The Development of Novel Functional Corn Flakes Produced from Different Types of Maize (Zea mays L.)

Abstract

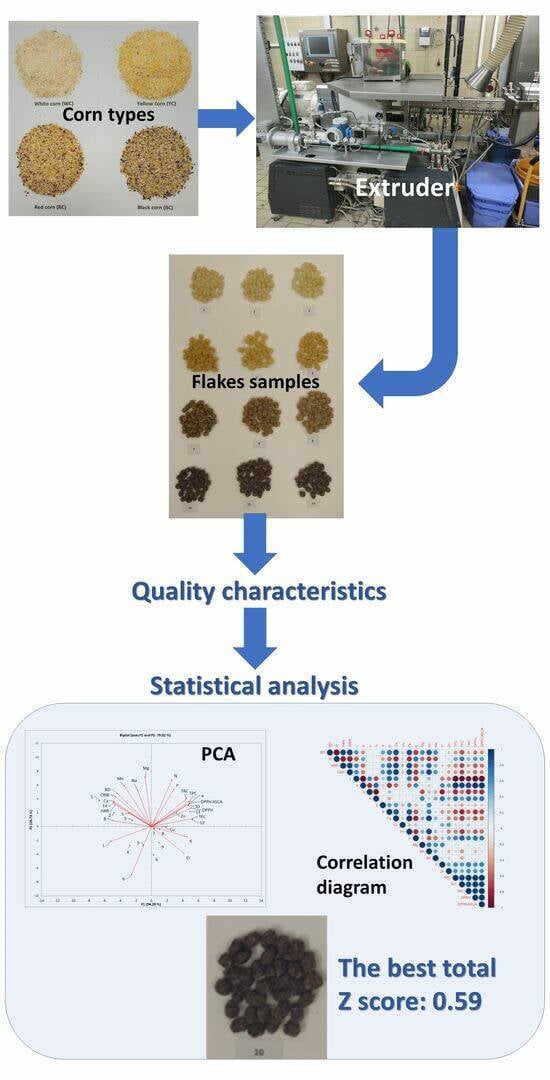

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extrusion Process

2.3. Flake Characterization

2.3.1. Bulk Density

2.3.2. Expansion Index

2.4. Texture Properties

2.5. Color Instrumental Analysis

2.6. Mineral Characteristics

2.7. Biochemical Characteristics

2.8. Methods of Statistical Analysis

2.8.1. Analysis of Variance

2.8.2. Correlation Analysis

2.8.3. Principle Component Analysis

2.8.4. Z-Score Analysis

3. Results and Discussion

3.1. Physical and Technological Characteristics of Flake Products

3.2. Functional Characteristics of Flake Products

3.3. Results of the Statistical Analysis

3.3.1. Results of the Correlation Analysis

3.3.2. Results of the PCA

3.3.3. Results of the Z-Score Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Petroni, K.; Pilu, R.; Tonelli, C. Anthocyanins in corn: A wealth of genes for human health. Planta 2014, 240, 901–911. [Google Scholar] [CrossRef] [PubMed]

- Colombo, R.; Ferron, L.; Papetti, A. Colored Corn: An Up-Date on Metabolites Extraction, Health Implication, and Potential Use. Molecules 2021, 26, 199. [Google Scholar] [CrossRef]

- Abdel-Aal, E.-S.M.; Hucl, P. A rapid method for quantifying total anthocyanins in blue aleurone and purple pericarp wheats. Cereal Chem. 1999, 76, 350–354. [Google Scholar] [CrossRef]

- Feng, X.; Pan, L.; Wang, Q.; Liao, Z.; Wang, X.; Zhang, X.; Lu, Y. Nutritional and physicochemical characteristics of purple sweet corn juice before and after boiling. PLoS ONE 2020, 15, e0233094. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Aal, E.S.M.; Young, C.; Rabalskij, I. Anthocyanin composition in black, blue, pink, purple, and red cereal grains. J. Agric. Food Chem. 2006, 54, 4696–4704. [Google Scholar] [CrossRef]

- Abdel-Aal, E.M.; Akhtar, H.; Rabalski, I.; Bryan, M. Accelerated, microwaveassisted, and conventional solvent extraction methods affect anthocyanin composition from colored grains. J. Food Sci. 2014, 79, C138–C146. [Google Scholar] [CrossRef]

- Guo, X.; He, X.; Dai, T.; Liu, W.; Liang, R.; Chen, J.; Liu, C. The physicochemical and pasting properties of purple corn flour ground by a novel low temperature impact mill. Innov. Food Sci. Emerg. 2021, 74, 102825. [Google Scholar] [CrossRef]

- Capriles a Vanessa, D.; Conti-Silva, A.C.; Arêas, J.A.G. Effects of oligofructose-enriched inulin addition before and after the extrusion process on the quality and postprandial glycemic response of corn-snacks. Food Biosci. 2021, 43, 101263. [Google Scholar] [CrossRef]

- Kesre, M.C.; Masatcioglu, T. Physical characteristics of corn extrudates supplemented with red lentil bran. LWT-Food Sci. Technol. 2022, 153, 112530. [Google Scholar] [CrossRef]

- Košutic, M. Extruded Flakes Product Supplemented with Sunflower and Dry Residue of Wild Oregano. Ph.D. Thesis, Faculty of Technology, University of Novi Sad, Novi Sad, Serbia, 2016. Available online: https://nardus.mpn.gov.rs/handle/123456789/6673 (accessed on 11 March 2022).

- Suarez, D.N.; Quintero-Ramos, A.; Mel´endez-Pizarro, C.O.; Zazueta-Morales, J.J.; Delgado, F.P.; Ruiz-Guti´errez, M.G. Evaluation of the physicochemical properties of third-generation snacks made from blue corn, black beans, and sweet chard produced by extrusion. LWT-Food Sci. Technol. 2021, 146, 111414. [Google Scholar] [CrossRef]

- Hegazy, H.; El-Fath, A.; El-Bedawey, A.; Rahma, E.H. Effect of Extrusion Process on Nutritional, Functional Properties and Antioxidant Activity of Germinated Chickpea Incorporated Corn Extrudes. AJFSN 2017, 4, 59–66. Available online: http://www.openscienceonline.com/journal/fsnr (accessed on 12 January 2017).

- Wani, S.A.; Kumar, P. Moisture sorption isotherms and evaluation of quality changes in extruded snacks during storage. LWT-Food Sci. Technol. 2016, 74, 448–455. [Google Scholar] [CrossRef]

- Peksa, A.; Kita, A.; Carbonell-Barrachina, A.A.; Miedzianka, J.; Kolniak-Ostek, J.; Tajner-Czopek, A.; Rytel, E.; Siwek, A.; Miarka, D.; Drozd, W. Sensory attributes and physicochemical features of corn snacks as affected by different flour types and extrusion conditions. LWT-Food Sci. Technol. 2016, 72, 26–36. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Washington, DA, USA, 2000. [Google Scholar]

- Kaluđerski, G.; Filipović, N. Methods for the Investigation of Cereals, Flour and Final Product Quality; Faculty of Technology: Novi Sad, Serbia, 1998; pp. 102–104. [Google Scholar]

- Han, Y.J.; Tra Tran, T.T.; Man Le, V.V. Corn snac with high fiber content: Effects of different fiber types on the product quality. LWT Food Sci. Technol. 2018, 96, 1–6. [Google Scholar] [CrossRef]

- Vallée, M.; Lu, X.; Narciso, J.O.; Li, W.; Qin, Y.; Brennan, M.A.; Brennan, C.S. Physical, predictive glycaemic response and antioxidative properties of black ear mushroom (Auricularia auricula) extrudates. Plant Foods Hum. Nutr. 2017, 72, 301–307. [Google Scholar] [CrossRef] [PubMed]

- Filipović, J.; Pezo, L.; Filipović, N.; Filipović, V.; Brkljača, J.; Krulj, J. The effects of ω-3 fatty acids and inulin addition to spelt pasta quality. LWT-Food Sci. Technol. 2015, 63, 43–51. [Google Scholar] [CrossRef]

- Rui, Y.K.; Yu, Q.Q.; Jin, Y.H.; Guo, J.; Luo, Y.B. Application of ICP-MS to the detection of forty elements in wine. Spectrosc. Spect. Anal. 2007, 27, 1015–1017. [Google Scholar]

- Mazarakioti, E.C.; Zotos, A.; Thomatou, A.A.; Kontogeorgos, A.; Patakas, A.; Ladavos, A. Inductively Coupled Plasma-Mass Spectrometry (ICP-MS), a Useful Tool in Authenticity of Agricultural Products’ and Foods’ Origin. Foods 2022, 11, 3705. [Google Scholar] [CrossRef]

- Makkar, H.P.S. Quantification of Tannins in Tree and Shrub Foliage: A Laboratory Manual. FAO/IAEA. 2000. Available online: https://www.osti.gov/etdeweb/servlets/purl/20286070 (accessed on 11 March 2022).

- Pękal, A.; Pyrzynska, K. Evaluation of aluminium complexation reaction for flavonoid content assay. Food Anal. Methods 2014, 7, 1776–1782. [Google Scholar] [CrossRef]

- Lee, J.; Durst, R.W.; Wrolstad, R.E. Determination of total monomeric anthocyanin pigment content of fruit juices, beverages, natural color-ants and wines by the pH differential method: Collaborative study. J. AOAC Int. 2005, 88, 1269–1278. [Google Scholar] [CrossRef]

- Chan, E.W.C.; Lim, Y.Y.; Che, Y.L. Antioxidant activity of Camellia sinensis leaves and tea from a lowland plantation in Malaysia. Food Chem. 2007, 102, 1214–1222. [Google Scholar] [CrossRef]

- Alamu, E.O.; Maziya, D.B.; Menkir, A.; Irondi, E.A.; Olaofe, O. Bioactive Composition and Free Radical Scavenging Activity of Fresh Orange Maize Hybrids: Impacts of Genotype, Maturity Stages, and Processing Methods. Front. Nutr. 2021, 8, 640563. [Google Scholar] [CrossRef] [PubMed]

- Jayalakshmi, T.; Santhakumaran, A. Statistical Normalization and Back Propagation for Classification. Int. J. Comput. Theory Eng. 2012, 3, 1793–8201. [Google Scholar]

- Filipović, V.; Lončar, B.; Filipović, J.; Nićetin, M.; Knežević, V.; Šeregelj, V.; Košutić, M.; Bodroža Solarov, M. Addition of Combinedly Dehydrated Peach to the Cookies—Technological Quality Testing and Optimization. Foods 2022, 11, 1258. [Google Scholar] [CrossRef] [PubMed]

- Košutić, M.; Filipović, J.; Pezo, L.; Plavšić, D.; Ivkov, M. Physical and sensory properties of corn flakes with added dry residue of wild oregano distillation. J. Serb. Chem. Soc. 2016, 81, 1013–1024. [Google Scholar] [CrossRef]

- Bokić, J.; Kojić, J.; Krulj, J.; Pezo, L.; Banjac, V.; Škrobot, D.; Tumbas Šaponjac, V.; Vidosavljević, S.; Stojkov, V.; Ilić, N.; et al. Development of a Novel Rice-Based Snack Enriched with Chicory Root: Physicochemical and Sensory Properties. Foods 2022, 11, 2393. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Pathania, S.; Sharma, A. Optimization of the extrusion process for development of high fibre soybean-rice ready-to-eat snacks using carrot pomace and cauliflower trimmings. LWT Food Sci. Technol. 2016, 74, 135–144. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, C.; Tang, X.; Zhou, J.; Li, H.; Zhang, H.; Liu, J. Physicochemical properties and microstructure of corn flour–cellulose fiber extrudates. Food Sci. Nutr. 2021, 9, 2497–2507. [Google Scholar] [CrossRef]

- Bisharat, G.I.; Oikonomopoulou, V.P.; Panagiotou, N.M.; Krokida, M.K.; Maroulis, Z.B. Effect of extrusion conditions on the structural properties of corn extrudates enriched with dehydrated vegetables. Food Res. Int. 2013, 53, 1–14. [Google Scholar] [CrossRef]

- Tsokolar-Tsikopoulos, K.C.; Katsavou, I.D.; Krokida, M.K. The effect of inulin addition on structural and textural properties of extruded products under several extrusion conditions. J. Food Sci. Technol. 2015, 52, 6170–6181. [Google Scholar] [CrossRef]

- Yao, N.; Jannink, J.I.; Alavi, S.; White, P.J. Physical and sensory characteristics of extruded products made from two oat lines with different β-glucan concentrations. Cereal Chem. 2006, 83, 692–699. [Google Scholar] [CrossRef]

- Anton, A.A.; Gary Fulcher, R.; Arntfield, S.D. Physical and nutritional impact of fortification of corn starch-based extruded snacks with common bean (Phaseolus vulgaris L.) flour: Effects of bean addition and extrusion cooking. Food Chem. 2009, 113, 989–996. [Google Scholar] [CrossRef]

- Yang, Z.; ZhaiInnovative, W. Identification and antioxidant activity of anthocyanins extracted from the seed and cob of purple corn (Zea mays L.). Food Sci. Emerg. Technol. 2010, 11, 169–176. [Google Scholar] [CrossRef]

- Vukadinović, V.; Vukadinović, V. Nutrition of Plants; Chapter 9; Faculty of Agriculture in Osjek: Osijek, Croatia, 2011; pp. 237–243. Available online: https://tlo-i-biljka.eu/Gnojidba/Ishrana_bilja_2011.pdf (accessed on 11 March 2022).

- Filipović, S.; Psodorov, Đ. Extrusion—General Characteristics; Chapter 1; Institute of Food Technology: Novi Sad, Serbia, 2013; pp. 15–48. [Google Scholar]

- Rusinek, R.; Gancarz, M.; Nawrocka, A. Application of an electronic nose with novel method for generation of smellprints for testing the suitability for consumption of wheat bread during 4-day storage. LWT-Food Sci. Technol. 2020, 117, 108665. [Google Scholar] [CrossRef]

| Corn Type | ||||

|---|---|---|---|---|

| WC | YC | RC | BC | |

| Moisture (%) | 14.3 | 13.6 | 12.7 | 12.4 |

| Particle size | ||||

| >350 µm | 82.1 | 81.5 | 83.5 | 84.1 |

| 250–350 µm | 9.5 | 8.7 | 8.6 | 7.0 |

| 150–250 µm | 3.7 | 4.9 | 3.5 | 3.1 |

| <150 µm | 4.7 | 4.9 | 4.4 | 5.8 |

| Color characteristics | ||||

| L | 82.52 | 77.93 | 64.06 | 61.75 |

| a | 0.71 | 2.38 | 3.63 | 1.36 |

| b | 12.86 | 24.56 | 19.24 | 15.61 |

| Corn Type | ||||

|---|---|---|---|---|

| WC | YC | RC | BC | |

| N (%) | 1.671 | 1.435 | 1.484 | 1.677 |

| S (%) | 0.248 | 0.244 | 0.253 | 0.250 |

| B (%) | 4.552 | 5.209 | 4.664 | 4.63 |

| Ca (mg/kg) | 701.50 | 687.20 | 699.30 | 677.70 |

| Cu (mg/kg) | 13.72 | 6.652 | 6.388 | 13.93 |

| Fe (mg/kg) | 1289 | 59.16 | 42.65 | 40.50 |

| K (mg/kg) | 2660 | 2720 | 2486 | 2822 |

| Mg (mg/kg) | 984.20 | 853.8 | 845.1 | 953 |

| Mn (mg/kg) | 73.11 | 6.932 | 6.016 | 7.712 |

| Na (mg/kg) | 99.78 | 112.80 | 113.00 | 112.00 |

| P (mg/kg) | 2566.3 | 2231.30 | 2130.0 | 2528.3 |

| Zn (mg/kg) | 29.78 | 20.72 | 19.54 | 26.20 |

| Corn Type | ||||

|---|---|---|---|---|

| WC | YC | RC | BC | |

| TPC (mg/g d.m) | 1.49 | 1.58 | 1.86 | 2.66 |

| TFC (mg/g d.m) | 0.03 | 0.07 | 0.11 | 0.35 |

| TAC (mg/g d.m) | nd * | nd | 0.0125 | 0.2705 |

| DPPH-test% | 60.09 | 69.23 | 84.75 | 80.94 |

| DPPH-testug&g ASCA | 2.66 | 3.21 | 4.41 | 4.08 |

| Sample | Type of Corn | Screw Speed (rpm) |

|---|---|---|

| 1 | White corn (WC) | 350 |

| 2 | White corn (WC) | 500 |

| 3 | White corn (WC) | 650 |

| 4 | Yellow corn (YC) | 350 |

| 5 | Yellow corn (YC) | 500 |

| 6 | Yellow corn (YC) | 650 |

| 7 | Red corn (RC) | 350 |

| 8 | Red corn (RC) | 500 |

| 9 | Red corn (RC) | 650 |

| 10 | Black corn (BC) | 350 |

| 11 | Black corn (BC) | 500 |

| 12 | Black corn (BC) | 650 |

| Sample | BD (kg/m3) | EI | HAR (N) | CRW (Nmm) |

|---|---|---|---|---|

| 1 | 26.77 ± 0.21 g | 1.90 ± 0.08 a | 101.31 ± 18.97 e | 12.98 ± 2.73 f |

| 2 | 23.77 ± 0.434 f | 1.91 ± 0.06 a | 89.89 ± 14.4 de | 8.87 ± 0.91 e |

| 3 | 18.84 ± 0.25 e | 2.01 ± 0.05 a | 56.07 ± 20.42 a | 5.87 ± 0.81 d |

| 4 | 16.26 ± 0.21 c | 2.39 ± 0.07 a | 77.43 ± 17.18 cd | 5.66 ± 0.68 cd |

| 5 | 12.78 ± 0.28 b | 2.62 ± 0.14 bc | 59.63 ± 14.09 ac | 3.74 ± 0.55 abc |

| 6 | 7.73 ± 0.27 a | 3.14 ± 0.12 a | 39.92 ± 6.35 ab | 2.40 ± 0.35 a |

| 7 | 15.84 ± 0.74 c | 2.40 ± 0.09 a | 54.90 ± 12.48 a | 4.55 ± 0.87 bcd |

| 8 | 12.77 ± 0.28 b | 2.54 ± 0.07 b | 44.37 ± 9.23 ab | 2.97 ± 0.58 ab |

| 9 | 7.72 ± 0.14 a | 3.10 ± 0.13 c | 31.49 ± 6.81 b | 2.27 ± 0.29 a |

| 10 | 13.90 ± 0.36 d | 2.59 ± 0.10 a | 53.79 ± 11.30 a | 4.41 ± 0.46 bcd |

| 11 | 12.28 ± 0.19 b | 2.76 ± 0.11 b | 43.56 ± 8.40 ab | 2.27 ± 0.97 a |

| 12 | 7.70 ± 0.27 a | 3.30 ± 0.06 d | 30.45 ± 6.84 b | 2.04 ± 1.09 a |

| Sample | L | a | b |

|---|---|---|---|

| 1 | 87.21 ± 0.16 c | −0.56 ± 0.09 a | 14.64 ± 0.14 b |

| 2 | 87.21 ± 0.13 c | −0.58 ± 0.04 a | 14.57 ± 0.07 b |

| 3 | 87.33 ± 0.29 c | −0.68 ± 0.10 a | 14.39 ± 0.13 b |

| 4 | 81.68 ± 0.33 b | −0.77 ± 0.14 ab | 25.06 ± 0.36 d |

| 5 | 81.73 ± 0.41 b | −0.99 ± 0.38 b | 25.13 ± 0.31 d |

| 6 | 81.40 ± 0.06 b | −0.72 ± 0.05 ab | 25.19 ± 0.23 d |

| 7 | 66.75 ± 0.73 d | 3.97 ± 0.06 d | 17.67 ± 0.37 c |

| 8 | 68.04 ± 0.11 e | 3.83 ± 0.10 cd | 18.03 ± 0.20 c |

| 9 | 66.68 ± 0.43 d | 3.67 ± 0.17 c | 17.84 ± 0.37 c |

| 10 | 50.46 ± 0.52 a | 8.92 ± 0.13 e | 8.41 ± 0.37 a |

| 11 | 50.41 ± 0.56 a | 9.19 ± 0.09 e | 8.40 ± 0.12 a |

| 12 | 50.73 ± 0.53 a | 9.59 ± 0.01 f | 8.49 ± 0.12 a |

| Sample | N (%) | S (%) | B (mg/kg) | Ca (mg/kg) | Cu (mg/kg) | Fe (mg/kg) | K (mg/kg) | Mg (mg/kg) | Mn (mg/kg) | Na (mg/kg) | P (mg/kg) | Zn (mg/kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.594 ± 0.01 ab | 0.455 ± 0.04 c | 7.305 ± 0.120 e | 506.2 ± 4.26 g | 10.72 ± 1.28 ab | 179.50 ± 15.84 e | 2237 ± 114 ab | 1001 ± 114.02 a | 11.25 ± 0.40 e | 35.92 ± 1.10 d | 2386 ± 256.59 a | 18.15 ± 1.16 a |

| 2 | 1.581 ± 0.0041 ab | 0.320 ± 0.039 ab | 6.236 ± 0.152 d | 423.3 ± 5.11 b | 15.15 ± 2.431 b | 149.70 ± 43.85 d | 2164 ± 93 a | 954.9 ± 53.06 a | 9.543 ± 0.97 d | 35.89 ± 0.77 d | 2408 ± 102.34 a | 20.95 ± 0.60 a |

| 3 | 1.523 ± 0.185 ab | 0.361 ± 0.068 abc | 5.805 ± 0.325 c | 247.1 ± 14.68 f | 38.99 ± 3.128 g | 80.63 ± 3.825 c | 2250 ± 267 ab | 965.8 ± 89.51 a | 8.16 ± 1.049 c | 35.68 ± 2.783 cd | 2578 ± 339.76 a | 35.48 ± 3.52 cd |

| 4 | 1.358 ± 0.162 a | 0.402 ± 0.073 bc | 6.182 ± 0.990 d | 202.4 ± 27.93 e | 19.02 ± 0.92 c | 78.56 ± 2.89 c | 2395 ± 187 abc | 869.6 ± 91.96 a | 6.955 ± 0.24 abc | 32.92 ± 2.40 abc | 2229 ± 274.84 a | 27.32 ± 2.05 c |

| 5 | 1.475 ± 0.226 ab | 0.371 ± 0.072 abc | 5.746 ± 0.383 bc | 135.2 ± 1.62 d | 22.57 ± 0.945 d | 59.16 ± 59.16 bc | 2483 ± 243 abc | 886.9 ± 65.50 a | 6.507 ± 0.347 ab | 33.32 ± 1.12 abc | 2315 ± 90.95 a | 39.68 ± 0.80 d |

| 6 | 1.426 ± 0.293 ab | 0.255 ± 0.054 a | 5.935 ± 0.306 d | 113.9 ± 1.68 c | 32.68 ± 1.018 e | 46.42 ± 0.928 ab | 2519 ± 286 bc | 900.3 ± 35.36 a | 6.072 ± 0.63 a | 31.37 ± 0.71 a | 2381 ± 181.95 a | 20.37 ± 0.75 a |

| 7 | 1.59 ± 0.01 ab | 0.305 ± 0.070 ab | 4.920 ± 0.640 ab | 81.25 ± 0.75 ab | 6.64 ± 0.58 a | 35.93 ± 1.33 ab | 2398 ± 184 abc | 951.8 ± 120.69 a | 6.401 ± 0.64 a | 35.47 ± 0.70 d | 2408 ± 161.57 a | 24.00 ± 0.73 b |

| 8 | 1.564 ± 0.20 ab | 0.321 ± 0.050 ab | 5.691 ± 0.230 bc | 78.26 ± 0.61 a | 21.17 ± 0.45 cd | 39.71 ± 0.44 ab | 2443 ± 96 abc | 946.3 ± 50.40 a | 6.44 ± 0.42 ab | 35.77 ± 0.87 d | 2419 ± 372.88 a | 49.11 ± 1.53 e |

| 9 | 1.511 ± 0.16 ab | 0.351 ± 0.100 abc | 5.424 ± 0.860 bc | 114.10 ± 1.87 c | 7.65 ± 0.96 ab | 47.29 ± 0.66 b | 2301 ± 97 abc | 895.6 ± 8.13 a | 6.58 ± 0.51 ab | 32.89 ± 0.90 abc | 2268 ± 182.73 a | 20.6 ± 0.47 a |

| 10 | 1.697 ± 0.10 b | 0.280 ± 0.056 ab | 5.288 ± 0.102 abc | 97.00 ± 1.691 bc | 34.71 ± 1.496 ef | 36.02 ± 0.998 ab | 2514 ± 93 bc | 958.1 ± 57.122 a | 7.123 ± 0.640 abc | 35.61 ± 1.051 d | 2562 ± 127.653 a | 59.77 ± 1.38 f |

| 11 | 1.643 ± 0.103 ab | 0.356 ± 0.069 abc | 4.958 ± 0.498 ab | 86.22 ± 1.804 ab | 14.81 ± 0.950 b | 42.97 ± 1.213 ab | 2623 ± 130 c | 972.1 ± 31.331 a | 7.658 ± 0.837 bc | 31.9 ± 1.170 ab | 2643 ± 274.770 a | 33.76 ± 1.17 b |

| 12 | 1.671 ± 0.088 b | 0.347 ± 0.042 abc | 4.845 ± 0.129 a | 68.12 ± 1.26 a | 36.25 ± 0.709 fg | 30.32 ± 0.855 a | 2554 ± 122 bc | 911.4 ± 1.402 a | 7.122 ± 0.147 abc | 34.34 ± 0.896 bc | 2546 ± 171.825 a | 38.42 ± 1.10 cd |

| TPC (mg/g d.m) | TFC (mg/g d.m) | TAC (mg/g d.m) | DPPH-Test% | DPPH-Test ug and g ASCA | |

|---|---|---|---|---|---|

| 1 | 0.82 ± 0.13 a | 0.41 ± 0.04 a | nd * | 43.06 ± 1.01 ab | 2.10 ± 0.04 b |

| 2 | 0.85 ± 0.07 a | 0.42 ± 0.02 a | nd | 39.62 ± 1.08 a | 2.02 ± 0.01 a |

| 3 | 0.74 ± 0.03 a | 0.44 ± 0.06 ab | nd | 41.74 ± 1.02 ab | 2.07 ± 0.03 ab |

| 4 | 0.83 ± 0.07 a | 0.48 ± 0.04 bcd | nd | 45.41 ± 1.82 bc | 2.22 ± 0.04 c |

| 5 | 0.81 ± 0.19 a | 0.51 ± 0.04 cde | nd | 48.08 ± 1.08 c | 2.30 ± 0.17 c |

| 6 | 0.83 ± 0.05 a | 0.56 ± 0.03 de | nd | 49.97 ± 1.82 c | 2.30 ± 0.13 c |

| 7 | 1.16 ± 0.07 b | 0.57 ± 0.05 de | 0.02 ± 0.01 ab | 65.93 ± 1.82 de | 3.27 ± 0.04 d |

| 8 | 1.30 ± 0.04 b | 0.56 ± 0.01 ef | 0.04 ± 0.01 b | 70.34 ± 1.53 e | 3.61 ± 0.04 e |

| 9 | 1.33 ± 0.07 b | 0.61 ± 0.04 f | 0.04 ± 0.01 b | 71.71 ± 1.91 e | 3.70 ± 0.05 e |

| 10 | 2.54 ± 0.07 d | 0.74 ± 0.05 i | 0.44 ± 0.02 c | 93.88 ± 2.69 f | 7.01 ± 0.05 g |

| 11 | 2.35 ± 0.05 c | 0.83 ± 0.04 h | 0.37 ± 0.03 d | 96.25 ± 2.77 f | 7.33 ± 0.04 h |

| 12 | 2.37 ± 0.06 cd | 0.72 ± 0.03 g | 0.33 ± 0.03 e | 91.31 ± 2.55 f | 6.56 ± 0.04 f |

| Samples | Segment Z Score | Total Z Score | |||

|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | ||

| 1 | 0.25 | 0.775919 | 0.782694 | 0.022228 | 0.39373 |

| 2 | 0.237484 | 0.775159 | 0.663111 | 0.021525 | 0.359754 |

| 3 | 0.370735 | 0.77582 | 0.554713 | 0.026851 | 0.374327 |

| 4 | 0.392256 | 0.939477 | 0.198479 | 0.072122 | 0.329855 |

| 5 | 0.497873 | 0.948249 | 0.294851 | 0.094881 | 0.393776 |

| 6 | 0.695851 | 0.937954 | 0.116665 | 0.126032 | 0.416424 |

| 7 | 0.45367 | 0.508628 | 0.403195 | 0.260882 | 0.391459 |

| 8 | 0.519961 | 0.531833 | 0.498063 | 0.30692 | 0.452355 |

| 9 | 0.71561 | 0.520823 | 0.21014 | 0.341012 | 0.447645 |

| 10 | 0.513748 | 0.021759 | 0.618253 | 0.938973 | 0.593643 |

| 11 | 0.552532 | 0.012602 | 0.373071 | 0.947071 | 0.545039 |

| 12 | 0.75 | 0.004676 | 0.396865 | 0.82111 | 0.571251 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Košutić, M.; Djalović, I.; Filipović, J.; Jakšić, S.; Filipović, V.; Nićetin, M.; Lončar, B. The Development of Novel Functional Corn Flakes Produced from Different Types of Maize (Zea mays L.). Foods 2023, 12, 4257. https://doi.org/10.3390/foods12234257

Košutić M, Djalović I, Filipović J, Jakšić S, Filipović V, Nićetin M, Lončar B. The Development of Novel Functional Corn Flakes Produced from Different Types of Maize (Zea mays L.). Foods. 2023; 12(23):4257. https://doi.org/10.3390/foods12234257

Chicago/Turabian StyleKošutić, Milenko, Ivica Djalović, Jelena Filipović, Snežana Jakšić, Vladimir Filipović, Milica Nićetin, and Biljana Lončar. 2023. "The Development of Novel Functional Corn Flakes Produced from Different Types of Maize (Zea mays L.)" Foods 12, no. 23: 4257. https://doi.org/10.3390/foods12234257