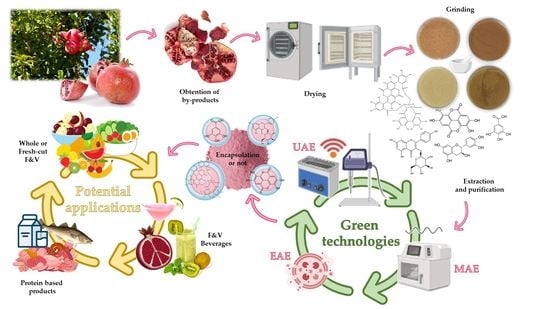

From Pomegranate Byproducts Waste to Worth: A Review of Extraction Techniques and Potential Applications for Their Revalorization

Abstract

:1. Background—Food Losses and Food Waste

2. Nutritional Composition of Pomegranate Byproducts

3. Scientific Literature Review

4. Pomegranate Peel Phenolic Compounds Extraction Techniques

4.1. Ultrasound-Assisted Extraction

4.1.1. Fundamentals

- i

- Contact with the solution: an ultrasonic probe is submerged directly into the solution (minimum energy losses), while in a US bath, the vessel container is immersed.

- ii

- Intensity of US: it is higher in the US probe than in the bath.

- iii

- Maximum power achieved: in a US probe, it is the nominal power, while in a US bath, the nominal power is the minimum that can be increased due to the modulators.

4.1.2. Ultrasound-Assisted Extraction from Pomegranate Peel

| Byproduct Characteristics | F (kHz) | Power Related Parameters | Solvent | Solid:Liquid Ratio | t (min) | T (°C) | Other Information | Extract Characterization | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Freeze-drying Powders < 254 µm cv information NA | NA | 500–1050 W | EtOH (40–80%) | 1:10/1:50 | 10–50 | NA | NA | Pn | [25] |

| Vacuum oven (45 °C, 36 h) Powders < 500 µm Bhagwa cv | NA | 350 W (Pulsed mode: A 10–100%) | EtOH (50%) | 0.1:10/0.3:10 0.5:10/0.6:10 0.8:10/1:10 | NA | NA | Duyt cycle: 10–90% | TPC, TFC, AOX (DPPH and ABTS), TAC | [26] |

| Cabinet hot drier (40 °C) Powders < 635 µm cv information NA | 20 | 2.4 to 59.2 W/cm2 (continuous) 59.2 W/cm2 (pulsed) | NA | 1:50 | 2–90 | 25 | Area probe: 1.267 cm2 Pulse duration/Interval: 2/1, 3/1, 4/1, 5/1, 6/1, 7/1, 9/1, 12/1, 2/5, 3/5,4/5, 5/5, 6/5, 7/5, 9/5, 12/5, 2/15, 3/15, 4/15, 5/15, 6/15, 7/15, 9/15, 12/15 Number of pulse repetition: 30, 60, 90, 120, 180, 270, 360, 540, 720 | TPC, AOX (DPPH) | [27] |

| Drier (40 °C, 48 h) cv and particle size information NA | 20 | 130 W (Pulsed mode: A 20 and 60% NP) | MetOH, EtOH, EtAc, MeOH (50%) | 1:10/1:50 | 4–60 | 25–45 | Ti–Al–V sonoprobe (13 mm) Pulse duration/pulse interval ratio 5/15 and 2/1 | Ph | [28] |

| Vacuum oven (40 °C) Powder 125–150 μm cv information NA | 30 | 50 W (A 30–70% NP) | EtOH (80%) | 1:40/1:120 | 5–50 | NA | Duty cycle (60–100%) Probe diameter 3 mm Length 80 mm | Pn | [32] |

| Air oven (40 °C, 18 h) Powders 3 mm cv information NA | 30.8 | 0–100 W/L | EtOH (0–100%) | 1:40 | 0–240 | 20–60 | NA | TPC, AOX (DPPH) | [29] |

| Microwave vacuum oven (45 °C, 36 h) Powders < 508 µm Kabuli cv | 20 | 700 W (A 40–80%) | Ac (30–90%) | 1:10/1:30 | 10–20 | 45 | Probe half-inch diameter Pulse-on and pulse-off time of 10 s. | Tn | [33] |

| Air oven (60 °C, 48 h) Powder 600–800 μm cv information NA | 40 | NA | EtOH (24–75%) | 1:3/1:16 | 4–55 | 26–93 | NA | EA | [30] |

| Fresh peel (more information NA) Small-grinded pieces (fine peel paste, 4 °C) cv information NA | 20 | 400–1600 W/L | NA | 2:10 | 5–50 | 30–70 | Pulsed mode: ‘on’ time (5 s) Pulse interval ‘off’ time (3 s) Probe: 3 cm submergence of sonicator | TPC | [34] |

| Dried (more information NA) Powders < 0.5 mm cv information NA | 40 | 500 W (A 50–80%) | MetOH, (30–70%) | 1:15 | 5–15 | 40 | Probe: 6 mm diameter, dipped up to 2 cm Duty cycle: 0.2–0.8 | TPC, TFC, AOX (DPPH and FRAP) | [35] |

| Laminar airflow drying oven (50 °C, 24 h) Powder particle size and cv information NA | 24 | NA | NA | 1:10 | 5–20 | 50 | Titanium probe: 14-mm diameter | TPC, EA, ChlA, GA | [36] |

| Hot air oven (40 °C, 48 h) Fine powder (more information NA) cv information NA | 45 | 360 W (A 40–100%) | NA | 0.1:1/1:10 | 5–45 | 40–80 | pH 3.5 to 6.0 | TPC | [37] |

| Technique information NA Powder 140–425 μm Sishe Kape- Ferdos cv | 20 | 400 W (A 20, 60 and 100%) | NA | 1:4 | 5–15 | NA | NA | TPC | [38] |

| Forced air oven (70 °C, 48 h) Powder particle size distribution: 25.4–0.105 mm (56%); 0.105–0.075 mm (17.9%); 0.075–0.037 mm (14.5%); <0.037 mm (11.6%) Brazilian Molar cv | 37–80 | 180 W (continuous, pulse, and sweep modes) | EtOH (70%) | 1:25 | 20 | 40–70 | NA | Pn, EA, TPC | [39] |

| Drier (40 °C, 48 h) Powder < 0.2 mm cv information NA | 20 | 130 W (Pulsed mode; 20–60%) | Sunflower oil Soy oil | 1:10/3:10 | NA | 10–60 | Ti-Al-V sonoprobe (13 mm) | TCC | [31] |

| Air-drier (7 days, 20 °C) Powder < 180 μm Malas cv | 24 | 53, 79, and 105 W/cm2 (pulse mode) | EtOH (70%) | 1:10 | 2–10 | NA | Area probe: 1.53 cm2 Duty cycle: 50%, 70%, and 90% | Pn, HbA | [40] |

| Traditional heating oven (40 °C, 48 h). Microwave drying (T < 100 °C, <5 min). Powder < 150 μm. Wonderful and Akko cv | 26 | 200 W (pulsed mode; A 50%) | EtOH (70%) | 1:40 | 10 | 45 | Duty cycle: 80% | EA, Pn | [41] |

| Hot air oven (50 °C, 48 h) Fine powder (more information NA) cv information NA | NA | NA | Ac, MetOH, EtOH (50–75%) | 1:20 | NA | 45 | NA | TPC, TFC | [42] |

| Air dried Room Temperature Particle size 0.3 mm cv information NA | 20 | 400 W A 70% | EtOH (70%) | 1:30 | 30 | 40 | Probe tip 2 cm 22.5% duty cycle | TPC, TFC, AOX (DPPH and FRAP) | [42] |

| Ventilated oven (42 °C, 3–4 days) Particle size 0.5 mm cv information NA | NA | NA | H2O; EtOH (70%); EtOH (100%); Ac (70%); Ac (100%); | NA | 23 | 45 | NA | TPC, EA, Pn, Individual Fvs | [43] |

| Convective oven 60 °C 22 h Particle size 420 μm Mollar de Elche cv | 20 | 750 W | H2O | 4:40 | NA | NA | Probe diameter 13 mm titanium | TPC, AOX (DPPH and ABTS) | [44] |

| Blanching (80 °C 3 m) + Tray drier 40 °C Particle size < 1 mm Wonderful cv | 40 | 700 W | EtOH (70%) | 1:15 | 60 | 40 °C | Ultrasound bath | TPC, TFC, TAC, Vit C, AOX (DPPH, FRAP and ABTS) | [45] |

| Tray drier 40 °C Particle size < 0.25 mm Bhagwa cv | 20 | 20–40% A | EtOH (70%) | 1:20 | 10–20 | 40–60 | 3 mm of probe diameter | Pn, EA, GA | [46] |

| Oven drier (more information NA) Particle size: size distribution using sieves: 0.85, 0.425, 0.25 and 0.18 mm cv information NA | 35 | 140 W | EtOH (30–50–70%) | 0.2:10 | 10–30 | 30–60 | Ultrasound bath | TPC, AOX (FRAP and DPPH) | [47] |

| Oven drier (45 °C 48 h) Particle size and cv information NA | 40 | NA | NA | 1:10 | 0–60 | 35–45 | Enzymatic pre-treatment | AOX (DPPH), TPC | [48] |

| Hot air in cabinet drier (40 °C) Particle size < 0.420 mm Wonderful cv | 20 | Continuous intensity: 2.4, 4.7, 7.1, 18.9, 23.7, 30.8, 37.9, 45.0, 52.1, and 59.2 W/cm2 | H2O | 1:50 | 2–90 min | 25 | Probe with area of 1.267 cm (continuous) | AOX (DPPH) | [27] |

| Hot air in cabinet drier (40 °C) Particle size < 0.420 mm Wonderful cv | 20 | Pulsed mode: 2.4, 4.7, 7.1, 18.9, 23.7, 30.8, 37.9, 45.0, 52.1, and 59.2 W/cm2 | H2O | 1:50 | 25 | Probe with area of 1.267 cm Pulsed duration/interval: 2/1, 3/1, 4/1, 5/1, 6/1, 7/1, 9/1, 12/1, 2/5, 3/5, 4/5, 5/5, 6/5, 7/5, 9/5, 12/5, 2/15, 3/15, 4/15, 5/15, 6/15, 7/15, 9/15, 12/15 Number pulse repetition: 30, 60, 90, 120, 180, 270, 360, 540, 720 | AOX (DPPH) | [27] | |

| Air-dried at 25 °C Particle size 0.75–2 mm cv information NA | NA | NA | EtOH (10–30–50–70–90%) | 1:10; 1:20; 1:30; 1:40; 1:50 | 5–65 | 25–80 | Pn, EA, GA, TPC | [49] | |

| Forced air oven 70 °C 48 h Large particle size: 0.297–1.410 mm, mean: 1.05 mm Small particle size: 0.177–1 mm, mean: 0.68 mm Wonderful cv | 19 | 0–800 W at the generator, or 0–38.5 W at the tip of the probe | H2O; EtOH (30–50–70%) | NA | 10 | 50–100 | 13 mm diameter probe Number of Cycles: 5 Assisted by pressurized liquid | Pn, EA, P | [50] |

4.2. Microwave-Assisted Extraction

4.2.1. Fundamentals

4.2.2. Microwave-Assisted Extraction from Pomegranate Peel

4.3. Enzymatic-Assisted Extraction

4.3.1. Fundamentals

- i.

- Solute concentration

- ii.

- Enzyme concentration: when the enzyme concentration increases, the reaction rate will increase until a point when there is no positive or negative effect of the continued increase in enzyme concentration.

- iii.

- Temperature: the optimum temperature for maximum enzyme activity depends on the type of enzyme since most of them are proteins which are denaturized and inactivated by heat.

- iv.

- pH: enzymes have a characteristic pH value for their optimum activity, being acidophilic (optimal pH values are <7) and alkalophilic enzymes (pH > 7). At pH values greater or lower than the optimal, the enzymatic activity—and therefore the reaction rate—decreases. Furthermore, the optimal value of enzyme concentration, temperature, and pH depends on the conditions of the medium/matrix in which it is found.

- v.

- The presence of inhibitors: molecules that temporarily or permanently interact with enzymes to reduce their activity and/or reaction rate. The inhibition can be classified as:

- a.

- Competitive: the inhibitor structure is like the substrate. The key bioactive compound and the complex substrate-enzyme is not formed.

- b.

- Acompetitive: the inhibitor structure is attached to the complex-enzyme.

- c.

- Non-competitive: the inhibitor attached to the active center of the enzyme and enzyme is misshapen.

- d.

- Mixed.

4.3.2. Enzyme-Assisted Extraction from Pomegranate Peel

| Byproduct Characteristics | Combined with | P (MPa) | Enzymes | Inactivation Enzymes | Solid/Liquid Ratio | t (min) | T (°C) | Extract Characterization | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Drier (40 °C) cv and particle size information NA | High pressure | 300 | 4% (vol) of pectinase 4% (vol) of cellulase | Water bath 90 °C 5 min Later ice bath | 1.6:100 | 15 | NA | TPC Individual Ph | [66] |

| Dried Room Temperature Particle size < 0.178 mm cv information NA | Supercritical carbon dioxide | NA | Pectinase, protease, and cellulase (25:25:50) | Water bath 90 °C 5 min Later ice bath | 2.8–3.9% of enzymes in the solvent | 60–120 | 35–60 | TPC | [67] |

| Drier (45 °C 48 h) cv and particle size information NA | Ultrasounds (Bath 40 kHz) | NA | Viscozyme® concentration 0–2 mL/100 mL solvent | NA | 1:10 | 0–60 | 30–50 | TPC, TFC, AOX (DPPH) | [48] |

| Dried (more information NA) cv and particle size information NA | Microwave (300, 400 and 600 W) | NA | Viscozyme® concentration 0.6% (v/w) pH 4.5 and 40 °C | NA | 1:20, 1:30, 1:40 g/mL EtOH 30% acidified | 90–150 | NA | AOX (FRAP and CUPRAC), TPC | [65] |

5. Pomegranate Peel Byproducts Incorporation Techniques

5.1. Powders/Flours

5.2. Liquid Extracts

5.3. Encapsulation

6. Potential Applications in the Food Industry

6.1. Fresh Whole F&V

6.2. Minimally Processed, or Fresh-Cut F&V

6.3. F&V Based Beverages

| Matrix | Pomegranate Peel Byproduct | Extraction | Incorporation Method | Benefit | Ref. | |

|---|---|---|---|---|---|---|

| Fresh whole F&V (pre- and postharvest) | Tomato | Drier (50–60 °C, 72 h) Fine powder (more information NA) cv information NA | Ratio 3:10 EtOH 48 h + evaporator (65 °C) + re-dissolved in sterile distilled water (0.05%, 0.5%, 1% and 5% w/v) | Preharvest. Tomato plants were sprayed in the leaves (bacteria inoculation) with the aqueous extract + 24 h drying | Antibacterial activity at least 15 days Replacing, reducing, or even alternating treatments involving copper compounds | [108] |

| Sage herb | Air dried (more information NA) Grinder (more information NA) cv information NA | 1:10 solid–liquid ratio in water or EtOH 80% 24 h + evaporator + water dilution | Preharvest. Added in the soil (2, 4, and 6 g per plot) | Higher dry mass and essential oils Inhibition of free radical scavenging | [109] | |

| Olive | Oven drier (40 °C) Powder home grinder (more information NA) Wonderful cv | 120 g/L EtOH solvent (50 and 80%) + 1% Citric acid | Postharvest. Treatment of 1 × 1-mm injuries and inoculated (C. acutatum) by 10 µL of pomegranate peel extract (12, 1.2, or 0.12 g/L) | Reduction of fungal and bacterial population | [110] | |

| Potato tubers | Air drier (28 °C, 10–15 days) Fine powder (more information NA) Baladi cv | 1:10 solid–liquid (MetOH) 48 h 28 °C + evaporator + oven 50 °C 48 h | Postharvest. Wound (3 × 3 mm φ and deep) + inoculation (F. sambucinum) (24 h) + dipping (1.25, 2.5, 5, 10, and 20 mg/mL water) + air dried (2 h at 28 °C). | Antifungal activity on the mycelial growth and spore germination | [111] | |

| Strawberry | Drying and particle size information NA Dente di caballo cv | US 40 °C 80% A 3 min (3 on, 8 off) Ratio 1:10 (H2O 25%, propanol 25%, ethanol 25% and methanol 25%) + evaporator + Freeze-drier + re-dissolved in water | Postharvest. Immersion (30 s in a 2 L solution of pomegranate peel extract) + air-drying (1 h) | Extension of shelf life Substitution of synthetic pesticides | [112] | |

| Sweet cherry | Oven drier (40 °C) Particle size NA Mollar de Elche cv | EtOH solvent (50 and 80%) + 1% Citric acid +evaporator + Water dilution | Postharvest. Dipping (2 min) in the pomegranate extract (12, 2.4 or 1.2 g/L) + air drying (2 h, 28 °C) + storage at 1 °C | Inhibition of all fungal spore germination | [113] | |

| Fresh whole F&V (pre- and postharvest) | Sweet cherry | Oven drier (40 °C) Fine powder < 470 µm cv information NA | 1:8 solid–liquid ratio (Water 28 °C 24 h) | Postharvest. Immersion in pomegranate peel extracts (3 min 20 °C) + room temperature drying | Pomegranate peel extracts and calcium sulphate coatings, alone or in combination, decreased weight loss, decay, respiration rate, and increased acidity, firmness, ascorbic acid, DPPH, TPC, and TAC | [114] |

| Apple | Oven drier (40 °C) Particle size NA Mollar de Elche cv | EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Postharvest. Wounds treated with 10 μL of pomegranate peel extract (12, 1.2 or 0.12 g/L) + inoculation (10 μL P. expansum) | Inhibition of fungal spore germination and decay of artificial inoculations | [113] | |

| Mango | Freeze drying (−45 °C, 94 h) Particle size and cv information NA | MetOH 45 °C 30 min + Bath US + evaporator + water dilution | Postharvest. Chitosan (2%) in 0.5% citric acid solution + Pullulan (2%) in water (50:50 ratios). During stiring: 1% glycerol + 5% of pomegranate peel extract (0.02 g/mL). Dipping for 2 min | Increase of firmness, TPC and AOX. Prolonged the shelf life | [115] | |

| Apricot | Drier (60 °C, 48 h) Particle size < 0.251 mm cv information NA | 80% EtOH 25 °C + evaporator | Postharvest. Chitosan coating solution (1% chitosan in glacial acetic 1% + 0.8% glycerol + Tween 80 + 0.50, 0.75, and 1% pomegranate peel extract) | Reduction of % decay and weight loss. Maintenance of DPPH radical scavenging activity, ascorbic acid content, titratable acidity and firmness. | [116] | |

| Figs | Air dried few days (more information NA) Pulverized (more information NA) cv information NA | Alcoholic buffer (EtOH 50%) | Postharvest. Alginic acid: agar (70:30) + 0.25 and 0.5% pomegranate peel extract Dipping in the coating solution + coating gelation | Prolonged the shelf life | [117] | |

| Dates | Drier (48 °C, 52 h) Ground peels (more information NA)cv information NA | EtOH 70% + evaporator + Water dilution | Postharvest. 1% Chitosan, 1% nanochitosan or 1% pomegranate peel extract in 1% glacial acetic | Growth inhibition of any fungal spore after 48 h of coating. | [118] | |

| Citrus | Hot air drier (50 °C, 48 h) Particle size 0.250 mm cv information NA | 2.5:10 Solid–liquid ratio (Ac, EtOH, MetOH, H2O, DMSO) + shaking (6 h) + re-extracted with water evaporation | Postharvest. Immersion of wounded lemons (2 × 1 mm long and wide tip) in pomegranate peel extract (pre-infection and post-infection with P. digitatum) + air drying | Prevention and control of P. digitatum | [119] | |

| Fresh whole F&V (pre- and postharvest) | Grapefruit | Oven drier (40 °C) Particle size information NA Mollar de Elche cv | EtOH solvent (50 and 80%) + 1% citric acid evaporator + water dilution | Postharvest. Wounds treated with 10 μL of pomegranate peel extract (12, 1.2 or 0.12 g/L) + inoculation 10 μL P. digitatum and P. italicum | Inhibition of all fungal spore germination and decay of artificial inoculations | [120] |

| Lemon | Oven drier (40 °C) Particle size information NA Mollar de Elche cv | EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Postharvest. Wounds treated with 10 μL of pomegranate peel extract (12, 1.2 or 0.12 g/L) + inoculation 10 μL P. digitatum and P. italicum | Inhibition of all fungal spore germination and decay of artificial inoculations | [113,120] | |

| Mandarin | Drier (70 °C, 48 h) Ground peels (more information NA) Shirine Shahvar cv | 0.25:10 solid–liquid ratio (60% EtOH + 0.1% citric acid) | Postharvest. Wounded (1 × 2 mm φ and depth) + dipping 1 min in pomegranate peel extract concentrations (25, 50, 75, 100%) + inoculation (P. italicum and P. digitatum) + drying | Reduction of % infected wound and lesion φ (75% or/and 100% extract). Increase of TPC, TFC, and PAL activity (75% or/and 100% extract) | [121] | |

| Orange | Drier (35 °C, 2 days) Particle size NA Gabsi cv | 1:10, 0.6:10, 0.3:10 solid–liquid ratio (MetOH or Water) + evaporated + drying (40 °C or freeze-drying) + re-dissolved in water | Postharvest. Chitosan coating solution (1% chitosan in glacial acetic 1% + 0.5% Locust bean gum + 20% glycerol + 7, 18, and 36% dry waster/MetOH pomegranate peel extract). Wounded oranges (4 times: 3 × 3 mm φ × deep) + Inoculation (20 μL of a P. digitatum) + drying + dipping in different coating solutions (2 min) | Controlled growth of Penicillium digitatum Reduction of postharvest decay | [122] | |

| Orange | Oven drier (40 °C) Particle size NA Mollar de Elche cv | EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Postharvest. Wounded oranges (3 times 2 × 2 mm φ and deep) + 20 μL pomegranate peel extract (12 g/L) + Inoculation (20 μL of a P. digitatum) + 1% citric acid + drying | Enhanced defense pathways (antibiotic biosynthesis) | [123] | |

| Fresh whole F&V (pre- and postharvest) | Guava | Drier (60 °C, 72 h) Particle size 0.420 mm Bhagwa cv | 1:10 solid–liquid ratio (80% EtOH) + evaporation | Postharvest. Chitosan (1% chitosan in glacial acetic 1% + 0.75% glycerol) and alginate solution (2% alginate + 10% glycerol + 2% calcium chloride) with 1% pomegranate peel extract | Preserved quality for 20 d under refrigeration | [124] |

| Capsicum | Drier (60 °C, 72 h) Particle size 0.420 mm Bhagwa cv | 1:10 solid–liquid ratio (80% EtOH) + evaporation | Postharvest. Chitosan (1% chitosan in glacial acetic 1% + 0.75% glycerol) and alginate solution (2% alginate + 10% glycerol + 2% calcium chloride) with 1% pomegranate peel extract | Inhibition of microbial growth. Preserved sensory quality. Extension of shelf life up to 25 d at 10 °C | [125] | |

| Pear | Drier (60 °C, 72 h) Particle size 0.420 mm Bhagwa cv | 1:10 solid–liquid ratio (80% EtOH) + evaporation | Postharvest. Chitosan (1% chitosan in glacial acetic 1% + 0.75% glycerol) and alginate solution (2% alginate + 10% glycerol + 2% calcium chloride) with 2% pomegranate peel extract | Lowered the cell wall degrading enzymes activity (firmness preservation) | [126] | |

| Fresh-cut/Minimally processed F&V | Fruit salad: nectarine and pineapple in cubes covered with fructose syrup | Oven drier (38 °C, 48 h) Particle size 500 mm Wonderful cv | Powder | 2.5–5% (w/v) of pomegranate peel powder at the container bottom | Inhibition of mesophilic bacteria, total psychrotrophic microorganisms, yeasts, and lactic acid bacteria No negative effect on sensory characteristics | [127] |

| Fresh-cut pear, apple and melon (plugs) | Oven drier (40 °C) Particle size NA Mollar de Elche cv | EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Inoculated plugs were dipped (10 min, 150 rpm) + dried (25 °C 30 min) | Reduction of Listeria monocytogenes | [128] | |

| Fresh-cut Golden apple wedges: thickness 30-mm and 30 g | Drying and particle size information NA Dente di cavallo cv | Pulsed UAE (10 min, <50 °C, 1:40, 26 kHz, 200 W, 40% A, 50% duty cycle) + encapsulation with pectin from citrus peel by spray drying | Enrichment with microencapsulates reconstituted in water 1:1 | Reduction of enzymatic browning. Color preservation | [129] | |

| Beverages | Carrot juice | Oven drier (40 °C) Grounded in a colloid mill (more information NA) cv information NA | High pressure-assisted extraction | 5 mg pomegranate peel extract per mL of carrot juice | Improvement of microbiological safety and AOX during storage. Color preservation | [130,131] |

| Beverages | Apple juice | Oven drier (55 °C, 12 h) Particle size and cv information NA | Maceration extraction (1:50, 80% EtOH 1 h shaking) | Different% of pomegranate peel extract (0–2%) | Enhancing sensory quality and AOX. Low toxicity with 1% of pomegranate peel extract | [132] |

| Kiwi juice | Information NA | Commercial pomegranate extract (PureBulk, Roseburg) | Extract incorporation (180 μg/mL kiwi juice) + US bath (40 kHz, 180 W, 20 °C, 10–30 min) | US and pomegranate extract combined treatment: higher reductions on yeast and molds | [133] | |

| Red wine | Green decoction: Boiled in water 60 min (1:40) Freeze-drying of the extract Wonderful cv | Powder | Purification to obtain the tannins. 8 analyzed tannins (1 g L−1 wine solution) | Increase of protein stability Increase of color stability Reduction of sulfites | [134] | |

| Symbiotic drink powder | Hot oven (40 °C, 48 h) Particle size Kitchen-miller (more information NA) cv information NA | Ethanolic extract (80%; 1:15) + evaporator + Freeze-drier | Formulation: beetroot peel extract powder (3%), pomegranate peel extract powder (1%), grape pomace extract powder (1.5%), quince seed gum (0.5%), stevia (4%), mint (0.1%) and water (89.9%). Pasteurization: 72 °C, 90 s | Maintenance of L. casei viability of the recommended level of 10−7 CFU/g | [135] |

7. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. Technical Platform on the Measurement and Reduction of Food Loss and Waste. 2022. Available online: https://www.fao.org/platform-food-loss-waste/en/ (accessed on 20 July 2022).

- FAO. Food Loss and Waste Database. 2022. Available online: https://www.fao.org/platform-food-loss-waste/flw-data/en/ (accessed on 20 July 2022).

- López–Gómez, A.; Ros–Chumillas, M.; Buendía-Moreno, L.; Martínez–Hernández, G.B. Active Cardboard Packaging with Encapsulated Essential Oils for Enhancing the Shelf Life of Fruit and Vegetables. Front. Nutr. 2020, 7, 559978. [Google Scholar] [CrossRef] [PubMed]

- Magangana, T.P.; Makunga, N.P.; Fawole, O.A.; Opara, U.L. Processing Factors Affecting the Phytochemical and Nutritional Properties of Pomegranate (Punica granatum L.) Peel Waste: A Review. Molecules 2020, 25, 4690. [Google Scholar] [CrossRef] [PubMed]

- Ko, K.; Dadmohammadi, Y.; Abbaspourrad, A. Nutritional and Bioactive Components of Pomegranate Waste Used in Food and Cosmetic Applications: A Review. Foods 2021, 10, 657. [Google Scholar] [CrossRef] [PubMed]

- Cano-Lamadrid, M.; Artés-Hernández, F. By-Products Revalorization with Non-Thermal Treatments to Enhance Phytochemical Compounds of Fruit and Vegetables Derived Products: A Review. Foods 2022, 11, 59. [Google Scholar] [CrossRef] [PubMed]

- Cano-Lamadrid, M.; Valverde, J.M.; Lipan, L.; Carbonell-Barrachina, Á.A.; Sendra, E. Introduction. The Age of Clean Label Foods. In The Age of Clean Label Foods; Galanakis, C.M., Ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–35. ISBN 978-3-030-96698-0. [Google Scholar]

- Artés-Hernández, F.; Castillejo, N.; Martínez-Zamora, L.; Martínez-Hernández, G.B. Phytochemical Fortification in Fruit and Vegetable Beverages with Green Technologies. Foods 2021, 10, 2534. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Sánchez, A.; Alacid, F.; Rubio-Arias, J.A.; Fernández-Lobato, B.; Ramos-Campo, D.J.; Aguayo, E. Consumption of Watermelon Juice Enriched in L-Citrulline and Pomegranate Ellagitannins Enhanced Metabolism during Physical Exercise. J. Agric. Food Chem. 2017, 65, 4395–4404. [Google Scholar] [CrossRef] [PubMed]

- Carrillo, C.; Nieto, G.; Martínez-Zamora, L.; Ros, G.; Kamiloglu, S.; Munekata, P.E.S.; Pateiro, M.; Lorenzo, J.M.; Fernández-López, J.; Viuda-Martos, M.; et al. Novel Approaches for the Recovery of Natural Pigments with Potential Health Effects. J. Agric. Food Chem. 2022, 70, 6864–6883. [Google Scholar] [CrossRef] [PubMed]

- Turker, S.; Polat, A.A.; Bindak, R. Seasonal Changes of Carbohydrates in Fruit Peels, Leaves and Shoots of Three Pomegranate (Punica granatum L.) Cultivars Grown in Upper Euphrates Basin. Sci. Hortic. 2022, 304, 111315. [Google Scholar] [CrossRef]

- Abid, M.; Renard, C.M.G.C.; Watrelot, A.A.; Fendri, I.; Attia, H.; Ayadi, M.A. Yield and Composition of Pectin Extracted from Tunisian Pomegranate Peel. Int. J. Biol. Macromol. 2016, 93, 186–194. [Google Scholar] [CrossRef]

- Talekar, S.; Patti, A.F.; Vijayraghavan, R.; Arora, A. An Integrated Green Biorefinery Approach towards Simultaneous Recovery of Pectin and Polyphenols Coupled with Bioethanol Production from Waste Pomegranate Peels. Bioresour. Technol. 2018, 266, 322–334. [Google Scholar] [CrossRef]

- Viuda-Martos, M.; Ruiz-Navajas, Y.; Martin-Sánchez, A.; Sánchez-Zapata, E.; Fernández-López, J.; Sendra, E.; Sayas-Barberá, E.; Navarro, C.; Pérez-Álvarez, J.A. Chemical, Physico-Chemical and Functional Properties of Pomegranate (Punica granatum L.) Bagasses Powder Co-Product. J. Food Eng. 2012, 110, 220–224. [Google Scholar] [CrossRef]

- Gullón, P.; Astray, G.; Gullón, B.; Tomasevic, I.; Lorenzo, J.M. Pomegranate Peel as Suitable Source of High-Added Value Bioactives: Tailored Functionalized Meat Products. Molecules 2020, 25, 2859. [Google Scholar] [CrossRef]

- Man, G.; Xu, L.; Wang, Y.; Liao, X.; Xu, Z. Profiling Phenolic Composition in Pomegranate Peel From Nine Selected Cultivars Using UHPLC-QTOF-MS and UPLC-QQQ-MS. Front. Nutr. 2022, 8. [Google Scholar] [CrossRef]

- Cano-Lamadrid, M.; Lech, K.; Calín-Sánchez, Á.; Rosas-Burgos, E.C.; Figiel, A.; Wojdyło, A.; Wasilewska, M.; Carbonell-Barrachina, Á.A. Quality of Pomegranate Pomace as Affected by Drying Method. J. Food Sci. Technol. 2018, 55, 1074–1082. [Google Scholar] [CrossRef]

- Alcaraz-Mármol, F.; Nuncio-Jáuregui, N.; Calín-Sánchez, Á.; Carbonell-Barrachina, Á.A.; Martínez, J.J.; Hernández, F. Determination of Fatty Acid Composition in Arils of 20 Pomegranates Cultivars Grown in Spain. Sci. Hortic. 2015, 197, 712–718. [Google Scholar] [CrossRef]

- Panja, P. Green Extraction Methods of Food Polyphenols from Vegetable Materials. Curr. Opin. Food Sci. 2018, 23, 173–182. [Google Scholar] [CrossRef]

- Gallo, M.; Ferrara, L.; Naviglio, D. Application of Ultrasound in Food Science and Technology: A Perspective. Foods 2018, 7, 164. [Google Scholar] [CrossRef]

- Chemat, F.; Zill-E-Huma; Khan, M.K. Applications of Ultrasound in Food Technology: Processing, Preservation and Extraction. Ultrason. Sonochemistry 2011, 18, 813–835. [Google Scholar] [CrossRef]

- Khadhraoui, B.; Fabiano-Tixier, A.S.; Robinet, P.; Imbert, R.; Chemat, F. Ultrasound Technology for Food Processing, Preservation, and Extraction. Green Food Process. Tech. Preserv. Transform. Extr. 2019, 24, 23–56. [Google Scholar] [CrossRef]

- Montefusco, A.; Durante, M.; Migoni, D.; de Caroli, M.; Ilahy, R.; Pék, Z.; Helyes, L.; Fanizzi, F.P.; Mita, G.; Piro, G.; et al. Analysis of the Phytochemical Composition of Pomegranate Fruit Juices, Peels and Kernels: A Comparative Study on Four Cultivars Grown in Southern Italy. Plants 2021, 10, 2521. [Google Scholar] [CrossRef]

- Yusoff, I.M.; Mat Taher, Z.; Rahmat, Z.; Chua, L.S. A Review of Ultrasound-Assisted Extraction for Plant Bioactive Compounds: Phenolics, Flavonoids, Thymols, Saponins and Proteins. Food Res. Int. 2022, 157, 111268. [Google Scholar] [CrossRef]

- Liu, Y.; Kong, K.W.; Wu, D.T.; Liu, H.Y.; Li, H.B.; Zhang, J.R.; Gan, R.Y. Pomegranate Peel-Derived Punicalagin: Ultrasonic-Assisted Extraction, Purification, and Its α-Glucosidase Inhibitory Mechanism. Food Chem. 2022, 374, 131635. [Google Scholar] [CrossRef]

- More, P.R.; Arya, S.S. Intensification of Bio-Actives Extraction from Pomegranate Peel Using Pulsed Ultrasound: Effect of Factors, Correlation, Optimization and Antioxidant Bioactivities. Ultrason. Sonochem. 2021, 72, 105423. [Google Scholar] [CrossRef]

- Pan, Z.; Qu, W.; Ma, H.; Atungulu, G.G.; McHugh, T.H. Continuous and Pulsed Ultrasound-Assisted Extractions of Antioxidants from Pomegranate Peel. Ultrason. Sonochem. 2011, 18, 1249–1257. [Google Scholar] [CrossRef] [PubMed]

- Kaderides, K.; Goula, A.M.; Adamopoulos, K.G. A Process for Turning Pomegranate Peels into a Valuable Food Ingredient Using Ultrasound-Assisted Extraction and Encapsulation. Innov. Food Sci. Emerg. Technol. 2015, 31, 204–215. [Google Scholar] [CrossRef]

- Dimitrov, K.; Pradal, D.; Vauchel, P.; Baouche, B.; Nikov, I.; Dhulster, P. Modeling and Optimization of Extraction and Energy Consumption during Ultrasound-Assisted Extraction of Antioxidant Polyphenols from Pomegranate Peels. Environ. Prog. Sustain. Energy 2019, 38, 13148. [Google Scholar] [CrossRef]

- Muñiz-Márquez, D.B.; Wong-Paz, J.E.; Aguilar-Zárate, P.; Sepúlveda, L.; Buenrostro-Figueroa, J.; Ascacio-Valdés, J.A.; Aguilar, C.N. Effect of Ultrasound on the Extraction of Ellagic Acid and Hydrolysis of Ellagitannins from Pomegranate Husk. Environ. Technol. Innov. 2021, 24, 102063. [Google Scholar] [CrossRef]

- Goula, A.M.; Ververi, M.; Adamopoulou, A.; Kaderides, K. Green Ultrasound-Assisted Extraction of Carotenoids from Pomegranate Wastes Using Vegetable Oils. Ultrason. Sonochem. 2017, 34, 821–830. [Google Scholar] [CrossRef]

- Rakshit, M.; Srivastav, P.P.; Bhunia, K. Kinetic Modeling of Ultrasonic-Assisted Extraction of Punicalagin from Pomegranate Peel. J. Food Process Eng. 2020, 43, e13533. [Google Scholar] [CrossRef]

- Rifna, E.J.; Dwivedi, M. Effect of Pulsed Ultrasound Assisted Extraction and Aqueous Acetone Mixture on Total Hydrolysable Tannins from Pomegranate Peel. Food Biosci. 2022, 45, 101496. [Google Scholar] [CrossRef]

- Selvakumar, P.; Karthik, V.; Kumar, P.S.; Asaithambi, P.; Kavitha, S.; Sivashanmugam, P. Enhancement of Ultrasound Assisted Aqueous Extraction of Polyphenols from Waste Fruit Peel Using Dimethyl Sulfoxide as Surfactant: Assessment of Kinetic Models. Chemosphere 2021, 263, 128071. [Google Scholar] [CrossRef]

- Kumar, A.; Srinivasa Rao, P. Optimization of Pulsed-Mode Ultrasound Assisted Extraction of Bioactive Compounds from Pomegranate Peel Using Response Surface Methodology. J. Food Meas. Charact. 2020, 14, 3493–3507. [Google Scholar] [CrossRef]

- Rajha, H.N.; Koubaa, M.; Boussetta, N.; Maroun, R.G.; Louka, N.; Lebovka, N.; Vorobiev, E. Selective Ultrasound-Assisted Aqueous Extraction of Polyphenols from Pomegranate Peels and Seeds. J. Food Process. Preserv. 2020, 44, e14545. [Google Scholar] [CrossRef]

- Siriangkhawut, W.; Didpinrum, P.; Khanhuathon, Y.; Ponhong, K.; Grudpan, K. Small-Scale Ultrasound-Assisted Extraction of Phenolics from Pomegranate Peels and Their Application as a Natural Reagent for the Colorimetric Assay of Iron. Anal. Lett. 2020, 53, 887–904. [Google Scholar] [CrossRef]

- Sharayei, P.; Azarpazhooh, E.; Zomorodi, S.; Ramaswamy, H.S. Ultrasound Assisted Extraction of Bioactive Compounds from Pomegranate (Punica granatum L.) Peel. LWT 2019, 101, 342–350. [Google Scholar] [CrossRef]

- Machado, A.P.D.F.; Sumere, B.R.; Mekaru, C.; Martinez, J.; Bezerra, R.M.N.; Rostagno, M.A. Extraction of Polyphenols and Antioxidants from Pomegranate Peel Using Ultrasound: Influence of Temperature, Frequency and Operation Mode. Int. J. Food Sci. Technol. 2019, 54, 2792–2801. [Google Scholar] [CrossRef]

- Kazemi, M.; Karim, R.; Mirhosseini, H.; Abdul Hamid, A. Optimization of Pulsed Ultrasound-Assisted Technique for Extraction of Phenolics from Pomegranate Peel of Malas Variety: Punicalagin and Hydroxybenzoic Acids. Food Chem. 2016, 206, 156–166. [Google Scholar] [CrossRef]

- Turrini, F.; Zunin, P.; Catena, S.; Villa, C.; Alfei, S.; Boggia, R. Traditional or Hydro-Diffusion and Gravity Microwave Coupled with Ultrasound as Green Technologies for the Valorization of Pomegranate External Peels. Food Bioprod. Process. 2019, 117, 30–37. [Google Scholar] [CrossRef]

- Ranjha, M.M.A.N.; Amjad, S.; Ashraf, S.; Khawar, L.; Safdar, M.N.; Jabbar, S.; Nadeem, M.; Mahmood, S.; Murtaza, M.A. Extraction of Polyphenols from Apple and Pomegranate Peels Employing Different Extraction Techniques for the Development of Functional Date Bars. Int. J. Fruit Sci. 2020, 20, S1201–S1221. [Google Scholar] [CrossRef]

- Hasnaoui, N. Pomegranate Peel Phenolics: One Step Water Extraction, in Vitro Antiproliferative Activity, and Effect on Sensory Attributes of Muffins and Cheese. Food Chem. 2022, 392, 133297. [Google Scholar] [CrossRef]

- Ordaz-Rodríguez, S.B.; Abadía-García, L.; Huerta-Manzanilla, E.L.; Mendoza-Sánchez, M. Ultrasound-Assisted Extraction of Pomegranate Peel Antioxidants: A Green Process to Obtain a Meat Preservative. J. Food Process. Preserv. 2022, 46, e16712. [Google Scholar] [CrossRef]

- Magangana, T.P.; Makunga, N.P.; la Grange, C.; Stander, M.A.; Fawole, O.A.; Opara, U.L. Blanching Pre-Treatment Promotes High Yields, Bioactive Compounds, Antioxidants, Enzyme Inactivation and Antibacterial Activity of ‘Wonderful’ Pomegranate Peel Extracts at Three Different Harvest Maturities. Antioxidants 2021, 10, 1119. [Google Scholar] [CrossRef] [PubMed]

- Foujdar, R.; Bera, M.B.; Chopra, H.K. Optimization of Process Variables of Probe Ultrasonic-Assisted Extraction of Phenolic Compounds from the Peel of Punica granatum Var. Bhagwa and It’s Chemical and Bioactivity Characterization. J. Food Process. Preserv. 2020, 44, e14317. [Google Scholar] [CrossRef]

- Tabaraki, R.; Heidarizadi, E.; Benvidi, A. Optimization of Ultrasonic-Assisted Extraction of Pomegranate (Punica granatum L.) Peel Antioxidants by Response Surface Methodology. Sep. Purif. Technol. 2012, 98, 16–23. [Google Scholar] [CrossRef]

- Nag, S.; Sit, N. Optimization of Ultrasound Assisted Enzymatic Extraction of Polyphenols from Pomegranate Peels Based on Phytochemical Content and Antioxidant Property. J. Food Meas. Charact. 2018, 12, 1734–1743. [Google Scholar] [CrossRef]

- Živković, J.; Šavikin, K.; Janković, T.; Ćujić, N.; Menković, N. Optimization of Ultrasound-Assisted Extraction of Polyphenolic Compounds from Pomegranate Peel Using Response Surface Methodology. Sep. Purif. Technol. 2018, 194, 40–47. [Google Scholar] [CrossRef]

- Sumere, B.R.; de Souza, M.C.; dos Santos, M.P.; Bezerra, R.M.N.; da Cunha, D.T.; Martinez, J.; Rostagno, M.A. Combining Pressurized Liquids with Ultrasound to Improve the Extraction of Phenolic Compounds from Pomegranate Peel (Punica granatum L.). Ultrason. Sonochem. 2018, 48, 151–162. [Google Scholar] [CrossRef]

- Santos, M.P.; Souza, M.C.; Sumere, B.R.; da Silva, L.C.; Cunha, D.T.; Bezerra, R.M.N.; Rostagno, M.A. Extraction of Bioactive Compounds from Pomegranate Peel (Punica granatum L.) with Pressurized Liquids Assisted by Ultrasound Combined with an Expansion Gas. Ultrason. Sonochem. 2019, 54, 11–17. [Google Scholar] [CrossRef]

- Motikar, P.D.; More, P.R.; Arya, S.S. A Novel, Green Environment-Friendly Cloud Point Extraction of Polyphenols from Pomegranate Peels: A Comparative Assessment with Ultrasound and Microwave-Assisted Extraction. Sep. Sci. Technol. 2021, 56, 1014–1025. [Google Scholar] [CrossRef]

- Gomez, L.; Tiwari, B.; Garcia-Vaquero, M. Emerging Extraction Techniques: Microwave-Assisted Extraction. Sustain. Seaweed Technol. 2020, 207–224. [Google Scholar] [CrossRef]

- Llompart, M.; Garcia-Jares, C.; Celeiro, M.; Dagnac, T. Extraction|Microwave-Assisted Extraction. Encycl. Anal. Sci. 2019, 67–77. [Google Scholar] [CrossRef]

- de Castro, M.D.L.; Castillo-Peinado, L.S. Microwave-Assisted Extraction of Food Components. Innov. Food Process. Technol. Extr. Sep. Compon. Modif. Process Intensif. 2016, 57–110. [Google Scholar] [CrossRef]

- Sparr Eskilsson, C.; Björklund, E. Analytical-Scale Microwave-Assisted Extraction. J. Chromatogr. A 2000, 902, 227–250. [Google Scholar] [CrossRef]

- Skenderidis, P.; Leontopoulos, S.; Petrotos, K.; Giavasis, I. Optimization of Vacuum Microwave-Assisted Extraction of Pomegranate Fruits Peels by the Evaluation of Extracts’ Phenolic Content and Antioxidant Activity. Foods 2020, 9, 1655. [Google Scholar] [CrossRef]

- Kaderides, K.; Papaoikonomou, L.; Serafim, M.; Goula, A.M. Microwave-Assisted Extraction of Phenolics from Pomegranate Peels: Optimization, Kinetics, and Comparison with Ultrasounds Extraction. Chem. Eng. Process.-Process Intensif. 2019, 137, 1–11. [Google Scholar] [CrossRef]

- Vladić, J.; Janković, T.; Živković, J.; Tomić, M.; Zdunić, G.; Šavikin, K.; Vidović, S. Comparative Study of Subcritical Water and Microwave-Assisted Extraction Techniques Impact on the Phenolic Compounds and 5-Hydroxymethylfurfural Content in Pomegranate Peel. Plant Foods Hum. Nutr. 2020, 75, 553–560. [Google Scholar] [CrossRef]

- Xia, J.L.; Li, P.J. Pectic Enzymes. Encycl. Food Chem. 2019, 270–276. [Google Scholar] [CrossRef]

- Díaz, A.B.; Bolívar, J.; de Ory, I.; Caro, I.; Blandino, A. Applicability of Enzymatic Extracts Obtained by Solid State Fermentation on Grape Pomace and Orange Peels Mixtures in Must Clarification. LWT-Food Sci. Technol. 2011, 44, 840–846. [Google Scholar] [CrossRef]

- Philipps-Wiemann, P. Proteases—General Aspects. Enzym. Hum. Anim. Nutr. Princ. Perspect. 2018, 257–266. [Google Scholar] [CrossRef]

- Wilson, D.B. Cellulases. Encycl. Microbiol. 2009, 252–258. [Google Scholar] [CrossRef]

- van Oort, M. Enzymes in Food Technology–Introduction. In Enzymes in Food Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009; pp. 1–17. ISBN 9781444309935. [Google Scholar]

- Kumar, M.; Tomar, M.; Punia, S.; Amarowicz, R.; Kaur, C. Evaluation of Cellulolytic Enzyme-Assisted Microwave Extraction of Punica granatum Peel Phenolics and Antioxidant Activity. Plant Foods Hum. Nutr. 2020, 75, 614–620. [Google Scholar] [CrossRef] [PubMed]

- Alexandre, E.M.C.; Silva, S.; Santos, S.A.O.; Silvestre, A.J.D.; Duarte, M.F.; Saraiva, J.A.; Pintado, M. Antimicrobial Activity of Pomegranate Peel Extracts Performed by High Pressure and Enzymatic Assisted Extraction. Food Res. Int. 2019, 115, 167–176. [Google Scholar] [CrossRef] [PubMed]

- Mushtaq, M.; Sultana, B.; Anwar, F.; Adnan, A.; Rizvi, S.S.H. Enzyme-Assisted Supercritical Fluid Extraction of Phenolic Antioxidants from Pomegranate Peel. J. Supercrit. Fluids 2015, 104, 122–131. [Google Scholar] [CrossRef]

- Costa, J.R.; Tonon, R.V.; Cabral, L.; Gottschalk, L.; Pastrana, L.; Pintado, M.E. Valorization of Agricultural Lignocellulosic Plant Byproducts through Enzymatic and Enzyme-Assisted Extraction of High-Value-Added Compounds: A Review. ACS Sustain. Chem. Eng. 2020, 8, 13112–13125. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Lipan, L.; Cano-Lamadrid, M.; Kharaghani, A.; Masztalerz, K.; Carbonell-Barrachina, Á.A.; Figiel, A. Comparison of Traditional and Novel Drying Techniques and Its Effect on Quality of Fruits, Vegetables and Aromatic Herbs. Foods 2020, 9, 1261. [Google Scholar] [CrossRef]

- Viuda-Martos, M.; Pérez-Álvarez, J.A.; Sendra, E.; Fernández-López, J. In vitro antioxidant properties of pomegranate (Punica granatum) peel powder extract obtained as coproduct in the juice extraction process. J. Food Process. Preserv. 2013, 37, 772–776. [Google Scholar] [CrossRef]

- Bhandari, B. 1-Introduction to Food Powders. In Handbook of Food Powders; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Shaston, UK, 2013; pp. 1–25. ISBN 978-0-85709-513-8. [Google Scholar]

- Yağmur, N.; Şahin, S. Encapsulation of Ellagic Acid from Pomegranate Peels in Microalgae Optimized by Response Surface Methodology and an Investigation of Its Controlled Released under Simulated Gastrointestinal Studies. J. Food Sci. 2020, 85, 998–1006. [Google Scholar] [CrossRef]

- Marcillo-Parra, V.; Tupuna-Yerovi, D.S.; González, Z.; Ruales, J. Encapsulation of Bioactive Compounds from Fruit and Vegetable By-Products for Food Application–A Review. Trends Food Sci. Technol. 2021, 116, 11–23. [Google Scholar] [CrossRef]

- Michalska, A.; Wojdyło, A.; Honke, J.; Ciska, E.; Andlauer, W. Drying-Induced Physico-Chemical Changes in Cranberry Products. Food Chem. 2018, 240, 448–455. [Google Scholar] [CrossRef]

- Michalska, A.; Lech, K. The Effect of Carrier Quantity and Drying Method on the Physical Properties of Apple Juice Powders. Beverages 2018, 4, 2. [Google Scholar] [CrossRef] [Green Version]

- Watson, M.A.; Lea, J.M.; Bett-Garber, K.L. Spray Drying of Pomegranate Juice Using Maltodextrin/Cyclodextrin Blends as the Wall Material. Food Sci. Nutr. 2017, 5, 820–826. [Google Scholar] [CrossRef]

- Carpena, M.; Garcia-Oliveira, P.; Lourenco-Lopez, C.; Gonzalez Pereira, A.; Fraga-Corral, M.; Angel Prieto, M.; Simal-Gandara, J. Freeze-Drying Encapsulation as a Mechanism of Choice in Oils: Methods and Mechanism. In Basic Protocols in Encapsulation of Food Ingredients; Gomez-Zavaglia, A., Ed.; Springer: New York, NY, USA, 2021; pp. 91–101. ISBN 978-1-0716-1649-9. [Google Scholar]

- Çam, M.; İçyer, N.C.; Erdoğan, F. Pomegranate Peel Phenolics: Microencapsulation, Storage Stability and Potential Ingredient for Functional Food Development. LWT-Food Sci. Technol. 2014, 55, 117–123. [Google Scholar] [CrossRef]

- Šavikin, K.; Nastić, N.; Janković, T.; Bigović, D.; Miličević, B.; Vidović, S.; Menković, N.; Vladić, J. Effect of Type and Concentration of Carrier Material on the Encapsulation of Pomegranate Peel Using Spray Drying Method. Foods 2021, 10, 1968. [Google Scholar] [CrossRef]

- Goula, A.M.; Lazarides, H.N. Integrated Processes Can Turn Industrial Food Waste into Valuable Food By-Products and/or Ingredients: The Cases of Olive Mill and Pomegranate Wastes. J. Food Eng. 2015, 167, 45–50. [Google Scholar] [CrossRef]

- Kaderides, K.; Goula, A.M. Encapsulation of Pomegranate Peel Extract with a New Carrier Material from Orange Juice By-Products. J. Food Eng. 2019, 253, 1–13. [Google Scholar] [CrossRef]

- Kaderides, K.; Mourtzinos, I.; Goula, A.M. Stability of Pomegranate Peel Polyphenols Encapsulated in Orange Juice Industry By-Product and Their Incorporation in Cookies. Food Chem. 2020, 310, 125849. [Google Scholar] [CrossRef]

- Yang, B.; Kealey, K.; Chen, J.; Solval, K.M. Developing Microencapsulated Powders Containing Polyphenols and Pectin Extracted from Georgia-Grown Pomegranate Peels. LWT 2022, 154, 112644. [Google Scholar] [CrossRef]

- Fathi, F.; Ebrahimi, S.N.; Pereira, D.M.; Estevinho, B.N.; Rocha, F. Preliminary Studies of Microencapsulation and Anticancer Activity of Polyphenols Extract from Punica granatum Peels. Can. J. Chem. Eng. 2021. [Google Scholar] [CrossRef]

- Endo, E.H.; Ueda-Nakamura, T.; Nakamura, C.V.; Filho, B.P.D. Activity of Spray-Dried Microparticles Containing Pomegranate Peel Extract against Candida Albicans. Molecules 2012, 17, 10094–10107. [Google Scholar] [CrossRef]

- Bustamante, A.; Hinojosa, A.; Robert, P.; Escalona, V. Extraction and Microencapsulation of Bioactive Compounds from Pomegranate (Punica granatum Var. Wonderful) Residues. Int. J. Food Sci. Technol. 2017, 52, 1452–1462. [Google Scholar] [CrossRef]

- Marín, D.; Alemán, A.; Montero, P.; Gómez-Guillén, M.C. Encapsulation of Food Waste Compounds in Soy Phosphatidylcholine Liposomes: Effect of Freeze-Drying, Storage Stability and Functional Aptitude. J. Food Eng. 2018, 223, 132–143. [Google Scholar] [CrossRef]

- Jafarian, M.; Taghinia, P.; Baeghbali, S.; Samadi Ghorbani Dozdozani, N. Application of Prunus Armeniaca Gum Exudates and Chitosan for Encapsulation of Pomegranate Peel Extract as a Natural Antioxidant. J. Food Meas. Charact. 2021, 15, 4992–4999. [Google Scholar] [CrossRef]

- Hamid; Thakur, N.S.; Thakur, A. Microencapsulation of Wild Pomegranate Flavedo Phenolics by Lyophilization: Effect of Maltodextrin Concentration, Structural Morphology, Functional Properties, Elemental Composition and Ingredient for Development of Functional Beverage. LWT 2020, 133, 110077. [Google Scholar] [CrossRef]

- Azarpazhooh, E.; Sharayei, P.; Zomorodi, S.; Ramaswamy, H.S. Physicochemical and Phytochemical Characterization and Storage Stability of Freeze-Dried Encapsulated Pomegranate Peel Anthocyanin and In Vitro Evaluation of Its Antioxidant Activity. Food Bioprocess Technol. 2019, 12, 199–210. [Google Scholar] [CrossRef]

- Okumuş, E.; Bakkalbaşı, E.; Javidipour, I.; Meral, R.; Ceylan, Z. A Novel Coating Material: Ellagitannins-Loaded Maltodextrin and Lecithin-Based Nanomaterials. Food Biosci. 2021, 42, 101158. [Google Scholar] [CrossRef]

- Sanhueza, L.; García, P.; Giménez, B.; Benito, J.M.; Matos, M.; Gutiérrez, G. Encapsulation of Pomegranate Peel Extract (Punica granatum L.) by Double Emulsions: Effect of the Encapsulation Method and Oil Phase. Foods 2022, 11, 310. [Google Scholar] [CrossRef]

- Bertolo, M.R.V.; Martins, V.C.A.; Horn, M.M.; Brenelli, L.B.; Plepis, A.M.G. Rheological and Antioxidant Properties of Chitosan/Gelatin-Based Materials Functionalized by Pomegranate Peel Extract. Carbohydr. Polym. 2020, 228, 115386. [Google Scholar] [CrossRef]

- Yağmur, N.; Şahin, S.; Korkmaz, E. Microencapsulation of Ellagic Acid Extracted from Pomegranate Peel onto Spirulina: Characterization, Loading, and Storage Stability Properties. J. Food Process. Preserv. 2021, 45, e15086. [Google Scholar] [CrossRef]

- Maroufi, L.Y.; Tabibiazar, M.; Ghorbani, M.; Jahanban-Esfahlan, A. Fabrication and Characterization of Novel Antibacterial Chitosan/Dialdehyde Guar Gum Hydrogels Containing Pomegranate Peel Extract for Active Food Packaging Application. Int. J. Biol. Macromol. 2021, 187, 179–188. [Google Scholar] [CrossRef]

- Costa, A.M.M.; Moretti, L.K.; Simões, G.; Silva, K.A.; Calado, V.; Tonon, R.V.; Torres, A.G. Microencapsulation of Pomegranate (Punica granatum L.) Seed Oil by Complex Coacervation: Development of a Potential Functional Ingredient for Food Application. LWT 2020, 131, 109519. [Google Scholar] [CrossRef]

- Eghbal, N.; Choudhary, R. Complex Coacervation: Encapsulation and Controlled Release of Active Agents in Food Systems. LWT 2018, 90, 254–264. [Google Scholar] [CrossRef]

- Kaderides, K.; Kyriakoudi, A.; Mourtzinos, I.; Goula, A.M. Potential of Pomegranate Peel Extract as a Natural Additive in Foods. Trends Food Sci. Technol. 2021, 115, 380–390. [Google Scholar] [CrossRef]

- Martínez-Zamora, L.; Ros, G.; Nieto, G. Designing a Clean Label Fish Patty with Olive, Citric, Pomegranate, or Rosemary Extracts. Plants 2020, 9, 659. [Google Scholar] [CrossRef]

- Martínez, L.; Castillo, J.; Ros, G.; Nieto, G. Antioxidant and Antimicrobial Activity of Rosemary, Pomegranate and Olive Extracts in Fish Patties. Antioxidants 2019, 8, 86. [Google Scholar] [CrossRef]

- Mekawi, E.M.; Sharoba, A.M.; Ramadan, M.F. Reduction of Acrylamide Formation in Potato Chips during Deep-Frying in Sunflower Oil Using Pomegranate Peel Nanoparticles Extract. J. Food Meas. Charact. 2019, 13, 3298–3306. [Google Scholar] [CrossRef]

- Chan, C.-L.; Gan, R.; Shah, N.P.; Corke, H. Enhancing Antioxidant Capacity of Lactobacillus Acidophilus-Fermented Milk Fortified with Pomegranate Peel Extracts. Food Biosci. 2018, 26, 185–192. [Google Scholar] [CrossRef]

- Palabiyik, I.; Toker, O.S.; Konar, N.; Gunes, R.; Güleri, T.; Alaşalvar, H.; Çam, M. Phenolics Release Kinetics in Sugared and Sugar-Free Chewing Gums: Microencapsulated Pomegranate Peel Extract Usage. Int. J. Food Sci. Technol. 2018, 53, 2657–2663. [Google Scholar] [CrossRef]

- da Silva Veloso, F.; Caleja, C.; Calhelha, R.C.; Pires, T.C.S.; Alves, M.J.; Barros, L.; Genena, A.K.; Barreira, J.C.M.; Ferreira, I.C.F.R. Characterization and Application of Pomegranate Epicarp Extracts as Functional Ingredients in a Typical Brazilian Pastry Product. Molecules 2020, 25, 1481. [Google Scholar] [CrossRef]

- Martins, Z.E.; Pinho, O.; Ferreira, I.M.P.L.V.O.; Jekle, M.; Becker, T. Development of Fibre-Enriched Wheat Breads: Impact of Recovered Agroindustrial by-Products on Physicochemical Properties of Dough and Bread Characteristics. Eur. Food Res. Technol. 2017, 243, 1973–1988. [Google Scholar] [CrossRef]

- Kumar, N.; Daniloski, D.; Pratibha; Neeraj; D’Cunha, N.M.; Naumovski, N.; Petkoska, A.T. Pomegranate Peel Extract–A Natural Bioactive Addition to Novel Active Edible Packaging. Food Res. Int. 2022, 156, 111378. [Google Scholar] [CrossRef]

- Castillejo, N.; Martínez-Hernández, G.B.; Artés-Hernández, F. Revalorized Broccoli By-Products and Mustard Improved Quality during Shelf Life of a Kale Pesto Sauce. Food Sci. Technol. Int. 2021, 27, 734–745. [Google Scholar] [CrossRef]

- Quattrucci, A.; Ovidi, E.; Tiezzi, A.; Vinciguerra, V.; Balestra, G.M. Biological Control of Tomato Bacterial Speck Using Punica granatum Fruit Peel Extract. Crop Prot. 2013, 46, 18–22. [Google Scholar] [CrossRef]

- Abd-Rabbu, H.S.; Wahba, H.E.; Khalid, K.A. Pomegranate Peel Modifies Growth, Essential Oil and Certain Chemicals of Sage (Salvia officinalis L.) Herb. Biocatal. Agric. Biotechnol. 2021, 33, 101978. [Google Scholar] [CrossRef]

- Pangallo, S.; Nicosia, M.G.L.D.; Agosteo, G.E.; Abdelfattah, A.; Romeo, F.V.; Cacciola, S.O.; Rapisarda, P.; Schena, L. Evaluation of a Pomegranate Peel Extract as an Alternative Means to Control Olive Anthracnose. Phytopathology 2017, 107, 1462–1467. [Google Scholar] [CrossRef]

- Elsherbiny, E.A.; Amin, B.H.; Baka, Z.A. Efficiency of Pomegranate (Punica granatum L.) Peels Extract as a High Potential Natural Tool towards Fusarium Dry Rot on Potato Tubers. Postharvest Biol. Technol. 2016, 111, 256–263. [Google Scholar] [CrossRef]

- Rongai, D.; Sabatini, N.; Pulcini, P.; di Marco, C.; Storchi, L.; Marrone, A. Effect of Pomegranate Peel Extract on Shelf Life of Strawberries: Computational Chemistry Approaches to Assess Antifungal Mechanisms Involved. J. Food Sci. Technol. 2018, 55, 2702–2711. [Google Scholar] [CrossRef] [PubMed]

- Li Destri Nicosia, M.G.; Pangallo, S.; Raphael, G.; Romeo, F.V.; Strano, M.C.; Rapisarda, P.; Droby, S.; Schena, L. Control of Postharvest Fungal Rots on Citrus Fruit and Sweet Cherries Using a Pomegranate Peel Extract. Postharvest Biol. Technol. 2016, 114, 54–61. [Google Scholar] [CrossRef]

- Parsa, Z.; Roozbehi, S.; Hosseinifarahi, M.; Radi, M.; Amiri, S. Integration of Pomegranate Peel Extract (PPE) with Calcium Sulphate (CaSO4): A Friendly Treatment for Extending Shelf-Life and Maintaining Postharvest Quality of Sweet Cherry Fruit. J. Food Process. Preserv. 2021, 45, e15089. [Google Scholar] [CrossRef]

- Kumar, N.; Pratibha; Neeraj; Petkoska, A.T.; AL-Hilifi, S.A.; Fawole, O.A. Effect of Chitosan–Pullulan Composite Edible Coating Functionalized with Pomegranate Peel Extract on the Shelf Life of Mango (Mangifera indica). Coatings 2021, 11, 764. [Google Scholar] [CrossRef]

- Gull, A.; Bhat, N.; Wani, S.M.; Masoodi, F.A.; Amin, T.; Ganai, S.A. Shelf Life Extension of Apricot Fruit by Application of Nanochitosan Emulsion Coatings Containing Pomegranate Peel Extract. Food Chem. 2021, 349, 129149. [Google Scholar] [CrossRef]

- Paolucci, M.; di Stasio, M.; Sorrentino, A.; la Cara, F.; Volpe, M.G. Active Edible Polysaccharide-Based Coating for Preservation of Fresh Figs (Ficus carica L.). Foods 2020, 9, 1793. [Google Scholar] [CrossRef]

- Alotaibi, M.A.; Tayel, A.A.; Zidan, N.S.; el Rabey, H.A. Bioactive Coatings from Nano-Biopolymers/Plant Extract Composites for Complete Protection from Mycotoxigenic Fungi in Dates. J. Sci. Food Agric. 2019, 99, 4338–4343. [Google Scholar] [CrossRef]

- Tayel, A.A.; El-Baz, A.F.; Salem, M.F.; El-Hadary, M.H. Potential Applications of Pomegranate Peel Extract for the Control of Citrus Green Mould. J. Plant Dis. Prot. 2009, 116, 252–256. [Google Scholar] [CrossRef]

- Pangallo, S.; Li Destri Nicosia, M.G.; Raphael, G.; Levin, E.; Ballistreri, G.; Cacciola, S.O.; Rapisarda, P.; Droby, S.; Schena, L. Elicitation of Resistance Responses in Grapefruit and Lemon Fruits Treated with a Pomegranate Peel Extract. Plant Pathol. 2017, 66, 633–640. [Google Scholar] [CrossRef]

- Givi, F.; Gholami, M.; Massah, A. Application of Pomegranate Peel Extract and Essential Oil as a Safe Botanical Preservative for the Control of Postharvest Decay Caused by Penicillium Italicum and Penicillium Digitatum on “Satsuma” Mandarin. J. Food Saf. 2019, 39, e12639. [Google Scholar] [CrossRef]

- Kharchoufi, S.; Parafati, L.; Licciardello, F.; Muratore, G.; Hamdi, M.; Cirvilleri, G.; Restuccia, C. Edible Coatings Incorporating Pomegranate Peel Extract and Biocontrol Yeast to Reduce Penicillium Digitatum Postharvest Decay of Oranges. Food Microbiol. 2018, 74, 107–112. [Google Scholar] [CrossRef]

- Belgacem, I.; Pangallo, S.; Abdelfattah, A.; Romeo, F.V.; Cacciola, S.O.; Li Destri Nicosia, M.G.; Ballistreri, G.; Schena, L. Transcriptomic Analysis of Orange Fruit Treated with Pomegranate Peel Extract (PGE). Plants 2019, 8, 101. [Google Scholar] [CrossRef]

- Nair, M.S.; Saxena, A.; Kaur, C. Effect of Chitosan and Alginate Based Coatings Enriched with Pomegranate Peel Extract to Extend the Postharvest Quality of Guava (Psidium guajava L.). Food Chem. 2018, 240, 245–252. [Google Scholar] [CrossRef]

- Nair, M.S.; Saxena, A.; Kaur, C. Characterization and Antifungal Activity of Pomegranate Peel Extract and Its Use in Polysaccharide-Based Edible Coatings to Extend the Shelf-Life of Capsicum (Capsicum annuum L.). Food Bioprocess Technol. 2018, 11, 1317–1327. [Google Scholar] [CrossRef]

- Megha, M.; Gill, P.S.; Jawandha, S.K.; Kaur, N.; Gill, M.S. Effect of Chitosan Coating Incorporated with Pomegranate Peel Extract on Pear Fruit Softening, Quality, and Cell Wall Degrading Enzymes during Cold Storage. J. Food Process. Preserv. 2021, 45, e15984. [Google Scholar] [CrossRef]

- Lacivita, V.; Incoronato, A.L.; Conte, A.; del Nobile, M.A. Pomegranate Peel Powder as a Food Preservative in Fruit Salad: A Sustainable Approach. Foods 2021, 10, 1359. [Google Scholar] [CrossRef] [PubMed]

- Belgacem, I.; Schena, L.; Teixidó, N.; Romeo, F.V.; Ballistreri, G.; Abadias, M. Effectiveness of a Pomegranate Peel Extract (PGE) in Reducing Listeria Monocytogenes in Vitro and on Fresh-Cut Pear, Apple and Melon. Eur. Food Res. Technol. 2020, 246, 1765–1772. [Google Scholar] [CrossRef]

- Turrini, F.; Boggia, R.; Donno, D.; Parodi, B.; Beccaro, G.; Baldassari, S.; Signorello, M.G.; Catena, S.; Alfei, S.; Zunin, P. From Pomegranate Marcs to a Potential Bioactive Ingredient: A Recycling Proposal for Pomegranate-Squeezed Marcs. Eur. Food Res. Technol. 2020, 246, 273–285. [Google Scholar] [CrossRef]

- Trigo, J.P.; Alexandre, E.M.C.; Oliveira, A.; Saraiva, J.A.; Pintado, M. Fortification of Carrot Juice with a High-Pressure-Obtained Pomegranate Peel Extract: Chemical, Safety and Sensorial Aspects. Int. J. Food Sci. Technol. 2020, 55, 1599–1605. [Google Scholar] [CrossRef]

- Trigo, J.P.; Alexandre, E.M.C.; Silva, S.; Costa, E.; Saraiva, J.A.; Pintado, M. Study of Viability of High Pressure Extract from Pomegranate Peel to Improve Carrot Juice Characteristics. Food Funct. 2020, 11, 3410–3419. [Google Scholar] [CrossRef] [PubMed]

- Altunkaya, A.; Hedegaard, R.V.; Harholt, J.; Brimer, L.; Gökmen, V.; Skibsted, L.H. Palatability and Chemical Safety of Apple Juice Fortified with Pomegranate Peel Extract. Food Funct. 2013, 4, 1468–1473. [Google Scholar] [CrossRef] [PubMed]

- Tomadoni, B.; Moreira, M.D.R.; Espinosa, J.P.; Ponce, A. Individual and Combined Effects of Pomegranate Extract and Ultrasonic Treatments on Kiwifruit Juice Quality Parameters. J. Food Process Eng. 2017, 40, e12339. [Google Scholar] [CrossRef]

- Canuti, V.; Cecchi, L.; Khatib, M.; Guerrini, L.; Mulinacci, N.; Zanoni, B. A New Extract from Pomegranate (Punica granatum L.) By-Products as a Potential Oenological Tannin: Preliminary Characterization and Comparison with Existing Commercial Products. Molecules 2020, 25, 4460. [Google Scholar] [CrossRef]

- Jouki, M.; Khazaei, N.; Rashidi-Alavijeh, S.; Ahmadi, S. Encapsulation of Lactobacillus Casei in Quince Seed Gum-Alginate Beads to Produce a Functional Synbiotic Drink Powder by Agro-Industrial by-Products and Freeze-Drying. Food Hydrocoll. 2021, 120, 106895. [Google Scholar] [CrossRef]

| Byproduct Characteristics | Power (W) | Pressure | Solvent | Solid/Liquid Ratio | T (min) | T (°C) | Other Information | Extract Characterization | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Milled frozen (more information NA) Wonderful cv | 2000, 4000, 6000 | Vacuum 355 mbar | NA | 1:10; 1:25; 1:40 | 10, 50, 90 | 40, 50, 60 | Industrial-type MAC-75 multimode MW extractor | TPC, AOX (DPPH) | [57] |

| Drier (40 °C, 48 h) Particle size ~0.1 mm cv information NA | 100, 173, 350, 527, 600 | 75 bar | H2O EtOH (50–70%) MetOH (50–70%) | 1:10; 1:17.3; 1:35; 1:52.7; 1:60 | 0.5–15 | NA | Multiwave closed MW system | TPC, AOX (DPPH), Pn, EA | [58] |

| Air-dried (4–5 days) Particle size 0.75–2 mm cv information NA | 470–800 | NA | EtOH (50%) | 1:10 | 20 | 41–72 | Home-made setup consisting of MW oven | TPC, GA, EA, Pn, HMF | [59] |

| Technology | Carriers | Target Compound/Activity | Ref. |

|---|---|---|---|

| Spray-drying | Maltrodextrin | F-TPC, UPLC-TPC, Pn, EA, P, GA | [78,79] |

| Maltrodextrin + others: Tween 80 (99:1); Skimmed milk powder (50:50); Whey protein isolate (50:50); Gum arabic (50:50) | NA (Yield/Stability) | [28,80] | |

| Skimmed milk power | NA (Yield/Stability) | [28,80] | |

| Orange juice byproduct | F-TPC, DPPH | [81,82] | |

| Maltodextrin/Pectin | TPC, Pn, EA | [83] | |

| Whey protein | Pn, EA, P, GA | [79] | |

| Arabic gum | Pn, EA | [84] | |

| Chitosan | Pn, EA | [84,85] | |

| Pectin | Pn, EA | [84] | |

| Modified starch | Pn, TPC, HTC, DPPH | [86] | |

| Alginate | NA (Yield/Stability) | [85] | |

| Freeze-drying | Soy phosphatidylcholine liposomes | Pn, EA, rutin, epifallocatechin, TPC | [87] |

| Maltodextrin (5 and 10%) and b-cyclodextrin (5 and 10%). | F-TPC, FRAP | [38] | |

| Prunus armeniaca gum exudates | FRAP, DPPH | [88] | |

| Chitosan | FRAP, DPPH | [88] | |

| Maltrodextrin | TPC, TFC, Pn, EA, FRAP, DPPH | [89] | |

| Maltodextrin and calcium alginate | ANCs, FRAP, DPPH | [90] | |

| Maltodextrin and soy lecitin | NA (Yield/Stability) | [91] | |

| Double emulsion | Water1 in Oil in Water2: Water1 (ethanolic solutions) in Oil (castor, soybean, sunflower, medium chain triglyceride and orange) in Water2 (aqueous solution with Tween80) | NA (Yield/Stability) | [92] |

| Ion gelation | Chitosan gel (1%):gelatin 2:1 | F-TPC, DPPH | [93] |

| Spirulina | TPC, DPPH | [72] | |

| Microalgae | EA | [94] | |

| Chitosan + others: Dialdehyde guar gum Gelatin-based materials | F-TPC, DPPH | [95] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano-Lamadrid, M.; Martínez-Zamora, L.; Castillejo, N.; Artés-Hernández, F. From Pomegranate Byproducts Waste to Worth: A Review of Extraction Techniques and Potential Applications for Their Revalorization. Foods 2022, 11, 2596. https://doi.org/10.3390/foods11172596

Cano-Lamadrid M, Martínez-Zamora L, Castillejo N, Artés-Hernández F. From Pomegranate Byproducts Waste to Worth: A Review of Extraction Techniques and Potential Applications for Their Revalorization. Foods. 2022; 11(17):2596. https://doi.org/10.3390/foods11172596

Chicago/Turabian StyleCano-Lamadrid, Marina, Lorena Martínez-Zamora, Noelia Castillejo, and Francisco Artés-Hernández. 2022. "From Pomegranate Byproducts Waste to Worth: A Review of Extraction Techniques and Potential Applications for Their Revalorization" Foods 11, no. 17: 2596. https://doi.org/10.3390/foods11172596