A Bayesian Approach to Describe and Simulate the pH Evolution of Fresh Meat Products Depending on the Preservation Conditions

Abstract

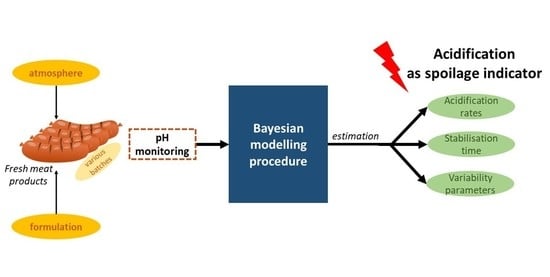

:1. Introduction

2. Materials and Methods

2.1. Products and pH Measurement

2.2. Formalisation of the Model

2.2.1. Deterministic Part

2.2.2. Stochastic Part

2.3. Parameters Inference

3. Results

3.1. Model Fit and Selection

3.2. Parameter Distribution

3.2.1. Stabilization Time and pH

3.2.2. Acidification Rate under Effects of Lactate and Atmospheres

3.2.3. Initial pH and Variability Sources

3.3. Possible Use of the Model for Simulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pellissery, A.J.; Vinayamohan, P.G.; Amalaradjou, M.A.R.; Venkitanarayanan, K. Spoilage bacteria and meat quality. In Meat Quality Analysis; Academic Press: New York, NY, USA, 2020; pp. 307–334. [Google Scholar] [CrossRef]

- Raimondi, S.; Nappi, M.R.; Sirangelo, T.M.; Leonardi, A.; Amaretti, A.; Ulrici, A.; Magnani, R.; Montanari, C.; Tabanelli, G.; Gardini, F.; et al. Bacterial community of industrial raw sausage packaged in modified atmosphere throughout the shelf life. Int. J. Food Microbiol. 2018, 280, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Shange, N.; Makasi, T.N.; Gouws, P.A.; Hoffman, L.C. The influence of normal and high ultimate muscle pH on the microbiology and colour stability of previously frozen black wildebeest (Connochaetes gnou) meat. Meat Sci. 2018, 135, 14–19. [Google Scholar] [CrossRef] [PubMed]

- Koutsoumanis, K.; Stamatiou, A.; Skandamis, P.; Nychas, G.-J.E. Development of a microbial model for the combined effect of temperature and pH on spoilage of ground meat, and validation of the model under dynamic temperature conditions. Appl. Environ. Microbiol. 2006, 72, 124–134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, X.; Youssef, M.K.; Gill, C.O.; Badoni, M.; López-Campos, Ó. Effects of meat pH on growth of 11 species of psychrotolerant clostridia on vacuum packaged beef and blown pack spoilage of the product. Food Microbiol. 2014, 39, 13–18. [Google Scholar] [CrossRef] [PubMed]

- Deumier, F.; Collignan, A. The effects of sodium lactate and starter cultures on pH, lactic acid bacteria, Listeria monocytogenes and Salmonella spp. levels in pure chicken dry fermented sausage. Meat Sci. 2003, 65, 1165–1174. [Google Scholar] [CrossRef]

- Mohsina, K.; Ratkowsky, D.A.; Bowman, J.P.; Powell, S.; Kaur, M.; Tamplin, M.L. Effect of glucose, pH and lactic acid on Carnobacterium maltaromaticum, Brochothrix thermosphacta and Serratia liquefaciens within a commercial heat-shrunk vacuum-package film. Food Microbiol. 2020, 91, 103515. [Google Scholar] [CrossRef]

- Chouliara, E.; Karatapanis, A.; Savvaidis, I.N.; Kontominas, M.G. Combined effect of oregano essential oil and modified atmosphere packaging on shelf-life extension of fresh chicken breast meat, stored at 4 degrees C. Food Microbiol. 2007, 24, 607–617. [Google Scholar] [CrossRef] [PubMed]

- Hasapidou, A.; Savvaidis, I.N. The effects of modified atmosphere packaging, EDTA and oregano oil on the quality of chicken liver meat. Food Res. Int. 2011, 44, 2751–2756. [Google Scholar] [CrossRef]

- Linton, M.; Connolly, M.; Houston, L.; Patterson, M.F. The control of Clostridium botulinum during extended storage of pressure-treated, cooked chicken. Food Control 2014, 37, 104–108. [Google Scholar] [CrossRef]

- Mataragas, M.; Zwietering, M.H.; Skandamis, P.N.; Drosinos, E.H. Quantitative microbiological risk assessment as a tool to obtain useful information for risk managers—Specific application to Listeria monocytogenes and ready-to-eat meat products. Int. J. Food Microbiol. 2010, 141, S170–S179. [Google Scholar] [CrossRef] [Green Version]

- McMillin, K.W. Where is MAP Going? A review and future potential of modified atmosphere packaging for meat. Meat Sci. 2008, 80, 43–65. [Google Scholar] [CrossRef] [PubMed]

- Heir, E.; Solberg, L.E.; Jensen, M.R.; Skaret, J.; Grøvlen, M.S.; Holck, A.L. Improved microbial and sensory quality of chicken meat by treatment with lactic acid, organic acid salts and modified atmosphere packaging. Int. J. Food Microbiol. 2022, 362, 109498. [Google Scholar] [CrossRef] [PubMed]

- Coroller, L.; Kan-King-Yu, D.; Leguerinel, I.; Mafart, P.; Membré, J.-M. Modelling of growth, growth/no-growth interface and nonthermal inactivation areas of Listeria in foods. Int. J. Food Microbiol. 2012, 152, 139–152. [Google Scholar] [CrossRef] [PubMed]

- Guillard, V.; Couvert, O.; Stahl, V.; Hanin, A.; Denis, C.; Huchet, V.; Chaix, E.; Loriot, C.; Vincelot, T.; Thuault, D. Validation of a predictive model coupling gas transfer and microbial growth in fresh food packed under modified atmosphere. Food Microbiol. 2016, 58, 43–55. [Google Scholar] [CrossRef]

- McKellar, R.C.; Lu, X. Modeling Microbial Responses in Food; CRC Press: New York, NY, USA, 2004; 360p. [Google Scholar] [CrossRef]

- Bettencourt, J.C.M.; Loiseau, G.; Grabulos, J.; Mestres, C. Modeling lactic fermentation of gowé using Lactobacillus starter culture. Microorganisms 2016, 4, 44. [Google Scholar]

- Garthwaite, P.H.; Kadane, J.B.; O’Hagan, A. Statistical methods for eliciting probability distributions. J. Am. Stat. Assoc. 2005, 100, 680–700. [Google Scholar] [CrossRef]

- Gelman, A. Prior distributions for variance parameters in hierarchical models (Comment on Article by Browne and Draper). Bayesian Anal. 2006, 1, 515–534. [Google Scholar] [CrossRef]

- Delignette-Muller, M.-L.; Cornu, M.; Pouillot, R.; Denis, J.B. Use of Bayesian modelling in risk assessment: Application to growth of Listeria monocytogenes and food flora in cold-smoked salmon. Int. J. Food Microbiol. 2006, 106, 195–208. [Google Scholar] [CrossRef]

- Cornu, M.; Billoir, E.; Bergis, H.; Beaufort, A.; Zuliani, V. Modeling microbial competition in food: Application to the behavior of Listeria monocytogenes and lactic acid flora in pork meat products. Food Microbiol. 2011, 28, 639–647. [Google Scholar] [CrossRef]

- Jaloustre, S.; Cornu, M.; Morelli, E.; Noël, V.; Delignette-Muller, M.L. Bayesian modeling of Clostridium perfringens growth in beef-in-sauce products. Food Microbiol. 2011, 28, 311–320. [Google Scholar] [CrossRef]

- Poirier, S.; Luong, N.-D.M.; Anthoine, V.; Guillou, S.; Membré, J.-M.; Moriceau, N.; Rezé, S.; Zagorec, M.; Feurer, C.; Frémaux, B.; et al. Large-scale multivariate dataset on the characterization of microbiota diversity, microbial growth dynamics, metabolic spoilage volatilome and sensorial profiles of two industrially produced meat products subjected to changes in lactate concentration and. Data Brief 2020, 30, 105453. [Google Scholar] [CrossRef]

- Afnor. Food Safety—Guidelines for the Drawing Up of Durability Studies—Chilled Perishable and Highly Perishable Foodstuffs; Afnor Publishing: Saint-Denis, France, 2018. [Google Scholar]

- Luong, N.-D.M.; Jeuge, S.; Coroller, L.; Feurer, C.; Desmonts, M.-H.; Moriceau, N.; Anthoine, V.; Gavignet, S.; Rapin, A.; Frémaux, B.; et al. Spoilage of fresh turkey and pork sausages: Influence of potassium lactate and modified atmosphere packaging. Food Res. Int. 2020, 137, 109501. [Google Scholar] [CrossRef] [PubMed]

- Lerasle, M.; Federighi, M.; Simonin, H.; Anthoine, V.; Rezé, S.; Chéret, R.; Guillou, S. Combined use of modified atmosphere packaging and high pressure to extend the shelf-life of raw poultry sausage. Innov. Food Sci. Emerg. Technol. 2014, 23, 54–60. [Google Scholar] [CrossRef]

- Plummer, M. JAGS: A program for analysis of Bayesian graphical models using Gibbs sampling. In Proceedings of the 3rd International Workshop on Distributed Statistical Computing (DSC 2003), Vienna, Austria, 20–22 March 2003; Available online: http://www.ci.tuwien.ac.at/Conferences/DSC-2003/ (accessed on 14 March 2022).

- R Core Team. R: A language and environment for statistical computing. In R Foundation for Statistical Computing; R Core Team: Vienna, Austria, 2017. [Google Scholar]

- Raftery, A.E.; Lewis, S.M. One long run with diagnostics: Implementation strategies for markov chain monte carlo. Stat. Sci. 1992, 7, 493–497. [Google Scholar] [CrossRef]

- Gelman, A.; Rubin, D.B. Inference from iterative simulation using multiple sequences. Stat. Sci. 1992, 7, 457–511. [Google Scholar] [CrossRef]

- Geweke, J. Evaluating the Accuray of Sampling-Based Approaches to the Calculation of Posterior Moments; Federal Reserve Bank of Minneapolis: Minneapolis, MN, USA, 1991. [Google Scholar]

- Spiegelhalter, D.J.; Best, N.G.; Carlin, B.P.; van Der Linde, A. Bayesian measures of model complexity and fit. J. Roy. Stat. Soc. 2002, 64, 583–639. [Google Scholar] [CrossRef] [Green Version]

- Crépet, A.; Stahl, V.; Carlin, F. Development of a hierarchical Bayesian model to estimate the growth parameters of Listeria monocytogenes in minimally processed fresh leafy salads. Int. J. Food Microbiol. 2009, 131, 112–119. [Google Scholar] [CrossRef]

- Dagnas, S.; Onno, B.; Membré, J.-M. Modeling growth of three bakery product spoilage molds as a function of water activity, temperature and pH. Int. J. Food Microbiol. 2014, 186, 95–104. [Google Scholar] [CrossRef]

- Pouillot, R.; Delignette-Muller, M.-L. Evaluating variability and uncertainty separately in microbial quantitative risk assessment using two R packages. Int. J. Food Microbiol. 2010, 142, 330–340. [Google Scholar] [CrossRef]

- Tovunac, I.; Galić, K.; Prpić, T.; Jurić, S. Effect of packaging conditions on the shelf-life of chicken frankfurters with and without lactate addition. Food Sci. Technol. Int. 2011, 17, 167–175. [Google Scholar] [CrossRef]

- Cegielska-Radziejewska, R.; Pikul, J. Sodium lactate addition on the quality and shelf Life of refrigerated sliced poultry sausage packaged in air or nitrogen Atmosphere. J. Food Prot. 2004, 67, 601–606. [Google Scholar] [CrossRef] [PubMed]

- Bouju-Albert, A.; Pilet, M.-F.; Guillou, S. Influence of lactate and acetate removal on the microbiota of french fresh pork sausages. Int. J. Food Microbiol. 2018, 76, 328–336. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, K.M.; Milkowski, A.L.; Glass, K.A. Inhibition of Clostridium perfringens growth by potassium lactate during an extended cooling of cooked uncured ground turkey breasts. J. Food Prot. 2013, 76, 1972–1976. [Google Scholar] [CrossRef]

- Al-Nehlawi, A.; Guri, S.; Guamis, B.; Saldo, J. Synergistic effect of carbon dioxide atmospheres and high hydrostatic pressure to reduce spoilage bacteria on poultry sausages. LWT-Food Sci. Technol. 2014, 58, 404–411. [Google Scholar] [CrossRef]

- Rodriguez, M.B.R.; Conte, C.A.; Carneiro, C.S.; Franco, R.M.; Mano, S.B. The effect of carbon dioxide on the shelf life of ready-to-eat shredded chicken breast stored under refrigeration. Poult. Sci. 2014, 93, 194–199. [Google Scholar] [CrossRef] [PubMed]

- Adams, K.R.; Niebuhr, S.E.; Dickson, J.S. Dissolved carbon dioxide and oxygen concentrations in purge of vacuum-packaged pork chops and the relationship to shelf life and models for estimating microbial populations. Meat Sci. 2015, 110, 1–8. [Google Scholar] [CrossRef]

- Saucier, L.; Gendron, C.; Gariépy, C. Shelf life of ground poultry meat stored under modified atmosphere. Poult. Sci. 2000, 79, 1851–1856. [Google Scholar] [CrossRef]

- Musavu Ndob, A.; Lebert, A. Prediction of pH and aw of pork meat by a thermodynamic model: New developments. Meat Sci. 2018, 138, 59–67. [Google Scholar] [CrossRef]

- Ellouze, M.; Pichaud, M.; Bonaiti, C.; Coroller, L.; Couvert, O.; Thuault, D.; Vaillant, R. Modelling pH evolution and lactic acid production in the growth medium of a lactic acid bacterium: Application to set a biological TTI. Int. J. Food Microbiol. 2008, 128, 101–107. [Google Scholar] [CrossRef]

| Symbol | Definition | Prior Distribution | |||

|---|---|---|---|---|---|

| Mean of the initial pH value across production batches | * | ||||

| Standard deviation of the initial pH across production batches | |||||

| Standard deviation of the pH value across measurement | |||||

| Additive effect of the “Air packaging” on acidification rate | |||||

| Additive effect of the “MAP1:70%O2-30%CO2” on acidification rate | |||||

| Additive effect of the “MAP2: 50%CO2-30%N2” on acidification rate | |||||

| Slope parameter characterising the effect of lactate on acidification rate | |||||

| Model 1 | Model 2 | Model 3 | Model 4 | ||

| Scale parameter characterising the effect of lactate on acidification rate | (fixed) | (fixed) | |||

| Time point (in days) at which the pH reaches the stabilisation phase | (fixed) | (fixed) | |||

| Model | Total Number of Parameters to Be Estimated | DIC |

|---|---|---|

| Model 1 | 7 (n fixed, θ fixed) | −274.8 |

| Model 2 | 8 (θ fixed) | −271.0 |

| Model 3 | 8 (n fixed) | −296.5 |

| Model 4 | 9 | −294.1 |

| Parameter | Estimated (Point Estimate—95% Credible Interval) | |

|---|---|---|

| Stabilisation time | ||

| (in days) | 12.9 | [12.1; 13.7] |

| Effect of lactate and atmosphere on acidification rate | ||

| −0.095 | [−0.119; −0.071] | |

| −2.430 | [−2.528; −2.340] | |

| −2.487 | [−2.587; −2.394] | |

| −2.339 | [−2.429; −2.254] | |

| (fixed) | ||

| Initial pH and variability sources | ||

| 6.49 | [6.41; 6.57] | |

| 0.10 | [0.07; 0.13] | |

| 0.15 | [0.14; 0.16] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luong, N.-D.M.; Coroller, L.; Zagorec, M.; Moriceau, N.; Anthoine, V.; Guillou, S.; Membré, J.-M. A Bayesian Approach to Describe and Simulate the pH Evolution of Fresh Meat Products Depending on the Preservation Conditions. Foods 2022, 11, 1114. https://doi.org/10.3390/foods11081114

Luong N-DM, Coroller L, Zagorec M, Moriceau N, Anthoine V, Guillou S, Membré J-M. A Bayesian Approach to Describe and Simulate the pH Evolution of Fresh Meat Products Depending on the Preservation Conditions. Foods. 2022; 11(8):1114. https://doi.org/10.3390/foods11081114

Chicago/Turabian StyleLuong, Ngoc-Du Martin, Louis Coroller, Monique Zagorec, Nicolas Moriceau, Valérie Anthoine, Sandrine Guillou, and Jeanne-Marie Membré. 2022. "A Bayesian Approach to Describe and Simulate the pH Evolution of Fresh Meat Products Depending on the Preservation Conditions" Foods 11, no. 8: 1114. https://doi.org/10.3390/foods11081114