Abstract

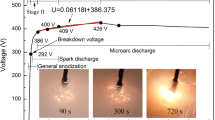

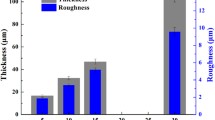

A mathematical interpretation model of micro-arc oxidation process parameters and ceramic coating properties in Ca/P electrolyte system was attempted to establish. The model includes micro-arc oxidation process parameters (power supply voltage U m , current density J, duty ratio ŋ, electrolyte conductivity and dielectric constant of anodic oxide gas), and the properties of ceramic coating (surface morphology, thickness, pores density, porosity, the average size of pores). The response of current during the process was studied. The properties of ceramic coating (morphologies, thickness and surface statistics) were measured by scanning electron microscopy (SEM), 3-D HIROX video microscope, TT230 coating and layer thickness measuring instrument and image analysis software ImageJx2.0. The current was measured by AC galvanometer GPM-8212. The molar conductivity of NaOH is the highest among the four electrolyte system components, and its concentration has the greatest impact on ceramic coating surface morphology. The analysis agrees with the experimental results in lower concentration (under 0.30 mol/L) extremely. However, there is a discrepancy at higher concentration (0.40 mol/L) since the much more molten metal during the reaction of MAO in higher conductivity electrolyte. Pores density is the major factor in determining the porosity. Current results show that ceramic coating had been generated at 40 s under the constant voltage system. The model provides a theoretical base for the interpretation of Ti alloy MAO process and determining the appropriate concentration of NaOH in Ca/P electrolyte system.

Similar content being viewed by others

References

Wu, H.H., Lu, X.Y., and Long, B.H., The effects of cathodic and anodic voltages on the characteristics of porous nanocrystalline titania film fabricated by microarc oxidation, Mater. Lett., 2005, vol. 59, pp. 370–375.

Yerokhin, A.L., Nie, X., and Leyland, A., Plasma electrolysis for surface engineering, Surf. Coat. Tech., 1999, vol. 122, nos. 2–3, pp. 73–93.

Anusavice, K.J. and Philips, R.W., Philips’ Science of Dental Materials, 11th ed., St. Louis: Elsevier, 2003, pp. 743–53.

Yuan-Hong Wang, Zhan-guo Liu, Jia-Hu Ouyang, et al., Preparation and high temperature oxidation resistance of micro-arc oxidation ceramic coatings formed on Ti2AlNb alloy, Appl. Surf. Sci., 2012, vol. 258, no. 22, pp. 8946–8952.

McKee, D.W., Savage, R.H., and Gunnoe, G., Chemical factors in carbon brush wear, Wear, 1972, vol. 22, no. 2, pp. 193–214.

Krishna, L.R., Somaraju, K.R.C., and Sundararajan, G., The tribological performance of ultra-hard ceramic composite coatings obtained through micro-arc oxidation, Surf. Coat. Tech., 2003, vol. 163–164, pp. 484–490.

Yerokhin, A.L., Leyland, A., and Matthews, A., Kinetic aspects of aluminium titanate layer formation on titanium alloys by plasma electrolytic oxidation, Appl. Surf. Sci., 2002, vol. 200, no. 1–4, pp. 172–184.

Dearnley, P.A., Dahm, K.L., and Murakami, R., Hard engineering surfaces for aluminium alloys, Tribology Ser., 2002, vol. 40, pp. 1373–1377.

Wenbin Xue, Chao Wang, Ruyi Chen, et al., Structure and properties characterization of ceramic coatings produced on Ti–6Al–4V alloy by micro-arc oxidation in aluminate solution, Mater. Lett., 2002, vol. 52, no. 6, pp. 435–441.

Tao Zhang, Xiaona Wu, Huayang Huang, et al., The beneficial influence of micro-arc oxidation-coated magnesium alloy on the adhesion, proliferation and osteogenic differentiation of bone marrow stromal cells, Mater. Lett., 2014, vol. 137, pp. 362–365.

Yonghao Gao, Yerokhin, A., Parfenov, E., et al., Application of voltage pulse transient analysis during plasma electrolytic oxidation for assessment of characteristics and corrosion behaviour of Caand P-containing coatings on magnesium, Electrochim. Acta, 2014, vol. 149, pp. 218–230.

Khalajabadi, S.Z., Kadir, M.R.A., Izman, S., et al., Effect of mechanical alloying on the phase evolution, microstructure and bio-corrosion properties of a Mg/HA/TiO2/MgO Nanocomposite, Ceram. Int., 2014, vol. 40, no. 10, pp. 16743–16759.

Gu, X.N., Li, N., Zhou, W.R., et al., Corrosion resistance and surface biocompatibility of a micro-arc oxidation coating on a Mg–Ca alloy, Acta Biomaterialia, 2011, vol. 7, no. 4, pp. 1880–1889.

Ho-Jun Song, Kyung-Ha Shin, Min-Suk Kook, et al., Effects of the electric conditions of AC-type micro-arc oxidation and hydrothermal treatment solution on the characteristics of hydroxyapatite formed on titanium, Surf. Coat. Tech., 2010, vol. 204, no. 14, pp. 2273–2278.

Malyshev, V.N. and Zorin, K.M., Features of micro-arc oxidation coatings formation technology in slurry electrolytes, Appl. Surf. Sci., 2007, vol. 254, no. 5, pp. 1511–1516.

Wang, Y.M., Wang, F.H., Xu, M.J., et al., Microstructure and corrosion behavior of coated AZ91 alloy by micro-arc oxidation for biomedical application, Appl. Surf. Sci., 2009, vol. 255, no. 22, pp. 9124–9131.

Ikonopisov, S., Theory of electrical breakdown during formation of barrier anodic films, Electrochim. Acta, 1977, vol. 22, no. 10, pp. 1077–1082.

Alebella, J.M., Montero, I., et al., Electron injection and avalanche during the anodic oxidation of tantalum, J. Electrochem. Soc., 1984, vol. 131, no. 5, pp. 1101–1108.

Wen, L., Wang, Y.M., Zhou, Y., et al., Iron-rich layer introduced by SMAT and its effect on corrosion resistance and wear behavior of 2024 Al alloy, Mater. Chem. Phys., 2011, vol. 126, no. 1–20, pp. 301–309.

Lee, Y.K., Lee, K., and Jung, T., Study on micro-arc oxidation of AZ31B magnesium alloy in alkaline metal silicate solution, Electrochem. Commun., 2006, vol. 10, no. 1, pp. 1716–1719.

Li Hanru, Introduction to Dielectric Physics, Cheng-du: Chengdu University of Science and Technology Press, 1990, p. 451.

Sun Bing, Discharge Plasma in Liquid and Its Application, Science Press Beijing, 2013, p. 251.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Shi, M., Li, H. A Mathematical interpretation model of Ti alloy micro-arc oxidation (MAO) process and its experimental study. Surf. Engin. Appl.Electrochem. 51, 468–477 (2015). https://doi.org/10.3103/S1068375515050142

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375515050142