Synthesis and Surface Observation of Montmorillonite/Polyaniline Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instruments

2.3. Preparation of PANI Composites

3. Results and Discussion

3.1. FT-IR Absorption Spectra

3.2. UV-Vis Absorption Spectra

3.3. Conductivity

3.4. Electron Spin Resonance

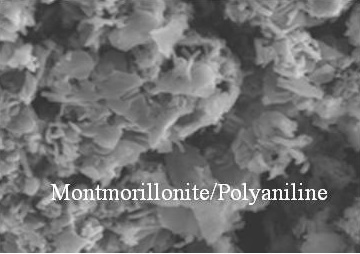

3.5. SEM Observation

3.6. X-Ray Diffraction

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Miura, S.; Umemura, Y.; Shiratori, Y.; Kitaoka, T. In situ synthesis of Ni/MgO catalysts on inorganic paper-like matrix for methane steam reforming. Chem. Eng. J. 2013, 229, 515–521. [Google Scholar] [CrossRef]

- Kitaoka, T. New frontier of paper-structured catalysts. J. Soc. Fiber Sci. Technol. 2018, 74, 16–19. [Google Scholar] [CrossRef]

- Detsi, E.; Onck, P.; De Hosson, J.T.M. Metallic muscles at work: High rate actuation in nanoporous gold/polyaniline composites. ACS Nano 2013, 7, 4299–4306. [Google Scholar] [CrossRef] [PubMed]

- Kawashima, H.; Goto, H. Preparation and properties of polyaniline in the presence of trehalose. Soft Nanosci. Lett. 2011, 1, 71–75. [Google Scholar]

- Tran, X.T.; Park, S.S.; Hussain, M.; Kim, H.T. Electroconductive and catalytic performance of polypyrrole/montmorillonite/silver composites synthesized through in situ oxidative polymerization. J. Appl. Polym. Sci. 2018, 135, 45986. [Google Scholar] [CrossRef]

- Olad, A.; Amini, M.; Rashidzadeh, A. Electrodeposition of homogeneous and adherent polypyrrole/Na+-cloisite nanocomposite on iron electrodes. Fibers Polym. 2012, 13, 475–480. [Google Scholar] [CrossRef]

- Lee, D.; Char, K.; Lee, S.W.; Park, Y.W. Structural changes of polyaniline/montmorillonite nanocomposites and their effects on physical properties. J. Mater. Chem. 2003, 13, 2942–2947. [Google Scholar] [CrossRef]

- Kazim, S.; Ahmad, S.; Pfleger, J.; Plestil, J.; Joshi, Y.M. Polyaniline–sodium montmorillonite clay nanocomposites: Effect of clay concentration on thermal, structural, and electrical properties. J. Mater. Sci. 2012, 47, 420–428. [Google Scholar] [CrossRef]

- Do Nascimento, G.M.; Constantino, V.R.L.; Landers, R.; Temperini, M.L.A. Spectroscopic characterization of polyaniline formed in the presence of montmorillonite clay. Polymer 2006, 47, 6131–6139. [Google Scholar] [CrossRef]

- Do Nascimento, G.M.; Constantino, V.R.L.; Temperini, M.L.A. Spectroscopic characterization of a new type of conducting polymer—Clay nanocomposite. Macromolecules 2002, 35, 7535–7537. [Google Scholar] [CrossRef]

- Mo, Z.; Zhang, C.; Zhao, G.; Zhang, P.; Wu, Y. Sonochemistry synthesis of lanthanum ions-doped polyaniline/montmorillonite nanocomposites and their conductivity and thermostability characterization. Asian J. Chem. 2015, 27, 467–472. [Google Scholar]

- Olad, A.; Azhar, F.F. Eco-friendly biopolymer/clay/conducting polymer nanocomposite: Characterization and its application in reactive dye removal. Fibers Polym. 2014, 15, 1321–1329. [Google Scholar] [CrossRef]

- Tang, J.; Jing, X.; Wang, B.; Wang, F. Infrared spectra of soluble polyaniline. Synth. Met. 1988, 24, 231–238. [Google Scholar] [CrossRef]

- Norris, I.D.; Shaker, M.M.; Ko, F.K.; MacDiarmid, A.G. Electrostatic fabrication of ultrafine conducting fibers: Polyaniline/polyethylene oxide blends. Synth. Met. 2000, 114, 109–114. [Google Scholar] [CrossRef]

- Pruneanu, S.; Veress, E.; Marian, I.; Oniciu, L. Characterization of polyaniline by cyclic voltammetry and UV-Vis absorption spectroscopy. J. Mater. Sci. 1999, 34, 2733–2739. [Google Scholar] [CrossRef]

- MacDiarmid, A.G. Synthetic metals. Angew. Chem. Int. Edit. 2001, 40, 2581–2590. [Google Scholar] [CrossRef]

- Goto, H. A possibility for construction of an iodine cleaning system based on doping for π-conjugated polymers. Polymers 2011, 3, 875–885. [Google Scholar] [CrossRef]

- Hopkins, A.R.; Lipeles, R.A.; Hwang, S.J. Morphology characterization of polyaniline nano-and microstructures. Synth. Met. 2008, 158, 594–601. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, Z.; Wan, M. Nanostructures of polyaniline doped with inorganic acids. Macromolecules 2002, 35, 5937–5942. [Google Scholar] [CrossRef]

- Sanches, E.A.; Soares, J.C.; Mafud, A.C.; Fernandes, E.G.R.; Leite, F.L.; Mascarenhas, Y.P. Structural characterization of chloride salt of conducting polyaniline obtained by XRD, SAXD, SAXS and SEM. J. Mol. Struct. 2013, 1036, 121–126. [Google Scholar] [CrossRef]

- Xia, Y.; Wiesinger, J.M.; MacDiarmid, A.G.; Epstein, A.J. Camphorsulfonic acid fully doped polyaniline emeraldine salt: Conformations in different solvents studied by an ultraviolet/visible/near-infrared spectroscopic method. Chem. Mater. 1995, 7, 443–445. [Google Scholar] [CrossRef]

- Chang, K.C.; Lai, M.C.; Peng, C.W.; Chen, Y.T.; Yeh, J.M.; Lin, C.L.; Yang, J.C. Comparative studies on the corrosion protection effect of DBSA-doped polyaniline prepared from in situ emulsion polymerization in the presence of hydrophilic Na+-MMT and organophilic organo-MMT clay platelets. Electrochim. Acta 2006, 51, 5645–5653. [Google Scholar] [CrossRef]

- Yeh, J.M.; Liou, S.J.; Lai, C.Y.; Wu, P.C.; Tsai, T.Y. Enhancement of corrosion protection effect in polyaniline via the formation of polyaniline—Clay nanocomposite materials. Chem. Mater. 2001, 13, 1131–1136. [Google Scholar] [CrossRef]

| Aniline (mg) | Montmorillonite (mg) | H2SO4 (mg) | APS (g) | Water (mL) | |

|---|---|---|---|---|---|

| PANI(H2SO4) 1 | 300 | - | 660 | 1.4 | 32 |

| Mt/PANI-1 | 300 | 300 | - | 1.4 | 32 |

| My/PANI-2 | 300 | 600 | - | 1.4 | 32 |

| PANI | Mt/PANI-1 | Mt/PANI-2 | Mt | Mt/PANI-1 (reduced) | Mt/PANI-2 (reduced) | |

|---|---|---|---|---|---|---|

| N=Q=N | 1591 | 1583 | 1578 | - | 1589 | 1590 |

| N–B–N | 1506 | 1500 | 1499 | - | 1504 | 1504 |

| B–B–Q | 1290 | 1300 | 1302 | - | 1293 | 1301 |

| B–B–B | 1230 | 1230 | 1248 | - | 1262 | 1243 |

| in-plane bending of the 1,4-ring | 1115, 1043 | 1113, 1038 | 1113, 1045 | - | 1123, 1042 | 1133, 1043 |

| Mt | - | ○ | ○ | ○ | ○ | ○ |

| Samples | Conductivity (S/cm) |

|---|---|

| PANI(H2SO4) | 1.6 × 10−3 |

| Mt/PANI-1 | 1.5 × 10−6 |

| Mt/PANI-2 | 2.1 × 10−5 |

| Samples | Diffraction Positions | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| PANI | - | - | 14.9 | 20.6 | - | 25.5 |

| Mt | 8.0 | - | 20.3 | 22.2 | - | |

| Mt/PANI-1 | 6.2 | - | - | 20.3 | 22.2 | 25.5 |

| Mt/PANI-2 | 6.2 | - | - | 20.3 | 22.2 | 25.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamabe, K.; Goto, H. Synthesis and Surface Observation of Montmorillonite/Polyaniline Composites. J. Compos. Sci. 2018, 2, 15. https://doi.org/10.3390/jcs2010015

Yamabe K, Goto H. Synthesis and Surface Observation of Montmorillonite/Polyaniline Composites. Journal of Composites Science. 2018; 2(1):15. https://doi.org/10.3390/jcs2010015

Chicago/Turabian StyleYamabe, Kohei, and Hiromasa Goto. 2018. "Synthesis and Surface Observation of Montmorillonite/Polyaniline Composites" Journal of Composites Science 2, no. 1: 15. https://doi.org/10.3390/jcs2010015