Application of Rapeseed Meal Protein Isolate as a Supplement to Texture-Modified Food for the Elderly

Abstract

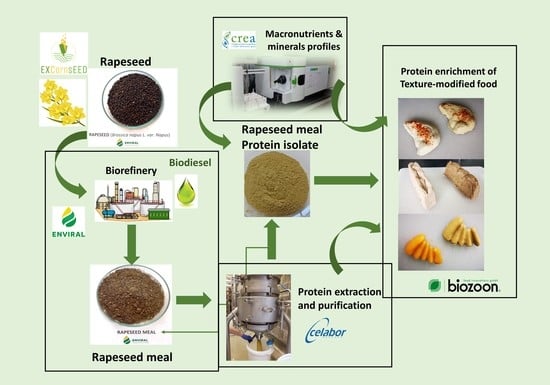

:1. Introduction

2. Materials and Methods

2.1. RSM Protein Isolate

2.2. Formulation and Preparation of Texture-Modified Food

2.3. Sensory Evaluations

2.4. Chemical Analyses

2.5. Quality Assurance

3. Results and Discussion

3.1. Food Formulation

3.2. Sensory Assessment

3.3. Nutritional Evaluations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. The Future of Food and Agriculture—Drivers and Triggers for Transformation. In The Future of Food and Agriculture, no. 3; FAO: Rome, Italy, 2022. [Google Scholar]

- FAO. Food Outlook—Biannual Report on Global Food Markets; FAO: Rome, Italy, 2022. [Google Scholar]

- van Vliet, S.; Kronberg, S.L.; Provenza, F.D. Plant-Based Meats, Human Health, and Climate Change. Front. Sustain. Food Syst. 2020, 4, 128. [Google Scholar] [CrossRef]

- Dominguez, L.J.; Bes-Rastrollo, M.; Basterra-Gortari, F.J.; Gea, A.; Barbagallo, M.; Martinez-Gonzalez, M.A. Association of a Dietary Score with Incident Type 2 Diabetes: The Dietary-Based Diabetes-Risk Score (DDS). PLoS ONE 2015, 10, e0141760. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Li, F.; Wang, L.; Zhang, D. Fruit and Vegetables Consumption and Risk of Hypertension: A Meta-Analysis. J. Clin. Hypertens. 2016, 18, 468–476. [Google Scholar] [CrossRef]

- Probst, Y.C.; Guan, V.X.; Kent, K. Dietary phytochemical intake from foods and health outcomes: A systematic review protocol and preliminary scoping. BMJ Open 2017, 7, e013337. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Springmann, M.; Wiebe, K.; Mason-D’Croz, D.; Sulser, T.B.; Rayner, M.; Scarborough, P. Health and nutritional aspects of sustainable diet strategies and their association with environmental impacts: A global modelling analysis with country-level detail. Lancet Planet Health 2018, 2, e451–e461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zurbau, A.; Au-Yeung, F.; Blanco Mejia, S.; Khan, T.A.; Vuksan, V.; Jovanovski, E.; Leiter, L.A.; Kendall, C.W.C.; Jenkins, D.J.A.; Sievenpiper, J.L. Relation of Different Fruit and Vegetable Sources With Incident Cardiovascular Outcomes: A Systematic Review and Meta-Analysis of Prospective Cohort Studies. J. Am. Heart Assoc. 2020, 9, e017728. [Google Scholar] [CrossRef]

- Naskar, J.; Jan, M.W.; Thomas, G.; George, P.J.; Rumjit, N.P.; Thomas, P.; Lai, C.W. Recent advancements of bionanocomposites in the food industry. In Woodhead Publishing Series in Composites Science and Engineering, Bionanocomposites for Food Packaging Applications; Ahmed, S., Ed.; Woodhead Publishing Series in Composite Sciences and Engineering; Elsevier: Amsterdam, The Netherlands, 2022; pp. 371–411. [Google Scholar] [CrossRef]

- Teleky, B.E.; Martău, G.A.; Vodnar, D.C. Physicochemical effects of Lactobacillus plantarum and Lactobacillus casei cocultures on soy–wheat flour dough fermentation. Foods 2020, 9, 1894. [Google Scholar] [CrossRef]

- Mookerjee, A.; Tanaka, T. Influence of enzymatic treatments on legume proteins for improved functional and nutritional properties: Expansion of legume protein utilization as food ingredients. Curr Opin. Food Sci. 2023, 49, 100974. [Google Scholar] [CrossRef]

- Kotecka-Majchrzak, K.; Sumara, A.; Fornal, E.; Montowska, M. Oilseed proteins—Properties and application as a food ingredient. Trends Food Sci. Technol. 2020, 106, 160–170. [Google Scholar] [CrossRef]

- Tallage Strategie Grains. EU Oilseed Report. Available online: www.strategie-grains.eu (accessed on 10 December 2022).

- Burton, E.J.; Scholey, D.V.; Williams, P.E.V. Types, properties and processing of bio-based animal feed. In Advances in Biorefineries. Biomass and Waste Supply Chain Exploitation; Waldron, K., Ed.; Woodhead Publishing: Sawston, UK, 2014; pp. 771–802. ISBN 9780857095213. [Google Scholar] [CrossRef]

- Di Lena, G.; Sanchez del Pulgar, J.; Lucarini, M.; Durazzo, A.; Ondrejíčková, P.; Oancea, F.; Frincu, R.-M.; Aguzzi, A.; Ferrari Nicoli, S.; Casini, I.; et al. Valorization Potentials of Rapeseed Meal in a Biorefinery Perspective: Focus on Nutritional and Bioactive Components. Molecules 2021, 26, 6787. [Google Scholar] [CrossRef]

- Aider, M.; Barbana, C. Canola proteins: Composition, extraction, functional properties, bioactivity, applications as a food ingre-dient and allergenicity-A practical and critical review. Trends Food Sci. Technol. 2011, 22, 21–39. [Google Scholar] [CrossRef]

- Campbell, L.; Rempel, C.B.; Wanasundara, J.P.D. Canola/rapeseed protein: Future opportunities and directions—Workshop proceedings of IRC 2015. Plants 2016, 5, 17. [Google Scholar] [CrossRef] [PubMed]

- Chmielewska, A.; Kozłowska, M.; Rachwał, D.; Wnukowski, P.; Amarowicz, R.; Nebesny, E.; Rosicka-Kaczmarek, J. Can-ola/rapeseed protein–nutritional value, functionality and food application: A review. Crit. Rev. Food Sci. Nutr. 2021, 61, 3836–3856. [Google Scholar] [CrossRef] [PubMed]

- Jones, O.G. Recent advances in the functionality of non-animal-sourced proteins contributing to their use in meat analogs. Curr. Opin. Food Sci. 2016, 7, 7–13. [Google Scholar] [CrossRef]

- Baugreet, S.; Kerry, J.P.; Allen, P.; Gallagher, E.; Hamill, R.M. Physicochemical characteristics of protein-enriched restructured beef steaks with phosphates, transglutaminase, and elasticised package forming. J. Food Qual. 2018, 2018, 4737602. [Google Scholar] [CrossRef] [Green Version]

- U.S. FDA. GRAS Generally Regarded as Safe Notice GRN No. 327. Cruciferin-Rich Canola/Rapeseed Protein Isolate and Napin-Rich Canola/Rapeseed Protein Isolate; U.S. Food and Drug Administration: Silver Spring, MD, USA, 2010. [Google Scholar]

- Von Der Haar, D.; Müller, K.; Bader-Mittermaier, S.; Eisner, P. Rapeseed proteins-Production methods and possible application ranges. OCL—Oilseeds Fats 2014, 21, D104. [Google Scholar] [CrossRef] [Green Version]

- Gerzhova, A. Extraction des Protéines de Canola Par des Solutions Aqueuses Électro-Activées, Optimisation des Conditions D’extraction et Étude de Leurs Propriétés Techno-Fonctionnelles. Ph.D. Thesis, Université Laval, Québec, QC, Canada, 2016. [Google Scholar]

- Wanasundara, J.P.D.; McIntosh, T.C.; Perera, S.P.; Withana-Gamage, T.S.; Mitra, P. Canola/rapeseed protein-functionality and nutrition. OCL—Oilseeds Fats Crops Lipids 2016, 23, D407. [Google Scholar] [CrossRef] [Green Version]

- Östbring, K.; Malmqvist, E.; Nilsson, K.; Rosenlind, I.; Rayner, M. The effects of oil extraction methods on recovery yield and emulsifying properties of proteins from rapeseed meal and press cake. Foods 2020, 9, 19. [Google Scholar] [CrossRef] [Green Version]

- Salah, K.; Olkhovatov, E.A.; Aïder, M. Effect of canola proteins on rice flour bread and mathematical modelling of the baking process. J. Food Sci. Technol. 2019, 56, 3744–3753. [Google Scholar] [CrossRef]

- Banovic, M.; Sveinsdóttir, K. Importance of being analogue: Female attitudes towards meat analogue containing rapeseed protein. Food Control 2021, 123, 107833. [Google Scholar] [CrossRef]

- United Nations, Department of Economic and Social Affairs, Population Division. World Population Ageing 2019; United Nations: New York, NY, USA, 2020; (ST/ESA/SER.A/444). [Google Scholar]

- DIN Deutsches Institut für Normung e., V. Sensory Analysis-Simple Descriptive Test; DIN 10964:2014-11; Beuth Verlag GmbH: Berlin, Germany, 2014. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis, 19th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2012. [Google Scholar]

- Prosky, L.; Asp, N.G.; Schweizer, T.F.; DeVries, J.W.; Furda, I. Determination of insoluble, soluble, and total dietary fiber in foods and food products: Interlaboratory study. J. Assoc. Off. Anal. Chem. 1988, 71, 1017–1023. [Google Scholar] [CrossRef] [PubMed]

- European Union. Regulation No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers, amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004. Off. J. Eur. Union 2011, L304/18. [Google Scholar]

- Yoshie-Stark, Y.; Wada, Y.; Schott, M.; Wäsche, A. Functional and bioactive properties of rapeseed protein concentrates and sensory analysis of food application with rapeseed protein concentrates. LWT 2006, 39, 503–512. [Google Scholar] [CrossRef]

- Korus, J.; Chmielewska, A.; Witczak, M.; Ziobro, R.; Juszczak, L. Rapeseed protein as a novel ingredient of gluten-free bread. Eur. Food Res. Technol. 2021, 247, 2015–2025. [Google Scholar] [CrossRef]

- Massoulard, A.; Bonnabau, H.; Gindre-Poulvelarie, L.; Baptistev, A.; Preux, P.-M.; Villemonteix, C.; Javerliat, V.; Fraysse, J.-L.; Desport, J.-C. Analysis of the food consumption of 87 elderly nursing home residents, depending on food texture. J. Nutr. Health Aging 2011, 15, 192–195. [Google Scholar] [CrossRef]

- SINU, Società Italiana di Nutrizione Umana. LARN, Livelli di Assunzione di Riferimento di Nutrienti ed Energia per la Popolazione Italiana; IV Revisione; SICS: Milan, Italy, 2016. [Google Scholar]

- Deer, R.R.; Volpi, E. Protein intake and muscle function in older adults. Curr. Opin. Clin. Nutr. Metab. Care 2015, 18, 248–253. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.B.; Wang, Z.; Xu, S.Y. Antioxidant and antithrombotic activities of rapeseed peptides. J. Am. Oil Chem. Soc. 2008, 85, 521–527. [Google Scholar] [CrossRef]

- Dai, C.; Zhang, W.; He, R.; Xiong, F.; Ma, H. Protein breakdown and release of antioxidant peptides during simulated gastrointestinal digestion and the absorption by everted intestinal sac of rapeseed proteins. LWT 2017, 86, 424–429. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Ruan, S.; Lu, F.; Tian, W.; Ma, H. Antihypertensive effect of rapeseed peptides and their potential in improving the effectiveness of captopril. J. Sci. Food Agric. 2021, 101, 3049–3055. [Google Scholar] [CrossRef]

- Stephen, A.M.; Champ, M.M.; Cloran, S.J.; Fleith, M.; van Lieshout, L.; Mejborn, H.; Burley, V.J. Dietary fibre in Europe: Current state of knowledge on definitions, sources, recommendations, intakes and relationships to health. Nutr. Res. Rev. 2017, 30, 149–190. [Google Scholar] [CrossRef] [Green Version]

- CREA. Tabelle di Composizione Degli Alimenti. Available online: https://www.crea.gov.it/en/-/tabella-di-composizione-degli-alimenti (accessed on 10 December 2022).

- CREA; Centro di Ricerca Alimenti e Nutrizione. Linee Guida Per Una Sana Alimentazione; Centro di Ricerca Alimenti e Nutrizione: Roma, Italy, 2018; ISBN 978-88-96597-01-9. Available online: https://www.crea.gov.it/web/alimenti-e-nutrizione/-/linee-guidaper-una-sana-alimentazione-2018 (accessed on 16 November 2022).

- DGE Deutsche Gesellschaft für Ernährung. DGE Quality Standard for Catering with “Meals on Wheels” and in Residential Homes for Elderly; Deutsche Gesellschaft für Ernährung: Bonn, Germany, 2022. [Google Scholar]

- DGE Deutsche Gesellschaft für Ernährung. DGE Quality Standard for Meals in Clinics, 1st ed.; DGE Deutsche Gesellschaft für Ernährun: Bonn, Germany, 2022. [Google Scholar]

- Visser, M.; Volkert, D.; Corish, C.; Geisler, C.; de Groot, L.C.; Cruz-Jentoft, A.J.; Lohrmann, C.; O’Connor, E.M.; Schindler, K.; de van der Schueren, M.A. Tackling the increasing problem of malnutrition in older persons: The Malnutrition in the Elderly (MaNuEL) Knowledge Hub. Nutr. Bull. 2017, 42, 178–186. [Google Scholar] [CrossRef] [Green Version]

- Aguilera, J.M.; Park, D.J. Texture-modified foods for the elderly: Status, technology and opportunities. Trends Food Sci. Technol. 2016, 57, 156–164. [Google Scholar] [CrossRef]

- Rusu, A.; Randriambelonoro, M.; Perrin, C.; Valk, C.; Álvarez, B.; Schwarze, A.-K. Aspects Influencing Food Intake and Approaches towards Personalising Nutrition in the Elderly. J. Popul. Ageing 2020, 13, 239–256. [Google Scholar] [CrossRef] [Green Version]

- Forstner, S.; Rusu, A. Development of personalised food for the nutrition of elderly consumers. In Know Your Food: Food Ethics and Innovation; Wageningen Academic Publishers: Wageningen, The Netherlands, 2015. [Google Scholar]

| RSM Protein Isolate | |||

|---|---|---|---|

| Unit | Batch 1 (Semi-Pilot-Scale) | Batch 2 (Full-Pilot-Scale) | |

| mean ± SD | mean ± SD | ||

| Moisture | g | 4.75 ± 0.02 | 3.35 ± 0.05 |

| Crude protein | g | 85.72 ± 0.34 | 81.72 ± 0.66 |

| Nonprotein N | g | 0.59 ± 0.11 | 0.29 ± 0.08 |

| Ash | g | 0.97 ± 0.17 | 3.22 ± 0.07 |

| Crude fat | g | 0.75 ± 0.06 | 1.69 ± 0.07 |

| Total dietary fiber | g | 3.20 ± 0.26 | 1.70 ± 0.17 |

| Carbohydrate | g | 4.61 ± 0.20 | 8.34 ± 0.57 |

| Potassium | mg | 26.88 ± 5.38 | 18.07 ± 2.92 |

| Phosphorus | mg | 743.18 ± 41.17 | 1370.88 ± 29.28 |

| Sodium | mg | 18.22 ± 0.40 | 3.55 ± 0.19 |

| Magnesium | mg | 6.73 ± 0.46 | 1.72 ± 0.21 |

| Calcium | mg | 91.61 ± 1.52 | 9.23 ± 0.66 |

| Zinc | mg | 0.73 ± 0.01 | 1.29 ± 0.03 |

| Manganese | mg | 0.18 ± 0.00 | 0.07 ± 0.03 |

| Copper | mg | 2.85 ± 0.07 | 1.83 ± 0.05 |

| TM Chicken Control | TM Chicken + RSM Protein | |

|---|---|---|

| Chicken breast (g) | 47.2 | 44.7 |

| Water (g) | 48.0 | 45.5 |

| GELEAhot instant® (g) | 4.0 | 4.0 |

| RSM protein (g) | - | 5.0 |

| Sunflower oil (g) | 0.8 | 0.8 |

| TM Carrots Control | TM Carrots + RSM Protein | |

|---|---|---|

| Carrots (g) | 48.0 | 45.5 |

| Water (g) | 48.0 | 45.5 |

| GELEAhot instant® (g) | 4.0 | 4.0 |

| RSM protein (g) | - | 5.0 |

| TM Bread Control | TM Bread + RSM Protein | |

|---|---|---|

| Bread (g) | 25.0 | 23.5 |

| Water (g) | 58.3 | 54.8 |

| SMOOTHBROT® mix (g) | 16.7 | 16.7 |

| RSM protein (g) | - | 5.0 |

| Batch 1 (Semi-Pilot) | Batch 2 (Full Pilot) | |||

|---|---|---|---|---|

| TM Chicken Control | TM Chicken + RSM Protein | TM Chicken Control | TM Chicken + RSM Protein | |

| mean ± SD | mean ± SD | mean ± SD | mean ± SD | |

| pH | 6.14 ± 0.01 | 5.89 ± 0.10 | 6.01 ± 0.15 | 5.63 ± 0.00 |

| Dry matter (g) | 22.95 ± 0.10 | 26.65 ± 0.01 | 23.45 ± 0.19 | 26.64 ± 0.39 |

| Moisture (g) | 77.05 ± 0.10 | 73.35 ± 0.10 | 76.55 ± 0.19 | 73.37 ± 0.39 |

| Crude protein (g) | 15.73 ± 0.20 | 19.53 ± 0.28 | 15.82 ± 0.34 | 18.80 ± 0.41 |

| Carbohydrates (g) | 3.08 ± 0.20 | 3.09 ± 0.20 | 1.95 ± 0.10 | 1.86 ± 0.10 |

| Ash (g) | 1.07 ± 0.03 | 1.10 ± 0.07 | 1.03 ± 0.04 | 1.20 ± 0.01 |

| Crude fat (g) | 1.87 ± 0.04 | 1.73 ± 0.02 | 2.60 ± 0.02 | 2.40 ± 0.08 |

| Total dietary fiber (g) | 1.20 ± 0.04 | 1.20 ± 0.18 | 2.05 ± 0.35 | 2.37 ± 0.37 |

| Energy value: | ||||

| kcal | 94 | 108 | 99 | 109 |

| kJ | 393 | 452 | 412 | 456 |

| Batch 1 (Semi-Pilot) | Batch 2 (Full Pilot) | |||

|---|---|---|---|---|

| TM Carrots Control | TM Carrots + RSM Protein | TM Carrots Control | TM Carrots + RSM Protein | |

| mean ± SD | mean ± SD | mean ± SD | mean ± SD | |

| pH | 6.45 ± 0.01 | 5.44 ± 0.01 | 6.73 ± 0.02 | 4.74 ± 0.04 |

| Dry matter (g) | 8.40 ± 0.06 | 17.45 ± 0.10 | 9.16 ± 0.10 | 13.32 ± 0.02 |

| Moisture (g) | 91.60 ± 0.06 | 82.55 ± 0.12 | 90.84 ± 0.10 | 86.68 ± 0.02 |

| Crude protein (g) | 0.46 ± 0.08 | 5.62 ± 0.08 | 0.37 ± 0.04 | 4.20 ± 0.06 |

| Carbohydrates (g) | 5.18 ± 0.20 | 7.47 ± 0.25 | 5.69 ± 0.15 | 5.81 ± 0.20 |

| Ash (g) | 0.65 ± 0.07 | 1.12 ± 0.01 | 0.23 ± 0.02 | 0.43 ± 0.01 |

| Crude fat (g) | 0.10 ± 0.01 | 0.10 ± 0.01 | 0.10 ± 0.02 | 0.10 ± 0.02 |

| Total dietary fiber (g) | 2.01 ± 0.02 | 3.14 ± 0.14 | 2.77 ± 0.11 | 2.78 ± 0.28 |

| Energy value: | ||||

| kcal | 27 | 60 | 31 | 47 |

| kJ | 113 | 251 | 128 | 195 |

| Batch 1 (Semi-Pilot) | Batch 2 (Full Pilot) | |||

|---|---|---|---|---|

| TM Bread Control | TM Bread + RSM Protein | TM Bread Control | TM Bread + RSM Protein | |

| mean ± SD | mean ± SD | mean ± SD | mean ± SD | |

| pH | 5.87 ± 0.01 | 5.53 ± 0.02 | 5.74 ± 0.21 | 4.80 ± 0.06 |

| Dry matter (g) | 38.02 ± 0.10 | 41.41 ± 0.10 | 33.28 ± 0.12 | 36.03 ± 0.72 |

| Moisture (g) | 61.98 ± 0.21 | 58.59 ± 0.30 | 66.72 ± 0.12 | 63.97 ± 0.72 |

| Crude protein (g) | 10.78 ± 0.15 | 14.90 ± 0.29 | 8.17 ± 0.13 | 11.51 ± 0.11 |

| Carbohydrates (g) | 18.36 ± 0.16 | 17.79 ± 0.05 | 17.79 ± 0.15 | 16.94 ± 0.10 |

| Ash (g) | 0.94 ± 0.16 | 0.88 ± 0.01 | 0.65 ± 0.04 | 0.72 ± 0.02 |

| Crude fat (g) | 3.11 ± 0.10 | 3.09 ± 0.01 | 2.31 ± 0.02 | 2.19 ± 0.04 |

| Total dietary fiber (g) | 4.83 ± 0.21 | 4.75 ± 0.26 | 4.36 ± 0.06 | 4.67 ± 0.05 |

| Energy value: | ||||

| kcal | 154 | 168 | 133 | 143 |

| kJ | 644 | 703 | 558 | 598 |

| Batch 1 (Semi-Pilot) | Batch 2 (Full Pilot) | |||

|---|---|---|---|---|

| TM Chicken Control | TM Chicken + RSM Protein | TM Chicken Control | TM Chicken + RSM Protein | |

| mean ± SD | mean ± SD | mean ± SD | mean ± SD | |

| Potassium | 295.02 ± 1.96 | 283.44 ± 3.44 | 278.22 ± 11.64 | 248.48 ± 1.97 |

| Phosphorus | 159.23 ± 2.40 | 192.95 ± 11.64 | 144.88 ± 5.03 | 205.68 ± 2.42 |

| Sodium | 171.51 ± 0.87 | 167.60 ± 0.23 | 119.13 ± 3.03 | 107.23 ± 0.72 |

| Magnesium | 23.92 ± 0.09 | 23.57 ± 0.01 | 21.82 ± 0.35 | 19.80 ± 0.22 |

| Calcium | 22.22 ± 0.44 | 27.18 ± 0.40 | 18.14 ± 0.48 | 17.10 ± 0.03 |

| Zinc | 0.39 ± 0.02 | 0.41 ± 0.00 | 0.40 ± 0.01 | 0.43 ± 0.00 |

| Manganese | 0.03 ± 0.00 | 0.04 ± 0.00 | 0.03 ± 0.00 | 0.03 ± 0.00 |

| Copper | 0.02 ± 0.00 | 0.19 ± 0.01 | 0.02 ± 0.00 | 0.11 ± 0.00 |

| Batch 1 (Semi-Pilot) | Batch 2 (Full Pilot) | |||

|---|---|---|---|---|

| TM Carrots Control | TM Carrots + RSM Protein | TM Carrots Control | TM Carrots + RSM Protein | |

| mean ± SD | mean ± SD | mean ± SD | mean ± SD | |

| Potassium | 163.87 ± 8.82 | 242.09 ± 9.40 | 63.54 ± 1.31 | 57.75 ± 2.36 |

| Phosphorus | 14.01 ± 0.93 | 73.55 ± 0.29 | 8.73 ± 0.17 | 79.33 ± 9.71 |

| Sodium | 158.00 ± 12.12 | 240.71 ± 8.74 | 23.65 ± 0.54 | 21.91 ± 0.47 |

| Magnesium | 5.68 ± 0.33 | 8.23 ± 0.12 | 4.89 ± 0.05 | 4.45 ± 0.06 |

| Calcium | 30.11 ± 2.70 | 50.12 ± 0.34 | 30.22 ± 0.16 | 27.28 ± 0.13 |

| Zinc | 0.12 ± 0.01 | 0.22 ± 0.01 | 0.11 ± 0.00 | 0.31 ± 0.01 |

| Manganese | 0.08 ± 0.01 | 0.13 ± 0.00 | 0.07 ± 0.00 | 0.07 ± 0.00 |

| Copper | 0.01 ± 0.00 | 0.23 ± 0.00 | 0.01 ± 0.00 | 0.21 ± 0.00 |

| Batch 1 (Semi-Pilot) | Batch 2 (Full Pilot) | |||

|---|---|---|---|---|

| TM Bread Control | TM Bread + RSM Protein | TM Bread Control | TM Bread + RSM Protein | |

| mean ± SD | mean ± SD | mean ± SD | mean ± SD | |

| Potassium | 125.17 ± 18.45 | 127.12 ± 6.61 | 107.79 ± 0.46 | 100.85 ± 2.34 |

| Phosphorus | 60.10 ± 8.32 | 105.57 ± 3.17 | 47.05 ± 0.22 | 107.74 ± 3.09 |

| Sodium | 175.35 ± 4.56 | 203.69 ± 5.23 | 124.14 ± 1.41 | 118.87 ± 2.69 |

| Magnesium | 22.99 ± 1.40 | 20.82 ± 0.48 | 14.90 ± 0.31 | 14.50 ± 0.13 |

| Calcium | 68.55 ± 1.13 | 72.52 ± 1.56 | 43.61 ± 0.36 | 43.87 ± 0.96 |

| Zinc | 0.68 ± 0.07 | 0.72 ± 0.01 | 0.48 ± 0.01 | 0.73 ± 0.03 |

| Manganese | 0.65 ± 0.10 | 0.68 ± 0.02 | 0.43 ± 0.01 | 0.43 ± 0.00 |

| Copper | 0.07 ± 0.00 | 0.24 ± 0.01 | 0.08 ± 0.00 | 0.22 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Lena, G.; Schwarze, A.-K.; Lucarini, M.; Gabrielli, P.; Aguzzi, A.; Caproni, R.; Casini, I.; Ferrari Nicoli, S.; Genuttis, D.; Ondrejíčková, P.; et al. Application of Rapeseed Meal Protein Isolate as a Supplement to Texture-Modified Food for the Elderly. Foods 2023, 12, 1326. https://doi.org/10.3390/foods12061326

Di Lena G, Schwarze A-K, Lucarini M, Gabrielli P, Aguzzi A, Caproni R, Casini I, Ferrari Nicoli S, Genuttis D, Ondrejíčková P, et al. Application of Rapeseed Meal Protein Isolate as a Supplement to Texture-Modified Food for the Elderly. Foods. 2023; 12(6):1326. https://doi.org/10.3390/foods12061326

Chicago/Turabian StyleDi Lena, Gabriella, Ann-Kristin Schwarze, Massimo Lucarini, Paolo Gabrielli, Altero Aguzzi, Roberto Caproni, Irene Casini, Stefano Ferrari Nicoli, Darleen Genuttis, Petra Ondrejíčková, and et al. 2023. "Application of Rapeseed Meal Protein Isolate as a Supplement to Texture-Modified Food for the Elderly" Foods 12, no. 6: 1326. https://doi.org/10.3390/foods12061326