Abstract

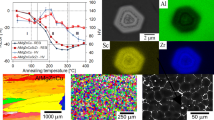

Isothermal sections of the diagram of the Al–Fe–Si–Zr alloy at temperatures of 450 and 600°C, as well as polythermal sections at concentrations of silicon up to 2 wt % and zirconium up to 1 wt %, are analyzed using computational methods with the help of Thermo-Calc software. It is shown that the favorable phase composition consisting of the aluminum solid solution (Al), the Al8Fe2Si phase, and Zr (which completely enters the composition of the solid solution (Al) during the formation of the cast billet) can be attained in equilibrium conditions at silicon concentrations of 0.27–0.47 wt %. To implement the above-listed structural components in nonequilibrium conditions and ensure that Zr enters the (Al) composition, experimental ingots were fabricated at an elevated cooling rate (higher than 10 K/s). A metallographic analysis of the cast structure of experimental samples revealed the desired structure with contents of 0.25 wt % Si and 0.3 wt % Zr in the alloy. The microstructure of the Al–1% Fe–0.3% Zr–0.5% Si alloy also contains the eutectic (Al) + Al8Fe2Si; however, the Al8Fe2Si phase partially transforms into Al3Fe. The structure of the alloy with 0.25 wt % Si in the annealing state at 600°C contains fragmented particles of the degenerate eutectic (Al) + Al8Fe2Si along the boundaries of dendritic cells. It is established that the Si: Fe = 1: 2 ratio in the alloy positively affects its mechanical properties, especially hardness, without substantially lowering the specific conductivity during annealing, which is explained by the formation of the particles of the Al8Fe2Si phase of the compact morphology in the structure. Moreover, silicon accelerates the decay of the solid solution by zirconium, which is evidenced by the experimental plots of the dependence of hardness and resistivity on the annealing step. The best complex of properties was shown by the Al–1% Fe–0.3% Zr–0.25% Si alloy in the annealing stage at 450°C with the help of the optimization function at specified values of hardness and resistivity.

Similar content being viewed by others

References

Vorontsova, L.A., Alyuminii i alyuminievye splavy v elektrotekhnicheskikh izdeliyakh (Aluminium and Aluminum Alloys in Electrical products), Moscow: Energiya, 1971.

Belov, N.A., Alabin, A.N., and Prokhorov, A.Yu., The influence of zirconium addition on the strength and electrical resistance of cold-rolled aluminum sheets, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2009, no. 4, pp. 42–47.

Alabin, A. and Belov, N., Effect of iron and silicon on strength and electrical resistivity of Al–Zr wire alloys, in: Proc. 13-th Inter. Conf. on Aluminum Alloys (ICAA13), Pittsburgh: Wiley, 2012, pp. 1539–1544.

Alabin, A.N., Belov, N.A., Korotkova, N.O., and Samoshina M.E., The effect of annealing on electrical resistivity and hardening of low-alloy alloys of the Al–Zr–Si system, Metalloved. Term. Obrab. Met., 2016, no. 9, pp. 16–20.

Booth-Morrison, C., Mao, Z., Diaz, M., Dunand, D.C., Wolverton, C., and Seidman, D.N., Role of silicon in accelerating the nucleation of Al3(Sc,Zr) precipitates in dilute Al–Sc–Zr alloys, Acta Mater., 2012, no. 60, pp. 4740–4752.

Liu, Ya., Tang, M., Wu, Ch., Wang, J., and Su, X., Progress on phase equilibria of the Al–Si–Zr system at 700 and 900oC, J. Alloys Compd., 2017, vol. 693, pp. 357–365.

Gao, T., Ceguerra, A., Breen, A., Liu, X., Wu, Y., and Ringer, S., Precipitation behaviors of cubic and tetragonal Zr-rich phase in Al–(Si–)Zr alloys. J. Alloys Compd., 2016, vol. 674, pp. 125–130.

Aluminum. Properties and Physical Metallurgy: Reference Book, Hatch, J.E., Ed., Metals Park, Ohio: Amer. Soc. for Metals, 1984.

Belov, N.A., Aksenov, A.A., and Eskin, D.G., Iron in Aluminum Alloys: Impurity and Alloying lement, London: Fransis and Tailor, 2002.

Uliasz, P., Knych, T., Mamala, A., and Smyrak, B., Investigation in properties’ design of heat resistant Al–Zr–Sc alloy wires assigned for electrical application’ in aluminum alloys: their physical and mechanical properties, Hirsch, J., Scrotzki, B., and Gottstein, G., in: Proc. 11-th Inter. Conf. on Aluminum Alloys (ICAA11), Aahen, Germany, 2008, pp. 248–255.

Deschamp, A. and Guyo, P., In situ small-angle scattering study of the precipitation kinetics in an Al–Zr–Sc alloy, Acta Mater., 2007, vol. 55, pp. 2775–2783.

Booth-Morrison, C., Seidman, D. N., and Dunand, D.C., Effect of Er additions on ambient and high-temperature strength of precipitation-strengthened Al–Zr–Sc–Si alloys, Acta Mater., 2012, vol. 60, pp. 3643–3654.

Çadirli, E., Tecer, H., Sahin, M., Yilmaz, E., Kirindi, T., and Gündüz, M. Effect of heat treatments on the microhardness and tensile strength of Al–0.25 wt % Zr alloy, J. Alloys Compd., 2015, vol. 632, pp. 229–237.

Guo, C., Du, Z., Li, C., Zhang, B., and Tao, M., Thermodynamic description of the Al–Fe–Zr system, Comp. Coup. Phase Diagr. Thermochem., 2008, vol. 32, pp. 637–649.

Moustafa, M.A., Effect of iron content on the formation of ß–Al5FeSi and porosity in Al–Si eutectic alloys, J. Mater. Proc. Technol., 2009, vol. 209, pp. 605–610.

Mahmoud, A.E., Mahfouz, M.G., and Gad-Elrab, H.G., Influence of zirconium on the grain refinement of Al 6063 alloy, J. Eng. Res. Appl., 2014, pp. 188–194.

Bespalov, V.M., Research of the combined processes of processing of alloys of the Al–Zr system for obtaining long-dimensioned deformed semifinished products of electrotechnical, Extended Abstract of Cand. Sci. Dissertation, Krasnoyarsk: SibFU, 2014.

Deng, Y., Yin, Zh., Pan, Q., Xu, G., Duan, Yu., and Wang, Y., Nano-structure evolution of secondary Al3(Sc1–xZrx) particles during superplastic deformation and their effects on deformation mechanism in Al–Zn–Mg alloys, J. Alloys Compd., 2017, vol. 695, pp. 142–153.

Taendl, J., Orthacker, A., Amenitsch, H., Kothleitner, G., and Poletti, C., Influence of the degree of scandium supersaturation on the precipitation kinetics of rapidly solidified Al–Mg–Sc–Zr alloys, Acta Mater., 2016, vol. 117, pp. 43–50.

Lin, Y.C., Xia Yu.-Chi., Qiang Jiang Yu., Hua-Min Zhou, and Lei-Ting Li, Precipitation hardening of 2024–T3 aluminum alloy during creep aging, Mater. Sci. Eng. A., 2013, vol. 565, pp. 420–429.

Muggerud, A., Marie, F., Mørtsell, E. A., Li, Ya., and Holmestad, R., Dispersoid strengthening in AA3xxx alloys with varying Mn and Si content during annealing at low temperatures, Mater. Sci. Eng. A., 2013, vol. 567, pp. 21–28.

Harrington, E., The desirability function, Ind. Quality Cont., 1965, no. 21, pp. 494–498.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.A. Belov, N.O. Korotkova, A.N. Alabin, S.S. Mishurov, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Tsvetnaya Metallurgiya, 2018, No. 2, pp. 50–58.

About this article

Cite this article

Belov, N.A., Korotkova, N.O., Alabin, A.N. et al. Influence of a Silicon Additive on Resistivity and Hardness of the Al–1% Fe–0.3% Zr Alloy. Russ. J. Non-ferrous Metals 59, 276–283 (2018). https://doi.org/10.3103/S1067821218030033

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218030033