Life Cycle Assessment of Electricity Generation from an Array of Subsea Tidal Kite Prototypes

Abstract

:1. Introduction

The Array of Powerplants

2. Materials and Methods

2.1. LCA of the DG500 Array

2.1.1. Goal and Scope

2.1.2. Life Cycle Inventory Analysis

Kite and Umbilical System

Gravity Based Foundation

Tidal Marine Substation and Sub-Hub

Cables

Onshore Substation

Transports and Power Plant Construction

Operation and Maintenance

Dismantling

Waste Management

Sensitivity and Scenario Analysis

2.2. Literature Review

3. Results

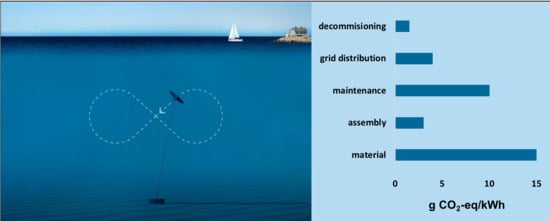

3.1. Environmental Profile and Dominance Analysis

3.2. Sensitivity/Scenario Analysis

3.3. Comparison with Available Technologies

4. Discussion

4.1. The DG500 Array

4.2. Current State and Improvement Potentials in LCA of Tidal Technologies

4.2.1. Maintenance

4.2.2. End-of-Life

4.2.3. Inclusion of Sensitivity and Uncertainty Analysis

4.2.4. Source of Data

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bruckner, T.; Bashmakov, I.; Mulugetta, Y.; Chum, H.; de la Vega Navarro, A.; Edmonds, J.; Faaij, A.; Fungtammasan, B.; Garg, A.; Hertwich, E. Climate Change 2014: Mitigation of Climate Change. Available online: https://www.ipcc.ch/report/ar5/wg3/ (accessed on 10 February 2018).

- Wind-Europe. Wind in Power 2017: Annual Combined Onshore and Offshore Wind Energy Statistics. Available online: https://windeurope.org/wp-content/uploads/files/about-wind/statistics/WindEurope-Annual-Statistics-2017.pdf (accessed on 14 March 2018).

- Turner, J.A. A realizable renewable energy future. Science 1999, 285, 687–689. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pedersen, E.; Persson Waye, K. Perception and annoyance due to wind turbine noise—A dose–Response relationship. J. Acoust. Soc. Am. 2004, 116, 3460–3470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kavousi-Fard, A. Modeling uncertainty in tidal current forecast using prediction interval-based SVR. IEEE Trans. Sustain. Energy 2017, 8, 708–715. [Google Scholar] [CrossRef]

- Iyer, A.; Couch, S.; Harrison, G.; Wallace, A. Variability and phasing of tidal current energy around the United Kingdom. Renew. Energy 2013, 51, 343–357. [Google Scholar] [CrossRef] [Green Version]

- Clarke, J.A.; Connor, G.; Grant, A.; Johnstone, C. Regulating the output characteristics of tidal current power stations to facilitate better base load matching over the lunar cycle. Renew. Energy 2006, 31, 173–180. [Google Scholar] [CrossRef]

- UK-Government. Wave and Tidal Energy: Part of the UK’s Energy Mix. Available online: https://www.gov.uk/guidance/wave-and-tidal-energy-part-of-the-uks-energy-mix (accessed on 7 June 2018).

- Magagna, D.; Uihlein, A. Ocean energy development in Europe: Current status and future perspectives. Int. J. Mar. Energy 2015, 11, 84–104. [Google Scholar] [CrossRef]

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef] [Green Version]

- Douglas, C.; Harrison, G.; Chick, J. Life cycle assessment of the Seagen marine current turbine. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2008, 222, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Arvesen, A.; Birkeland, C.; Hertwich, E.G. The importance of ships and spare parts in LCAs of offshore wind power. Environ. Sci. Technol. 2013, 47, 2948–2956. [Google Scholar] [CrossRef] [Green Version]

- Uihlein, A. Life cycle assessment of ocean energy technologies. Int. J. Life Cycle Assess. 2016, 21, 1425–1437. [Google Scholar] [CrossRef] [Green Version]

- Minesto. Our Technology. Available online: https://minesto.com/our-technology (accessed on 10 October 2018).

- Schuchert, P.; Kregting, L.; Pritchard, D.; Savidge, G.; Elsäßer, B. Using coupled hydrodynamic biogeochemical models to predict the effects of tidal turbine arrays on phytoplankton dynamics. J. Mar. Sci. Eng. 2018, 6, 58. [Google Scholar] [CrossRef] [Green Version]

- Kregting, L.; Elsaesser, B.; Kennedy, R.; Smyth, D.; O’Carroll, J.; Savidge, G. Do changes in current flow as a result of arrays of tidal turbines have an effect on benthic communities? PLoS ONE 2016, 11, e0161279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torosian, R.; Elmehag, E. Life Cycle Assessment of an Ocean Energy Power Plant: Evaluation and Analysis of the Energy Payback Time with Comparison Between Sweden and Tanzania. Bachelor’s Thesis, University of Skövde, Skövde, Sweden, 2013. [Google Scholar]

- Arvidsson, R.; Tillman, A.M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental assessment of emerging technologies: Recommendations for prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 14040: 2006. Environmental Management-Life Cycle Assessment-Principles and Framework; European Committee for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- EPD. Product Category Rules According to ISO 14025. Product Group Classification: UN CPC 171 and 173 Electricity, Steam and Hot/Cold Water Generation and Distribution. Available online: https://www.environdec.com/PCR/Detail/?Pcr=5802 (accessed on 10 April 2018).

- Ciroth, A. ICT for environment in life cycle applications openLCA—A new open source software for life cycle assessment. Int. J. Life Cycle Assess. 2007, 12, 209. [Google Scholar] [CrossRef]

- Ecoinvent. Ecoinvent 3.3. Available online: https://www.ecoinvent.org/database/ecoinvent-33/ecoinvent-33.html (accessed on 5 October 2018).

- Huijbregts, M.; Steinmann, Z.; Elshout, P.; Stam, G.; Verones, F.; Vieira, M.; Hollander, A.; Zijp, M.; Van Zelm, R. ReCiPe 2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization. Available online: http://www.rivm.nl/en/Documents_and_publications/Scientific/Reports/2016/december/ReCiPe_2016_A_harmonized_life_cycle_impact_assessment_method_at_midpoint_and_endpoint_level_Report_I_Characterization (accessed on 14 March 2018).

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. USA 2015, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ABB. Environmental Product Declaration for ACS 600 Frequency Converter, 250 kW Power. Available online: https://library.e.abb.com/public/3aad93ad845f4988c1256d630040684a/9780_EPD%20for%20ACS600lowres.pdf (accessed on 5 May 2018).

- ABB. Environmental Product Declaration for DMI Type DC Machine—180-471 kW Power Range. Available online: https://library.e.abb.com/public/afa1510442415fc6c1256d640022e99f/Product%20Declaration%20S-P%2000009%20rev%20P.pdf?x-sign=OyM9xKoFDAa4dPThofiDKCm97rt8S8RMi44z0+gUbTGWTmR2A (accessed on 5 May 2018).

- Jotun. Jotamastic 87 Aluminium Technical Data Sheet. Available online: https://www.jotun.com/Datasheets/Download?url=%2FTDS%2FTDS__523__Jotamastic%2087%20Aluminium__Euk__GB.pdf (accessed on 20 April 2018).

- Romaniw, Y.A. The Relationship between Light-Weighting with Carbon Fiber Reinforced Polymers and the Life Cycle Environmental Impacts of Orbital Launch Rockets. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2013. [Google Scholar]

- ABB. Environmental Product Declaration for Large Distribution Transformer 10 MVA. Available online: https://library.e.abb.com/public/57c1d5721712c65fc1256de9003d9401/10%20MVA.pdf?x-sign=6lm9n20/x6U8CFRRScbospcDaLlja81Ojv7/HOHBz/v5vzJXGGbHPmzEbj+cXcQI (accessed on 5 May 2018).

- Nexans. Submarine Power Cables. Available online: http://www.nexans.com/Germany/2013/SubmPowCables_FINAL_10jun13_engl.pdf (accessed on 20 April 2018).

- Jivén, K.; Sjöbris, A.; Nilsson, M.; Ellis, J.; Traegaardh, P.; Nordstroem, M. LCA-Ship, Design Tool for Energy Efficient Ships-A Life Cycle Analysis Program for Ships, Final Report. Available online: http://www.mariterm.se/wp-content/uploads/2016/08/Final-report-LCA-ship.pdf (accessed on 7 February 2018).

- Andersen, N.; Eriksson, O.; Hillman, K.; Wallhagen, M. Wind Turbines’ End-of-Life: Quantification and Characterisation of Future Waste Materials on a National Level. Energies 2016, 9, 999. [Google Scholar] [CrossRef] [Green Version]

- Haapala, K.R.; Prempreeda, P. Comparative life cycle assessment of 2.0 MW wind turbines. Int. J. Sustain. Manuf. 2014, 3, 170–185. [Google Scholar] [CrossRef]

- Nordelöf, A.; Poulikidou, S.; Chordia, M.; Bitencourt de Oliveira, F.; Tivander, J.; Arvidsson, R. Methodological Approaches to End-Of-Life Modelling in Life Cycle Assessments of Lithium-Ion Batteries. Batteries 2019, 5, 51. [Google Scholar] [CrossRef] [Green Version]

- Kaddoura, M.; Kambanou, M.L.; Tillman, A.-M.; Sakao, T. Is Prolonging the Lifetime of Passive Durable Products a Low-Hanging Fruit of a Circular Economy? A Multiple Case Study. Sustainability 2019, 11, 4819. [Google Scholar] [CrossRef] [Green Version]

- Khare, V. Prediction, investigation, and assessment of novel tidal–solar hybrid renewable energy system in India by different techniques. Int. J. Sustain. Energy 2019, 38, 447–468. [Google Scholar] [CrossRef]

- Amponsah, N.Y.; Troldborg, M.; Kington, B.; Aalders, I.; Hough, R.L. Greenhouse gas emissions from renewable energy sources: A review of lifecycle considerations. Renew. Sustain. Energy Rev. 2014, 39, 461–475. [Google Scholar] [CrossRef]

- Walker, S.; Howell, R. Life cycle comparison of a wave and tidal energy device. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 325–337. [Google Scholar] [CrossRef]

- Kelly, K.; McManus, M.; Hammond, G. An energy and carbon life cycle assessment of tidal power case study: The proposed Cardiff–Weston severn barrage scheme. Energy 2012, 44, 692–701. [Google Scholar] [CrossRef] [Green Version]

- Douziech, M.l.; Hellweg, S.; Verones, F. Are Wave and Tidal Energy Plants New Green Technologies? Environ. Sci. Technol. 2016, 50, 7870–7878. [Google Scholar] [CrossRef]

- Woollcombe-Adams, C.; Watson, M.; Shaw, T. Severn Barrage tidal power project: Implications for carbon emissions. Water Environ. J. 2009, 23, 63–68. [Google Scholar] [CrossRef]

- Walker, S.; Howell, R.; Hodgson, P.; Griffin, A. Tidal energy machines: A comparative life cycle assessment study. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2015, 229, 124–140. [Google Scholar] [CrossRef] [Green Version]

- Rule, B.M.; Worth, Z.J.; Boyle, C.A. Comparison of life cycle carbon dioxide emissions and embodied energy in four renewable electricity generation technologies in New Zealand. Environ. Sci. Technol. 2009, 43, 6406–6413. [Google Scholar] [CrossRef] [PubMed]

- Paredes, M.G.; Padilla-Rivera, A.; Güereca, L.P. Life cycle assessment of ocean energy technologies: A systematic review. J. Mar. Sci. Eng. 2019, 7, 322. [Google Scholar] [CrossRef] [Green Version]

- ClimateXChange. Wave & Tidal Energy: State of the Industry. Available online: https://www.climatexchange.org.uk/media/3100/state-of-the-wave-and-tidal-industry-report.pdf (accessed on 5 December 2019).

| Specification | Amount | Note |

|---|---|---|

| Rated power total | 12 MW | - |

| Rated power per DG500 | 0.5 MW | - |

| Energy yielded | 2 GWh/year 1 | Per DG500 |

| DG500s in array | 24 | Installed offshore |

| DG500s onshore | 2 | Ready for swap-out during maintenance |

| TMS in array | 4 | Each TMS connects six DG500s |

| Onshore substation | 1 | - |

| Distance from shore | 8 km | - |

| Onshore distance to grid | 4.5 km | - |

| Water current velocity | 1.2–2.4 m/s | - |

| Installation depth | 60–120 m | - |

| Lifetime of array | 25 years | - |

| Part | Lifetime (Years) | Replacement Rate (per Year) |

|---|---|---|

| Nacelle innards | 10 1 | 10% |

| Umbilical cable | 20 | 5% |

| Tether | 5 | 20% |

| Scenario | Power Rating (KW) | Avg. Power Output (GWh/yr) | Kites in Array (pcs) | GBF Type | GBF Reuse | Tether Lifetime (yr) | TMS in Array (pcs) |

|---|---|---|---|---|---|---|---|

| Base Case | 500 | 2 | 24 | Concrete | No | 5 | 4 |

| BT | 500 | 2 | 24 | Concrete | No | 10 | 4 |

| BTR | 500 | 2 | 24 | Concrete | Once | 10 | 4 |

| Bsteel | 500 | 2 | 24 | Steel | No | 5 | 4 |

| Bhybrid | 500 | 2 | 24 | Hybrid | No | 5 | 4 |

| Optimistic | 500 | 3 | 24 | Concrete | No | 5 | 4 |

| Favorable site | 750 | 3 | 18 | Concrete | No | 5 | 0 |

| Ref. | Name | Year | Location | CO2 Intensity (gCO2/kWh) | Power Rating (MW) | Lifetime (yr) | Capacity Factor (%) | Impact Assessment Method | EOL Method Described | Maintenance | Grid | Sensitivity | Source of Data |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| this | DG500 | 2018 | Wales | 26.3 | 0.5 | 25 | 46 | ReCiPe 2010 | Yes | MAIN + SP | Yes | Yes | Comp |

| [40] | HS1000 | 2016 | Scotland | 37 | 1 | 25 | 40 | ReCiPe 2008 | Yes | MAIN + SP | No | Yes | Comp |

| [40] | Hydratidal | 2016 | Norway | 20.1 | 1.5 | 25 | 38 | ReCiPe 2008 | Yes | MAIN + SP | No | Yes | Comp |

| [40] | SeaGen | 2016 | Northern Ireland | 25.5 | 1.2 | 25 | 44 | ReCiPe 2008 | Yes | MAIN + SP | No | Yes | Lit |

| [40] | Annapolis | 2016 | Canada | 3.9 | 20 | 75 | 29 | ReCiPe 2008 | Yes | MAIN + SP | No | Yes | Lit |

| [42] | DeepGen | 2015 | UK | 34.2 | 1 | 25 | 18 | Other 1 | Vague | MAIN | No | No | Comp |

| [42] | OpenHydro | 2015 | UK | 19.6 | 2 | 20 | 24 | Other 1 | Vague | MAIN | No | No | Comp |

| [42] | SR2000 | 2015 | UK | 23.8 | 2 | 20 | 21 | Other 1 | Vague | MAIN | No | No | Comp |

| [42] | Flumill | 2015 | UK | 18.5 | 2 | 20 | 21 | Other 1 | Vague | MAIN | No | No | Comp |

| [39] | Severn Barrage | 2012 | UK | 56.2 | 7200 | 120 | 27 | IPCC2007 GWP 100a | EOL excluded | SP | No | Yes | Lit |

| [43] | Crest Energy | 2009 | New Zealand | 1.8 | 0.385 | 100 | 37 | Other 1 | Vague | MAIN + SP | No | No | Lit |

| [41] | Severn Barrage | 2009 | UK | 5.7 | 7200 | 100 | 28 | Other 1 | EOL excluded | Excluded | No | No | Lit |

| [11] | SeaGen | 2008 | Northern Ireland | 15 | 1.2 | 20 | 48 | Other 1 | Vague | MAIN + SP | No | Yes | Comp |

| Impact Category | Unit (kWhe−1) | Impact |

|---|---|---|

| Aluminum Requirement | g | 0.042 |

| Cement Requirement | g | 3.400 |

| Copper Requirement | g | 0.041 |

| Iron Requirement | g | 0.850 |

| Non-renewable Energy Demand | MJ | 0.410 |

| Land Occupation | m2 ·yr | 0.002 |

| Global Warming Potential | g CO2 eq | 26.300 |

| Acidification Potential | g SO2 eq | 0.200 |

| Freshwater Eutrophication Potential | mg P eq | 7.100 |

| Freshwater Ecotoxicity | g 1,4 DB eq | 0.420 |

| Photochemical Ozone-creation Potential | g C2H4 eq | 0.200 |

| Particulate Matter Formation | g PM10 eq | 0.075 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaddoura, M.; Tivander, J.; Molander, S. Life Cycle Assessment of Electricity Generation from an Array of Subsea Tidal Kite Prototypes. Energies 2020, 13, 456. https://doi.org/10.3390/en13020456

Kaddoura M, Tivander J, Molander S. Life Cycle Assessment of Electricity Generation from an Array of Subsea Tidal Kite Prototypes. Energies. 2020; 13(2):456. https://doi.org/10.3390/en13020456

Chicago/Turabian StyleKaddoura, Mohamad, Johan Tivander, and Sverker Molander. 2020. "Life Cycle Assessment of Electricity Generation from an Array of Subsea Tidal Kite Prototypes" Energies 13, no. 2: 456. https://doi.org/10.3390/en13020456