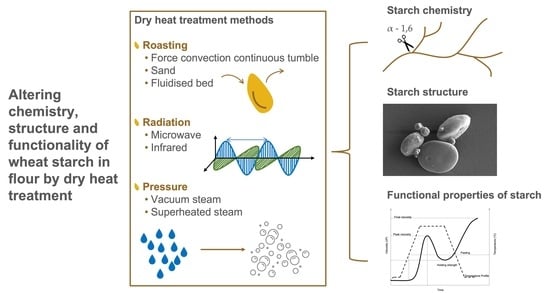

Holistic View of Starch Chemistry, Structure and Functionality in Dry Heat-Treated Whole Wheat Kernels and Flour

Abstract

:1. Introduction

2. Dry Heat Treatment

2.1. Roasting

2.1.1. Forced Convection Continuous Tumble (FCCT) Roasting

2.1.2. Sand Roasting

2.1.3. Fluidised Bed Roaster (FBR)

2.2. Radiation

2.2.1. Microwave Heating

2.2.2. Infrared (IR) Treatment

2.3. Pressure

2.3.1. Superheated Steam Treatment

2.3.2. Vacuum Steam Treatment

2.3.3. Gun Puffing

3. Properties of Starch in Heat-Treated Wheat

3.1. Chemical and Structural Properties

3.1.1. Chemical Composition of Starch Granules

3.1.2. Endosperm and Starch Granule Morphology

3.1.3. Crystallinity

3.1.4. Milling Performance and Starch Damage

3.2. Functional Properties

3.2.1. Thermal Behaviour of Starch

3.2.2. Degree of Gelatinisation

3.2.3. Water Absorption

3.2.4. Solubility of Starch and Swelling Power

3.2.5. Pasting

3.2.6. Cooling of Starch Gels

3.2.7. Interactions with Other Components

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shewry, P.R.; Hey, S.J. The contribution of wheat to human diet and health. Food Energy Secur. 2015, 4, 178–202. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Wang, L.; Zhu, H.; Li, Z. Superheated steam treatment improved flour qualities of wheat in suitable conditions. J. Food Process. Preserv. 2017, 41, e13238. [Google Scholar] [CrossRef]

- Fu, Z.Q.; Wang, L.J.; Li, D.; Zhou, Y.G.; Adhikari, B. The effect of partial gelatinization of corn starch on its retrogradation. Carbohydr. Polym. 2013, 97, 512–517. [Google Scholar] [CrossRef] [PubMed]

- Delatte, S.; Doran, L.; Blecker, C.; De Mol, G.; Roiseux, O.; Gofflot, S.; Malumba, P. Effect of pilot-scale steam treatment and endogenous alpha-amylase activity on wheat flour functional properties. J. Cereal Sci. 2019, 88, 38–46. [Google Scholar] [CrossRef]

- Calvin, O. Starch and modified starch in bread making: A review. Afr. J. Food Sci. 2016, 10, 344–351. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Sang, S.; Xu, D.; Jin, Y.; Chen, Y.; Xu, X. The contribution of superheated steam treatment of wheat flour to the cake quality. LWT—Food Sci. Technol. 2021, 141, 110958. [Google Scholar] [CrossRef]

- Padalino, L.; Del Nobile, M.A.; la Gatta, B.; Rutigliano, M.; Di Luccia, A.; Conte, A. Effects of microwave treatment of durum wheat kernels on quality characteristics of flour and pasta. Food Chem. 2019, 283, 454–461. [Google Scholar] [CrossRef]

- Snelling, J.; Malekmohammadi, S.; Bergholz, T.M.; Ohm, J.; Simsek, S. Effect of vacuum steam treatment of hard red spring wheat on flour quality and reduction of escherichia coli O121 and salmonella enteritidis PT 30. J. Food Prot. 2020, 83, 836–843. [Google Scholar] [CrossRef]

- Maniglia, B.C.; Castanha, N.; Rojas, M.L.; Augusto, P.E. Emerging technologies to enhance starch performance. Curr. Opin. Food Sci. 2021, 37, 26–36. [Google Scholar] [CrossRef]

- Murthy, K.V.; Ravi, R.; Bhat, K.K.; Raghavarao, K.S.M.S. Studies on roasting of wheat using fluidized bed roaster. J. Food Eng. 2008, 89, 336–342. [Google Scholar] [CrossRef]

- Schoeman, L.; Manley, M. Oven and Forced Convection Continuous Tumble (FCCT) Roasting: Effect on Physicochemical, Structural and Functional Properties of Wheat Grain. Food Bioprocess Technol. 2019, 12, 166–182. [Google Scholar] [CrossRef]

- Sruthi, N.U.; Premjit, Y.; Pandiselvam, R.; Kothakota, A.; Ramesh, S.V. An overview of conventional and emerging techniques of roasting: Effect on food bioactive signatures. Food Chem. 2021, 348, 129088. [Google Scholar] [CrossRef]

- Whent, M.; Huang, H.; Xie, Z.; Lutterodt, H.; Yue, L.; Fuerst, E.P.; Morris, C.F.; Yu, L.; Luthria, D. Phytochemical composition, anti-inflammatory, and antiproliferative activity of whole wheat flour. J. Agric. Food Chem. 2012, 60, 2129–2135. [Google Scholar] [CrossRef]

- De Brier, N.; Gomand, S.V.; Donner, E.; Paterson, D.; Delcour, J.A.; Lombi, E.; Smolders, E. Distribution of minerals in wheat grains (Triticum aestivum L.) and in roller milling fractions affected by pearling. J. Agric. Food Chem. 2015, 63, 1276–1285. [Google Scholar] [CrossRef]

- Laddomada, B.; Caretto, S.; Mita, G. Wheat bran phenolic acids: Bioavailability and stability in whole wheat-based foods. Molecules 2015, 20, 15666–15685. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, D.; Sang, S.; Jin, Y.; Xu, X.; Cui, B. Effect of superheated steam treatment on the structural and digestible properties of wheat flour. Food Hydrocoll. 2021, 112, 106362. [Google Scholar] [CrossRef]

- Ranganathan, V.; Nunjundiah, I.T.; Bhattacharya, S. Effect of roasting on rheological and functional properties of sorghum flour. Food Sci. Technol. Int. 2014, 20, 579–589. [Google Scholar] [CrossRef]

- Bucsella, B.; Takács, Á.; Vizer, V.; Schwendener, U.; Tömösközi, S. Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours. Food Chem. 2016, 190, 990–996. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Q.; Wu, H.; Su, C.; Ge, X.; Shen, H.; Han, L.; Yu, X.; Li, W. The influence of repeated versus continuous dry-heating on the performance of wheat starch with different amylose content. LWT—Food Sci. Technol. 2021, 136, 110380. [Google Scholar] [CrossRef]

- Andrejko, D.; Grochowicz, J.; Goździewska, M.; Kobus, Z. Influence of infrared treatment on mechanical strength and structure of wheat grains. Food Bioprocess Technol. 2011, 4, 1367–1375. [Google Scholar] [CrossRef]

- Schoeman, L.; Du Plessis, A.; Manley, M. Non-destructive characterisation and quantification of the effect of conventional oven and forced convection continuous tumble (FCCT) roasting on the three-dimensional microstructure of whole wheat kernels using X-ray micro-computed tomography (μCT). J. Food Eng. 2016, 187, 1–13. [Google Scholar] [CrossRef]

- Cattaneo, S.; Hidalgo, A.; Masotti, F.; Stuknyte, M.; Brandolini, A.; De Noni, I. Heat damage and in vitro starch digestibility of puffed wheat kernels. Food Chem. 2015, 188, 286–293. [Google Scholar] [CrossRef]

- Huber, K.C.; Bemiller, J.N. Carbohydrates. In Fennema’s Food Chemistry; Damodaran, S., Ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 91–170. [Google Scholar]

- Germishuys, Z.; Manley, M. X-ray micro-computed tomography evaluation of bubble structure of freeze-dried dough and foam properties of bread produced from roasted wheat flour. Innov. Food Sci. Emerg. Technol. 2021, 73, 102766. [Google Scholar] [CrossRef]

- Schoeman, L. Characterisation and Quantification of Microstructure, Physicochemical and Functional Properties of Oven and Forced Convection Continuous Tumble Roasted Cereal Grains. Doctoral Dissertation, Stellenbosch University, Stellenbosch, South Africa, 2017. [Google Scholar]

- Zhang, S. Antioxidant Properties and Effect of Forced Convection Roasting on South African Wheats. Master Thesis, Stellenbosch University, Stellenbosch, South Africa, 2016. [Google Scholar]

- Gujral, H.S.; Sharma, P.; Rachna, S. Effect of sand roasting on beta glucan extractability, physicochemical and antioxidant properties of oats. LWT—Food Sci. Technol. 2011, 44, 2223–2230. [Google Scholar] [CrossRef]

- Dhua, S.; Kheto, A.; Singh Sharanagat, V.; Singh, L.; Kumar, K.; Nema, P.K. Quality characteristics of sand, pan and microwave roasted pigmented wheat (Triticum aestivum). Food Chem. 2021, 365, 130372. [Google Scholar] [CrossRef]

- Palav, T.; Seetharaman, K. Impact of microwave heating on the physico-chemical properties of a starch-water model system. Carbohydr. Polym. 2007, 67, 596–604. [Google Scholar] [CrossRef]

- Penner, M.H. Basic Principles of Spectroscopy. In Food Analysis; Nielsen, S.S., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 9781441914781. [Google Scholar]

- Pronyk, C.; Cenkowski, S.; Muir, W.E. Drying Foodstuffs with Superheated Steam. Dry. Technol. 2004, 22, 899–916. [Google Scholar] [CrossRef]

- Liu, Y.; Guan, E.; Li, M.; Bian, K.; Wen, J.; Ren, C. Improvement of cake quality by superheated steam treatment of wheat. J. Cereal Sci. 2020, 95, 103046. [Google Scholar] [CrossRef]

- Shah, M.K.; Asa, G.; Sherwood, J.; Graber, K.; Bergholz, T.M. Efficacy of vacuum steam pasteurization for inactivation of Salmonella PT 30, Escherichia coli O157:H7 and Enterococcus faecium on low moisture foods. Int. J. Food Microbiol. 2017, 244, 111–118. [Google Scholar] [CrossRef]

- Mariotti, M.; Alamprese, C.; Pagani, M.A.; Lucisano, M. Effect of puffing on ultrastructure and physical characteristics of cereal grains and flours. J. Cereal Sci. 2006, 43, 47–56. [Google Scholar] [CrossRef]

- Cauvain, S. Technology of breadmaking. In Technology of Breadmaking; Springer: Perth, Australia, 2015; pp. 1–408. ISBN 9783319146874. [Google Scholar]

- Ortolan, F.; Brites, L.T.G.; Montenegro, F.M.; Schmiele, M.; Steel, C.J.; Clerici, M.T.P.S.; Almeida, E.L.; Chang, Y.K. Effect of extruded wheat flour and pre-gelatinized cassava starch on process and quality parameters of French-type bread elaborated from frozen dough. Food Res. Int. 2015, 76, 402–409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muralikrishna, G.; Nirmala, M. Cereal α-amylases—An overview. Carbohydr. Polym. 2005, 60, 163–173. [Google Scholar] [CrossRef]

- Sharma, P.; Gujral, H.S. Effect of sand roasting and microwave cooking on antioxidant activity of barley. Food Res. Int. 2011, 44, 235–240. [Google Scholar] [CrossRef]

- Balet, S.; Guelpa, A.; Fox, G.; Manley, M. Rapid Visco Analyser (RVA) as a tool for measuring starch-related physiochemical properties in cereals: A review. Food Anal. Methods 2019, 12, 2344–2360. [Google Scholar] [CrossRef]

- Oyeyinka, S.A.; Singh, S.; Adebola, P.O.; Gerrano, A.S.; Amonsou, E.O. Physicochemical properties of starches with variable amylose contents extracted from bambara groundnut genotypes. Carbohydr. Polym. 2015, 133, 171–178. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Liu, J.; Xie, F.; Chen, L. Supramolecular structure of A- and B-type granules of wheat starch. Food Hydrocoll. 2013, 31, 68–73. [Google Scholar] [CrossRef]

- Qiao, D.; Zhang, B.; Huang, J.; Xie, F.; Wang, D.K. Hydration-induced crystalline transformation of starch polymer under ambient conditions. Int. J. Biol. Macromol. 2017, 103, 152–157. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Wang, L.; Zhu, H.; Li, Z. Modification of physicochemical properties and in vitro digestibility of wheat flour through superheated steam processing. J. Cereal Sci. 2017, 74, 231–237. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, Q.; Feng, N.; Wang, J.; Wang, S.; He, Z. Characterization of A- and B-type starch granules in Chinese wheat cultivars. J. Integr. Agric. 2016, 15, 2203–2214. [Google Scholar] [CrossRef] [Green Version]

- Blazek, J. Role of Amylose in Structure-Function Relationship in Starches from Australian Wheat Varieties. Doctoral Dissertation, University of Sydney, Sydney, Australia, 2008. [Google Scholar]

- Niu, B.; Chao, C.; Cai, J.; Yan, Y.; Copeland, L.; Wang, S.; Wang, S. The effect of NaCl on the formation of starch-lipid complexes. Food Chem. 2019, 299, 125133. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E. Stone milling versus roller milling: A systematic review of the effects on wheat flour quality, dough rheology, and bread characteristics. Trends Food Sci. Technol. 2020, 97, 147–155. [Google Scholar] [CrossRef]

- Kang, M.J.; Kim, M.J.; Kwak, H.S.; Kim, S.S. Effects of milling methods and cultivars on physicochemical properties of whole-wheat flour. J. Food Qual. 2019, 2019, 3416905. [Google Scholar] [CrossRef] [Green Version]

- Ma, S.; Li, L.; Wang, X.-X.; Zheng, X.-L.; Bian, K.; Bao, Q.-D. Effect of mechanically damaged starch from wheat flour on the quality of frozen dough and steamed bread. Food Chem. 2016, 202, 120–124. [Google Scholar] [CrossRef]

- Germishuys, Z. X-ray Micro-Computed Tomography (μCT) Evaluation of Bubble Structure to Determine Quality of Dough and Bread Made from Roasted Wheat Flour. Doctoral Dissertation, Stellenbosch University, Stellenbosch, South Africa, 2021. [Google Scholar]

- Delcour, J.A.; Hoseney, R.C. Principles of Cereal Science and Technology, 3rd ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Olaerts, H.; Vandekerckhove, L.; Courtin, C.M. A closer look at the bread making process and the quality of bread as a function of the degree of preharvest sprouting of wheat (Triticum aestivum). J. Cereal Sci. 2018, 80, 188–197. [Google Scholar] [CrossRef]

- Vamadevan, V.; Bertoft, E. Impact of different structural types of amylopectin on retrogradation. Food Hydrocoll. 2018, 80, 88–96. [Google Scholar] [CrossRef]

- Svihus, B.; Uhlen, A.K.; Harstad, O.M. Effect of starch granule structure, associated components and processing on nutritive value of cereal starch: A review. Anim. Feed Sci. Technol. 2005, 122, 303–320. [Google Scholar] [CrossRef]

- Ding, Q.B.; Ainsworth, P.; Plunkett, A.; Tucker, G.; Marson, H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J. Food Eng. 2006, 73, 142–148. [Google Scholar] [CrossRef]

- Blazek, J.; Copeland, L. Pasting and swelling properties of wheat flour and starch in relation to amylose content. Carbohydr. Polym. 2008, 71, 380–387. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, L.; Li, Z. Modification of protein structure and dough rheological properties of wheat flour through superheated steam treatment. J. Cereal Sci. 2017, 76, 222–228. [Google Scholar] [CrossRef]

- Besbes, E.; Le Bail, A.; Seetharaman, K. Impact of local hydrothermal treatment during bread baking on soluble amylose, firmness, amylopectin retrogradation and water mobility during bread staling. J. Food Sci. Technol. 2016, 53, 304–314. [Google Scholar] [CrossRef] [Green Version]

- Hug-Iten, S.; Escher, F.; Conde-Petit, B. Staling of Bread: Role of Amylose and Amylopectin and Influence of Starch-Degrading Enzymes. Cereal Chem. 2003, 80, 654–661. [Google Scholar] [CrossRef]

- Germishuys, Z.; Delcour, J.A.; Deleu, L.J.; Manley, M. Characterization of white flour produced from roasted wheats differing in hardness and protein content. Cereal Chem. 2020, 97, 339–348. [Google Scholar] [CrossRef]

- Guo, X.N.; Wu, S.H.; Zhu, K.X. Effect of superheated steam treatment on quality characteristics of whole wheat flour and storage stability of semi-dried whole wheat noodle. Food Chem. 2020, 322, 126738. [Google Scholar] [CrossRef] [PubMed]

- De Almeida, J.L.; Pareyt, B.; Gerits, L.R.; Delcour, J.A. Effect of wheat grain steaming and washing on lipase activity in whole grain flour. Cereal Chem. 2014, 91, 321–326. [Google Scholar] [CrossRef]

- Poudel, R.; Rose, D.J. Changes in enzymatic activities and functionality of whole wheat flour due to steaming of wheat kernels. Food Chem. 2018, 263, 315–320. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gili, R.D.; Palavecino, P.M.; Cecilia Penci, M.; Martinez, M.L.; Ribotta, P.D. Wheat germ stabilization by infrared radiation. J. Food Sci. Technol. 2017, 54, 71–81. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panyoo, A.E.; Emmambux, M.N. Amylose–lipid complex production and potential health benefits: A mini-review. Starch/Staerke 2017, 69, 1600203. [Google Scholar] [CrossRef]

| Dry Heat Treatment Methods | Structural and Functional Properties | References |

|---|---|---|

| Sand roasting | Significant puffing; lowered bulk density Increased water absorption capacity | [38] [28] |

| Microwave heating | Lower pasting temperatures; higher peak viscosity; lower final viscosity; lack of granule swelling; increased water absorption during cooking | [7,29] |

| Infrared treatment | Reduction of grain compressive resistance; gelatinisation from the centre of the grain | [20] |

| Gun puffing | Significant puffing; lower peak and final viscosity; increased water absorption capacity and water solubility indexes | [34] |

| Vacuum steam treatment | No change in functionality at optimum conditions | [8] |

| Superheated steam | Partial gelatinisation; wider pasting temperature range; decreased pasting temperature; increased viscosity; higher swelling power; increased breakdown and setback viscosity | [2,43] |

| Forced convection continuous tumble (FCCT) roasting | Gelatinisation; increased water absorption capacity; increased pasting properties; less destructive changes and less gelatinisation compared to oven roasting | [11] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

van Rooyen, J.; Simsek, S.; Oyeyinka, S.A.; Manley, M. Holistic View of Starch Chemistry, Structure and Functionality in Dry Heat-Treated Whole Wheat Kernels and Flour. Foods 2022, 11, 207. https://doi.org/10.3390/foods11020207

van Rooyen J, Simsek S, Oyeyinka SA, Manley M. Holistic View of Starch Chemistry, Structure and Functionality in Dry Heat-Treated Whole Wheat Kernels and Flour. Foods. 2022; 11(2):207. https://doi.org/10.3390/foods11020207

Chicago/Turabian Stylevan Rooyen, Jana, Senay Simsek, Samson Adeoye Oyeyinka, and Marena Manley. 2022. "Holistic View of Starch Chemistry, Structure and Functionality in Dry Heat-Treated Whole Wheat Kernels and Flour" Foods 11, no. 2: 207. https://doi.org/10.3390/foods11020207