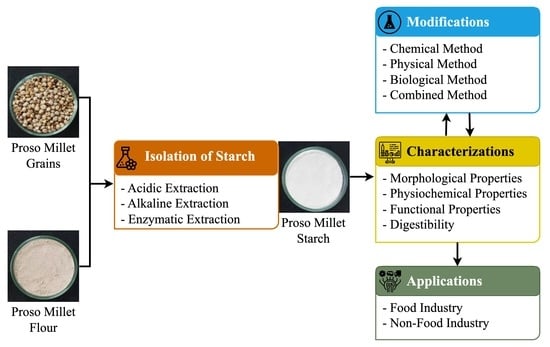

A Review on Isolation, Characterization, Modification, and Applications of Proso Millet Starch

Abstract

:1. Introduction

2. Isolation, Yield, and Composition of Proso Millet Starch

3. Morphology and Crystallinity of Proso Millet Starch

4. Physiological and Functional Properties

4.1. Swelling Power and Solubility

4.2. Pasting Properties

4.3. Thermal Properties

4.4. Retrogradation

4.5. Freeze–Thaw Stability

4.6. Digestibility

5. Starch Modifications

5.1. Acid Treatment

5.2. Hydrothermal Treatment

5.3. Dry Heat Treatment (DHT)

5.4. Ultra-High-Pressure (UHP) Treatment

5.5. Fermentation

5.6. Dual Modifications

6. Potential Applications and Future Perspectives

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. Cereal Supply and Demand Brief World Food Situation Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 26 March 2020).

- Yousaf, L.; Hou, D.; Liaqat, H.; Shen, Q. Millet: A review of its nutritional and functional changes during processing. Food Res. Int. 2021, 142, 110197. [Google Scholar] [CrossRef]

- Huang, J.; Yu, H.; Guan, X.; Wang, G.; Guo, R. Accelerated dryland expansion under climate change. Nat. Clim. Chang. 2016, 6, 166–171. [Google Scholar] [CrossRef]

- Adekunle, A.; Lyew, D.; Orsat, V.; Raghavan, V. Helping agribusinesses—Small millets value chain—To grow in India. Agriculture 2018, 8, 44. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Tomer, V.; Kaur, A.; Kumar, V.; Gupta, K. Millets: A solution to agrarian and nutritional challenges. Agric. Food Secur. 2018, 7, 31. [Google Scholar] [CrossRef]

- Zhu, F. Structure, physicochemical properties, and uses of millet starch. Food Res. Int. 2014, 64, 200–211. [Google Scholar] [CrossRef]

- Kumar, S.R.; Sadiq, M.B.; Anal, A.K. Comparative study of physicochemical and functional properties of pan and microwave cooked underutilized millets (proso and little). LWT 2020, 128, 109465. [Google Scholar] [CrossRef]

- Annor, G.A.; Tyl, C.; Marcone, M.; Ragaee, S.; Marti, A. Why do millets have slower starch and protein digestibility than other cereals? Trends Food Sci. Technol. 2017, 66, 73–83. [Google Scholar] [CrossRef]

- Zhang, T.; Li, K.; Ding, X.; Sui, Z.; Yang, Q.Q.; Shah, N.P.; Liu, G.; Corke, H. Starch properties of high and low amylose proso millet (Panicum miliaceum L.) genotypes are differentially affected by varying salt and pH. Food Chem. 2021, 337, 127784. [Google Scholar] [CrossRef] [PubMed]

- Boukail, S.; Macharia, M.; Miculan, M.; Masoni, A.; Calamai, A.; Palchetti, E.; Dell’Acqua, M. Genome wide association study of agronomic and seed traits in a world collection of proso millet (Panicum miliaceum L.). BMC Plant Biol. 2021, 21, 330. [Google Scholar] [CrossRef] [PubMed]

- Habiyaremye, C.; Matanguihan, J.B.; D’Alpoim Guedes, J.; Ganjyal, G.M.; Whiteman, M.R.; Kidwell, K.K.; Murphy, K.M. Proso millet (Panicum miliaceum L.) and its potential for cultivation in the Pacific Northwest, US: A review. Front. Plant Sci. 2017, 7, 1961. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, Y.; Liu, J.; Ma, Q.; Gao, Y.; Yang, Q.; Gao, X.; Feng, B. Cleaner production of proso millet (Panicum miliaceum L.) in salt-stressed environment using re-watering: From leaf structural alleviations to multi-omics responses. J. Clean. Prod. 2022, 334, 130205. [Google Scholar] [CrossRef]

- Devisetti, R.; Yadahally, S.N.; Bhattacharya, S. Nutrients and antinutrients in foxtail and proso millet milled fractions: Evaluation of their flour functionality. LWT-Food Sci. Technol. 2014, 59, 889–895. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, W.; Li, J.; Gong, X.; Feng, B. Physicochemical properties of starches in proso (non-waxy and waxy) and foxtail millets (non-waxy and waxy). Molecules 2019, 24, 1743. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Zhang, P.; Qu, Y.; Gao, X.; Liang, J.; Yang, P.; Feng, B. Comparison of physicochemical properties and cooking edibility of waxy and non-waxy proso millet (Panicum miliaceum L.). Food Chem. 2018, 257, 271–278. [Google Scholar] [CrossRef]

- Mahajan, P.; Bera, M.B.; Panesar, P.S.; Chauhan, A. Millet starch: A review. Int. J. Biol. Macromol. 2021, 180, 61–79. [Google Scholar] [CrossRef]

- Thakur, K.; Sharma, S.; Sharma, R. Morphological and functional properties of millet starches as influenced by different modification techniques: A review. Starke 2023, 75, 2200184. [Google Scholar] [CrossRef]

- Bangar, S.P.; Ashogbon, A.O.; Dhull, S.B.; Thirumdas, R.; Kumar, M.; Hasan, M.; Chaudhary, V.; Pathem, S. Proso-millet starch: Properties, functionality, and applications. Int. J. Biol. Macromol. 2021, 190, 960–968. [Google Scholar] [CrossRef]

- El Halal, S.L.M.; Kringel, D.H.; da Rosa Zavareze, E.; Dias, A.R.G. Methods for extracting cereal starches from different sources: A review. Starke 2019, 71, 1900128. [Google Scholar] [CrossRef]

- Liu, Q. Understanding starches and their role in foods. In Food Carbohydrates: Chemistry, Physical Properties and Applications; Cui, S.W., Ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 309–355. [Google Scholar] [CrossRef]

- Punia, S.; Kumar, M.; Siroha, A.K.; Kennedy, J.F.; Dhull, S.B.; Whiteside, W.S. Pearl millet grain as an emerging source of starch: A review on its structure, physicochemical properties, functionalization, and industrial applications. Carbohydr. Polym. 2021, 260, 117776. [Google Scholar] [CrossRef]

- Sun, Q.; Gong, M.; Li, Y.; Xiong, L. Effect of dry heat treatment on the physicochemical properties and structure of proso millet flour and starch. Carbohydr. Polym. 2014, 110, 128–134. [Google Scholar] [CrossRef]

- Yanez, G.A.; Walker, C.E. Effect of tempering parameters on extraction and ash of proso millet flours, and partial characterization of proso starch. Cereal Chem. 1986, 63, 164–167. [Google Scholar]

- Cornejo-Ramírez, Y.I.; Martínez-Cruz, O.; Del Toro-Sánchez, C.L.; Wong-Corral, F.J.; Borboa-Flores, J.; Cinco-Moroyoqui, F.J. The structural characteristics of starches and their functional properties. CyTA J. Food 2018, 16, 1003–1017. [Google Scholar] [CrossRef]

- Annor, G.A.; Marcone, M.; Bertoft, E.; Seetharaman, K. Physical and molecular characterization of millet starches. Cereal Chem. 2014, 91, 286–292. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, J.; Meng, X.; Zhang, D.; Zhao, G. Characterization of proso millet starches from different geographical origins of China. Food Sci. Biotechnol. 2014, 23, 1371–1377. [Google Scholar] [CrossRef]

- Yañez, G.A.; Walker, C.E.; Nelson, L.A. Some chemical and physical properties of proso millet (Panicum milliaceum) starch. J. Cereal Sci. 1991, 13, 299–305. [Google Scholar] [CrossRef]

- Singh, M.; Adedeji, A.A. Characterization of hydrothermal and acid modified proso millet starch. LWT-Food Sci. Technol. 2017, 79, 21–26. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Lin, Q.; Cui, T.; Xiao, H. Structural and physical properties of starches isolated from six varieties of millet grown in China. Int. J. Food Prop. 2014, 17, 2344–2360. [Google Scholar] [CrossRef]

- Ashogbon, A.O.; Akintayo, E.T. Recent trend in the physical and chemical modification of starches from different botanical sources: A review. Starke 2014, 66, 41–57. [Google Scholar] [CrossRef]

- Zarnkow, M.; Mauch, A.; Back, W.; Arendt, E.K.; Kreisz, S. Proso millet (Panicum miliaceum L.): An evaluation of the microstructural changes in the endosperm during the malting process by using scanning-electron and confocal laser microscopy. J. Inst. Brew. 2007, 113, 355–364. [Google Scholar] [CrossRef]

- Nor Nadiha, M.Z.; Fazilah, A.; Bhat, R.; Karim, A.A. Comparative susceptibilities of sago, potato and corn starches to alkali treatment. Food Chem. 2010, 121, 1053–1059. [Google Scholar] [CrossRef]

- Li, W.; Gao, J.; Saleh, A.S.M.; Tian, X.; Wang, P.; Jiang, H.; Zhang, G. The modifications in physicochemical and functional properties of proso millet starch after ultra-high pressure (UHP) process. Starke 2018, 70, 1700235. [Google Scholar] [CrossRef]

- Kim, S.K.; Choi, H.J.; Kang, D.K.; Kim, H.Y. Starch properties of native proso millet (Panicum miliaceum L.). Agron. Res. 2012, 10, 311–318. [Google Scholar]

- Kumari, S.K.; Thayumanavan, B. Characterization of starches of proso, foxtail, barnyard, kodo, and little millets. Plant Foods Hum. Nutr. 1998, 53, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hu, A.; Wang, X.; Zheng, J. Physicochemical and in vitro digestion of millet starch: Effect of moisture content in microwave. Int. J. Biol. Macromol. 2019, 134, 308–315. [Google Scholar] [CrossRef] [PubMed]

- Chao, G.; Gao, J.; Liu, R.; Wang, L.; Li, C.; Wang, Y.; Qu, Y.; Feng, B. Starch physicochemical properties of waxy proso millet (Panicum Miliaceum L.). Starke 2014, 66, 1005–1012. [Google Scholar] [CrossRef]

- Mir, S.A.; Bosco, S.J.D. Cultivar difference in physicochemical properties of starches and flours from temperate rice of Indian Himalayas. Food Chem. 2014, 157, 448–456. [Google Scholar] [CrossRef]

- Yoo, S.H.; Jane, J.L. Structural and physical characteristics of waxy and other wheat starches. Carbohydr. Polym. 2002, 49, 297–305. [Google Scholar] [CrossRef]

- Hoover, R. Composition, molecular structure, and physicochemical properties of tuber and root starches: A review. Carbohydr. Polym. 2001, 45, 253–267. [Google Scholar] [CrossRef]

- Xiao, Y.; Zheng, M.; Yang, S.; Li, Z.; Liu, M.; Yang, X.; Lin, N.; Liu, J. Physicochemical properties and in vitro digestibility of proso millet starch after addition of Proanthocyanidins. Int. J. Biol. Macromol. 2021, 168, 784–791. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L.; Yang, T.; Ma, Y.; McClements, D.J.; Ren, F.; Tian, Y.; Jin, Z. A review of structural transformations and properties changes in starch during thermal processing of foods. Food Hydrocoll. 2021, 113, 106543. [Google Scholar] [CrossRef]

- Brites, C.M.; Santos, C.A.L.D.; Bagulho, A.S.; Beirão-Da-Costa, M.L. Effect of wheat puroindoline alleles on functional properties of starch. Eur. Food Res. Technol. 2008, 226, 1205–1212. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Zhang, T.; Narayanamoorthy, S.; Jin, C.; Sui, Z.; Li, Z.; Li, S.; Wu, K.; Liu, G.; Corke, H. Diversity analysis of starch physicochemical properties in 95 proso millet (Panicum miliaceum L.) accessions. Food Chem. 2020, 324, 126863. [Google Scholar] [CrossRef] [PubMed]

- Koch, K.; Jane, J. Morphological changes of granules of different starches by surface gelatinization with calcium chloride. Cereal Chem. 2000, 77, 115–120. [Google Scholar] [CrossRef]

- Gao, H.; Cai, J.; Han, W.; Huai, H.; Chen, Y.; Wei, C. Comparison of starches isolated from three different Trapa species. Food Hydrocoll. 2014, 37, 174–181. [Google Scholar] [CrossRef]

- Fujita, S.; Fujiyama, G. The study of melting temperature and enthalpy of starch from rice, barley, wheat, foxtail-and proso-millets. Starke 1993, 45, 436–441. [Google Scholar] [CrossRef]

- Tomita, Y.; Sugimoto, Y.; Sakamoto, S.; Fuwa, H. Some properties of starches of grain amaranths and several millets. J. Nutr. Sci. Vitaminol. 1981, 27, 471–484. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Srichuwong, S.; Isono, N.; Jiang, H.; Mishima, T.; Hisamatsu, M. Freeze–thaw stability of starches from different botanical sources: Correlation with structural features. Carbohydr. Polym. 2012, 87, 1275–1279. [Google Scholar] [CrossRef]

- Magallanes-Cruz, P.A.; Flores-Silva, P.C.; Bello-Perez, L.A. Starch structure influences its digestibility: A review. J. Food Sci. 2017, 82, 2016–2023. [Google Scholar] [CrossRef] [Green Version]

- Leong, S.Y.; Duque, S.M.; Muhammad Abduh, S.B.; Oey, I. Carbohydrates. In Innovative Thermal and Non-Thermal Processing, Bioaccessibility and Bioavailability of Nutrients and Bioactive Compounds; Barba, F.J., Saraiva, J.M.A., Cravotto, G., Lorenzo, J.M., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 171–206. [Google Scholar] [CrossRef]

- Chai, Y.; Wang, M.; Zhang, G. Interaction between amylose and tea polyphenols modulates the postprandial glycemic response to high-amylose maize starch. J. Agric. Food Chem. 2013, 61, 8608–8615. [Google Scholar] [CrossRef]

- Sajilata, M.G.; Singhal, R.S.; Kulkarni, P.R. Resistant starch–A review. Compr. Rev. Food Sci. Food Saf. 2006, 5, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.; Zhao, N.; Jiang, F.; Ji, X.; Feng, B.; Liang, J.; Yu, X.; Du, S.-K. Structure, physicochemical, functional and in vitro digestibility properties of non-waxy and waxy proso millet starches. Int. J. Biol. Macromol. 2023, 224, 594–603. [Google Scholar] [CrossRef] [PubMed]

- Jyothi, A.N.; Moorthy, S.N.; Rajasekharan, K.N. Effect of cross-linking with epichlorohydrin on the properties of cassava (Manihot esculenta Crantz) starch. Starke 2006, 58, 292–299. [Google Scholar] [CrossRef]

- Hoover, R. Acid-treated starches. Food Rev. Int. 2000, 16, 369–392. [Google Scholar] [CrossRef]

- Hoover, R. The impact of heat-moisture treatment on molecular structures and properties of starches isolated from different botanical sources. Crit. Rev. Food Sci. Nutr. 2010, 50, 835–847. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.R.; Tangsrianugul, N.; Sriprablom, J.; Wongsagonsup, R.; Wansuksri, R.; Suphantharika, M. Effect of heat-moisture treatment on the physicochemical properties and digestibility of proso millet flour and starch. Carbohydr. Polym. 2023, 307, 120630. [Google Scholar] [CrossRef]

- Zheng, M.-Z.; Xiao, Y.; Yang, S.; Liu, H.-M.; Liu, M.-H.; Yaqoob, S.; Xu, X.-Y.; Liu, J.-S. Effects of heat–moisture, autoclaving, and microwave treatments on physicochemical properties of proso millet starch. Food Sci. Nutr. 2020, 8, 735–743. [Google Scholar] [CrossRef] [Green Version]

- Pratiwi, M.; Faridah, D.N.; Lioe, H.N. Structural changes to starch after acid hydrolysis, debranching, autoclaving-cooling cycles, and heat moisture treatment (HMT): A review. Starke 2018, 70, 1700028. [Google Scholar] [CrossRef]

- Zeng, F.; Ma, F.; Kong, F.; Gao, Q.; Yu, S. Physicochemical properties and digestibility of hydrothermally treated waxy rice starch. Food Chem. 2015, 172, 92–98. [Google Scholar] [CrossRef]

- Błaszczak, W.; Fornal, J.; Kiseleva, V.I.; Yuryev, V.P.; Sergeev, A.I.; Sadowska, J. Effect of high pressure on thermal, structural and osmotic properties of waxy maize and Hylon VII starch blends. Carbohydr. Polym. 2007, 68, 387–396. [Google Scholar] [CrossRef]

- Li, W.; Bai, Y.; Mousaa, S.A.S.; Zhang, Q.; Shen, Q. Effect of high hydrostatic pressure on physicochemical and structural properties of rice starch. Food Bioprocess Technol. 2012, 5, 2233–2241. [Google Scholar] [CrossRef]

- Bian, X.; Chen, J.-R.; Yang, Y.; Yu, D.-H.; Ma, Z.-Q.; Ren, L.-K.; Wu, N.; Chen, F.-L.; Liu, X.-F.; Wang, B.; et al. Effects of fermentation on the structure and physical properties of glutinous proso millet starch. Food Hydrocoll. 2022, 123, 107144. [Google Scholar] [CrossRef]

- Sun, X.; Saleh, A.S.M.; Lu, Y.; Sun, Z.; Zhang, X.; Ge, X.; Shen, H.; Yu, X.; Li, W. Effects of ultra-high pressure combined with cold plasma on structural, physicochemical, and digestive properties of proso millet starch. Int. J. Biol. Macromol. 2022, 212, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Chaiwat, W.; Wongsagonsup, R.; Tangpanichyanon, N.; Jariyaporn, T.; Deeyai, P.; Suphantharika, M.; Fuongfuchat, A.; Nisoa, M.; Dangtip, S. Argon plasma treatment of tapioca starch using a semi-continuous downer reactor. Food Bioprocess Technol. 2016, 9, 1125–1134. [Google Scholar] [CrossRef]

- Sun, Q.; Gong, M.; Li, Y.; Xiong, L. Effect of retrogradation time on preparation and characterization of proso millet starch nanoparticles. Carbohydr. Polym. 2014, 111, 133–138. [Google Scholar] [CrossRef] [PubMed]

- Jhan, F.; Shah, A.; Gani, A.; Ahmad, M.; Noor, N. Nano-reduction of starch from underutilised millets: Effect on structural, thermal, morphological and nutraceutical properties. Int. J. Biol. Macromol. 2020, 159, 1113–1121. [Google Scholar] [CrossRef]

- Zhu, F. Underutilized and unconventional starches: Why should we care? Trends Food Sci. Technol. 2020, 100, 363–373. [Google Scholar] [CrossRef]

- Bangar, S.P.; Sandhu, K.S.; Rusu, A.V.; Kaur, P.; Purewal, S.S.; Kaur, M.; Kaur, N.; Trif, M. Proso-millet-starch-based edible films: An innovative approach for food industries. Coatings 2021, 11, 1167. [Google Scholar] [CrossRef]

- Baek, S.-K.; Song, K.B. Characterization of active biodegradable films based on proso millet starch and curcumin. Starke 2019, 71, 1800174. [Google Scholar] [CrossRef]

- Bangar, S.P.; Siroha, A.K.; Nehra, M.; Trif, M.; Ganwal, V.; Kumar, S. Structural and film-forming properties of millet starches: A comparative study. Coatings 2021, 11, 954. [Google Scholar] [CrossRef]

- Han, M.; Dang, K.; Wang, J.; Gao, L.; Wang, H.; Ivanistau, A.; Yang, Q.; Feng, B. New type of food processing material: The crystal structure and functional properties of waxy and non-waxy proso millet resistant starches. Molecules 2021, 26, 4283. [Google Scholar] [CrossRef]

- Dahal, A.; Sadiq, M.B.; Anal, A.K. Improvement of quality of corn and proso millet-based gluten-free noodles with the application of hydrocolloids. J. Food Process. Preserv. 2021, 45, e15165. [Google Scholar] [CrossRef]

- Nagarajaiah, S.B.; Ramakrishna, M.G.; Prakash, J. Nutritional, antioxidant and sensory properties of value added muffins. Curr. Nutr. Food Sci. 2019, 15, 454–466. [Google Scholar] [CrossRef]

- Fathi, B.; Aalami, M.; Kashaninejad, M.; Sadeghi Mahoonak, A. Utilization of heat-moisture treated proso millet flour in production of gluten-free pound cake. J. Food Qual. 2016, 39, 611–619. [Google Scholar] [CrossRef]

- Banerjee, A.; Sarkar, A.K. Extraction, characterization, and evaluation of proso millet starch in textile printing. AATCC J. Res. 2015, 2, 14–19. [Google Scholar] [CrossRef]

- Schoenlechner, R.; Szatmari, M.; Bagdi, A.; Tömösközi, S. Optimisation of bread quality produced from wheat and proso millet (Panicum miliaceum L.) by adding emulsifiers, transglutaminase and xylanase. LWT-Food Sci. Technol. 2013, 51, 361–366. [Google Scholar] [CrossRef]

| Source | Starch Yield (%) | Protein (%) | Amylose (%) | Lipid (%) | Reference |

|---|---|---|---|---|---|

| Proso millet | 93.7 | - | 33.9 | - | [25] |

| 92.19–94.60 | 0.27–0.67 | 14.92–17.37 | 0.13–0.25 | [26] | |

| - | 0.69–4.31 | 27.2–29.1 | 0.59–0.6 | [23] | |

| 61.8–68.2 | 1.1–2.1 | 29.2–32.6 | - | [27] | |

| 87.27–94.60 | 1.07–1.30 | 2.80–32.80 | 0.01 | [14] | |

| - | 0.48 | 1.61 | 0.01 | [22] | |

| 54.1 | 1.21 | 28.51 | 0.27 | [28] | |

| - | 0.45 | 0.38 | - | [29] |

| Starch Source | Type | Size (µm) | Shape | Reference |

|---|---|---|---|---|

| Proso millet | NS | 3–10 | Oval, polygonal, irregular, and spherical | [33] |

| UHP | - | Structural disruption, gel-like structure formed | [33] | |

| NS | 2.5–17 | Few spherical and mostly polygonal | [25] | |

| NS | 0.3–12 | Few small spherical granules and mainly uniform large or small polygonal | [26] | |

| NS | 3–10 | Few small spheres and large polygonal shape | [29] | |

| NS | 4.3–8.9 | Mostly polygonal with some elliptical granules having rounded edges and surface pores | [34] | |

| NS | 5–12 | Round and smooth | [22] | |

| DHT | - | Smooth and plump surface with large lumps | [22] | |

| NS | 1.8–13.5 | Bimodal distribution, small spherical and large polygonal | [27] | |

| NS | 1.3–8 | Bimodal distribution, large polygonal, small and large spherical | [35] | |

| NS | 4.49–4.70 | Regular, polygonal, and round shape, along with the characteristic Maltese cross structure | [14] | |

| NS | 1.54–11.7 | Mainly polygonal and round shape, larger and smaller granules make honey-comb structure | [9] |

| Starch (g/mL) | Method | Unit | PV | BD | SB | PT (°C) | Reference |

|---|---|---|---|---|---|---|---|

| - | BVA | BU | 72.5–74.5 | [27] | |||

| - | BVA | BU | 520 | 50 | 330 | 75.8 | [35] |

| 3.5/25 | DHR | Pa.s | 4.60 | 2.60 | 1.69 | 79.23 | [28] |

| 3/25 | RVA | cP | 2807 | 1746 | 1634 | 57.40 | [33] |

| 3/25 | RVA | cP | 2372 | 1792 | 582 | - | [29] |

| 3/25 | RVA | cP | 2822 | 1854 | 501 | 76 | [22] |

| 2.5/25 | RVA | cP | 2284.5 | 913 | 372.5 | 79.18 | [41] |

| 2/25 | RVA | cP | 2134–3515 | 488–967 | 197–1102 | 63.60–63.80 | [37] |

| 3/25 | RVA | cP | 2110–3286 | 1114–2189 | 279–1478 | 77.8–80.9 | [14] |

| 2/26 | RVA | cP | 2215–3585 | 511–1437 | 752–1435 | 78.8–82.8 | [44] |

| - | BVA | BU | 219–457 | 79.5–240 | 115.05–201.5 | - | [26] |

| Starch Water Ratio (w/w) | Heating Rate (°C/min) | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) | References |

|---|---|---|---|---|---|---|

| 1:3 | 5 | 68.4 | 72.2 | 13.1 | [25] | |

| 1:3 | 10 | 72.7–73.6 | 75.8–77.6 | 84.4–89.5 | 13.2–14.8 | [23] |

| 1:2 | 5 | 65.8–80.2 | 6.4–11.4 | [47] | ||

| 1:2.7 | 10 | 67.8–69.0 | 69–73.9 | 75.5–81.8 | 13.2–14.8 | [27] |

| 1:2 | 5 | 62–69 | 67–74 | 77–78 | 9.6–12.6 | [48] |

| 1:2 | 10 | 68.65 | 71.37 | 80.04 | 15.03 | [22] |

| 1:2 | 10 | 71.95 | 77.36 | 87.42 | 14.98 | [41] |

| 1:2 | 10 | 68.56 | 74.53 | 82.43 | 5.16 | [29] |

| 1:3 | 10 | 73.1–76.4 | 78.0–81.5 | 79.3–86.0 | 0.81–4.48 | [34] |

| 1:3 | 10 | 67.4–75.5 | 71.5–79.0 | 76.5–84.0 | 11.9–17.6 | [44] |

| 1:3 | 10 | 66.81–70.01 | 72.79–76.55 | 78.30–82.44 | 10.40–14.46 | [26] |

| 1:2 | 10 | 64.6–71.1 | 70.5–77.9 | 77.4–82.3 | 9.6–10.8 | [14] |

| 1:3 | 10 | 67.9–72.7 | 74.6–76.1 | 80.4–81.2 | 10.37–12.65 | [37] |

| 1:2 | 10 | 72.93 | 78.61 | 94.55 | 3.83 | [28] |

| 1:4 | 10 | 64.16 | 68.45 | 79.09 | 10.58 | [33] |

| Proso Millet Type | Characteristics | Applications | References |

|---|---|---|---|

| Native PMS and PMS-k-carrageenan blend | The PMS film showed higher antioxidant activity than the PMS-k-carrageenan blend film but lower water permeability and solubility. | Edible film | [71] |

| Native PMS with curcumin (0–3%) | The antioxidant activity and the water and light barrier properties of the PMS film increased with increasing curcumin concentration. | Packaging film | [72] |

| Native PMS | The total film produced using native PMS proved to be a suitable packaging material for food products. | Packaging film | [73] |

| Native waxy and non-waxy PMS | RS content of waxy and non-waxy PMS was increased by HMT. | Functional foods | [74] |

| Native proso millet flour | Incorporation of hydrocolloids and proso millet flour into corn-based noodles resulted in enhanced texture and nutrition attributes of the noodles. | Gluten-free noodles | [75] |

| Native proso millet flour | Incorporation of proso millet flour to wheat flour muffins improved nutritional quality and antioxidant activity. | Bakery products | [76] |

| HMT proso millet flour | Incorporation of HMT proso millet flour to gluten-free millet cake improved the quality of the cake. | Gluten-free bakery products | [77] |

| Native PMS | The use of PMS as a thickener in textile printing improved the quality of the print. | Textile printing | [78] |

| Native proso millet flour | The quality of bread made from a wheat/proso millet mixed flour (50:50) was improved to be acceptable by addition of emulsifier and enzymes. | Bakery products | [79] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, S.R.; Tangsrianugul, N.; Suphantharika, M. A Review on Isolation, Characterization, Modification, and Applications of Proso Millet Starch. Foods 2023, 12, 2413. https://doi.org/10.3390/foods12122413

Kumar SR, Tangsrianugul N, Suphantharika M. A Review on Isolation, Characterization, Modification, and Applications of Proso Millet Starch. Foods. 2023; 12(12):2413. https://doi.org/10.3390/foods12122413

Chicago/Turabian StyleKumar, Simmi Ranjan, Nuttinee Tangsrianugul, and Manop Suphantharika. 2023. "A Review on Isolation, Characterization, Modification, and Applications of Proso Millet Starch" Foods 12, no. 12: 2413. https://doi.org/10.3390/foods12122413