Evaporative Cooling Options for Building Air-Conditioning: A Comprehensive Study for Climatic Conditions of Multan (Pakistan)

Abstract

:1. Introduction

2. Proposed Evaporative Cooling Systems’ Configuration

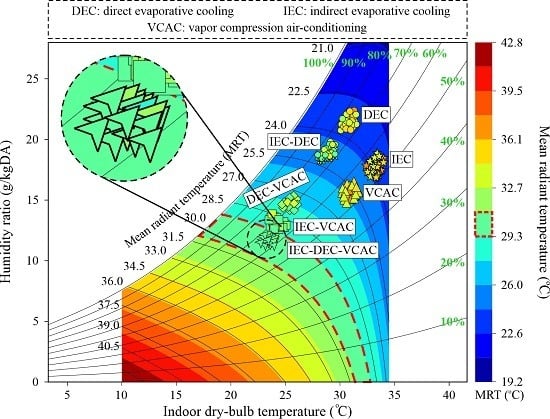

- DEC system (Figure 2a): It cools process air isenthalpically (process 1–2). The DEC system can cool the process air up to wet-bulb temperature of the ambient air.

- IEC system (Figure 2b): The working air (process 1–3) is cooled isenthalpically like DEC, and the cooling affect is transferred to product air by heat transfer between wet and dry channels. The fact sensibly cools the product air (process 1–2) up to wet-bulb temperature.

- VCAC system (Figure 2c): It is the conventional compressor-based vapor compression air conditioning unit that cools the process air below the dew point. The required conditions are obtained by mixing/reheating the product air (process 1–2, dotted line).

- IEC-DEC (Figure 2d): It is a double stage EC unit that cools the air by indirect (process 1–2) followed by direct (process 2–3) EC concepts.

- DEC-VCAC (Figure 2e): It is a hybrid system composed of DEC (process 1–2) and VCAC (process 2–3) units.

- IEC-VCAC (Figure 2f): It is a hybrid system composed of IEC (process 1–2) and VCAC (process 2–3) units.

- IEC-DEC-VCAC (Figure 2g): It is also a hybrid system that is composed of IEC (process 1–2), IEC (process 2–3) and VCAC (process 3–4) units.

3. Materials and Methods

3.1. Building Energy Simulation

3.1.1. Building Layout

3.1.2. Energy Simulation

3.2. Energy Estimations

3.2.1. Cooling Loads

3.2.2. Thermal Comfort Indices

4. Results and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ∆T | Difference between outside and supply air temperatures (°C) |

| AC | Air–conditioning |

| ACH | Air change per hour |

| Ag | Surface area of window (m2) |

| AHU | Air handling unit |

| As | Surface area of wall (m2) |

| ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers |

| clo | Clothing insulation unit (1 clo 0.155 m2 °C W−1) |

| Clothinsul | Clothing insulation (clo) |

| COP | Coefficient of performance |

| Cp | Specific heat capacity of air (1.005 kJ kg−1 K−1) |

| DAC | Desiccant air-conditioning system |

| DBT | Dry bulb temperature |

| DEC | Direct evaporative cooling system |

| DX | Direct expansion |

| E | Surface emissivity constant |

| EC | Evaporative cooling systems |

| hconv | Convective heat transfer coefficient (W m−2 °C−1) |

| height | Height of human body (m) |

| hfg | Latent heat of evaporation (kJ kg−1) |

| hin | Total enthalpy of air at inlet side (J kg−1) |

| ho | Heat transfer coefficient (W m−2 °C) |

| hout | Total enthalpy of air at supply side (J kg−1) |

| HVAC | Heating, ventilation, and air-conditioning |

| IEC | Indirect evaporative cooling system |

| Lf | Load factor of motor |

| m | Mass flow rate (kg s−1) |

| MEC | Maisotsenko-cycle based evaporative cooling |

| Met | Metabolic rate of body per area (W m−2) |

| min | Air infiltration inflow rate (m3 h−1) |

| MRT | Mean radiant temperature (°C) |

| Pa | Vapor pressure of air (Pa) |

| Pfloor | Floor perimeter (m) |

| PMV | Predicted mean vote |

| PPD | Predicted percentage of dissatisfaction (%) |

| Pr | Power of motor (W) |

| Q | Cooling capacity (kW) |

| Qc | Heat transfer through center of glazing (W) |

| Qe | Heat transfer through edge of glazing (W) |

| Qext | Heat gains through exterior surfaces (W) |

| Qf | Heat transfer through frame of glazing (W) |

| Qglazing | Heat gains through windows (W) |

| Qhb | Heat gains through human body (W) |

| Ql,i | Latent heat gains through air infiltration (W) |

| Qlat | Latent heat gains from skin and lungs (W) |

| Qlatent | Total latent energy transfer (W) |

| Qm | Heat gains through fan motor (W) |

| Qnet | Total cooling capacity (W) |

| Qs,i | Sensible heat gains through air infiltration (W) |

| Qsens | Sensible heat gains from skin and lungs (W) |

| Qsensible | Total sensible energy transfer (W) |

| qsolar | Incident solar radiation (W m−2) |

| Qsp | Heat gains through floor perimeter (W) |

| Qwall | Heat gains through walls (W) |

| Qwork | Heat loss from working human body (W m−2) |

| Rc | Thermal resistance of clothes (m2 °C W−1) |

| rcb | Ratio of clothed to naked body |

| Ta | Ambient air temperature (°C) |

| Tair | Temperature of conditioned air (°C) |

| Tcloth | Temperature of clothes (°C) |

| Tin | Inside air temperature (°C) |

| TOA | Outside air temperature (°C) |

| Tout | Outside air temperature (°C) |

| Ts | Surface air temperature (°C) |

| Ts–a | Sol-air temperature (°C) |

| TSA | Supply air temperature (°C) |

| Tsur | Mean temperature of surrounding surfaces (°C) |

| u | Volumetric flow of air (m3 s−1) |

| uair | Velocity of air flow (m s−1) |

| Uf | Utilization factor |

| Ufloor | Overall heat transfer coefficient of floor (W m−1 °C−1) |

| Ug | Overall heat transfer coefficient of glazing (W m−1 °C−1) |

| Uwall | Overall heat transfer coefficient (W m−1 °C−1) |

| V | Building volume (m3) |

| VCAC | Vapor compression air–conditioning system |

| W | Work input (kW) |

| WBE | Wet-bulb effectiveness |

| WBT | Wet-bulb temperature |

| Xin | Inside air humidity ratio (g g−1) |

| Xmin | Minimum of inlet and outlet air humidity ratios (kg/kg) |

| Xout | Outside air humidity ratio (g g−1) |

| αsolar | Solar absorptivity constant |

| εwb | Wet–bulb effectiveness (-) |

| ηm | Efficiency of motor |

| ρair | Density of air (kg m−3) |

| φ | Solar incident angle relative to the latitude |

References

- Wang, S.; Tang, R. Supply-based feedback control strategy of air-conditioning systems for direct load control of buildings responding to urgent requests of smart grids. Appl. Energy 2017, 201, 419–432. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V.S. Overview of the Maisotsenko cycle—A way towards dew point evaporative cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Saha, B.B.; Koyama, S. Steady-state investigation of water vapor adsorption for thermally driven adsorption based greenhouse air-conditioning system. Renew. Energy 2016, 86, 785–795. [Google Scholar] [CrossRef]

- Cheng, F.; Li, Y.; Zhang, X.; Li, X. Effect of different absorbents on actual performance of the absorption air-conditioning system based on capacitive deionization regeneration method. Appl. Therm. Eng. 2020, 172, 115130. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Online Data Services; International Energy Agency (IEA): Paris, France, 2017. [Google Scholar]

- Afroz, Z.; Shafiullah, G.M.; Urmee, T.; Higgins, G. Modeling techniques used in building HVAC control systems: A review. Renew. Sustain. Energy Rev. 2018, 83, 64–84. [Google Scholar] [CrossRef]

- Yang, Z.; Ghahramani, A.; Becerik-Gerber, B. Building occupancy diversity and HVAC (heating, ventilation, and air conditioning) system energy efficiency. Energy 2016, 109, 641–649. [Google Scholar] [CrossRef] [Green Version]

- Kojok, F.; Fardoun, F.; Younes, R.; Outbib, R. Hybrid cooling systems: A review and an optimized selection scheme. Renew. Sustain. Energy Rev. 2016, 65, 57–80. [Google Scholar] [CrossRef]

- Duan, Z.; Zhan, C.; Zhang, X.; Mustafa, M.; Zhao, X.; Alimohammadisagvand, B.; Hasan, A. Indirect evaporative cooling: Past, present and future potentials. Renew. Sustain. Energy Rev. 2012, 16, 6823–6850. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, X.; Zhan, C.; Dong, X.; Chen, H. Energy saving potential of a counter-flow regenerative evaporative cooler for various climates of China: Experiment-based evaluation. Energy Build. 2017, 148, 199–210. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Li, J.; Zhao, X. Energy savings of hybrid dew-point evaporative cooler and micro-channel separated heat pipe cooling systems for computer data centers. Energy 2018, 163, 629–640. [Google Scholar] [CrossRef] [Green Version]

- Matsui, K.; Thu, K.; Miyazaki, T. A Hybrid Power Cycle using an Inverted Brayton Cycle with an Indirect Evaporative Device for Waste-heat Recovery. Appl. Therm. Eng. 2020, 115029. [Google Scholar] [CrossRef]

- Farmahini-Farahani, M.; Delfani, S.; Esmaeelian, J. Exergy analysis of evaporative cooling to select the optimum system in diverse climates. Energy 2012, 40, 250–257. [Google Scholar] [CrossRef]

- Lin, J.; Bui, D.T.; Wang, R.; Chua, K.J. On the exergy analysis of the counter-flow dew point evaporative cooler. Energy 2018, 165, 958–971. [Google Scholar] [CrossRef]

- Alklaibi, A.M. Experimental and theoretical investigation of internal two-stage evaporative cooler. Energy Convers. Manag. 2015, 95, 140–148. [Google Scholar] [CrossRef]

- Fikri, B.; Sofia, E.; Putra, N. Experimental analysis of a multistage direct-indirect evaporative cooler using a straight heat pipe. Appl. Therm. Eng. 2020, 171, 115133. [Google Scholar] [CrossRef]

- Khalajzadeh, V.; Farmahini-Farahani, M.; Heidarinejad, G. A novel integrated system of ground heat exchanger and indirect evaporative cooler. Energy Build. 2012, 49, 604–610. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Rajput, S.P.S. Experimental analysis of an evaporative–vapour compression based combined air conditioning system for required comfort conditions. Appl. Therm. Eng. 2017, 115, 326–336. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, X.; Liu, J.; Zhang, Q. Dynamic simulation of a hybrid dew point evaporative cooler and vapour compression refrigerated system for a building using EnergyPlus. J. Build. Eng. 2019, 21, 287–301. [Google Scholar] [CrossRef]

- Zhou, S.; Gong, L.; Liu, X.; Shen, S. Mathematical modeling and performance analysis for multi-effect evaporation/multi-effect evaporation with thermal vapor compression desalination system. Appl. Therm. Eng. 2019, 159, 113759. [Google Scholar] [CrossRef]

- Rostamzadeh, H.; Rostamzadeh, J.; Matin, P.S.; Ghaebi, H. Novel dual-loop bi-evaporator vapor compression refrigeration cycles for freezing and air-conditioning applications. Appl. Therm. Eng. 2018, 138, 563–582. [Google Scholar] [CrossRef]

- Hong, H.; Li, W.; Gu, C. Performance study on a mechanical vapor compression evaporation system driven by Roots compressor. Int. J. Heat Mass Transf. 2018, 125, 343–349. [Google Scholar] [CrossRef]

- Kim, M.-H.; Jeong, J.-W. Cooling performance of a 100% outdoor air system integrated with indirect and direct evaporative coolers. Energy 2013, 52, 245–257. [Google Scholar] [CrossRef]

- Hasan, A. Indirect evaporative cooling of air to a sub-wet bulb temperature. Appl. Therm. Eng. 2010, 30, 2460–2468. [Google Scholar] [CrossRef]

- Delfani, S.; Esmaeelian, J.; Pasdarshahri, H.; Karami, M. Energy saving potential of an indirect evaporative cooler as a pre-cooling unit for mechanical cooling systems in Iran. Energy Build. 2010, 42, 2169–2176. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Bozorgmehr, M.; Delfani, S.; Esmaeelian, J. Experimental investigation of two-stage indirect/direct evaporative cooling system in various climatic conditions. Build. Environ. 2009, 44, 2073–2079. [Google Scholar] [CrossRef]

- Chiesa, G.; Huberman, N.; Pearlmutter, D. Geo-climatic potential of direct evaporative cooling in the Mediterranean Region: A comparison of key performance indicators. Build. Environ. 2019, 151, 318–337. [Google Scholar] [CrossRef]

- Sohani, A.; Sayyaadi, H. Thermal comfort based resources consumption and economic analysis of a two-stage direct-indirect evaporative cooler with diverse water to electricity tariff conditions. Energy Convers. Manag. 2018, 172, 248–264. [Google Scholar] [CrossRef]

- Jaber, S.; Ezzat, A.W. Investigation of energy recovery with exhaust air evaporative cooling in ventilation system. Energy Build. 2017, 139, 439–448. [Google Scholar] [CrossRef]

- Aparicio-Ruiz, P.; Schiano-Phan, R.; Salmerón-Lissén, J.M. Climatic applicability of downdraught evaporative cooling in the United States of America. Build. Environ. 2018, 136, 162–176. [Google Scholar] [CrossRef] [Green Version]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maruyama, T.; Maeda, S.; Nakamura, T. Water vapor sorption kinetics of polymer based sorbents: Theory and experiments. Appl. Therm. Eng. 2016, 106, 192–202. [Google Scholar] [CrossRef]

- Hanif, S.; Sultan, M.; Miyazaki, T. Effect of relative humidity on thermal conductivity of zeolite-based adsorbents: Theory and experiments. Appl. Therm. Eng. 2019, 150, 11–18. [Google Scholar] [CrossRef]

- Shabir, F.; Sultan, M.; Miyazaki, T.; Saha, B.B.; Askalany, A.; Ali, I.; Zhou, Y.; Ahmad, R.; Shamshiri, R.R. Recent updates on the adsorption capacities of adsorbent-adsorbate pairs for heat transformation applications. Renew. Sustain. Energy Rev. 2020, 119, 109630. [Google Scholar] [CrossRef]

- Kim, M.-H.; Yoon, D.-S.; Kim, H.-J.; Jeong, J.-W. Retrofit of a liquid desiccant and evaporative cooling-assisted 100% outdoor air system for enhancing energy saving potential. Appl. Therm. Eng. 2016, 96, 441–453. [Google Scholar] [CrossRef]

- Ham, S.-W.; Lee, S.-J.; Jeong, J.-W. Operating energy savings in a liquid desiccant and dew point evaporative cooling-assisted 100% outdoor air system. Energy Build. 2016, 116, 535–552. [Google Scholar] [CrossRef]

- Cuce, P.M. Thermal performance assessment of a novel liquid desiccant-based evaporative cooling system: An experimental investigation. Energy Build. 2017, 138, 88–95. [Google Scholar] [CrossRef]

- Cho, H.-J.; Jeong, J.-W. Evaluation of thermal comfort in an office building served by a liquid desiccant-assisted evaporative cooling air-conditioning system. Energy Build. 2018, 172, 361–370. [Google Scholar] [CrossRef]

- Kashif Shahzad, M.; Qadar Chaudhary, G.; Ali, M.; Ahmed Sheikh, N.; Shahid Khalil, M.; Rashid, T.U. Experimental evaluation of a solid desiccant system integrated with cross flow Maisotsenko cycle evaporative cooler. Appl. Therm. Eng. 2018, 128, 1476–1487. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. An overview of solid desiccant dehumidification and air conditioning systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Sultan, M.; Mahmood, M.H.; Miyazaki, T.; Koyama, S.; Khan, Z.M. Close and open cycle adsorption kinetics: Development of correlation for desiccant air-conditioning. J. Eng. Appl. Sci. 2016, 35, 59–66. [Google Scholar]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Experimental evaluation of desiccant dehumidification and air-conditioning system for energy-efficient storage of dried fruits. Build. Serv. Eng. Res. Technol. 2019, 0143624419893660. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Mahmood, M.; Mahmood Khan, Z. Solar assisted evaporative cooling based passive air-conditioning system for agricultural and livestock applications. J. Eng. Sci. Technol. 2018, 13, 693–703. [Google Scholar]

- Sultan, M.; Miyazaki, T. Energy-efficient air-conditioning systems for nonhuman applications. In Refrigeration; Ekren, O., Ed.; InTech: London, UK, 2017. [Google Scholar]

- Sultan, M.; Miyazaki, T.; Koyama, S. Optimization of adsorption isotherm types for desiccant air-conditioning applications. Renew. Energy 2018, 121, 441–450. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Koyama, S.; Khan, Z.M. Performance evaluation of hydrophilic organic polymer sorbents for desiccant air-conditioning applications. Adsorpt. Sci. Technol. 2018, 36, 311–326. [Google Scholar] [CrossRef] [Green Version]

- Kashif, M.; Niaz, H.; Sultan, M.; Miyazaki, T.; Feng, Y.; Usman, M.; Shahzad, M.W.; Niaz, Y.; Waqas, M.M.; Ali, I. Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies 2020, 13, 2675. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Niaz, H.; Sultan, M.; Khan, A.; Mahmood, M.; Feng, Y.; Mahmood Khan, Z.; Niaz, E.D.Y.; Ali, I.; Imran, M. Study on evaporative cooling assisted desiccant air-conditioning system for livestock application in Pakistan. Fresenius Environ. Bull. 2019, 28, 8623–8633. [Google Scholar]

- Chen, J.; Ding, R.; Li, Y.; Lin, X.; Chen, Y.; Luo, X.; Yang, Z. Application of a vapor–liquid separation heat exchanger to the air conditioning system at cooling and heating modes. Int. J. Refrig. 2019, 100, 27–36. [Google Scholar] [CrossRef]

- ASHRAE Handbook of Fundamentals. Am. Soc. Heating, Refrig; Air-Conditioning Eng. Inc.: Atlanta, GA, USA, 2013.

- Havenith, G.; Kuklane, K.; Fan, J.; Hodder, S.; Ouzzahra, Y.; Lundgren, K.; Au, Y.; Loveday, D. A database of static clothing thermal insulation and vapor permeability values of non-Western ensembles for use in ASHRAE standard 55, ISO 7730, and ISO 9920. ASHRAE Trans. 2015, 121, 197–215. [Google Scholar]

- Designbuilder Software Limited. DesignBuilder 6.1; Designbuilder Software Limited: Stroud, UK, 2020. [Google Scholar]

- U.S. Department of Energy (DOE); National Renewable Energy Laboratory (NREL). EnergyPlus 9.3; U.S. Department of Energy (DOE): Washington, DC, USA; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2020.

- Shen, B.; New, J.; Baxter, V. Air source integrated heat pump simulation model for EnergyPlus. Energy Build. 2017, 156, 197–206. [Google Scholar] [CrossRef]

- Kang, W.H.; Lee, J.M.; Yeon, S.H.; Park, M.K.; Kim, C.H.; Lee, J.H.; Moon, J.W.; Lee, K.H. Modeling, calibration, and sensitivity analysis of direct expansion AHU-Water source VRF system. Energy 2020, 199, 117435. [Google Scholar] [CrossRef]

- Seo, B.; Yoon, Y.B.; Yu, B.H.; Cho, S.; Lee, K.H. Comparative analysis of cooling energy performance between water-cooled VRF and conventional AHU systems in a commercial building. Appl. Therm. Eng. 2020, 170, 114992. [Google Scholar] [CrossRef]

- Naderi, E.; Sajadi, B.; Behabadi, M.A.; Naderi, E. Multi-objective simulation-based optimization of controlled blind specifications to reduce energy consumption, and thermal and visual discomfort: Case studies in Iran. Build. Environ. 2020, 169, 106570. [Google Scholar] [CrossRef]

- Im, P.; Joe, J.; Bae, Y.; New, J.R. Empirical validation of building energy modeling for multi-zones commercial buildings in cooling season. Appl. Energy 2020, 261, 114374. [Google Scholar] [CrossRef]

- Salata, F.; Ciancio, V.; Dell’Olmo, J.; Golasi, I.; Palusci, O.; Coppi, M. Effects of local conditions on the multi-variable and multi-objective energy optimization of residential buildings using genetic algorithms. Appl. Energy 2020, 260, 114289. [Google Scholar] [CrossRef]

- Rosso, F.; Ciancio, V.; Dell’Olmo, J.; Salata, F. Multi-objective optimization of building retrofit in the Mediterranean climate by means of genetic algorithm application. Energy Build. 2020, 216, 109945. [Google Scholar] [CrossRef]

- Wang, H.; Lu, W.; Wu, Z.; Zhang, G. Parametric analysis of applying PCM wallboards for energy saving in high-rise lightweight buildings in Shanghai. Renew. Energy 2020, 145, 52–64. [Google Scholar] [CrossRef]

- Qiu, C.; Yi, Y.K.; Wang, M.; Yang, H. Coupling an artificial neuron network daylighting model and building energy simulation for vacuum photovoltaic glazing. Appl. Energy 2020, 263, 114624. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; Iovane, T.; Mauro, G.M.; Napolitano, D.F.; Ruggiano, A.; Viscido, L. A real industrial building: Modeling, calibration and Pareto optimization of energy retrofit. J. Build. Eng. 2020, 29, 101186. [Google Scholar] [CrossRef]

- Troup, L.N.; Fannon, D.J.; Eckelman, M.J. Spatio-temporal changes among site-to-source conversion factors for building energy modeling. Energy Build. 2020, 213, 109832. [Google Scholar] [CrossRef]

- Martin, M.; Wong, N.H.; Hii, D.J.C.; Ignatius, M. Comparison between simplified and detailed EnergyPlus models coupled with an urban canopy model. Energy Build. 2017, 157, 116–125. [Google Scholar] [CrossRef]

- Qin, H.; Pan, W. Energy use of subtropical high-rise public residential buildings and impacts of energy saving measures. J. Clean. Prod. 2020, 254, 120041. [Google Scholar] [CrossRef]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- Bojić, M.; Nikolić, N.; Nikolić, D.; Skerlić, J.; Miletić, I. Toward a positive-net-energy residential building in Serbian conditions. Appl. Energy 2011, 88, 2407–2419. [Google Scholar] [CrossRef]

- Woods, J.; Bonnema, E. Regression-based approach to modeling emerging HVAC technologies in EnergyPlus: A case study using a Vuilleumier-cycle heat pump. Energy Build. 2019, 186, 195–207. [Google Scholar] [CrossRef]

- Anđelković, A.S.; Mujan, I.; Dakić, S. Experimental validation of a EnergyPlus model: Application of a multi-storey naturally ventilated double skin façade. Energy Build. 2016, 118, 27–36. [Google Scholar] [CrossRef]

- Cho, H.M.; Wi, S.; Chang, S.J.; Kim, S. Hygrothermal properties analysis of cross-laminated timber wall with internal and external insulation systems. J. Clean. Prod. 2019, 231, 1353–1363. [Google Scholar] [CrossRef]

- Karimi, M.S.; Fazelpour, F.; Rosen, M.A.; Shams, M. Comparative study of solar-powered underfloor heating system performance in distinctive climates. Renew. Energy 2019, 130, 524–535. [Google Scholar] [CrossRef]

- Ceballos-Fuentealba, I.; Álvarez-Miranda, E.; Torres-Fuchslocher, C.; del Campo-Hitschfeld, M.L.; Díaz-Guerrero, J. A simulation and optimisation methodology for choosing energy efficiency measures in non-residential buildings. Appl. Energy 2019, 256, 113953. [Google Scholar] [CrossRef]

- Zhang, A.; Bokel, R.; van den Dobbelsteen, A.; Sun, Y.; Huang, Q.; Zhang, Q. An integrated school and schoolyard design method for summer thermal comfort and energy efficiency in Northern China. Build. Environ. 2017, 124, 369–387. [Google Scholar] [CrossRef]

- Abdeen, A.; Serageldin, A.A.; Ibrahim, M.G.E.; El-Zafarany, A.; Ookawara, S.; Murata, R. Experimental, analytical, and numerical investigation into the feasibility of integrating a passive Trombe wall into a single room. Appl. Therm. Eng. 2019, 154, 751–768. [Google Scholar] [CrossRef]

- Venkateswara Rao, V.; Datta, S.P. A feasibility assessment of single to multi/hybrid evaporative coolers for building air-conditioning across diverse climates in India. Appl. Therm. Eng. 2020, 168, 114813. [Google Scholar] [CrossRef]

- Thermal Energy System Specialists LLC. TRNSYS 17; Thermal Energy System Specialists LLC: Madison, WI, USA, 2019. [Google Scholar]

- ASHRAE Standards Committee. ANSI/ASHRAE Standard 143-2007, Method of Test for Rating Indirect Evaporative Coolers; ASHRAE Standards Committee: Atlanta, GA, USA, 2007. [Google Scholar]

- DuBois, D.F. A formula to estimate the approximate surface area if height and body mass be known. Arch. Intern. Med. 1916, 17, 863–871. [Google Scholar] [CrossRef] [Green Version]

- Cengel, Y. Heat and Mass Transfer: Fundamentals and Applications; McGraw-Hill Higher Education: New York, NY, USA, 2014; ISBN 0077654765. [Google Scholar]

- Kreider, J.F.; Curtiss, P.S.; Rabl, A. Heating and Cooling of Buildings: Design for Efficiency; CRC Press: Boca Raton, FL, USA, 2009; ISBN 1439882509. [Google Scholar]

- ISO. ISO 7730, Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- Raza, H.M.U. Investigation of Evaporative Cooling Based Low-Cost Air-Conditioning Technologies for Pakistan. Master’s Thesis (Hons.), Bahauddin Zakariya University, Multan, Pakistan, 2018. [Google Scholar]

- Teitelbaum, E.; Jayathissa, P.; Miller, C.; Meggers, F. Design with Comfort: Expanding the psychrometric chart with radiation and convection dimensions. Energy Build. 2020, 209, 109591. [Google Scholar] [CrossRef]

- Yousuf, I.; Ghumman, A.R.; Hashmi, H.N.; Kamal, M.A. Carbon emissions from power sector in Pakistan and opportunities to mitigate those. Renew. Sustain. Energy Rev. 2014, 34, 71–77. [Google Scholar] [CrossRef]

| Construction Type | Properties | Values |

|---|---|---|

| Layer 1 (outer wall) | Brickwork outer | 0.1016 m |

| Layer 2 (outer wall) | Cement/plaster/mortar—cement | 0.0127 m |

| Layer 3 (outer wall) | Brickwork inner | 0.1016 m |

| Layer 4 (outer wall) | Cement/plaster/mortar—cement | 0.0127 m |

| Medium weight flat roof Layer 1 | 8 in. concrete | 0.2032 m |

| Medium weight flat roof Layer 2 | Cement/plaster/mortar—cement | 0.0127 m |

| Floor (Layer 1) | Cast concrete (dense) | 0.127 m |

| Floor (Layer 2) | 2 in. concrete | 0.0508 m |

| Doors | Lightweight plywood | 0.0381 m |

| Glazing/ window | Generic clear | 0.003 m |

| Fixed height/width | Height | 1.83 m |

| - | Width | 1.52 m |

| Frame type/width | Aluminum | 0.04 m |

| Total building area | 3251.74 m2 | |

| Total conditioned area | 847.5 m2 | |

| Density Inputs | ||

| Lighting power density | Normalized (varies zone to zone) | 2.5 W m−2 |

| - | Radiant fraction | 0.72 |

| - | Visible fraction | 0.18 |

| Occupancy | Density (varies zone to zone) | 0.295/conditioned area |

| Workday schedule | On at | 08:00 am |

| - | Off at | 04:00 pm |

| Clothing (Shalwar, Kameez) [50,51] | Winter | 1.145 clo |

| (1 clo = 0.155 m2 °C W−1) | Summer | 0.775 clo |

| Air Handling Unit (AHU) | ||

| Fan | Total efficiency | 75% |

| Fan type | Constant air volume (CAV) | |

| AHU type | Central air-conditioning system | |

| Motor efficiency | 85% | |

| Fan pressure | 600 Pa | |

| COP of VCAC | 3 | |

| Thermostat and humidistat setpoint | 24 °C and 60% | |

| Direct research special | Design wet-bulb effectiveness (WBE) | 0.90 |

| Indirect research special | Design WBE | 0.605 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noor, S.; Ashraf, H.; Sultan, M.; Khan, Z.M. Evaporative Cooling Options for Building Air-Conditioning: A Comprehensive Study for Climatic Conditions of Multan (Pakistan). Energies 2020, 13, 3061. https://doi.org/10.3390/en13123061

Noor S, Ashraf H, Sultan M, Khan ZM. Evaporative Cooling Options for Building Air-Conditioning: A Comprehensive Study for Climatic Conditions of Multan (Pakistan). Energies. 2020; 13(12):3061. https://doi.org/10.3390/en13123061

Chicago/Turabian StyleNoor, Shazia, Hadeed Ashraf, Muhammad Sultan, and Zahid Mahmood Khan. 2020. "Evaporative Cooling Options for Building Air-Conditioning: A Comprehensive Study for Climatic Conditions of Multan (Pakistan)" Energies 13, no. 12: 3061. https://doi.org/10.3390/en13123061