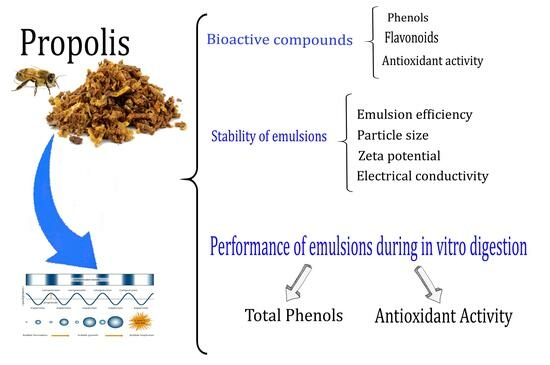

Stability, Content of Bioactive Compounds and Antioxidant Activity of Emulsions with Propolis Extracts during Simulated In Vitro Digestion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Propolis Sources

2.2. Extraction Method and Preparation of Extracts

2.3. Preparation, Characterization and Stability of Emulsions

2.4. Encapsulation Efficiency

2.5. In Vitro Digestion of Emulsions with Propolis Extracts

2.6. Determination of Bioactive Compounds

2.6.1. Quantification of Total Phenols

2.6.2. Quantification of Total Flavonoids

2.7. Antioxidant Activity

2.7.1. ABTS Free Radical Inhibition Activity

2.7.2. DPPH Free Radical Inhibition Activity

2.8. Statistical Analysis

3. Results and Discussion

3.1. Bioactive Compounds and Antioxidant Activity of Propolis Extracts

3.1.1. Total Phenols

3.1.2. Total Flavonoids

3.1.3. Antioxidant Activity

3.2. Stability of Emulsions

3.2.1. Emulsion Efficiency

3.2.2. Particle Size

3.2.3. Zeta Potential

3.2.4. Electrical Conductivity

3.3. Behavior of Bioactive Compounds from Emulsions during Simulated In Vitro Digestion

3.3.1. Total Phenols

3.3.2. Total Flavonoids

3.3.3. Antioxidant Activity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, S.; Zhang, C.-P.; Wang, K.; Li, G.Q.; Hu, F.-L. Recent Advances in the Chemical Composition of Propolis. Molecules 2014, 19, 19610–19632. [Google Scholar] [CrossRef] [PubMed]

- NOM. Norma Oficial Mexicana NOM-003-SAG/GAN-2017, Propóleos, Producción y Especificaciones Para Su Procesamiento. Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=5500103&fecha=06/10/2017#gsc.tab=0 (accessed on 19 January 2024).

- Zulhendri, F.; Chandrasekaran, K.; Kowacz, M.; Ravalia, M.; Kripal, K.; Fearnley, J.; Perera, C.O. Antiviral, Antibacterial, Antifungal, and Antiparasitic Properties of Propolis: A Review. Foods 2021, 10, 1360. [Google Scholar] [CrossRef] [PubMed]

- Irigoiti, Y.; Navarro, A.; Yamul, D.; Libonatti, C.; Tabera, A.; Basualdo, M. The use of propolis as a functional food ingredient: A review. Trends Food Sci. Technol. 2021, 115, 297–306. [Google Scholar] [CrossRef]

- Mountford-McAuley, R.; Prior, J.; Clavijo McCormick, A. Factors affecting propolis production. J. Apic. Res. 2023, 62, 162–170. [Google Scholar] [CrossRef]

- Giampieri, F.; Quiles, J.L.; Cianciosi, D.; Forbes-Hernández, T.Y.; Orantes-Bermejo, F.J.; Alvarez-Suarez, J.M.; Battino, M. Bee Products: An Emblematic Example of Underutilized Sources of Bioactive Compounds. J. Agric. Food Chem. 2022, 70, 6833–6848. [Google Scholar] [CrossRef] [PubMed]

- Hossain, R.; Quispe, C.; Khan, R.A.; Saikat, A.S.M.; Ray, P.; Ongalbek, D.; Yeskaliyeva, B.; Jain, D.; Smeriglio, A.; Trombetta, D.; et al. Propolis: An update on its chemistry and pharmacological applications. Chin. Med. 2022, 17, 100. [Google Scholar] [CrossRef]

- Salatino, A.; Salatino, M.L.F. Scientific note: Often quoted, but not factual data about propolis composition. Apidologie 2021, 52, 312–314. [Google Scholar] [CrossRef]

- Kasote, D.; Bankova, V.; Viljoen, A.M. Propolis: Chemical diversity and challenges in quality control. Phytochem. Rev. 2022, 21, 1887–1911. [Google Scholar] [CrossRef]

- Nandre, V.S.; Bagade, A.V.; Kasote, D.M.; Lee, J.H.J.; Kodam, K.M.; Kulkarni, M.V.; Ahmad, A. Antibacterial activity of Indian propolis and its lead compounds against multi-drug resistant clinical isolates. J. Herb. Med. 2021, 29, 100479. [Google Scholar] [CrossRef]

- Gonçalves, A.; Estevinho, B.N.; Rocha, F. Methodologies for simulation of gastrointestinal digestion of different controlled delivery systems and further uptake of encapsulated bioactive compounds. Trends Food Sci. Technol. 2021, 114, 510–520. [Google Scholar] [CrossRef]

- Li, C.; Yu, W.; Wu, P.; Chen, X.D. Current in vitro digestion systems for understanding food digestion in human upper gastrointestinal tract. Trends Food Sci. Technol. 2020, 96, 114–126. [Google Scholar] [CrossRef]

- Seraglio, S.K.T.; Schulz, M.; Gonzaga, L.V.; Fett, R.; Costa, A.C.O. Current status of the gastrointestinal digestion effects on honey: A comprehensive review. Food Chem. 2021, 357, 129807. [Google Scholar] [CrossRef]

- Saliba, A.S.M.C.; Quirino, D.J.G.; Favaro-Trindade, C.S.; Sartori, A.G.d.O.; Massarioli, A.P.; Lazarini, J.G.; de Souza Silva, A.P.; Alencar, S.M.d. Effects of simulated gastrointestinal digestion/epithelial transport on phenolics and bioactivities of particles of brewer’s spent yeasts loaded with Brazilian red propolis. Food Res. Int. 2023, 173, 113345. [Google Scholar] [CrossRef] [PubMed]

- Alencar, S.M.; Sartori, A.G.O.; Dag, D.; Batista, P.S.; Rosalen, P.L.; Ikegaki, M.; Kong, F. Dynamic gastrointestinal digestion/intestinal permeability of encapsulated and nonencapsulated Brazilian red propolis: Active compounds stability and bioactivity. Food Chem. 2023, 411, 135469. [Google Scholar] [CrossRef] [PubMed]

- Alegría, A.; Garcia-Llatas, G.; Cilla, A. Static Digestion Models: General Introduction. In The Impact of Food Bioactives on Health: In Vitro and Ex Vivo Models; Verhoeckx, K., Cotter, P., López-Expósito, I., Kleiveland, C., Lea, T., Mackie, A., Requena, T., Swiatecka, D., Wichers, H., Eds.; Springer: Cham, Switzerland, 2015; pp. 3–12. [Google Scholar] [CrossRef]

- Baysan, U.; Zungur Bastıoğlu, A.; Coşkun, N.Ö.; Konuk Takma, D.; Ülkeryıldız Balçık, E.; Sahin-Nadeem, H.; Koç, M. The effect of coating material combination and encapsulation method on propolis powder properties. Powder Technol. 2021, 384, 332–341. [Google Scholar] [CrossRef]

- Jansen-Alves, C.; Victoria, F.N.; Borges, C.D.; Zambiazi, R.C. Encapsulation of propolis extract in ovalbumin protein particles: Characterization and in vitro digestion. Nat. Prod. Res. 2023, 1–5. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Huamán-Carrión, M.L.; Ramos-Pacheco, B.S.; De la Cruz, G.; Arévalo-Quijano, J.C.; Muñoz-Saenz, J.C.; Muñoz-Melgarejo, M.; Quispe-Quezada, U.R.; et al. Microencapsulation of Propolis and Honey Using Mixtures of Maltodextrin/Tara Gum and Modified Native Potato Starch/Tara Gum. Foods 2023, 12, 1873. [Google Scholar] [CrossRef] [PubMed]

- Shakoury, N.; Aliyari, M.A.; Salami, M.; Emam-Djomeh, Z.; Vardhanabhuti, B.; Moosavi-Movahedi, A.A. Encapsulation of propolis extract in whey protein nanoparticles. LWT 2022, 158, 113138. [Google Scholar] [CrossRef]

- Dias, D.R.; Botrel, D.A.; Fernandes, R.V.D.B.; Borges, S.V. Encapsulation as a tool for bioprocessing of functional foods. Curr. Opin. Food Sci. 2017, 13, 31–37. [Google Scholar] [CrossRef]

- Grgić, J.; Šelo, G.; Planinić, M.; Tišma, M.; Bucić-Kojić, A. Role of the Encapsulation in Bioavailability of Phenolic Compounds. Antioxidants 2020, 9, 923. [Google Scholar] [CrossRef]

- Seibert, J.B.; Bautista-Silva, J.P.; Amparo, T.R.; Petit, A.; Pervier, P.; Dos Santos Almeida, J.C.; Azevedo, M.C.; Silveira, B.M.; Brandão, G.C.; de Souza, G.H.B.; et al. Development of propolis nanoemulsion with antioxidant and antimicrobial activity for use as a potential natural preservative. Food Chem. 2019, 287, 61–67. [Google Scholar] [CrossRef]

- Sonawane, S.H.; Bhanvase, B.A.; Sivakumar, M.; Potdar, S.B. 1—Current overview of encapsulation. In Encapsulation of Active Molecules and Their Delivery System; Sonawane, S.H., Bhanvase, B.A., Sivakumar, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–8. [Google Scholar]

- Özer, E.D. Propolis and Potential Use in Food Products. Turk. J. Agric.-Food Sci. Technol. 2020, 8, 1139–1144. [Google Scholar] [CrossRef]

- Pant, K.; Sharma, A.; Chopra, H.K.; Nanda, V. Impact of biodiversification on propolis composition, functionality, and application in foods as natural preservative: A review. Food Control 2024, 155, 110097. [Google Scholar] [CrossRef]

- Pobiega, K.; Kraśniewska, K.; Gniewosz, M. Application of propolis in antimicrobial and antioxidative protection of food quality—A review. Trends Food Sci. Technol. 2019, 83, 53–62. [Google Scholar] [CrossRef]

- Vlaicu, P.A.; Untea, A.E.; Varzaru, I.; Saracila, M.; Oancea, A.G. Designing Nutrition for Health—Incorporating Dietary By-Products into Poultry Feeds to Create Functional Foods with Insights into Health Benefits, Risks, Bioactive Compounds, Food Component Functionality and Safety Regulations. Foods 2023, 12, 4001. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Yang, T.; Sanchez, C.A.; Hamilton, J.M.; Fonseca, J.M. Nutrition by Design: Boosting Selenium Content and Fresh Matter Yields of Salad Greens with Preharvest Light Intensity and Selenium Applications. Front. Nutr. 2021, 8, 787085. [Google Scholar] [CrossRef] [PubMed]

- Brodkorb, A.; Egger, L.; Alminger, M.; Alvito, P.; Assunção, R.; Ballance, S.; Bohn, T.; Bourlieu-Lacanal, C.; Boutrou, R.; Carrière, F.; et al. INFOGEST static in vitro simulation of gastrointestinal food digestion. Nat. Protoc. 2019, 14, 991–1014. [Google Scholar] [CrossRef]

- Dima, C.; Assadpour, E.; Dima, S.; Jafari, S.M. Bioavailability and bioaccessibility of food bioactive compounds; overview and assessment by in vitro methods. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2862–2884. [Google Scholar] [CrossRef]

- Fernández-García, E.; Carvajal-Lérida, I.; Pérez-Gálvez, A. In vitro bioaccessibility assessment as a prediction tool of nutritional efficiency. Nutr. Res. 2009, 29, 751–760. [Google Scholar] [CrossRef]

- Plaza, M.; Cifuentes, A.; Ibáñez, E. In the search of new functional food ingredients from algae. Trends Food Sci. Technol. 2008, 19, 31–39. [Google Scholar] [CrossRef]

- Crozier, A.; Del Rio, D.; Clifford, M.N. Bioavailability of dietary flavonoids and phenolic compounds. Mol. Asp. Med. 2010, 31, 446–467. [Google Scholar] [CrossRef]

- Lucas-González, R.; Viuda-Martos, M.; Álvarez, J.A.P.; Fernández-López, J. Changes in bioaccessibility, polyphenol profile and antioxidant potential of flours obtained from persimmon fruit (Diospyros kaki) co-products during in vitro gastrointestinal digestion. Food Chem. 2018, 256, 252–258. [Google Scholar] [CrossRef]

- Stafussa, A.P.; Maciel, G.M.; Bortolini, D.G.; Maroldi, W.V.; Ribeiro, V.R.; Fachi, M.M.; Pontarolo, R.; Bach, F.; Pedro, A.C.; Haminiuk, C.W.I. Bioactivity and bioaccessibility of phenolic compounds from Brazilian fruit purees. Future Foods 2021, 4, 100066. [Google Scholar] [CrossRef]

- Osés, S.M.; Pascual-Maté, A.; Fernández-Muiño, M.A.; López-Díaz, T.M.; Sancho, M.T. Bioactive properties of honey with propolis. Food Chem. 2016, 196, 1215–1223. [Google Scholar] [CrossRef] [PubMed]

- Espino-Manzano, S.O.; León-López, A.; Aguirre-Álvarez, G.; González-Lemus, U.; Prince, L.; Campos-Montiel, R.G. Application of Nanoemulsions (W/O) of Extract of Opuntia oligacantha C.F. Först and Orange Oil in Gelatine Films. Molecules 2020, 25, 3487. [Google Scholar] [CrossRef] [PubMed]

- Minekus, M.; Alminger, M.; Alvito, P.; Ballance, S.; Bohn, T.; Bourlieu, C.; Carrière, F.; Boutrou, R.; Corredig, M.; Dupont, D.; et al. A standardised static in vitro digestion method suitable for food—An international consensus. Food Funct. 2014, 5, 1113–1124. [Google Scholar] [CrossRef] [PubMed]

- Rababah, T.M.; Al-Omoush, M.; Brewer, S.; Alhamad, M.; Yang, W.; Alrababah, M.; Al-Ghzawi, A.A.-M.; Al-u’datt, M.; Ereifej, K.; Alsheyab, F.; et al. Total Phenol, Antioxidant Activity, Flavonoids, Anthocyanins and Color of Honey as Affected by Floral Origin Found in the Arid and Semiarid Mediterranean Areas. J. Food Process. Preserv. 2014, 38, 1119–1128. [Google Scholar] [CrossRef]

- Arvouet-Grand, A.; Vennat, B.; Pourrat, A.; Legret, P. Standardisation d’un extrait de propolis et identification des principaux constituants. J. Pharm. Belg. 1994, 49, 462–468. [Google Scholar] [PubMed]

- Pimentel-González, D.J.; Jiménez-Alvarado, R.; Hernández-Fuentes, A.D.; Figueira, A.C.; Suarez-Vargas, A.; Campos-Montiel, R.G. Potentiation of Bioactive Compounds and Antioxidant Activity in Artisanal Honeys Using Specific Heat Treatments. J. Food Biochem. 2016, 40, 47–52. [Google Scholar] [CrossRef]

- Turkmen, N.; Sari, F.; Poyrazoglu, E.S.; Velioglu, Y.S. Effects of prolonged heating on antioxidant activity and colour of honey. Food Chem. 2006, 95, 653–657. [Google Scholar] [CrossRef]

- Cavalaro, R.I.; Cruz, R.G.D.; Dupont, S.; de Moura Bell, J.; Vieira, T. In vitro and in vivo antioxidant properties of bioactive compounds from green propolis obtained by ultrasound-assisted extraction. Food Chem. X 2019, 4, 100054. [Google Scholar] [CrossRef] [PubMed]

- Peixoto, M.; Freitas, A.S.; Cunha, A.; Oliveira, R.; Almeida-Aguiar, C. Mixing Propolis from Different Apiaries and Harvesting Years: Towards Propolis Standardization? Antibiotics 2022, 11, 1181. [Google Scholar] [CrossRef] [PubMed]

- Ozdal, T.; Ceylan, F.D.; Eroglu, N.; Kaplan, M.; Olgun, E.O.; Capanoglu, E. Investigation of antioxidant capacity, bioaccessibility and LC-MS/MS phenolic profile of Turkish propolis. Food Res. Int. 2019, 122, 528–536. [Google Scholar] [CrossRef]

- Rivero-Cruz, J.F.; Granados-Pineda, J.; Pedraza-Chaverri, J.; Pérez-Rojas, J.M.; Kumar-Passari, A.; Diaz-Ruiz, G.; Rivero-Cruz, B.E. Phytochemical Constituents, Antioxidant, Cytotoxic, and Antimicrobial Activities of the Ethanolic Extract of Mexican Brown Propolis. Antioxidants 2020, 9, 70. [Google Scholar] [CrossRef]

- Hernández Zarate, M.S.; Abraham Juárez, M.d.R.; Cerón García, A.; Ozuna López, C.; Gutiérrez Chávez, A.J.; Segoviano Garfias, J.D.J.N.; Avila Ramos, F. Flavonoids, phenolic content, and antioxidant activity of propolis from various areas of Guanajuato, Mexico. Food Sci. Technol. 2018, 38, 210–215. [Google Scholar] [CrossRef]

- Okińczyc, P.; Widelski, J.; Szperlik, J.; Żuk, M.; Mroczek, T.; Skalicka-Woźniak, K.; Sakipova, Z.; Widelska, G.; Kuś, P.M. Impact of Plant Origin on Eurasian Propolis on Phenolic Profile and Classical Antioxidant Activity. Biomolecules 2021, 11, 68. [Google Scholar] [CrossRef]

- Paulo, F.; Paula, V.; Estevinho, L.M.; Santos, L. Propolis microencapsulation by double emulsion solvent evaporation approach: Comparison of different polymeric matrices and extract to polymer ratio. Food Bioprod. Process. 2021, 127, 408–425. [Google Scholar] [CrossRef]

- Jansen-Alves, C.; Fernandes, K.F.; Crizel-Cardozo, M.M.; Krumreich, F.D.; Borges, C.D.; Zambiazi, R.C. Microencapsulation of Propolis in Protein Matrix Using Spray Drying for Application in Food Systems. Food Bioprocess Technol. 2018, 11, 1422–1436. [Google Scholar] [CrossRef]

- Syukri, Y.; Fitria, A.; Hanifah, S.; Idrati, M. Development of New Indonesian Propolis Extract-Loaded Self-emulsifying: Characterization, Stability and Antibacterial Activity. Adv. Pharm. Bull. 2021, 11, 120–129. [Google Scholar] [CrossRef]

- Lara-Abia, S.; Lobo, G.; Pérez-Pascual, N.; Welti-Chanes, J.; Cano, M.P. Improvement in the Stability and Bioaccessibility of Carotenoid and Carotenoid Esters from a Papaya By-Product Using O/W Emulsions. Foods 2023, 12, 2654. [Google Scholar] [CrossRef]

- Boyraci, M.C.; Kemal, M.E.; Degirmenci, A. Evaluating Bioactivity and Bioaccessibility Properties of Turkish Propolis Extracts Prepared with Various Solvents. J. Apitherapy Nat. 2019, 2, 7–11. [Google Scholar] [CrossRef]

- Wojtunik-Kulesza, K.; Oniszczuk, A.; Oniszczuk, T.; Combrzyński, M.; Nowakowska, D.; Matwijczuk, A. Influence of In Vitro Digestion on Composition, Bioaccessibility and Antioxidant Activity of Food Polyphenols-A Non-Systematic Review. Nutrients 2020, 12, 1401. [Google Scholar] [CrossRef] [PubMed]

- Yesiltas, B.; Capanoglu, E.; Firatligil-Durmus, E.; Sunay, A.E.; Samanci, T.; Boyacioglu, D. Investigating the in-vitro bioaccessibility of propolis and pollen using a simulated gastrointestinal digestion System. J. Apic. Res. 2014, 53, 101–108. [Google Scholar] [CrossRef]

- Gomes Sá, S.H.; Chalella Mazzocato, M.; Saliba, A.; Alencar, S.M.; Sílvia Favaro-Trindade, C. Evaluation of the release, stability and antioxidant activity of Brazilian red propolis extract encapsulated by spray-drying, spray-chilling and using the combination of both techniques. Food Res. Int. 2023, 164, 112423. [Google Scholar] [CrossRef] [PubMed]

| Extract | Total Phenols g GAE/100 g | Total Flavonoids g QE/100 g | ABTS+ g GAE/100 g | DPPH+ g GAE/100 g |

|---|---|---|---|---|

| T | 33.32 ± 0.13 a | 20.59 ± 0.276 a | 8.69 ± 0.87 c | 21.66 ± 0.78 a |

| SP | 32.83 ± 0.44 ab | 5.17 ± 0.99 b | 14.31 ± 0.94 a | 19.83 ± 0.51 b |

| SJ | 32.58 ± 0.30 b | 3.67 ± 0.17 c | 14.01 ± 0.86 b | 21.63 ± 0.51 a |

| Phase | Total Phenols g GAE/100 g | Total Flavonoids g QE/100 g | ||

|---|---|---|---|---|

| Day 0 | Day 77 | Day 0 | Day 77 | |

| GPET | 1.48 ± 0.37 abA | 1.42 ± 0.17 abA | 1.19 ± 0.35 aB | 1.10 ± 0.32 aB |

| GPESP | 1.53 ± 0.18 abA | 1.40 ± 0.10 abA | 2.63 ± 0.03 bcdB | 0.243 ± 0.03 bcdB |

| GPESJ | 1.51 ± 0.17 abA | 1.31± 0.72 bA | 2.15 ± 0.03 cdB | 0.199 ± 0.02 dB |

| IPET | 1.65 ± 0.12 abA | 1.59 ± 0.25 abA | 0.92 ± 0.85 abcB | 0.97 ± 0.90 abB |

| IPESP | 1.76 ± 0.10 aA | 1.81 ± 0.11 aA | 0.25 ± 0.01 bcdB | 0.32 ± 0.02 bcdB |

| IPESJ | 1.50 ± 0.39 abA | 1.56 ± 0.54 abA | 0.16 ± 0.05 dB | 0.21 ± 0.07 cdB |

| Treatment | ABTS+ g GAE/100 g | DPPH+ g GAE/100 g | ||

|---|---|---|---|---|

| Day 0 | Day 77 | Day 0 | Day 77 | |

| GPET | 0.40 ± 0.06 bcA | 0.36 ± 0.026 cA | 0.85 ± 0.046 aB | 0.85 ± 0.068 aB |

| GPESP | 0.61 ± 0.014 aA | 0.57 ± 0.019 abA | 0.70 ± 0.042 aB | 0.70 ± 0.064 aB |

| GPESJ | 0.70 ± 0.014 aA | 0.65 ± 0.003 aA | 0.75 ± 0.049 aB | 0.74 ± 0.068 aB |

| IPET | 0.38 ± 0.012 cA | 0.43 ± 0.003 bcA | 1.00 ± 0.045 aB | 0.873 ± 0.074 aB |

| IPESP | 0.64 ± 0.029 aA | 0.56 ± 0.025 abA | 0.68 ± 0.023 aB | 0.74 ± 0.048 aB |

| IPESJ | 0.66 ± 0.030 aA | 0.57 ± 0.015 abA | 0.83 ± 0.029 aB | 0.82 ± 0.049 aB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González Montiel, L.; León-López, A.; García-Ceja, A.; Franco-Fernández, M.J.; Pérez-Soto, E.; Cenobio-Galindo, A.d.J.; Campos-Montiel, R.G.; Aguirre-Álvarez, G. Stability, Content of Bioactive Compounds and Antioxidant Activity of Emulsions with Propolis Extracts during Simulated In Vitro Digestion. Foods 2024, 13, 779. https://doi.org/10.3390/foods13050779

González Montiel L, León-López A, García-Ceja A, Franco-Fernández MJ, Pérez-Soto E, Cenobio-Galindo AdJ, Campos-Montiel RG, Aguirre-Álvarez G. Stability, Content of Bioactive Compounds and Antioxidant Activity of Emulsions with Propolis Extracts during Simulated In Vitro Digestion. Foods. 2024; 13(5):779. https://doi.org/10.3390/foods13050779

Chicago/Turabian StyleGonzález Montiel, Lucio, Arely León-López, Adelfo García-Ceja, Melitón Jesús Franco-Fernández, Elizabeth Pérez-Soto, Antonio de Jesús Cenobio-Galindo, Rafael G. Campos-Montiel, and Gabriel Aguirre-Álvarez. 2024. "Stability, Content of Bioactive Compounds and Antioxidant Activity of Emulsions with Propolis Extracts during Simulated In Vitro Digestion" Foods 13, no. 5: 779. https://doi.org/10.3390/foods13050779