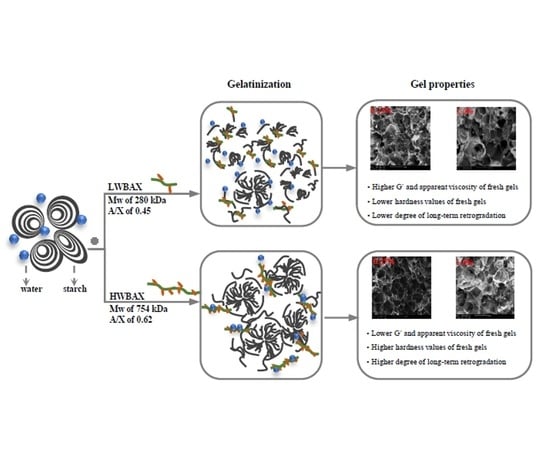

Gelatinization, Retrogradation and Gel Properties of Wheat Starch–Wheat Bran Arabinoxylan Complexes

Abstract

:1. Introduction

2. Results and Discussion

2.1. Pasting Characteristics of Starch/WBAX Composite Systems

2.2. Thermal Analysis

2.3. FTIR

2.4. Steady Shear Rheological Properties

2.5. Dynamic Rheological Properties

2.6. Microstructure of Gels

2.7. The Degree of Long-Term Retrogradation

2.8. Textural Attributes of Gels

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Pasting Properties

4.3. Fourier Transform Infrared (FTIR) Analysis

4.4. Differential Scanning Calorimetry (DSC)

4.5. Rheological Properties

4.6. Microstructure

4.7. TPA Analysis

4.8. Statistical Analysis

Author Contributions

Funding

Conflicts of Interest

References

- Wang, S.; Wang, J.; Yu, J.; Wang, S. Effect of fatty acids on functional properties of normal wheat and waxy wheat starches: A structural basis. Food Chem. 2016, 190, 285–292. [Google Scholar] [CrossRef] [PubMed]

- Copeland, L.; Blazek, J.; Salman, H.; Tang, M.C. Form and functionality of starch. Food Hydrocoll. 2009, 23, 1527–1534. [Google Scholar] [CrossRef]

- Annable, P.; Fitton, M.; Harris, B.; Phillips, G.; Williams, P. Phase behaviour and rheology of mixed polymer systems containing starch. Food Hydrocoll. 1994, 8, 351–359. [Google Scholar] [CrossRef]

- Ma, S.; Zhu, P.; Wang, M. Effects of konjac glucomannan on pasting and rheological properties of corn starch. Food Hydrocoll. 2019, 89, 234–240. [Google Scholar] [CrossRef]

- Chen, T.; Fang, S.; Zuo, X.; Liu, Y. Effect of curdlan and xanthan polysaccharides on the pasting, rheological and thermal properties of rice starch. J. Food Sci. Technol. 2016, 53, 4076–4083. [Google Scholar] [CrossRef] [Green Version]

- Ring, S.G.; Colonna, P.; I’Anson, K.J.; Kalichevsky, M.T.; Miles, M.; Morris, V.J.; Orford, P.D. The gelation and crystallisation of amylopectin. Carbohydr. Res. 1987, 162, 277–293. [Google Scholar] [CrossRef]

- Dobosz, A.; Sikora, M.; Krystyjan, M.; Tomasik, P.; Lach, R.; Borczak, B.; Berski, W.; Lukasiewicz, M. Short-and long-term retrogradation of potato starches with varying amylose content. J. Sci. Food Agric. 2019, 99, 2393–2403. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- BeMiller, J.N. Pasting, paste, and gel properties of starch–hydrocolloid complexes. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Zhao, Q.; Tian, H.; Chen, L.; Zeng, M.; Qin, F.; Wang, Z.; He, Z.; Chen, J. Interactions between soluble soybean poly-saccharide and starch during the gelatinization and retrogradation: Effects of selected starch varieties. Food Hydrocoll. 2021, 118, 106765. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, M.; Li, E.; Xiao, Y.; Wen, H.; Ren, Y.; Xie, J. Effect of Mesona chinensis polysaccharide on pasting, rheo-logical and structural properties of corn starches varying in amylose contents. Carbohydr. Polym. 2020, 230, 115713. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, H.; Xia, Y.; Ai, L. Effects of tamarind seed polysaccharide on gelatinization, rheological, and structural properties of corn starch with different amylose/amylopectin ratios. Food Hydrocoll. 2020, 105, 105854. [Google Scholar] [CrossRef]

- Izydorczyk, M.; Biliaderis, C.; Bushuk, W. Oxidative gelation studies of water-soluble pentosans from wheat. J. Cereal Sci. 1990, 11, 153–169. [Google Scholar] [CrossRef]

- Mendis, M.; Simsek, S. Arabinoxylans and human health. Food Hydrocoll. 2014, 42, 239–243. [Google Scholar] [CrossRef]

- Qiu, S.; Yadav, M.P.; Liu, Y.; Chen, H.; Tatsumi, E.; Yin, L. Effects of corn fiber gum with different molecular weights on the gelatinization behaviors of corn and wheat starch. Food Hydrocoll. 2016, 53, 180–186. [Google Scholar] [CrossRef]

- Hou, C.; Zhao, X.; Tian, M.; Zhou, Y.; Yang, R.; Gu, Z.; Wang, P. Impact of water extractable arabinoxylan with different molecular weight on the gelatinization and retrogradation behavior of wheat starch. Food Chem. 2020, 318, 126477. [Google Scholar] [CrossRef]

- Gudmundsson, M.; Eliasson, A.-C.; Bengtsson, S.; Aman, P.P. The Effects of Water Soluble Arabinoxylan on Gelatinization and Retrogradation of Starch. Starch Starke 1991, 43, 5–10. [Google Scholar] [CrossRef]

- Liu, S.; Xiao, Y.; Shen, M.; Zhang, X.; Wang, W.; Xie, J. Effect of sodium carbonate on the gelation, rheology, texture and structural properties of maize starch-Mesona chinensis polysaccharide gel. Food Hydrocoll. 2019, 87, 943–951. [Google Scholar] [CrossRef]

- Brennan, C.S.; Suter, M.; Matia-Merino, L.; Luethi, T.; Ravindran, G.; Goh, K.; Ovortrup, J. Gel and pasting behaviour of fenugreek-wheat starch and fenugreek–wheat flour complexes. Starch Starke 2006, 58, 527–535. [Google Scholar] [CrossRef]

- Rojas, J.; Rosell, C.; de Barber, C.B. Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll. 1999, 13, 27–33. [Google Scholar] [CrossRef]

- Shi, X.; BeMiller, J.N. Effects of food gums on viscosities of starch suspensions during pasting. Carbohydr. Polym. 2002, 50, 7–18. [Google Scholar] [CrossRef]

- Funami, T.; Kataoka, Y.; Omoto, T.; Goto, Y.; Asai, I.; Nishinari, K. Effects of non-ionic polysaccharides on the gelatinization and retrogradation behavior of wheat starch. Food Hydrocoll. 2005, 19, 1–13. [Google Scholar] [CrossRef]

- Alloncle, M.; Lefebvre, J.; Llamas, G.; Doublier, J.L. A rheological characterization of cereal starch-galactomannan mixtures. Cereal Chem. 1989, 66, 90–93. [Google Scholar]

- Alloncle, M.; Doublier, J.-L. Viscoelastic properties of maize starch/hydrocolloid pastes and gels. Food Hydrocoll. 1991, 5, 455–467. [Google Scholar] [CrossRef]

- Conde-Petit, B.; Pfirter, A.; Escher, F. Influence of xanthan on the rheological properties of aqueous starch-emulsifier systems. Food Hydrocoll. 1997, 11, 393–399. [Google Scholar] [CrossRef]

- Luo, D.; Li, Y.; Xu, B.; Ren, G.; Li, P.; Li, X.; Han, S.; Liu, J. Effects of inulin with different degree of polymerization on gelatinization and retrogradation of wheat starch. Food Chem. 2017, 229, 35–43. [Google Scholar] [CrossRef]

- Lii, C.Y.; Tsai, M.L.; Tseng, K.H. Effect of amylose content on the rheological property of rice starch. Cereal Chem. 1996, 73, 415–420. [Google Scholar]

- Qiu, S.; Yadav, M.P.; Chen, H.; Liu, Y.; Tatsumi, E.; Yin, L. Effects of corn fiber gum (CFG) on the pasting and thermal behaviors of maize starch. Carbohydr. Polym. 2015, 115, 246–252. [Google Scholar] [CrossRef]

- Pongsawatmanit, R.; Temsiripong, T.; Ikeda, S.; Nishinari, K. Influence of tamarind seed xyloglucan on rheological properties and thermal stability of tapioca starch. J. Food Eng. 2006, 77, 41–50. [Google Scholar] [CrossRef]

- Chen, L.; Ren, F.; Zhang, Z.; Tong, Q.; Rashed, M.M.A. Effect of pullulan on the short-term and long-term retrogradation of rice starch. Carbohydr. Polym. 2015, 115, 415–421. [Google Scholar] [CrossRef]

- Grossutti, M.; Dutcher, J.R. Correlation Between Chain Architecture and Hydration Water Structure in Polysaccharides. Biomacromolecules 2016, 17, 1198–1204. [Google Scholar] [CrossRef] [PubMed]

- Higgins, H.G.; Stewart, C.M.; Harrington, K.J. Infrared spectra of cellulose and related polysaccharides. J. Polym. Sci. 1961, 51, 59–84. [Google Scholar] [CrossRef]

- Liu, Q.; Charlet, G.; Yelle, S.; Arul, J. Phase transition in potato starch–water system I. Starch gelatinization at high moisture level. Food Res. Int. 2002, 35, 397–407. [Google Scholar] [CrossRef]

- Sammon, C.; Bajwa, G.; Timmins, P.; Melia, C.D. The application of attenuated total reflectance Fourier transform infrared spectroscopy to monitor the concentration and state of water in solutions of a thermally responsive cellulose ether during gelation. Polymer 2006, 47, 577–584. [Google Scholar] [CrossRef]

- Donmez, D.; Pinho, L.; Patel, B.; Desam, P.; Campanella, O.H. Characterization of starch–water interactions and their effects on two key functional properties: Starch gelatinization and retrogradation. Curr. Opin. Food Sci. 2021, 39, 103–109. [Google Scholar] [CrossRef]

- Krüger, A.; Ferrero, C.; Zaritzky, N.E. Modelling corn starch swelling in batch systems: Effect of sucrose and hydrocol-loids. J. Food Eng. 2003, 58, 125–133. [Google Scholar] [CrossRef]

- Chen, L.; Tong, Q.; Ren, F.; Zhu, G. Pasting and rheological properties of rice starch as affected by pullulan. Int. J. Biol. Macromol. 2014, 66, 325–331. [Google Scholar] [CrossRef]

- Ren, Y.; Jiang, L.; Wang, W.; Xiao, Y.; Liu, S.; Luo, Y.; Shen, M.; Xie, J. Effects of Mesona chinensis Benth polysaccharide on physicochemical and rheological properties of sweet potato starch and its interactions. Food Hydrocoll. 2020, 99, 105371. [Google Scholar] [CrossRef]

- Singh, A.; Geveke, D.J.; Yadav, M.P. Improvement of rheological, thermal and functional properties of tapioca starch by using gum arabic. LWT 2017, 80, 155–162. [Google Scholar] [CrossRef]

- Clark, A.H. Structural and mechanical properties of biopolymer gels. In Food Polymers, Gels and Colloids; Dickinson, E., Ed.; Royal Society and Chemistry: London, UK, 1991; pp. 322–337. [Google Scholar]

- Rosalina, I.; Bhattacharya, M. Dynamic rheological measurements and analysis of starch gels. Carbohydr. Polym. 2002, 48, 191–202. [Google Scholar] [CrossRef]

- Goesaert, H.; Brijs, K.; Veraverbeke, W.; Courtin, C.; Gebruers, K.; Delcour, J. Wheat flour constituents: How they impact bread quality, and how to impact their functionality. Trends Food Sci. Technol. 2005, 16, 12–30. [Google Scholar] [CrossRef]

- Lee, S.-W.; Rhee, C. Effect of heating condition and starch concentration on the structure and properties of freeze-dried rice starch paste. Food Res. Int. 2007, 40, 215–223. [Google Scholar] [CrossRef]

- Hedayati, S.; Niakousari, M. Microstructure, pasting and textural properties of wheat starch-corn starch citrate composites. Food Hydrocoll. 2018, 81, 1–5. [Google Scholar] [CrossRef]

| Peak Viscosity (cP) | Breakdown (mPas) | Final Viscosity (mPas) | Setback (mPas) | Peak Time (s) | Pasting Temp (°C) | ||

|---|---|---|---|---|---|---|---|

| WS-LWBAX | 0.25% | 2916.33 ± 7.77 c | 836.00 ± 34.39 b | 4078.67 ± 29.09 c | 2004.00 ± 5.29 c | 10.60 ± 0.07 b | 87.62 ± 0.25 a |

| 1.0% | 5109.67 ± 17.62 a | 2266.00 ± 36.76 a | 5783.33 ± 34.96 a | 2929.67 ± 9.50 a | 10.37 ± 0.04 c | 67.84 ± 0.18 c | |

| WS-HWBAX | 0.25% | 2491.00 ± 37.24 d | 620.67 ± 1.15 c | 3621.67 ± 9.45 d | 1745.67 ± 24.91 d | 10.75 ± 0.11 b | 88.02 ± 0.23 a |

| 1.0% | 3706.00 ± 39.95 b | 782.33 ± 27.47 b | 5280.00 ± 65.34 b | 2358.00 ± 54.74 b | 11.39 ± 0.13 a | 86.75 ± 0.18 b |

| To (°C) | Tp (°C) | Tc (°C) | ΔHgel (mJ/g) | |

|---|---|---|---|---|

| WS-LWBAX 0.25% | 57.24 ± 0.02 c | 62.76 ± 0.27 c | 67.79 ± 0.01 c | 9.00 ± 0.01 a |

| WS-LWBAX 1.0% | 57.39 ± 0.12 c | 62.89 ± 0.23 c | 67.63 ± 0.54 c | 8.30 ± 0.21 b |

| WS-HWBAX 0.25% | 58.47 ± 0.33 b | 63.95 ± 0.04 b | 69.29 ± 0.18 b | 8.34 ± 0.05 b |

| WS-HWBAX 1.0% | 59.74 ± 0.41 a | 64.73 ± 0.04 a | 69.86 ± 0.06 a | 7.44 ± 0.05 c |

| Samples | G′ | G″ | ||||

|---|---|---|---|---|---|---|

| Slope | Intercept | R2 | Slope | Intercept | R2 | |

| WS–HBAX 1% | 0.338 | 2.630 | 0.99 | 0.459 | 1.961 | 0.99 |

| WS–HBAX 0.25% | 0.119 | 2.149 | 0.99 | 0.539 | 0.643 | 0.99 |

| WS–LWBAX 1% | 0.3034 | 3.254 | 0.99 | 0.411 | 2.612 | 0.99 |

| WS–LWBAX 0.25% | 0.135 | 2.530 | 0.98 | 0.494 | 1.215 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, W.; Yin, L.; Zhang, M.; Zhang, M.; Jia, X. Gelatinization, Retrogradation and Gel Properties of Wheat Starch–Wheat Bran Arabinoxylan Complexes. Gels 2021, 7, 200. https://doi.org/10.3390/gels7040200

Yan W, Yin L, Zhang M, Zhang M, Jia X. Gelatinization, Retrogradation and Gel Properties of Wheat Starch–Wheat Bran Arabinoxylan Complexes. Gels. 2021; 7(4):200. https://doi.org/10.3390/gels7040200

Chicago/Turabian StyleYan, Wenjia, Lijun Yin, Minghao Zhang, Meng Zhang, and Xin Jia. 2021. "Gelatinization, Retrogradation and Gel Properties of Wheat Starch–Wheat Bran Arabinoxylan Complexes" Gels 7, no. 4: 200. https://doi.org/10.3390/gels7040200