, C.; Luo, X.; Shen, L.; Xue, Y. Tailoring mechanical and antibacterial properties of chitosan/gelatinnanofiber membranes with Fe3O4 nanoparticles for potential wound dressing application. Appl. Surf. Sci. 2016, 369, 92–500. [Google Scholar] [CrossRef]

- Peer, P.; Polaskova, M.; Musilova, L. Superhydrophobic poly (vinyl butyral) nanofibrous membrane containing various silica nanoparticles. J. Text. Inst. 2019, 110, 1508–1514. [Google Scholar] [CrossRef]

- Panthi, G.; Park, M.; Kim, H.Y.; Park, S.J. Electrospun polymeric nanofibers encapsulated with nanostructured materials and their applications: A review. J. Ind. Eng. Chem. 2015, 242, 1–13. [Google Scholar] [CrossRef]

- Al-Enizi, A.M.; Zagho, M.M.; Elzatahry, A.A. Polymer-based electrospun nanofibers for biomedical applications. Nanomaterials 2018, 8, 259. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ge, L.; Zhao, Y.S.; Mo, T.; Li, J.R.; Li, P. Immobilization of glucose oxidase in electrospun nanofibrous membranes for food preservation. Food Control. 2012, 26, 88–193. [Google Scholar] [CrossRef]

- Rasouli, R.; Barhoum, A.; Bechelany, M.; Dufresne, A. Nanofibers for biomedical and healthcare applications. Macromol. Biosci. 2019, 19, 1800256. [Google Scholar] [CrossRef]

- Rivero, P.J.; Urrutia, A.; Goicoechea, J.; Arregui, F.J. Nanomaterials for functional textliles and fibers. Nanoscale Res. Lett. 2015, 10, 501. [Google Scholar] [CrossRef] [Green Version]

- Shahkaramipour, N.; Tran, T.N.; Ramanan, S.; Lin, H. Membranes with surface-enhanced antifouling properties for water purification. Membranes 2017, 7, 7010013. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Li, C.W.; Li, X.; Zhou, M.; Sun, J.B.; Sheng, F.F.; Shi, S.J.; Lu, L.C. Zinc oxide/silver bimetallic nanoencapsulated in PVP/PCL nanofibers for improved antibacterial activity. Artif. Cell Nanomed. Biotechnol. 2018, 46, 1248–1257. [Google Scholar] [CrossRef] [Green Version]

- Machado, R.; Da Costa, A.; Silva, D.M.; Gomes, A.C.; Casal, M.; Sencadas, V. Antibacterial and antifungal activity of poly(lactic acid)-bovine lactoferrin nanofiber membranes. Macromol. Biosci. 2018, 18, 1700324. [Google Scholar] [CrossRef]

- Rieger, K.A.; Schiffman, J.D. Electrospinning an essential oil: Cinnamaldehyde enhances the antimicrobial efficacy of chitosan/poly (ethylene oxide) nanofibers. Carbohydr. Polym. 2014, 113, 561–568. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.Y.; Yin, M.L.; Jiang, Z.M.; Pan, N.Y.; Ren, X.H.; Huang, T.S. Antibacterial poly(3-hydroxybutyrate-co-4-hydroxybutyrate) fibrous membranes containing quaternary ammonium salts. Polym. Adv. Technol. 2016, 27, 1617–1624. [Google Scholar] [CrossRef]

- Kurtz, I.S.; Schiffman, J.D. Current and emerging approaches to engineer antibacterial and antifouling electrospun nanofibers. Materials 2018, 11, 1059. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dolezalova, I.; Janis, R.; Bunkova, L.; Slobodian, P.; Vicha, R. Preparation, characterization and antibacterial activity of 1-monoacylglycerol of adamantane-1-carboxylic acid. J. Food Biochem. 2013, 34, 544–553. [Google Scholar]

- Sevcikova, P.; Kasparkova, V.; Hauerlandova, I.; Humpolicek, P.; Kucekova, Z.; Bunkova, L. Formulation, antibacterial activity, and cytotoxicity of 1-monoacylglycerol microemulsions. Eur. J. Lipid Sci. Technol. 2014, 116, 448–457. [Google Scholar]

- Vltavska, P.; Kasparkova, V.; Janis, R.; Bunkova, L. Antifungal and antibacterial effects of 1-monocaprylin on textile materials. Eur. J. Lipid Sci. Technol. 2012, 114, 849–856. [Google Scholar] [CrossRef]

- Preuss, H.G.; Echard, B.; Enig, M.; Brook, I.; Elliott, T.B. Minimum inhibitory concentrations of herbal essential oils and monolaurin for gram-positive and gram-negative bacteria. Mol. Cell. Biochem. 2005, 272, 29–34. [Google Scholar] [CrossRef]

- Altieri, C.; Bevilacqua, A.; Cardillo, D.; Sinigaglia, M. Effectiveness of fatty acids and their monoglycerides against gram-negative pathogens. Int. J. Food Sci. Technol. 2009, 44, 359–366. [Google Scholar] [CrossRef]

- Bunkova, L.; Krejci, J.; Janis, R.; Kasparkova, V.; Vltavska, P.; Kulendova, L.; Bunka, F. Influence of monoacylglycerols on growth inhibition of micromycetes in vitro and on bread. Eur. J. Lipid Sci. Technol. 2010, 112, 173–179. [Google Scholar] [CrossRef]

- Norn, V. Emulsifiers in Food Technology, 2nd ed.; Wiley Blackwell Publishing: Juelsminde, Denmark, 2015. [Google Scholar]

- Jackman, J.; Yoon, B.K.; Li, D.; Cho, N. Nanotechnology formulations for antibacterial free fatty acids and monoglycerides. Molecules 2016, 21, 305. [Google Scholar] [CrossRef] [Green Version]

- Thormar, H.; Hilmarsson, H. Glycerol monocaprate (monocaprin) reduces contamination by Escherichia coli and Salmonella enteritidis in hard surfaces. Food Control. 2012, 25, 505–510. [Google Scholar] [CrossRef]

- Araujo, E.S.; Nascimento, M.L.F.; De Oliveira, H.P. Influence of triton X-100 on PVA fibers production by the electrospinning technique. Fibres Text. East. Eur. 2013, 100, 39–43. [Google Scholar]

- Lin, T.; Wang, H.; Wang, X. The charge effect of cationic surfactants on the elimination of fiber beads in the electrospinning of polystyrene. Nanotechnology 2004, 15, 1375–1381. [Google Scholar] [CrossRef]

- Park, J.A.; Kim, S.B. Anti-biofouling enhancement of a polycarbonate membrane with functionalized poly (vinyl alcohol) electrospun nanofibers: Permeation flux, biofilm formation, contact, and regeneration tests. J. Membr. Sci. 2017, 540, 192–199. [Google Scholar] [CrossRef]

- Francolini, I.; Vuotto, C.; Piozzi, A.; Donelli, G. Antifouling and antimicrobial biomaterials: An overview. APMIS 2017, 125, 392–417. [Google Scholar] [CrossRef] [Green Version]

- Nthunya, L.N.; Gutierrez, L.; Nxumalo, E.N. f-MWCNTs/AgNPs-coated superhydrophobic PVDF nanofiber membrane for organic, colloidal, and biofouling mitigation in direct contact membrane distillation. J. Environ. Chem. Eng. 2020, 8, 103654. [Google Scholar] [CrossRef]

- Spasova, M.; Manolova, N.; Markova, N.; Rashkov, I. Superhydrophobic PVDF and PVDF-HFP nanofibrous mats with antibacterial and antibiofouling properties. Appl. Surf. Sci. 2016, 363, 363–371. [Google Scholar] [CrossRef]

- Goetz, L.A.; Jalvo, B.; Rosal, R.; Mathew, A.P. Superhydrophilic anti-fouling electrospun cellulose acetate membranes coated with chitin nanocrystals for water filtration. J. Membr. Sci. 2016, 510, 238–248. [Google Scholar] [CrossRef]

- Pan, S.; Ke, X.; Wang, T.Y.; Liu, Q.; Zhong, L.B.; Zheng, Y.M. Synthesis of silver nanoparticles embedded electrospun PAN nanofiber thin-film composite forward osmosis membrane to enhance performance and antimicrobial activity. Ind. Eng. Chem. Res. 2019, 58, 984–993. [Google Scholar] [CrossRef]

- Sallem, H.; Trabzon, L.; Kilic, A.; Zaidi, S.J. Recent advances in nanofibrous membranes: Production and applications in water treatment and desalination. Desalination 2020, 478, 114178. [Google Scholar] [CrossRef]

- Yalcinkaya, F. Experimental study on electrospun polyvinyl butyral nanofibers using a non-solvent system. Fibers Polym. 2015, 16, 2544–2551. [Google Scholar] [CrossRef]

- Basturk, E.; Cakmakci, E.; Madakbas, S.; Kahraman, M.V. Surface and proton conductivity properties of electrospun poly (vinyl butyral)/polyaniline nanofibers. Adv. Polym. Technol. 2018, 37, 1774–1781. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, J.C.; Dar, M.A.; Shim, H.W.; Kim, D.W. Superior lithium storage in nitrogen-doped carbon nanofibers with open-channels. Chem. Eng. J. 2017, 315, 1–9. [Google Scholar] [CrossRef]

- Li, Y.; Jiao, M.; Zhao, H.; Yang, M. Humidity sensing properties of the composite of electrospun crosslinked polyelectrolyte nanofibers decorated with Ag nanoparticles. Sens. Actuators B Chem. 2018, 273, 133–142. [Google Scholar] [CrossRef]

- Peer, P.; Cvek, M.; Urbanek, M.; Sedlacik, M. Preparation of electrospun magnetic polyvinyl butyral/Fe2O3 nanofubrous membranes for effective removal of iron irons from groundwater. J. Appl. Polym. Sci. 2020, e49576. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Komarek, M. Polyvinyl butyral (PVB) nanofiber/nanoparticle-covered yarns for antibacterial textile surfaces. Int. J. Mol. Sci. 2019, 20, 4317. [Google Scholar] [CrossRef] [Green Version]

- Janis, R.; Klasek, A.; Krejci, J.; Bobalova, J. Influence of some chromium complexes on the conversion rate of glycidol—Fatty acid reaction. Tenside Urfactants Deterg. 2005, 42, 44–48. [Google Scholar] [CrossRef]

- Bunkova, L.; Bunka, F.; Janis, R.; Krejci, J.; Dolezalkova, I.; Pospisil, Z.; Ruzicka, J.; Tremlova, B. Comparison of antibacterial effect of seven 1-monoglycerides on food-borne pathogens or spoilage bacteria. Acta Vet. Brno 2011, 80, 29–39. [Google Scholar] [CrossRef] [Green Version]

- Peer, P.; Stenicka, M.; Pavlinek, V.; Filip, P. An electrorheological investigation of PVB solutions in connection with their electrospinning qualities. Polym. Test. 2014, 39, 115–121. [Google Scholar] [CrossRef]

- Peer, P.; Stenicka, M.; Pavlinek, V.; Filip, P. The storage ability of polyvinylbutyral solutions from an electrospinnability standpoint. Polym. Degrad. Stab. 2014, 105, 134–139. [Google Scholar] [CrossRef]

- Merchan, M.; Sedlarikova, J.; Friedrich, M.; Sedlarik, V.; Saha, P. Thermoplastic modification of medical grade polyvinyl chloride with various antibiotics: Effect of antibiotic chemical structure on mechanical, antibacterial properties, and release activity. Polym. Bull. 2011, 67, 997–1016. [Google Scholar] [CrossRef]

- ISO 22196. Measurement of Antibacterial Activity on Plastics and Other Non-Porous Surfaces; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Michalska-Sionkowska, M.; Walczak, M.; Sionkowska, A. Antimicrobial activity of collagen material with thymol addition for potential application as wound dressing. Polym. Test. 2017, 63, 360–366. [Google Scholar] [CrossRef]

- Park, J.; Kim, S. Preparation and characterization of antimicrobial electrospun poly (vinyl alcohol) nanofibers containing benzyl triethylammonium chloride. React. Funct. Polym. 2015, 93, 30–37. [Google Scholar] [CrossRef]

- Theron, S.A.; Zussman, E.; Yarin, A.L. Experimental investigation of the governing parameters in the electrospinning of polymer solutions. Polymer 2004, 45, 2017–2030. [Google Scholar] [CrossRef]

- Juang, Y.H.; Kim, H.Y.; Lee, D.R.; Park, S.Y. Characterization of PVOH nonwoven mats prepared from surfactant-polymer system via electrospinning. Macromol. Res. 2005, 13, 385–390. [Google Scholar] [CrossRef] [Green Version]

- Fang, W.; Yang, S.; Yuan, T.Q.; Charlton, A.; Sun, R.C. Effect of various surfactants on alkali lignin electrospinning ability and spun fibers. Ind. Eng. Chem. Res. 2017, 56, 9551–9559. [Google Scholar] [CrossRef] [Green Version]

- Chinatangul, N.; Limmatvapirat, C.; Nunthanid, J.; Luangtana-Anan, M.; Sriamornsak, P.; Limmatvapirat, S. Design and characterization of monolaurin loaded electrospun shellac nanofibers with antimicrobial activity. Asian J. Pharm. Sci. 2018, 13, 459–471. [Google Scholar] [CrossRef]

- Peer, P.; Polaskova, M.; Suly, P. Rheology of poly (vinyl butyral) solution containing fumed silica in correlation with electrospinning. Chin. J. Polym. Sci. 2018, 36, 742–748. [Google Scholar] [CrossRef]

- Jia, L.; Qin, X. The effect of different surfactants on the electrospinning poly (vinyl alcohol) (PVA) nanofibers. J. Therm. Anal. Calorim. 2012, 112, 595–605. [Google Scholar] [CrossRef]

- Yener, F.; Yalcinkaya, B. Electrospinning of polyvinyl butyral in different solvents. E-Polym. 2013, 21, 229–242. [Google Scholar] [CrossRef]

- Abutaleb, S.; Lolla, D.; Aljuhani, A.; Shin, H.U.; Rajala, J.W.; Chase, G. Effects of surfactants on the morphology and properties of electrosupn polyetherimide fibers. Fibers 2017, 5, 33. [Google Scholar] [CrossRef] [Green Version]

- Clarizia, G.; Tasselli, F.; Simari, C.; Nicotera, I.; Bernardo, P. Solution casting blending: An effective way for tailoring gas transport and mechanical properties of poly (vinyl butyral) and Pebax2533. J. Phys. Chem. C 2019, 123, 11264–11272. [Google Scholar] [CrossRef]

- Kaewmanee, P.C.; Wongsatayanon, B.; Durand, A. Encapsulation of bioactive compounds (monocaprin and monolaurin) into polymeric nanoparticles. Mater. Sci. Forum. 2018, 916, 147–152. [Google Scholar] [CrossRef]

- Vasoya, J.; Desai, H.H.; Gumaste, S.G.; Tillotson, J.; Kelemen, D.; Dalrymple, D.M.; Serajuddin, A.T. Development of solid dispersion by holt melt extrusion using mixtures of polyoxyglycerides with polymers as carriers for increasing dissolution rate of a model poorly soluble drugs. J. Pharm. Sci. 2018, 108, 888–896. [Google Scholar] [CrossRef]

- Tlili, I.; Alkanhal, T.A. Nanotechnology for water purification: Electrospun nanofibrous membrane in water and wastewater treatment. J. Water Reuse Desalin. 2019, 9, 232–248. [Google Scholar] [CrossRef]

- Peer, P.; Cmarova, A.; Stenicka, M. Surface wettability of polyvinyl butyral nanofibrous membranes. World J. Text. Eng. 2018, 4, 8–14. [Google Scholar]

- Beigmoradi, R.; Samimi, A.; Mohebbi-Kalhori, D. Fabrication of polymeric nanofibrous mats with controllable structure and enhanced wetting behavior using one-step electrospinning. Polymer 2018, 143, 271–280. [Google Scholar] [CrossRef]

- Chen, S.; Liu, G.; He, H.; Zhou, C.; Yan, X.; Zhang, J. Physical structure induced hydrophobicity analyzed from electrospinning and coating polyvinyl butyral films. Adv. Condens. Matter Phys. 2019, 23, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Yoon, B.K.; Jackman, J.A.; Valle-Gonzales, E.; Cho, N.J. Antibacterial free fatty acids and monoglycerides: Biological activities, experimental testing, and therapeutic applications. Int. J. Mol. Sci. 2018, 19, 1114. [Google Scholar] [CrossRef] [Green Version]

- Thormar, H.; Hilmarsson, H.; Bergsson, G. Stable concentrated emulsions of the 1-monoglyceride of capric acid (monocaprin) with microbicidal activities against the food-borne bacteria campylobacter jejuni, Salmonella spp., and Escherichia coli. Appl. Environ. Microb. 2016, 72, 522–526. [Google Scholar] [CrossRef] [Green Version]

- Jones, A. Killer plastics: Antimicrobial additives for polymers. Plast. Eng. 2008, 64, 34–40. [Google Scholar] [CrossRef]

- Peliskova, M.; Slobodian, P.; Sedlarik, V.; Zatloukal, M.; Kuritka, I. Electrospun polyurethane membrane with Ag/ZnO microparticles as an antibacterial surface on polyurethane sheets. J. Appl. Polym. Sci. 2016, 133, 43020. [Google Scholar] [CrossRef]

- Nguyen, T.; Roddick, F.; Fan, L. Biofouling of water treatment membranes: A review of the underlying causes, monitoring techniques and control measures. Membranes 2012, 2, 804–840. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Focarete, M.L.; Gualandi, C.; Ramakrishna, S. Filtering Media by Electrospinning; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

| Escherichia coli ATCC 25922 | Staphylococcus aureus ATCC 25923 | |

|---|---|---|

| Time (min) | % R | % R |

| 60 | −1.61 a | 22.83 a |

| 120 | −0.72 a | 18.76 a |

| 300 | −7.76 a | 22.12 a |

| 1440 | −7.49 a | −5.72 b |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peer, P.; Sedlaříková, J.; Janalíková, M.; Kučerová, L.; Pleva, P. Novel Polyvinyl Butyral/Monoacylglycerol Nanofibrous Membrane with Antifouling Activity. Materials 2020, 13, 3662. https://doi.org/10.3390/ma13173662

Peer P, Sedlaříková J, Janalíková M, Kučerová L, Pleva P. Novel Polyvinyl Butyral/Monoacylglycerol Nanofibrous Membrane with Antifouling Activity. Materials. 2020; 13(17):3662. https://doi.org/10.3390/ma13173662

Chicago/Turabian StylePeer, Petra, Jana Sedlaříková, Magda Janalíková, Liliana Kučerová, and Pavel Pleva. 2020. "Novel Polyvinyl Butyral/Monoacylglycerol Nanofibrous Membrane with Antifouling Activity" Materials 13, no. 17: 3662. https://doi.org/10.3390/ma13173662