Supply Systems of Non-Thermal Plasma Reactors. Construction Review with Examples of Applications

Abstract

:Featured Application

Abstract

1. Introduction

- Decomposition of nitrogen and sulfur oxides in flue gases and volatile organic compounds (VOCs) emitted during various industrial processes—many hazardous organic compounds are readily attacked by exciting species, free radicals, electrons, ions, and/or UV photons generated in low temperature plasma [5,6,7];

- Generation of hydrogen H and elemental sulfur S from hydrogen sulfide H2S;

- Water purification by ozone treatment. The ozone synthesis typically takes place in electrical discharges in air or oxygen. They produce strongly oxidizing agents, such as OH*, H*, O*, O3, and hydrogen peroxide H2O2. Moreover, the strong electric fields of electric discharges and UV radiation are also lethal to several kinds of microorganisms in water [5,11];

- Removal of hazardous organic pollutants from waste water—pulsed corona discharges, dielectric barrier discharges (DBDs), and contact glow discharge electrolysis techniques are being studied also for the purpose of water cleaning;

- Sterilization of human and animal tissues, blood and surface wounds;

- Assisting skin cancer therapy;

- Odontology—caries therapy;

- Coating of implants, contact optical lens, dentures with biocompatible films;

- Live tissue engineering—fabrication of bioactive agents and medicines, immobilization of biological molecules, cell surface modification to control their behavior, improvement of blood adhesion;

- Sterilization of medical and surgical instruments, especially made of materials and fabrics not resistant to high temperature;

- Medical diagnostics—fabrication biosensors based on polymers and thin amorphous films for medical and bio-chemical analysis.

- Food pasteurization, disinfection, and preservation—O3 is used in common refrigerators as a deodorizing and antimicrobial agent;

- Food storage packages sterilization;

- Storing agriculture products—ozone increasing storage life, sanitizing fruit and vegetable surfaces;

- Plant growth enhancement and fruit formation processes;

- Seed germination;

- Ozone-aided corn steeping process—to replace current SO2 application.

- Efficient and controllable plasma reactor’s power supply systems with a wide range of changes in the properties (voltage shape and frequency, range of regulation), which are an inseparable part of the plasma-chemical installation that determines industrial implementation [35,36,37,38,39,40,41,42,43,44,45].

2. Non-Thermal Plasma Reactors

- Transformer systems using the properties of magnetic circuits;

- Systems with power electronics elements.

- Supply voltage—constant, sine, impulse;

- The presence of additional ignition system of the discharge or its absence;

- NTP reactor power and attainable power of the PSS;

- The ability to adjust the current value and maintain its continuity in the entire area of the plasma reactor operation;

- Ability of the power source to work in automatic control and regulation systems and adjustment of parameters to various process gases and their mixtures;

- Correct cooperation with the power supply network;

- High efficiency;

- Simplicity and safety of use;

- Low capital and operating costs.

3. Transformer Power Supply Systems for Plasma Reactors

3.1. Integrated Power Supply Systems

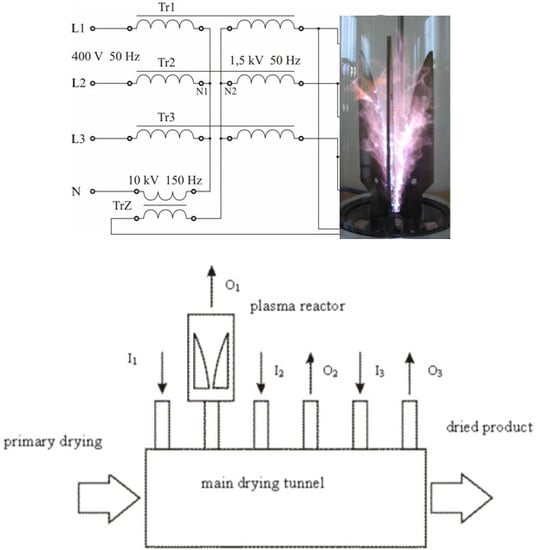

IPSS of GAD Multielectrode Plasma Reactors

3.2. A Five-Column Transformer as a Power Supply for a GAD Plasma Reactor

4. Power Electronics Supply Systems for NTPR

4.1. AC/DC/AC PSS for a GAD Plasma Reactor

4.2. Micro-Gliding Arc Discharge (μGAD) Power Supply System with Push-Pull Inverter

4.3. DBDs Power System with Frequency Resonant Inverter

4.4. RF Power Supply System of APPJ

5. Selected Issues of Designing Power Systems for NT Plasma Reactors

6. Conclusions

Conflicts of Interest

References

- Non-thermal Plasma Techniques for Pollution Control; Penetrante, M.; Shirley, E. (Eds.) Schultheis, NATO ASI Series G: Ecological Science, Part A and B; Springer: Berlin/Heidelberg, Germany, 1993; Volume 34. [Google Scholar]

- Roth, J.R. Industrial Plasma Engineering; Institute of Physics Publishing: Bristol, UK; Philadelphia, PA, USA, 1995. [Google Scholar]

- Kogelschatz, U. Dielectric barrier discharges: Their History, Discharge Physics and Industrial Applications. Plasma Chem. Plasma Process. 2003, 23, 1–4. [Google Scholar] [CrossRef]

- Jiang, B.; Zheng, J.; Qiu, S.; Wu, M.; Zhang, Q.; Yan, Z.; Xue, Q. Review on electrical discharge plasma technology for wastewater remediation. Chem. Eng. J. 2014, 236, 348–368. [Google Scholar] [CrossRef]

- Czernichowski, A.; Lesueur, H. Multi-electrodes high pressure gliding discharges reactor and its application for some waste gas and vapor incineration. In Proceedings of the Plasma Applied to Waste Treatment First Annual INEL Conference, Idaho Falls, ID, USA, 16–17 January 1991. [Google Scholar]

- Hasanbeigi, A.; Price, L. A technical review of emerging technologies for energy and water efficiency and pollution reduction in the textile industry. J. Clean. Prod. 2015, 95, 30–44. [Google Scholar] [CrossRef] [Green Version]

- Gavrilescu, M.; Demnerová, K.; Aamand, J.; Agathos, S.; Fava, F. Emerging pollutants in the environment: Present and future challenges in biomonitoring, ecological risks and bioremediation. New Biotechnol. 2015, 32, 147–156. [Google Scholar] [CrossRef] [PubMed]

- Carmen, F.; Szilagyi, H.; Hegyi, A. Environment and Pollution Management of Pollution Volatile Organic Compounds in Cluj-Napoca. Present Environ. Sustain. Dev. 2016, 10, 207–217. [Google Scholar] [CrossRef] [Green Version]

- Pawłat, J.; Wolny-Koładka, K.; Terebun, P.; Kwiatkowski, M.; Diatczyk, J.; Sudhakaran, M.S.P.; Mok, Y.S. Application of gliding arc plasma reactor for pre-treatment municipal wastes for alternative fuels production. In Proceedings of the 23rd International Conference on Advanced Oxidation Technologies for Treatment of Water, Air and Soil (AOTs-23), Clearwater Beach, FL, USA, 13–16 November 2017. [Google Scholar]

- Fridman, G.; Shereshevsky, A.; Peddinghaus, M.; Gutsol, A.; Vasilets, V.; Brooks, A.; Fridman, A. Bio-medical applications of non-thermal atmospheric pressure plasma. In Proceedings of the 37th AIAA Plasma dynamics and Lasers Conference, San Francisco, CA, USA, 5–8 June 2006. [Google Scholar]

- Pawłat, J.; Stryczewska, H.D.; Ebihara, K.; Mitsugi, F.; Sung, T.L. AOTs and solar energy for air, water and soil treatment. Trans. Mater. Res. Soc. Jpn. 2014, 39, 117–120. [Google Scholar] [CrossRef] [Green Version]

- Stryczewska, H.; Joanna Pawłat, J. Technologies of air, water and soil treatment based on solar energy and advanced oxidation processes. Mod. Power Eng. 2011, 1, 176–197. [Google Scholar]

- Komarzyniec, G.; Muszański, R.; Stryczewska, H.; Diatczyk, J. Solar powered ozone installation for water treatment in swimming pools. In Proceedings of the Workshop on Progress in New Methods of Water and Waste Water Cleaning, Gdańsk, Poland, 4–5 July 2011. [Google Scholar]

- Stryczewska, H.D.; Ebihara, K.; Muszański, R. Mobile installations of air, water and soil treatment with ozone. In Proceedings of the 23rd International Conference on Advanced Oxidation Technologies for Treatment of Water, Air and Soil (AOTs-23), Clearwater Beach, FL, USA, 13–16 November 2017; pp. 43–44. [Google Scholar]

- Yamashita, Y.; Yamashita, T.; Hashimoto, Z.; Ebihara, K.; Mitsugi, F.; Stryczewska, H.; Pawłat, J.; Teil, S.; Sung, T.L. Backpack-type ozone-mist sterilization system developed for non-chemical agriculture processes. In Proceedings of the 8th International Conference ELMECO-8 “Electromagnetic Devices and Processes in Environment Protection” Joint with 11th Seminar AoS-11 “Applications of Superconductors”, Nałęczów, Poland, 28 September–1 October 2014. [Google Scholar]

- Stryczewska, H.; Pawłat, J. Environmental and biomedical applications of gliding arc discharge plasma. In Proceedings of the 3rd International Conference on Photocatalytic and Advanced Oxidation Technologies for Treatment of Water, Air, Soil and Surfaces, Gdańsk, Poland, 1–4 September 2015. [Google Scholar]

- Miyamoto, K.; Ikehara, S.; Takei, H.; Akimoto, Y.; Sakakita, H.; Ishikawa, K.; Ueda, M.; Ikeda, J.; Yamagishi, M.; Kim, J.; et al. Red blood cell coagulation induced by low temperature plasma treatment. Arch. Biochem. Biophys. 2016, 605, 95–101. [Google Scholar] [CrossRef]

- Mitra, A.; Morfill, G.E.; Shimizu, T.; Steffes, B.; Isbary, G.; Schmidt, H.U.; Li, Y.F.; Zimmermann, Z.L. Applications in plasma medicine: A SWOT approach. Compos. Interfaces 2012, 19, 231–238. [Google Scholar] [CrossRef]

- Mohd Nasir, N.; Lee, B.K.; Yap, S.S.; Thong, K.L.; Yap, S.L. Cold plasma inactivation of chronic wound bacteria. Arch. Biochem. Biophys. 2016, 605, 76–85. [Google Scholar] [CrossRef]

- Niedźwiedź, I.; Adam Waśko, A.; Pawłat, J.; Polak-Berecka, M. The State of Research on Antimicrobial Activity of Cold Plasma. Pol. J. Microbiol. 2019, 68, 153–164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Przekora, A.; Pawłat, J.; Terebun, P.; Duday, D.; Canal, C.; Hermans, S.; Audemar, M.; Labay, C.; Thomann, J.S.; Ginalska, G. The effect of low temperature atmospheric nitrogen plasma on MC3T3-E1 preosteoblast proliferation and differentiation in vitro. J. Phys. D Appl. Phys. 2019, 52, 1–10. [Google Scholar] [CrossRef]

- Takayama, M.; Ebihara, K.; Stryczewska, H.; Ikegami, T.; Gyoutoku, Y.; Kubo, K.; Tachibana, M. Ozone generation by dielectric barrier discharge for soil sterilization. Thin Solid Films 2006, 506, 396–399. [Google Scholar] [CrossRef]

- Komarzyniec, G.; Stryczewska, H.D.; Janowski, T.; Diatczyk, J. Special Transformers in Power Systems of Arc Plasma Reactors. In Proceedings of the 1st Central European Symposium on Plasma Chemistry, Gdańsk, Poland, 28–31 May 2006. [Google Scholar]

- Stryczewska, H.D.; Ebihara, K.; Takayama, M.; Gyoutoku, Y.; Tachibana, M. Non-Thermal Plasma-Based Technology for Soil Treatment. Plasma Process. Polym. 2005, 2, 238–245. [Google Scholar] [CrossRef]

- Stryczewska, H. Non-thermal plasma aided soil decontamination. In Proceedings of the 17th International Conference on Advanced Oxidation Technologies for Treatment of Water, Air and Soil (AOTs-17), San Diego, CA, USA, 7–10 November 2011. [Google Scholar]

- Ebihara, K.; Stryczewska, H.; Mitsugi, F.; Ikegami, T.; Sakai, T.; Pawłat, J.; Teil, S. Recent development of ozone treatment for agricultural soil sterilization and biomedical. Przegląd Elektrotechniczny 2012, 88, 92–94. [Google Scholar]

- Ebihara, K.; Mitsugi, F.; Ikegami, T.; Yamashita, Y.; Yamashita, T.; Hashimoto, Y.; Stryczewska, H.; Pawłat, J.; Teil, S.; Sung, T.L.; et al. Biological evaluation of gaseous ozone spray system for non-chemical sterilization. In Proceedings of the 8th International Conference ELMECO-8 “Electromagnetic Devices and Processes in Environment Protection” Joint with 11th Seminar AoS-11 “Applications of Superconductors”, Nałęczów, Poland, 28 September–1 October 2014. [Google Scholar]

- Ebihara, K.; Mitsugi, F.; Yamashita, Y.; Yamashita, T.; Baba, S.; Aoqui, S.; Mitsugi, F.; Ikegami, T.; Stryczewska, H. Ozone-mist sterilization and web-based management for greenhouse agriculture. In Proceedings of the International Conference on Electromagnetic Devices and Processes in Environment Protection with Seminar Applications of Superconductors (ELMECO & AoS), Nałęczów, Poland, 3–6 December 2017. [Google Scholar]

- Stryczewska, H.; Pawłat, J.; Ebihara, K. Plasma treatment for agriculture applications. In Proceedings of the 4th International Conference on Plasma Medicine—ICPM4, Orléans, France, 17–21 June 2012. [Google Scholar]

- Starek, A.; Pawłat, J.; Chudzik, B.; Kwiatkowski, M.; Terebun, P.; Sagan, A.; Andrejko, D. Evaluation of selected microbial and physicochemical parameters of fresh tomato juice after cold atmospheric pressure plasma treatment during refrigerated storage. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Pavlovich, M.J.; Ono, T.; Galleher, C.; Curtis, B.; Clark, D.S.; Machala, Z.; Graves, D.B. Air spark-like plasma source for antimicrobial NOx generation. J. Phys. D Appl. Phys. 2014, 47, 505202. [Google Scholar] [CrossRef]

- Li, S.; Tang, Z.; Gu, F. Experimental study on temperature characteristics and energy conversion in packed bed reactor with dielectric barrier discharge. Heat Mass Transf. 2010, 46, 851–857. [Google Scholar] [CrossRef]

- Hrycak, B.; Czylkowski, D.; Miotk, R.; Dors, M.; Jasinski, M.; Mizeraczyk, J. Hydrogen production from ethanol in nitrogen microwave plasma at atmospheric pressure. Open Chem. 2014, 13. [Google Scholar] [CrossRef]

- Diatczyk, J.; Giżewski, T.; Kapka, L.; Komarzyniec, G.; Pawłat, J.; Stryczewska, H. Generation of non-equilibrium low-temperature plasma in the array of gliding arc plasma reactors. In Proceedings of the 7th International Conference “Electromagnetic Devices and Processes in Environment Protection” Elmeco-7 Joint with 10th Seminar “Applications of Superconductors” AoS-10, Nałęczów, Poland, 28–30 September 2011. [Google Scholar]

- Kong, C.; Gao, J.; Zhu, J.; Ehn, A.; Aldén, M.; Li, Z. Characterization of an AC glow-type gliding arc discharge in atmospheric air with a current-voltage lumped model. Phys. Plasmas 2017, 24. [Google Scholar] [CrossRef] [Green Version]

- Stryczewska, H.D.; Jakubowski, T.; Kalisiak, S.; Giżewski, T.; Pawłat, J. Power systems of plasma reactors for non-thermal plasma generation. J. Adv. Oxid. Technol. 2013, 16, 52–62. [Google Scholar] [CrossRef]

- Stryczewska, H.D.; Komarzyniec, G. Properties of Gliding Arc (GA) Reactors Energized from AC/DC/AC Power Convectors. In Proceedings of the IEEE Region 8 SIBIRCON 2010 International Conference on Computational Technologies in Electrical and Electronics Engineering, Irkutsk, Russia, 11–15 July 2010; pp. 744–749. [Google Scholar]

- Selerowic, W.; Piechna, J.; Opalinska, T.; Ulejczyk, B. Experimental Investigation of the Dynamics and Space Range of the Gliding Arc in Three-Electrode System. IEEE Trans. Plasma Sci. 2011, 39, 2866–2867. [Google Scholar] [CrossRef]

- El-Zein, A.; Talaat, M.; El-Aragi, G.; El-Amawy, A. Experimental Model to Study the Characteristics of Gliding Arc Plasma Reactor with Argon/Nitrogen. J. Electr. Eng. 2015, 15, 64–67. [Google Scholar]

- Sun, S.R.; Kolev, S.; Wang, H.X.; Bogaerts, A. Investigations of discharge and post-discharge in a gliding arc: A 3D computational study. Plasma Sources Sci. Technol. 2017, 26, 05501. [Google Scholar] [CrossRef]

- Baba, T.; Takeuchi, Y.; Stryczewska, H.; Aoqui, S. A study of simple power supply system with 6 electrodes configuration on gliding arc discharge. In Proceedings of the 7th International Conference “Electromagnetic Devices and Processes in Environment Protection” Elmeco-7 Joint with 10th Seminar “Applications of Superconductors” AoS-10, Nałęczów, Poland, 28–30 September 2011. [Google Scholar]

- Jaroszyński, L. Analiza Plazmowego Reaktora Łukowego Wykorzystującego Nieliniowość Magnetowodów Transformatorów Układu Zasilającego (Analysis of the Plasma Arc Reactor Using the Nonlinearity of the Power Supply Transformers’ Magnetic Cores). Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2000. (In Polish). [Google Scholar]

- Stryczewska, H.D. Technologie Plazmowe w Energetyce i Inżynierii Środowiska/Plasma Technologies in Energy and Environmental Engineering; Electrotechnical Committee of Polish Academy of Science PAN: Lublin, Poland, 2009; p. 212. ISBN 978-83-7497-070-9. (In Polish) [Google Scholar]

- Komarzyniec, G. Analiza Pracy Transformatora Pięciokolumnowego w Układzie Zasilania Łukowego Reaktora Plazmowgo (Analysis of the Five Column Transformer Operations in the Arc Plasma Reactor Supply). Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2008. (In Polish). [Google Scholar]

- Krupski, L. Analiza Współpracy Przekształtnikowego Układu Zasilającego z Miniaturowym Generatorem Plazmy Nietermicznej (Analysis of Cooperation of the Converter Supply System with the Miniature Non-Thermal Plasma Generator). Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2019. (In Polish). [Google Scholar]

- Billings, K.H.; Morey, T. Switch Mode Power Supply Handbook; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Stryczewska, H.D.; Janowski, T.; Komarzyniec, G. Gliding Arc Discharge in the Triple-Electrode System. Acta Agrophysica 2002, 80, 63–70. [Google Scholar]

- Janowski, T.; Stryczewska, H. Hybrid Power Supply of Plasmotron to Carry-out Chemical Reactions. PL172,170. 29 August 1997. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/117ab1e1e5987b7e6818248ec00299aa#search=%22PL%20172170%22 (accessed on 5 May 2020).

- Janowski, T.; Stryczewska, H. AC Plasmotron for Chemical Reactions. PL172,152. 29 August 1997. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/ec86dc74cbff19fedc40ee50c35dd713#search=%22PL%20172152%22 (accessed on 5 May 2020).

- Stryczewska, H. Power System of Low Temperature Plasma Reactor. PL180,063. 29 December 2000. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/98c98b603f983f8ce62792f4d4f548c4#search=%22PL%20180063%22 (accessed on 5 May 2020).

- Stryczewska, H.; Janowski, T. Plasma Reactor Power Supply. PL193,498. 28 February 2007. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/f1746602d81bcea2e48941bb5a124814#search=%22PL%20193%20498,%20Janowski%22 (accessed on 5 May 2020).

- Pawłat, J.; Terebun, P.; Kwiatkowski, M.; Tarabová, B.; Kovaľová, Z.; Kučerová, K.; Machala, Z.; Janda, M.; Hensel, K. Evaluation of oxidative species in gaseous and liquid phase generated by mini-gliding arc discharge. Plasma Chem. Plasma Process. 2019, 39, 627–642. [Google Scholar] [CrossRef] [Green Version]

- Pawłat, J.; Diatczyk, J.; Stryczewska, H.D. Low-temperature plasma for exhaust gas purification from paint shop—A case study. Przegląd Elektrotechniczny 2011, 87, 245–248. [Google Scholar]

- Sobacchi, M.G.; Saveliev, A.V.; Fridman, A.A.; Gutsol, A.F.; Kennedy, L.A. Experimental assessment of pulsed corona discharge for treatment of VOC emissions. Plasma Chem. Plasma Process. 2003, 23, 347–370. [Google Scholar] [CrossRef]

- Stryczewska, H.D.; Sikorski, A.; Ruszczyk, A.; Komarzyniec, G. Gliding arc plasma reactor supplied from AC/DC/AC inverter. In Proceedings of the 18th International Symposium on Plasma Chemistry, Kyoto, Japan, 26–31 August 2007. [Google Scholar]

- Kalisiak, S.; Holub, M.; Jakubowski, T. Resonant inverter with output voltage pulse-phase-shift control for DBD plasma reactor supply. In Proceedings of the 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–9. [Google Scholar]

- Terebun, P.; Kwiatkowski, M.; Krupski, P.; Pawłat, J.; Diatczyk, J.; Janda, M.; Hensel, K.; Machala, Z. High speed camera imaging of mini glidarc discharge. In Proceedings of the SAPP 20th Symposium on Application of Plasma Processes, COST TD1208 Workshop on Application of Gaseous Plasma with Liquids, Tatranská Lomnica, Slovakia, 17–22 January 2015; pp. 283–287. [Google Scholar]

- Dasan, B.G.; Onal-Ulusoy, B.; Pawłat, J.; Diatczyk, J.; Sen, Y.; Mutlu, M. A new and simple approach for decontamination of food contact surfaces with gliding arc discharge atmospheric non-thermal plasma. Food Bioprocess Technol. 2016, 10, 1–12. [Google Scholar] [CrossRef]

- Krupski, P.; Kwiatkowski, M.; Terebun, P.; Pawłat, J.; Machala, Z.; Hensel, K. Zastosowanie reaktora plazmowego Miniaturized GlidArc w usuwaniu kontaminatu bakteryjnego z powierzchni teflonu/Application of the Miniaturized GlidArc plasma reactor in removing bacterial contamination from the surface of Teflon. Przegląd Elektrotechniczny 2016, 6, 127–130. (In Polish) [Google Scholar]

- Pawłat, J.; Samoń, R.; Stryczewska, H.D.; Diatczyk, J.; Giżewski, T. RF-powered atmospheric pressure plasma jet for surface treatment. Eur. Phys. J. Appl. Phys. 2013, 61. [Google Scholar] [CrossRef]

- Pawłat, J.; Samoń, R.; Giżewski, T.; Diatczyk, J.; Janowski, W.; Stryczewska, H. RF-powered atmospheric pressure plasma jet for surface treatment. In Proceedings of the HAKONE XIII: International Symposium on High Pressure Low Temperature Plasma Chemistry, Kazimierz Dolny, Poland, 9–14 September 2012. [Google Scholar]

- Ram, P.V.; Bhat, K.N.; Mala, R.C. Multiple output push-pull converter with post regulated buck converters. In Proceedings of the 2017 International Conference on Smart Grids, Power and Advanced Control Engineering (ICSPACE), Bangalore, India, 17–19 August 2017; pp. 231–236. [Google Scholar]

- Huiskamp, T.; Takamura, N.; Namihira, T.; Pemen, A.J.M. Matching a Nanosecond Pulse Source to a Streamer Corona Plasma Reactor with a DC Bias. IEEE Trans. Plasma Sci. 2015, 43, 617–624. [Google Scholar] [CrossRef] [Green Version]

- Krupski, P.; Stryczewska, H.D. The Investigation of the Properties of High-voltage Transformer in Nonthermal Plasma Pulse Power Supply. In Proceedings of the IEEE Explore-Post Conference Materials of 14th Selected Issues of Electrical Engineering and Electronics (WZEE) Conference, Szczecin, Poland, 19–21 November 2018; pp. 1–4. [Google Scholar]

- Krupski, P.; Stryczewska, H. System and Method of Supplying a Plasma Reactor with a Gliding Arc Discharge. PL233,868B1. 31 December 2019. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/d100bb62cb87548cc9a19c392e177dd2#search=%22PL%20193498%22 (accessed on 5 May 2020).

- Diatczyk, J.; Pawłat, J.; Stryczewska, H.D.; Krupski, P.; Terebun, P.; Kwiatkowski, M. Microplasma Reactor with an Adjustable Distance between the Electrodes for Surface Treatment. PL222,477. 29 July 2016. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/665450da4adc31070c7887a97be1cd16#search=%22PL%20222477%22 (accessed on 5 May 2020).

- Diatczyk, J.; Pawłat, J.; Stryczewska, H.D.; Terebun, P.; Kwiatkowski, M. The Method and Device for Generating Non-Equilibrium Low-Temperature Plasma. PL226,367. 31 July 2017. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/ee199f5e469792b48a81a5c6a8b274f1#search=%22PL%20226367%22 (accessed on 5 May 2020).

- Pawłat, J. Atmospheric pressure plasma jet for sterilization of heat sensitive surfaces. Przegląd Elektrotechniczny 2012, 10, 139–140. [Google Scholar]

- Dünnbier, M.; Schmidt-Bleker, A.; Winter, J.; Wolfram, M.; Hippler, R.; Weltmann, K.D.; Reuter, S. Ambient air particle transport into the effluent of a cold atmospheric-pressure argon plasma jet investigated by molecular beam mass spectroscopy. J. Phys. D Appl. Phys. 2013, 46, 435203. [Google Scholar] [CrossRef]

- Mounir, L.; Tamer, A. Arc-free atmospheric pressure cold plasma jets: A review. Plasma Proc. Polym. 2007, 4, 777–778. [Google Scholar]

- Kwiatkowski, M.; Terebun, P.; Krupski, P.; Diatczyk, J.; Pawłat, J.; Stryczewska, H. Angles on polymeric material exposed on plasma generated in dielectric barrier discharge plasma jet. In Proceedings of the 8th International Conference ELMECO-8 “Electromagnetic Devices and Processes in Environment Protection” Joint with 11th Seminar AoS-11 “Applications of Superconductors”, Nałęczów, Poland, 28 September–1 October 2014. [Google Scholar]

- Krupski, P.; Stryczewska, H. Thermal imaging of surfaces treated by cooled plasma jet. Przegląd Elektrotechniczny 2018, 94, 79–82. [Google Scholar] [CrossRef] [Green Version]

- Pawłat, J.; Terebun, P.; Kwiatkowski, M.; Diatczyk, J. RF atmospheric plasma jet surface treatment of paper. J. Phys. D Appl. Phys. 2016, 49, 374001. [Google Scholar]

- Pawłat, J.; Terebun, P.; Kwiatkowski, M.; Krupski, P.; Diatczyk, J.; Murakami, T. Surface treatment of high-impact polystyrene using RF-APPJ. In Proceedings of the SAPP 20th Symposium on Application of Plasma Processes, COST TD1208 Workshop on Application of Gaseous Plasma with Liquids, Tatranská Lomnica, Slovakia, 17–22 January 2015; pp. 310–313. [Google Scholar]

- Stryczewska, H.D. Analiza Pracy Magnetycznego Potrajacza Częstotliwości Jako Źródła Zasilania Odbiornika Nieliniowego na Przykładzie Wytwornicy Ozonu (Analysis of Magnetic Frequency Tripler Operation as a Power Source for a Non-linear Receiver on the Example of an Ozone Generator). Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 1986. (In Polish). [Google Scholar]

- Stryczewska, H.D. Elektromagnetyczny Układ Zasilania Reaktorów Plazmowych ze Ślizgającym się Wyładowaniem Łukowym; Series: Elektryka; LUT University Publisher: Lublin, Poland, 1998; p. 146. ISBN 83-87270-82-2. (In Polish) [Google Scholar]

- Stryczewska, H.D. Analiza Zintegrowanych Zasilaczy Elektromagnetycznych w Urządzeniach Wyładowczych; Series: Elektryka; LUT University Publisher: Lublin, Poland, 1996; p. 132. (In Polish) [Google Scholar]

- Terebun, P. Wpływ Parametrów Reaktora APPJ o Częstotliwości Radiowej na Skuteczność Modyfikacji i Dekontaminacji Powierzchni. Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2019. (In Polish). [Google Scholar]

- Mazurek, P.; Pawłat, J. Badania natężeń pól elektrycznych i magnetycznych generowanych przez instalację reaktorów plazmowych. Rocz. Ochr. Srodowiska Annu. Set Environ. Prot. 2016, 18, 567–578. [Google Scholar]

- Mazurek, P. Selected methods to improve the electromagnetic compatibility of the plasma reactor. Przegląd Elektrotechniczny 2012, 88, 158–160. [Google Scholar]

- Pawłat, J. Electrical Discharges in Humid Environments. Generators, Effects, Application; LUT University Publisher: Lublin, Poland, 2013; p. 141. ISBN 978-83-63569-37-2. [Google Scholar]

- Diatczyk, J. Badanie Pola Temperatury w Komorze Wyładowczej Reaktora Plazmowego. Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2007. (In Polish). [Google Scholar]

| Height of Reaction Chamber | 500 mm |

| Diameter of reaction chamber | 114 mm |

| Ignition electrode material | Tungsten 1 mm |

| Working electrodes material | acid proof steel 0H18N |

| Number of working electrodes | 3 |

| Length of working electrodes | 210 mm |

| Distance between electrodes in the ignition/ quenching zones | 5mm/50mm |

| Gas flow rate | (0.5–20) m3/h |

| PROPANE | BUTANE | ||||

|---|---|---|---|---|---|

| Initial concentration (volume) | % | 1.26 | 0.48 | 0.85 | 0.345 |

| Abatement level | % | 54 | 22 | 47 | 19 |

| Flow rate | m3 /h | 74 | 88 | 75 | 87 |

| Active power | kW | 4.3 | 3.8 | 4.2 | 4.1 |

| Gas temperature (inlet) | °C | 25 | 22 | 28 | 28 |

| Gas temperature (outlet) | °C | 410 | 188 | 400 | 210 |

| SEI kWh/m3 | 0.057 | 0.044 | 0.056 | 0.047 | |

| SER kWh/kg | 4.3 | 21 | 5.4 | 28 | |

| Chemical Compound | Measurement 1 at Air Mixture Velocity 4 m/s | Measurement 2 at Air Mixture Velocity 6m/s | ||||

|---|---|---|---|---|---|---|

| Retention Time | Amount of Pollutants % | Retention Time | Amount of Pollutants % | |||

| min | before Treatment | after Treatment | min | before Treatment | after Treatment | |

| methyl ethyl ketone | 13.78 | 0.38 | 7.38 | 13.749 | 0.28 | 4.70 |

| ethyl acetate | 14.85 | 13.39 | 9.20 | 14.828 | 13.37 | 8.96 |

| 1-butanol | 18.47 | 1.09 | 2.14 | 18.462 | 1.06 | 1.20 |

| benzene | 21.12 | 10.25 | 9.90 | 21.118 | 10.15 | 10.47 |

| heptane | 21.33 | 66.36 | 62.0 | 21.338 | 68.10 | 65.8 |

| toluene | 21.97 | 6.32 | 5.70 | 21.976 | 6.59 | 6.24 |

| butyl acetate | 23.32 | 0.23 | 0.09 | 23.325 | 0.29 | 0.06 |

| ethyl benzene | 23.62 | 0.23 | 0.16 | 23.621 | 0.25 | 0.20 |

| xylene | 24.44 | 0.58 | 0.44 | 24.446 | 0.61 | 0.53 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stryczewska, H.D. Supply Systems of Non-Thermal Plasma Reactors. Construction Review with Examples of Applications. Appl. Sci. 2020, 10, 3242. https://doi.org/10.3390/app10093242

Stryczewska HD. Supply Systems of Non-Thermal Plasma Reactors. Construction Review with Examples of Applications. Applied Sciences. 2020; 10(9):3242. https://doi.org/10.3390/app10093242

Chicago/Turabian StyleStryczewska, Henryka Danuta. 2020. "Supply Systems of Non-Thermal Plasma Reactors. Construction Review with Examples of Applications" Applied Sciences 10, no. 9: 3242. https://doi.org/10.3390/app10093242