Abstract

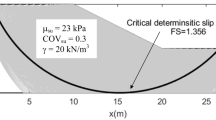

Large deformation analysis of slope failure is important for hazard and risk assessment of infrastructure. Recent studies have revealed that spatial variability of soil properties can significantly affect the probability of slope failure. However, due to limitations of traditional numerical tools, the influence of spatial variability of soil properties on the post-failure behavior of slopes has not been fully understood. Therefore, in this study, we aimed to investigate the effects of the cross-correlation between cohesion and the friction angle on the probability of slope failure and post-failure behavior (e.g. run-out distance, influence distance, and influence zone) using a random material point method (RMPM). The study showed that mesh size, strength reduction shape factor parameter, and residual strength all play critical roles in the calculated post-failure behavior of a slope. Based on stochastic Monte Carlo simulation, the effects of cross-correlation between cohesion and the friction angle on the probability of slope failure, and its run-out distance, influence distance, influence zone, and sliding volume were studied. The study also showed that material point method (MPM) has great advantages compared with the finite element method (FEM) in handling large deformations.

Abstract

目的

土体性质的空间变异性是其固有属性, 虽然目前极限平衡法或有限元法结合随机场理论已经广泛地应用于可靠性分析土质边坡的稳定性, 然而这些数值方法本身具有一定的局限性, 难以模拟边坡的大变形破坏, 因此可能低估边坡失稳的风险。此外, 土体中的抗剪强度参数, 即粘聚力和摩擦角通常具有互相关性, 而之前的大变形研究忽略了这个性质。因此, 本文旨在利用随机物质点法, 考虑粘聚力与摩擦角的空间变异性和互相关性, 对边坡的失稳概率及失稳后特征进行分析, 从而定量地评估边坡潜在的失稳风险。

创新点

1. 通过在均质土坡中的分析, 揭示了网格大小、强度折减形状因子和残余强度对物质点法模拟中边坡安全系数及失稳后特征的影响;2. 基于蒙特卡洛模拟, 明确了粘聚力与摩擦角的互相关性对边坡失稳概率以及失稳后特征的影响, 从而定量地评估了边坡失稳的潜在风险; 3.对比分析了随机物质点法与随机有限元法在模拟边坡失稳变形中的差异。

方法

1. 通过物质点法确定性地分析网格大小、强度折减形状因子和残余强度对均质土坡模拟结果的影响;2. 使用随机物质点法, 评估不同粘聚力与摩擦角互相关系数下边坡的失稳概率、失稳后特征以及相应的失稳风险;3. 比较分析随机物质点法与随机有限元法在边坡失稳变形模拟中的差异。

结论

1. 在随机物质点法模拟中, 边坡的失稳概率随粘聚力与摩擦角互相关系数的增大而显著增大, 而边坡失稳后特征随互相关系数的增大而略微增大(5%~10%)。2. 当使用摩尔库伦应变软化模型时, 物质点法会面临网格依赖性问题;网格越密, 计算的边坡安全系数与失稳特征均趋向收敛, 但相应的计算时间显著增大;考虑到计算的效率与准确性, 对于本文案例, 0.5 m大小的网格较优。3. 当网格大小一定时, 强度折减形状因子和残余强度会影响物质点法的计算结果;在本案例中, 相较于残余粘聚力, 残余摩擦角对边坡的失稳后特征影响更大。4. 随机物质点法与随机有限元法所计算出的边坡失稳概率相近, 说明两种方法均适用于模拟边坡失稳中的小变形, 同时也说明0.4 m的位移失稳准则在物质点法计算中可替代传统的安全系数来判断边坡失稳的发生。5. 需要注意的是随机有限元法可能严重地低估边坡的失稳风险;这主要是因为当网格发生畸变时, 随机有限元法将会终止计算, 从而无法模拟边坡的大变形破坏;对于随机物质点法, 其可以有效地模拟边坡失稳的全过程。

Similar content being viewed by others

References

Abbo AJ, Sloan SW, 1995. A smooth hyperbolic approximation to the Mohr-Coulomb yield criterion. Computers & Structures, 54(3):427–441. https://doi.org/10.1016/0045-7949(94)00339-5

Bandara S, Soga K, 2015. Coupling of soil deformation and pore fluid flow using material point method. Computers and Geotechnics, 63:199–214. https://doi.org/10.1016/j.compgeo.2014.09.009

Bandara S, Ferrari A, Laloui L, 2016. Modelling landslides in unsaturated slopes subjected to rainfall infiltration using material point method. International Journal for Numerical and Analytical Methods in Geomechanics, 40(9): 1358–1380. https://doi.org/10.1002/nag.2499

Cheng HZ, Chen J, Chen RP, et al., 2018. Risk assessment of slope failure considering the variability in soil properties. Computers and Geotechnics, 103:61–72. https://doi.org/10.1016/j.compgeo.2018.07.006

Cho SE, 2010. Probabilistic assessment of slope stability that considers the spatial variability of soil properties. Journal of Geotechnical and Geoenvironmental Engineering, 136(7):975–984. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000309

Feng K, Wang G, Huang D, et al., 2021a. Material point method for large-deformation modeling of coseismic landslide and liquefaction-induced dam failure. Soil Dynamics and Earthquake Engineering, 150:106907. https://doi.org/10.1016/j.soildyn.2021.106907

Feng K, Huang D, Wang G, 2021b. Two-layer material point method for modeling soil-water interaction in unsaturated soils and rainfall-induced slope failure. Acta Geotechnica, 16:2529–2551. https://doi.org/10.1007/s11440-021-01222-9

Griffiths DV, Lane PA, 1999. Slope stability analysis by finite elements. Géotechnique, 49(3):387–403. https://doi.org/10.1680/geot.1999.49.3.387

Huang D, Wang G, Du C, et al., 2020. An integrated SEMNewmark model for physics-based regional coseismic landslide assessment. Soil Dynamics and Earthquake Engineering, 132:106066. https://doi.org/10.1016/j.soildyn.2020.106066

Huang J, Lyamin AV, Griffiths DV, et al., 2013. Quantitative risk assessment of landslide by limit analysis and random fields. Computers and Geotechnics, 53:60–67. https://doi.org/10.1016/j.compgeo.2013.04.009

Hungr O, Leroueil S, Picarelli L, 2014. The Varnes classification of landslide types, an update. Landslides, 11(2):167–194. https://doi.org/10.1007/s10346-013-0436-y

Li DQ, Jiang SH, Cao ZJ, et al., 2015. A multiple response-surface method for slope reliability analysis considering spatial variability of soil properties. Engineering Geology, 187:60–72. https://doi.org/10.1016/j.enggeo.2014.12.003

Li DQ, Xiao T, Cao ZJ, et al., 2016. Enhancement of random finite element method in reliability analysis and risk assessment of soil slopes using subset simulation. Landslides, 13(2):293–303. https://doi.org/10.1007/s10346-015-0569-2

Liu LL, Cheng YM, Zhang SH, 2017. Conditional random field reliability analysis of a cohesion-frictional slope. Computers and Geotechnics, 82:173–186. https://doi.org/10.1016/j.compgeo.2016.10.014

Liu X, Wang Y, Li DQ, 2019. Investigation of slope failure mode evolution during large deformation in spatially variable soils by random limit equilibrium and material point methods. Computers and Geotechnics, 111:301–312. https://doi.org/10.1016/j.compgeo.2019.03.022

Liu X, Wang Y, Li DQ, 2020. Numerical simulation of the 1995 rainfall-induced Fei Tsui Road landslide in Hong Kong: new insights from hydro-mechanically coupled material point method. Landslides, 17(12):2755–2775. https://doi.org/10.1007/s10346-020-01442-2

Ng CWW, Qu CX, Cheung RWM, et al., 2021. Risk assessment of soil slope failure considering copula-based rotated anisotropy random fields. Computers and Geotechnics, 136:104252. https://doi.org/10.1016/j.compgeo.2021.104252

Oliver J, Huespe AE, 2004. Continuum approach to material failure in strong discontinuity settings. Computer Methods in Applied Mechanics and Engineering, 193(30–32): 3195–3220. https://doi.org/10.1016/j.cma.2003.07.013

Soga K, Alonso E, Yerro A, et al., 2016. Trends in large-deformation analysis of landslide mass movements with particular emphasis on the material point method. Géotechnique, 66(3):248–273. https://doi.org/10.1680/jgeot.15.LM.005

Sulsky D, Chen Z, Schreyer HL, 1994. A particle method for history-dependent materials. Computer Methods in Applied Mechanics and Engineering, 118(1–2):179–196. https://doi.org/10.1016/0045-7825(94)90112-0

Sulsky D, Zhou SJ, Schreyer HL, 1995. Application of a particle-in-cell method to solid mechanics. Computer Physics Communications, 87(1–2):236–252. https://doi.org/10.1016/0010-4655(94)00170-7

Vanmarcke EH, 1983. Random Fields: Analysis and Synthesis. MIT Press, Cambridge, USA.

Wang B, Vardon PJ, Hicks MA, 2016a. Investigation of retrogressive and progressive slope failure mechanisms using the material point method. Computers and Geotechnics, 78:88–98. https://doi.org/10.1016/j.compgeo.2016.04.016

Wang B, Hicks MA, Vardon PJ, 2016b. Slope failure analysis using the random material point method. Géotechnique Letters, 6(2):113–118. https://doi.org/10.1680/jgele.16.00019

Wang B, Vardon PJ, Hicks MA, 2018. Rainfall-induced slope collapse with coupled material point method. Engineering Geology, 239:1–12. https://doi.org/10.1016/j.enggeo.2018.02.007

Wang MX, Tang XS, Li DQ, et al., 2020. Subset simulation for efficient slope reliability analysis involving copula-based cross-correlated random fields. Computers and Geotechnics, 118:103326. https://doi.org/10.1016/j.compgeo.2019.103326

Wang MY, Liu Y, Ding YN, et al., 2020. Probabilistic stability analyses of multi-stage soil slopes by bivariate random fields and finite element methods. Computers and Geotechnics, 122:103529. https://doi.org/10.1016/j.compgeo.2020.103529

Wang Y, Qin ZW, Liu X, et al., 2019. Probabilistic analysis of post-failure behavior of soil slopes using random smoothed particle hydrodynamics. Engineering Geology, 261:105266. https://doi.org/10.1016/j.enggeo.2019.105266

Yerro A, Alonso EE, Pinyol NM, 2015. The material point method for unsaturated soils. Géotechnique, 65(3):201–217. https://doi.org/10.1680/geot.14.P.163

Yerro Colom A, 2015. MPM Modelling of Landslides in Brittle and Unsaturated Soils. PhD Thesis, Universitat Politècninca de Catalunya, Barcelona, Spain.

Yin YP, Li B, Wang WP, et al., 2016. Mechanism of the December 2015 catastrophic landslide at the Shenzhen landfill and controlling geotechnical risks of urbanization. Engineering, 2(2):230–249. https://doi.org/10.1016/J.ENG.2016.02.005

Zhang WJ, Xiao DQ, 2019. Numerical analysis of the effect of strength parameters on the large-deformation flow process of earthquake-induced landslides. Engineering Geology, 260:105239. https://doi.org/10.1016/j.enggeo.2019.105239

Zhang YB, Xu Q, Chen GQ, et al., 2014. Extension of discontinuous deformation analysis and application in cohesive-frictional slope analysis. International Journal of Rock Mechanics and Mining Sciences, 70:533–545. https://doi.org/10.1016/j.ijrmms.2014.06.005

Zhu H, Zhang LM, 2013. Characterizing geotechnical anisotropic spatial variations using random field theory. Canadian Geotechnical Journal, 50(7):723–734. https://doi.org/10.1139/cgj-2012-0345

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the Fund of Hong Kong Research Grants Council (RGC) (No. 16214519), China

Contributors

Chuan-xiang QU: conceptualization, formal analysis, investigation, software, writing-original draft, writing-review & editing. Gang WANG: conceptualization, methodology, funding acquisition, supervision, validation, writing-review & editing. Ke-wei FENG: methodology, software, validation. Zhen-dong XIA: validation, software.

Conflict of interest

Chuan-xiang QU, Gang WANG, Ke-wei FENG, and Zhen-dong XIA declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Qu, Cx., Wang, G., Feng, Kw. et al. Large deformation analysis of slope failure using material point method with cross-correlated random fields. J. Zhejiang Univ. Sci. A 22, 856–869 (2021). https://doi.org/10.1631/jzus.A2100196

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A2100196