Statistical and Predictive Analyses of the Strength Development of a Cement-Treated Clayey Soil

Abstract

:1. Introduction

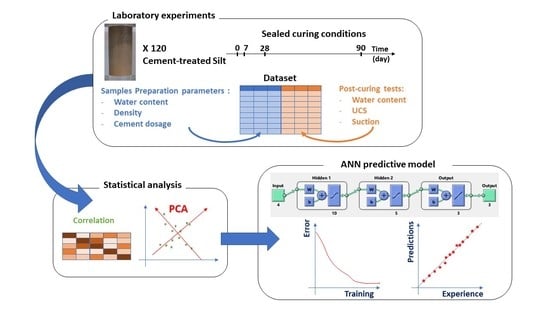

2. Experimental Program

2.1. Materials

2.2. Sample Preparation and Pre-Curing Tests

2.3. Post-Curing Tests

2.4. Repeatability Checking

3. Results and Discussion

3.1. Impact of Initial State Parameters on Post-Curing Properties

3.2. Role of Void–Cement Ratio

3.3. The Soil-Water Potential as an Indicator of the Mechanical Performance?

4. Statistical and Predictive Modelling

4.1. Correlation Analysis

4.2. Principal Components Analysis

4.3. Artificial Neural Network Predictive Model

5. Conclusions

- A significant correlation between moisture content variation and suction increase during the curing period was evidenced. Since the curing was performed under sealed conditions, this can be attributed to the cement hydration process. This results in water loss and an associated increase in the soil suction. Therefore, suction and moisture content variation can be considered as indicators of the setting reaction kinetics.

- Moisture content variation over the curing time appeared almost independent of the initial moisture content. This establishes that setting reactions in the range of the investigated moisture content are not impeded by the water availability in the system. Strength increase is thus not limited by the initial moisture content in the investigated range.

- The statistical analysis showed that, beyond the cement content, both dry density and initial moisture content cannot be considered separately to explain the resulting strength in the case of the studied silty soil. This can be explained by the fact that both parameters together control the initial soil microstructure.

- The results indicated that the chemical processes were controlled by a combination of the initial state parameters that are difficult to put into perspective when each parameter is varied separately. Furthermore, the void–cement ratio, a combined porosity–dosage parameter suggested in the literature, was shown to be relevant only when the dosage and the curing time are constant.

- To cope with the complexity of the parameters’ interactions, a statistics-based data analysis corroborated the observations and led to the definition of new variables (PCs) as uncorrelated combinations of the initial ones. The principal components were then used to train a multi-layer ANN designed to predict mechanical performance and variation of the water content, as well as suction evolution, with curing time. The regression performance of the predictive model was satisfactory and tests on unseen data provided tendencies that were consistent with the experimental dataset trends. This model was shown to be able to make reasonable predictions of the post-curing hydromechanical parameters based on the initial state parameters.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baghabra Al-Amoudi, O.S. Characterization and Chemical Stabilization of Al-Qurayyah Sabkha Soil. J. Mater. Civ. Eng. 2002, 14, 478–484. [Google Scholar] [CrossRef]

- Bahar, R.; Benazzoug, M.; Kenai, S. Performance of compacted cement-stabilised soil. Cem. Concr. Compos. 2004, 26, 811–820. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenvironmental Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Sariosseiri, F.; Muhunthan, B. Effect of cement treatment on geotechnical properties of some Washington State soils. Eng. Geol. 2009, 104, 119–125. [Google Scholar] [CrossRef]

- Bellezza, I.; Fratalocchi, E. Effectiveness of cement on hydraulic conductivity of compacted soil–cement mixtures. Proc. Inst Civ. Eng. Ground Improv. 2007, 10, 77–90. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Pereshkafti, M.R.S.; Parsaei, B.; Javadi, A.A. Stabilised expansive soil behaviour during wetting and drying. Int. J. Pavement Eng. 2013, 14, 418–427. [Google Scholar] [CrossRef]

- Mehenni, A.; Cuisinier, O.; Masrouri, F. Impact of Lime, Cement, and Clay Treatments on the Internal Erosion of Compacted Soils. J. Mater. Civ. Eng. 2016, 28, 04016071. [Google Scholar] [CrossRef]

- Jayasinghe, C.; Kamaladasa, N. Compressive strength characteristics of cement stabilized rammed earth walls. Constr. Build. Mater. 2007, 21, 1971–1976. [Google Scholar] [CrossRef]

- Lepakshi, R.; Venkatarama Reddy, B.V. Shear strength parameters and Mohr-Coulomb failure envelopes for cement stabilised rammed earth. Constr. Build. Mater. 2020, 249, 118708. [Google Scholar] [CrossRef]

- Tripura, D.D.; Gupta, S.; Debbarma, B.; Deep, R.S.S. Flexural strength and failure trend of bamboo and coir reinforced cement stabilized rammed earth wallettes. Constr. Build. Mater. 2020, 242, 117986. [Google Scholar] [CrossRef]

- Ho, L.S.; Nakarai, K.; Duc, M.; Le Kouby, A.; Maachi, A.; Sasaki, T. Analysis of strength development in cement-treated soils under different curing conditions through microstructural and chemical investigations. Constr. Build. Mater. 2018, 166, 634–646. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, C.L.; Chiu, A.C.F. Soil–Water Transfer Mechanism for Solidified Dredged Materials. J. Geotech. Geoenviron. Eng. 2007, 133, 588–598. [Google Scholar] [CrossRef]

- Ho, L.S.; Nakarai, K.; Ogawa, Y.; Sasaki, T.; Morioka, M. Strength development of cement-treated soils: Effects of water content, carbonation, and pozzolanic reaction under drying curing condition. Constr. Build. Mater. 2017, 134, 703–712. [Google Scholar] [CrossRef]

- Cuisinier, O.; Auriol, J.-C.; Le Borgne, T.; Deneele, D. Microstructure and hydraulic conductivity of a compacted lime-treated soil. Eng. Geol. 2011, 123, 187–193. [Google Scholar] [CrossRef]

- Russo, G.; Modoni, G. Fabric changes induced by lime addition on a compacted alluvial soil. Géotechnique Lett. 2013, 3, 93–97. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M.; Jaksa, M.B. A dimensional description of the unconfined compressive strength of artificially cemented fine-grained soils. J. Adhes. Sci. Technol. 2020, 34, 1679–1703. [Google Scholar] [CrossRef]

- Williamson, S.; Cortes, D.D. Dimensional analysis of soil–cement mixture performance. Géotechnique Lett. 2014, 4, 33–38. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F.; Lachowski, E.E.; Glasser, F.P. Clinker mineral hydration at reduced relative humidities. Cem. Concr. Res. 1999, 29, 1505–1512. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T.S. Clay–Water/Cement Ratio Identity for Cement Admixed Soft Clays. J. Geotech. Geoenviron. Eng. 2005, 131, 187–192. [Google Scholar] [CrossRef]

- Menaceur, H.; Cuisinier, O.; Masrouri, F.; Eslami, H. Impact of monotonic and cyclic suction variations on the thermal properties of a stabilized compacted silty soil. Transp. Geotech. 2021, 28, 100515. [Google Scholar] [CrossRef]

- Stoltz, G.; Cuisinier, O.; Masrouri, F. Weathering of a lime-treated clayey soil by drying and wetting cycles. Eng. Geol. 2014, 181, 281–289. [Google Scholar] [CrossRef]

- Morales Hernández, L.; Garzón Garzón, E.; Sánchez-Soto, P.J.; Romero Morales, E. Simultaneous biocementation and compaction of a soil to avoid the breakage of cementitious structures during the execution of earthwork constructions. Geotechnics 2023, 3, 224–253. [Google Scholar] [CrossRef]

- Kang, O.O.; Kim, Y.S.; Kang, J.G. Predictive strength model of cement-treated fine-grained soils using key parameters: Consideration of the total water/cement and soil/cement ratios. Case Stud. Constr. Mater. 2023, 18, e02069. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Z.; Liu, F.; Yang, Y.; Wan, Y.; Huo, W.; Yang, L. Efficient machine learning compressive strength of cement stabilized soft soil. Constr. Build. Mater. 2023, 392, 131887. [Google Scholar] [CrossRef]

- ASTM. Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- LCPC-SETRA. Réalisation des Remblais et des Couches de Forme: Guide Technique; LCPC and SETRA: Paris, France, 1992. [Google Scholar]

- Corté, J.-F.; Magnan, J.-P.; Guidoux, Y. Traitement des sols à la Chaux et/ou aux Liants Hydrauliques: Application à la Réalisation des Remblais et des Couches de Forme; LCPC and SETRA: Paris, France; Bagneux, France, 2000. [Google Scholar]

- ASTM. Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Metergroup. Soil Water Potential Lab Instrumentation, METER Group, Inc. USA. 2017. Available online: www.metergroup.com (accessed on 17 May 2023).

- ASTM. Test Method of Measuring Humidity with Cooled-Surface Condensation (Dew-Point) Hygrometer; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Lê, S.; Josse, J.; Husson, F. FactoMineR: An R Package for Multivariate Analysis. J. Stat. Softw. 2008, 25, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Mathworks. Statistics and Machine Learning ToolboxTM User’s Guide 2020, Version 11.7; The MathWorks, Inc.: Natick, MA, USA, 2020. [Google Scholar]

| Liquid limit | 28.5% |

| Plasticity index | 8.0% |

| Passing 63 μm-sieve | 99.2% |

| Clay content (<2 μm) | 6.0% |

| Specific gravity Gs | 2.64 |

| Preparation/Curing Parameters | Values |

|---|---|

| Dry density (Mg/m3) | 1.6–1.7–1.77–1.87 |

| Initial water content wi (%) | 11–12.5–14.4–16.5–18 |

| Cement content (%) | 3–6 |

| Curing time (day) | 0–7–28–90 |

| Post-curing measured parameters UCS (kPa) Suction s (kPa) Final water content wf (%) | |

| Calculated parameters Variation of water content Δw (%) Void/cement ratio η/Civ |

| wi | ρd | c | tc | η/Civ | s | Δw | UCS | |

|---|---|---|---|---|---|---|---|---|

| wi | 1.00 | 0.01 | 0.01 | 0.00 | −0.01 | −0.30 | 0.04 | −0.11 |

| ρd | 1.00 | −0.02 | 0.01 | −0.25 | −0.06 | 0.00 | 0.54 | |

| c | 1.00 | −0.01 | −0.96 | 0.07 | −0.15 | 0.45 | ||

| tc | 1.00 | 0.01 | 0.79 | 0.91 | 0.47 | |||

| η/Civ | 1.00 | −0.05 | 0.14 | −0.57 | ||||

| s | 1.00 | 0.72 | 0.37 | |||||

| Δw | 1.00 | 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdallah, A.; Russo, G.; Cuisinier, O. Statistical and Predictive Analyses of the Strength Development of a Cement-Treated Clayey Soil. Geotechnics 2023, 3, 465-479. https://doi.org/10.3390/geotechnics3020026

Abdallah A, Russo G, Cuisinier O. Statistical and Predictive Analyses of the Strength Development of a Cement-Treated Clayey Soil. Geotechnics. 2023; 3(2):465-479. https://doi.org/10.3390/geotechnics3020026

Chicago/Turabian StyleAbdallah, Adel, Giacomo Russo, and Olivier Cuisinier. 2023. "Statistical and Predictive Analyses of the Strength Development of a Cement-Treated Clayey Soil" Geotechnics 3, no. 2: 465-479. https://doi.org/10.3390/geotechnics3020026