Introduction: There is an increasing interest in designing and engineering bone repair materials of similar composition, structure and properties with the native bone microenvironment to reconstruct the degenerative or defective bones. In this respect, the injectable hydrogels have been paid particular attentions in bone regeneration domain due to their biomimetic extracellular matrix (ECM) structure, good biocompatibility, intrinsic cellular affinity, minimal invasive performance and excellent fitting and shaping features. In this study, an injectable thermo-sensitive aminated alginate-g-PNIPAAm (AAlg-g-PNIPAAm) hydrogel enhanced by biomimetic peptide nanofibers and nano-hydroxyapatite (nHA) was prepared and studied for bone regeneration.

Materials and Methods: AAlg-g-PNIPAAm was synthesized as our previously reported method and dissolved in DI water at a concentration of 6wt% prior to use. The peptide C12VAVAVAGRGDSEEE-OH was supported by GL Biochem (Shanghai) Ltd. and dissolved in DI water (pH=7.4) at a concentration of 2wt% to obtain the self-assembling nanofibers. The two stored solutions were then mixed in an equal volume with subsequent addition of nHA at a solid content of 20% to yield the precursor solution of hydrogel. The thermo-sensitive hydrogel would be formed with addition of Ca2+ solution and subsequent incubation at 37 oC. The thermo-sensitive hydrogels were then intensively explored from the morphologies, rheological mechanical properties, in vivo degradation and biological compatibility, and the osteoblast proliferation and differentiation properties to evaluate their potential for bone regeneration.

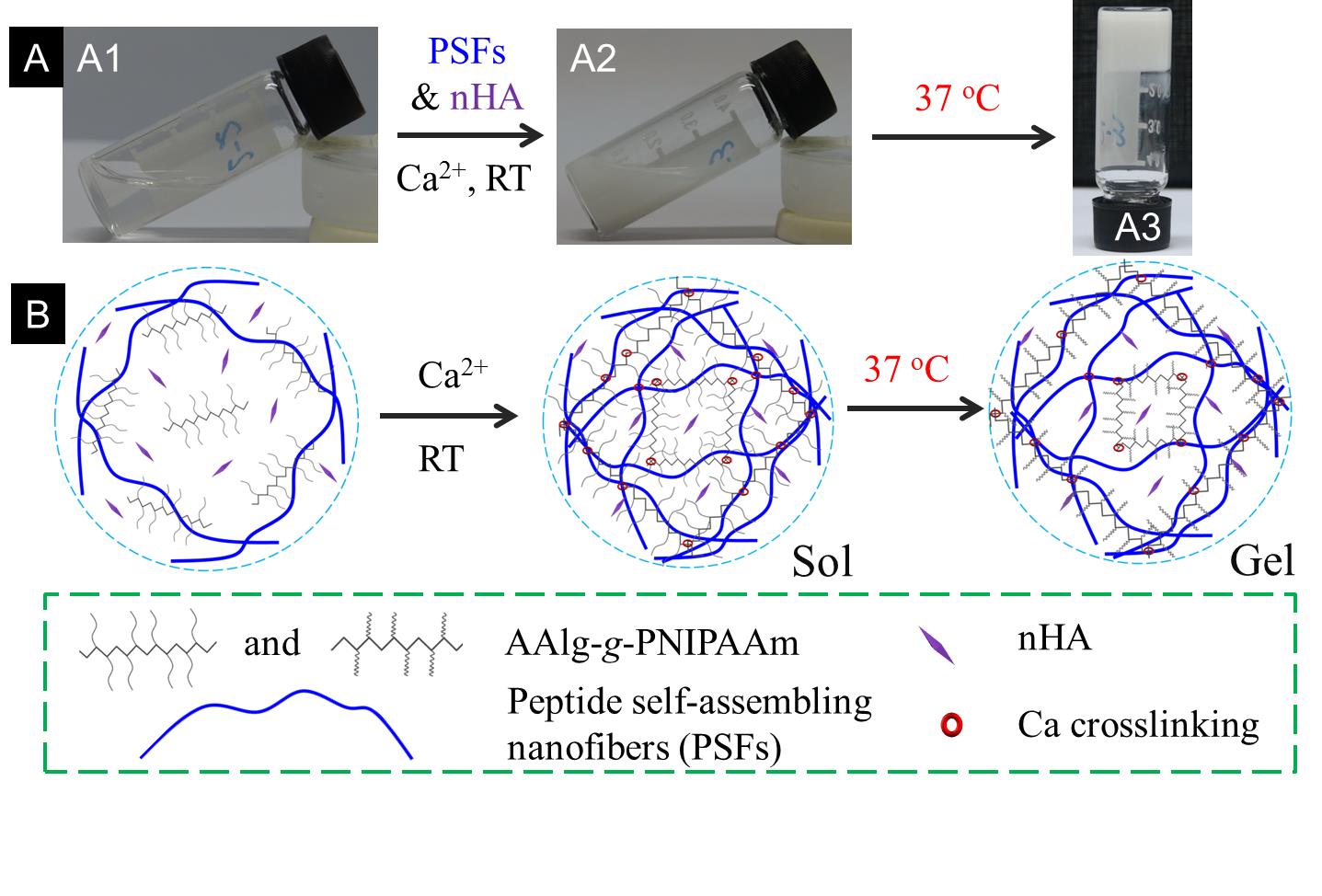

Results and Discussion: In general condition, AAlg-g-PNIPAAm solution at a concentration of 3% is a transparent fluid (Figure 1A-1), even with good mobility after adding the peptide self-assembling solution, nHA and Calcium ion (Figure 1A-2). However, once the precursor solution was incubated at 37 oC, it gradually transformed into a stable hydrogel within 5-10 min (Figure 1A-3), demonstrating it’s injectable and thermo-sensitive properties. A proposed gelation mechanism in Figure 1B discovered the peptide can enhance the hydrogel structure by the inter-crosslinking interaction from the abundant carboxyl group, and the hydrophobic behavior transformation of PNIPAAm determined the hydrogel formation above the LCST.

Figure 1. Preparation and Formation of the thermo-sensitive hydrogel. Photograph of the precursor solutions and hydrogel (A), and a proposed gelation mechanism (B).

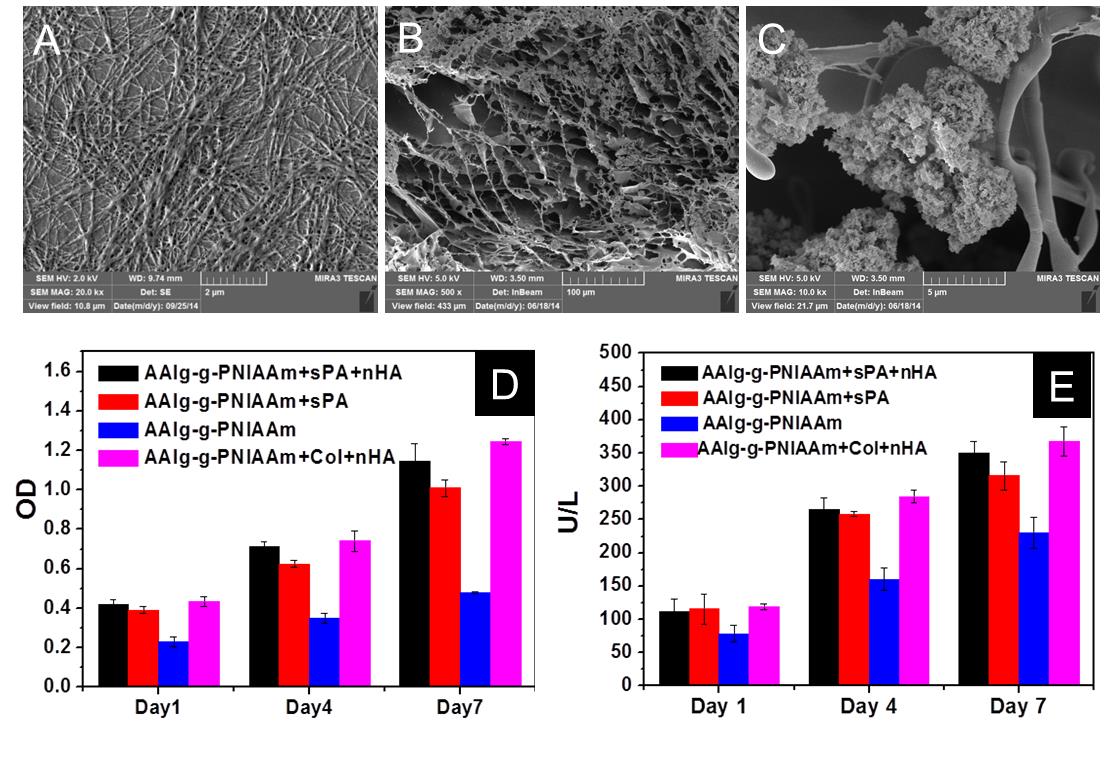

As shown in figure 2A, the biomimetic peptide self-assembled into well-defined nanofibers, which enriched carboxyl group on their surface can chemically and physically interact with AAlg-g-PNIPAAm to enhance the scaffold structure during Calcium ion crosslinking (Figure 1B). The composite hydrogel presented well interconnected porous structure with nHA well distributed (Figure 2B&C). Figure 2D&E revealed that the thermo-sensitive composite hydrogel was conducive to the proliferation and differentiation of osteoblasts, even approaching to the results of collagen substituted hydrogel. Moreover, the injectable hydrogel presented no obvious local tissue reaction and comparatively matching degradation performance from the results of subcutaneous injection.

Figure 2. Morphologies of peptide self-assembling solution (A) and final thermo-sensitive hydrogel (B&C). Proliferation and differentiation of osteoblasts in the hydrogel (B&C).

Conclusion: An injectable thermo-sensitive hydrogel composed of AAlg-g-PNIPAAm, biomimetic peptide nanofibers and nHA was fabricated and studied. The thermo-sensitive composite hydrogel has suitable gelation time, well interconnected porous structure and good biocompatibility, and more importantly it is conductive to the proliferation and differentiation of osteoblasts. The thermo-sensitive composite hydrogel can be a promising injectable bone material for minimally invasive repair of individual bone defects.

National Natural Science Foundation of China (51303094, 51403116); Shenzhen Science and Technology Development Fund Project (CXZZ20130322165836774); Shenzhen Strategic Emerging Industries Special Fund Project (JCYJ20130401174221011)

References:

[1] Tan RW, She ZD, Wang MB, Fang Z, Liu YS, Feng QL. Thermo-sensitive alginate-based injectable hydrogel for tissue engineering Carbohydrate Polymers. 2012, 87, 1515-1521.

[2] Yasmeen S, Lo MK, Bajracharya S, Roldo M. Injectable Scaffolds for Bone Regeneration. Langmuir 2014, 30, 12977-12985.