Additive and Substractive Surface Structuring by Femtosecond Laser Induced Material Ejection and Redistribution

Abstract

:1. Introduction

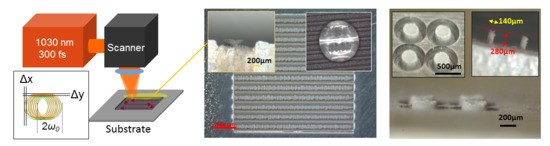

2. Materials and Methods

3. Results

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Sedao, X.; Abou Saleh, A.; Rudenko, A.; Douillard, T.; Esnouf, C.; Reynaud, S.; Maurice, C.; Pigeon, F.; Garrelie, F.; Colombier, J.-P. Self-Arranged Periodic Nanovoids by Ultrafast Laser-Induced Near-Field Enhancement. ACS Photonics 2018, 5, 1418–1426. [Google Scholar] [CrossRef]

- Saint-Pierre, D.; Granier, J.; Egaud, G.; Baubeau, E.; Mauclair, C. Fast Uniform Micro Structuring of DLC Surfaces Using Multiple Ultrashort Laser Spots through Spatial Beam Shaping. Phys. Procedia 2016, 83, 1178–1183. [Google Scholar] [CrossRef]

- Liu, Z.; Siegel, J.; Garcia-Lechuga, M.; Epicier, T.; Lefkir, Y.; Reynaud, S.; Bugnet, M.; Vocanson, F.; Solis, J.; Vitrant, G.; et al. Three-Dimensional Self-Organization in Nanocomposite Layered Systems by Ultrafast Laser Pulses. ACS Nano 2017, 11, 5031–5040. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mauclair, C.; Cheng, G.; Huot, N.; Audouard, E.; Rosenfeld, A.; Hertel, I.V.; Stoian, R. Dynamic ultrafast laser spatial tailoring for parallel micromachining of photonic devices in transparent materials. Opt. Express 2009, 17, 3531–3542. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Mann, G.; Krüger, J.; Marcinkowski, M.; Eberstein, M. Femtosecond laser-induced removal of silicon nitride layers from doped and textured silicon wafers used in photovoltaics. Thin Solid Films 2013, 542, 420–425. [Google Scholar] [CrossRef]

- Nie, B.; Yang, L.; Huang, H.; Bai, S.; Wan, P.; Liu, J. Femtosecond laser additive manufacturing of iron and tungsten parts. Appl. Phys. A 2015, 119, 1075–1080. [Google Scholar] [CrossRef]

- Nie, B.; Huang, H.; Bai, S.; Liu, J. Femtosecond laser melting and resolidifying of high-temperature powder materials. Appl. Phys. A 2015, 118, 37–41. [Google Scholar] [CrossRef]

- Delaporte, P.; Alloncle, A.-P. Laser-induced forward transfer: A high resolution additive manufacturing technology. Opt. Laser Technol. 2016, 78, 33–41. [Google Scholar] [CrossRef]

- Piqué, A.; Serra, P. Laser Printing of Functional Materials: 3D Microfabrication, Electronics and Biomedicine; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Mingareev, I.; Bonhoff, T.; El-Sherif, A.F.; Meiners, W.; Kelbassa, I.; Biermann, T.; Richardson, M. Femtosecond laser post-processing of metal parts produced by laser additive manufacturing. J. Laser Appl. 2013, 25, 052009. [Google Scholar] [CrossRef] [Green Version]

- Baubeau, E.; Missemer, F.; Bertrand, P. System and Method for Additively Manufacturing by Laser Melting of a Powder Bed 2017. U.S. Patent 15,762,482, 27 September 2018. [Google Scholar]

- Eichstädt, J.; Huis, A.J. Analysis of Irradiation Processes for Laser-Induced Periodic Surface Structures. Phys. Procedia 2013, 41, 650–660. [Google Scholar] [CrossRef]

- Zhigilei, L.V.; Lin, Z.; Ivanov, D.S. Atomistic Modeling of Short Pulse Laser Ablation of Metals: Connections between Melting, Spallation, and Phase Explosion†. J. Phys. Chem. C 2009, 113, 11892–11906. [Google Scholar] [CrossRef]

- Temmler, A.; Küpper, M.; Walochnik, M.A.; Lanfermann, A.; Schmickler, T.; Bach, A.; Greifenberg, T.; Oreshkin, O.; Willenborg, E.; Wissenbach, K.; et al. Surface structuring by laser remelting of metals. J. Laser Appl. 2017, 29, 012015. [Google Scholar] [CrossRef]

- Sedao, X.; Mathieu, L.; Rudenko, A.; Pascale-Hamri, A.; Faure, N.; Colombier, J.-P.; Mauclair, C. Influence of Pulse Repetition Rate on Morphology and Material Removal Efficiency of Ultrafast Laser Ablated Metallic Surfaces. Opt. Laser Eng. Submitted.

- Zuhlke, C.A.; Anderson, T.P.; Alexander, D.R. Formation of multiscale surface structures on nickel via above surface growth and below surface growth mechanisms using femtosecond laser pulses. Opt. Express 2013, 21, 8460–8473. [Google Scholar] [CrossRef] [PubMed]

- Anisimov, S.I.; Luk’yanchuk, B.S. Selected problems of laser ablation theory. Phys.-Usp. 2002, 45, 293. [Google Scholar] [CrossRef]

- Colombier, J.P.; Combis, P.; Audouard, E.; Stoian, R. Guiding heat in laser ablation of metals on ultrafast timescales: an adaptive modeling approach on aluminum. New J. Phys. 2012, 14, 013039. [Google Scholar] [CrossRef] [Green Version]

- Volkov, A.N.; Zhigilei, L.V. Melt dynamics and melt-through time in continuous wave laser heating of metal films: Contributions of the recoil vapor pressure and Marangoni effects. Int. J. Heat Mass Trans. 2017, 112, 300–317. [Google Scholar] [CrossRef]

- Bourquard, F.; Loir, A.-S.; Donnet, C.; Garrelie, F. In situ diagnostic of the size distribution of nanoparticles generated by ultrashort pulsed laser ablation in vacuum. Appl. Phys. Lett. 2014, 104, 104101. [Google Scholar] [CrossRef]

- Noël, S.; Hermann, J.; Itina, T. Investigation of nanoparticle generation during femtosecond laser ablation of metals. Appl. Surf. Sci. 2007, 253, 6310–6315. [Google Scholar] [CrossRef]

- Amoruso, S.; Ausanio, G.; Bruzzese, R.; Vitiello, M.; Wang, X. Femtosecond laser pulse irradiation of solid targets as a general route to nanoparticle formation in a vacuum. Phys. Rev. B 2005, 71, 033406. [Google Scholar] [CrossRef]

- Guillermin, M.; Colombier, J.P.; Valette, S.; Audouard, E.; Garrelie, F.; Stoian, R. Optical emission and nanoparticle generation in Al plasmas using ultrashort laser pulses temporally optimized by real-time spectroscopic feedback. Phys. Rev. B 2010, 82, 035430. [Google Scholar] [CrossRef]

- Tsakiris, N.; Anoop, K.K.; Ausanio, G.; Gill-Comeau, M.; Bruzzese, R.; Amoruso, S.; Lewis, L.J. Ultrashort laser ablation of bulk copper targets: Dynamics and size distribution of the generated nanoparticles. J. Appl. Phys. 2014, 115, 243301. [Google Scholar] [CrossRef]

- Rudenko, A.; Mauclair, C.; Garrelie, F.; Stoian, R.; Colombier, J.P. Light absorption by surface nanoholes and nanobumps. Appl. Surf. Sci. 2019, 470, 228–233. [Google Scholar] [CrossRef]

- Dufour, R.; Perry, G.; Harnois, M.; Coffinier, Y.; Thomy, V.; Senez, V.; Boukherroub, R. From micro to nano reentrant structures: hysteresis on superomniphobic surfaces. Colloid Polym Sci 2013, 291, 409–415. [Google Scholar] [CrossRef]

- Li, J.; Qin, Q.H.; Shah, A.; Ras, R.H.A.; Tian, X.; Jokinen, V. Oil droplet self-transportation on oleophobic surfaces. Sci. Adv. 2016, 2, e1600148. [Google Scholar] [CrossRef] [Green Version]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sedao, X.; Lenci, M.; Rudenko, A.; Pascale-Hamri, A.; Colombier, J.-P.; Mauclair, C. Additive and Substractive Surface Structuring by Femtosecond Laser Induced Material Ejection and Redistribution. Materials 2018, 11, 2456. https://doi.org/10.3390/ma11122456

Sedao X, Lenci M, Rudenko A, Pascale-Hamri A, Colombier J-P, Mauclair C. Additive and Substractive Surface Structuring by Femtosecond Laser Induced Material Ejection and Redistribution. Materials. 2018; 11(12):2456. https://doi.org/10.3390/ma11122456

Chicago/Turabian StyleSedao, Xxx, Matthieu Lenci, Anton Rudenko, Alina Pascale-Hamri, Jean-Philippe Colombier, and Cyril Mauclair. 2018. "Additive and Substractive Surface Structuring by Femtosecond Laser Induced Material Ejection and Redistribution" Materials 11, no. 12: 2456. https://doi.org/10.3390/ma11122456