Abstract

Earth-based building material processing is a challenge for new constructions. Moreover, field measurements to obtain the rheological properties of fresh materials are required in building applications. However, existing field-oriented tests were designed for more flowable materials, and new protocols for stiff materials are rarely available. In this paper, a field-oriented test of yield stress is developed for earth-based building materials accurate enough to identify small variations for demanding applications. The squeeze test is used as the reference measurement of yield stress. For pure clays and two clay-based materials, yield stresses could not be easily linked to two existing tests: the Atterberg limits and the falling plunger. Finally, a weighted plunger test was used to measure the yield stress as accurately as the squeeze test. The development of yield stress measurements for fresh earthen materials will help implement new building techniques on the field.

Similar content being viewed by others

References

Van Damme H, Houben H (2018) Earth concrete Stabilization revisited. Cem Concr Res 114:90–102. https://doi.org/10.1016/j.cemconres.2017.02.035

Melià P, Ruggieri G, Sabbadini S, Dotelli G (2014) Environmental impacts of natural and conventional building materials: a case study on earth plasters. J Clean Prod 80:179–186. https://doi.org/10.1016/j.jclepro.2014.05.073

Ghezzehei TA, Or D (2001) Rheological properties of wet soils and clays under steady and oscillatory stresses. Soil Sci Soc Am J 65:624–637. https://doi.org/10.2136/sssaj2001.653624x

Estellé P, Lanos C, Ea L et al (2011) High torque vane rheometer for concrete: principle and validation from rheological measurements. Appl Rhenol 22:1–7. https://doi.org/10.3933/ApplRheol-22-12881

Coussot P (2005) Rheometry of pastes, suspensions, and granular materials: applications in industry and environment. Wiley, Hoboken

De Larrard F, Ferraris CF, Sedran T (1996) Fresh concrete: a Herschel-Bulkley material. Mater Struct Constr 31:494–498. https://doi.org/10.1007/bf02480474

Perrot A, Rangeard D, Levigneur A (2016) Linking rheological and geotechnical properties of kaolinite materials for earthen construction. Mater Struct Constr 49:4647–4655. https://doi.org/10.1617/s11527-016-0813-9

Perrot A, Rangeard D, Lecompte T (2018) Field-oriented tests to evaluate the workability of cob and adobe. Mater Struct Constr 51:1–10. https://doi.org/10.1617/s11527-018-1181-4

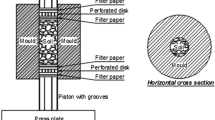

Engmann J, Servais C, Burbidge AS (2005) Squeeze flow theory and applications to rheometry: a review. J Nonnewton Fluid Mech 132:1–27. https://doi.org/10.1016/J.JNNFM.2005.08.007

Toutou Z, Roussel N, Lanos C (2005) The squeezing test: a tool to identify firm cement-based material’s rheological behaviour and evaluate their extrusion ability. Cem Concr Res 35:1891–1899. https://doi.org/10.1016/j.cemconres.2004.09.007

Meeten GH (2004) Effects of plate roughness in squeeze-flow rheometry. J Nonnewton Fluid Mech 124:51–60. https://doi.org/10.1016/j.jnnfm.2004.07.003

Cardoso FA, John VM, Pileggi RG (2009) Rheological behavior of mortars under different squeezing rates. Cem Concr Res 39:748–753. https://doi.org/10.1016/j.cemconres.2009.05.014

Cardoso FA, John VM, Pileggi RG, Banfill PFG (2014) Characterisation of rendering mortars by squeeze-flow and rotational rheometry. Cem Concr Res 57:79–87. https://doi.org/10.1016/j.cemconres.2013.12.009

Huang TA (2008) Utility of squeeze flow in the food industry. AIP Conf Proc 1027:1280–1282. https://doi.org/10.1063/1.2964544

Estellé P, Lanos C, Mélinge Y, Servais C (2006) On the optimisation of a texture analyser in squeeze flow geometry. Meas J Int Meas Confed 39:771–777. https://doi.org/10.1016/j.measurement.2006.02.004

Wang YC, Muthukumarappan K, Ak MM, Gunasekaran S (1998) A device for evaluating melt/flow characteristics of cheeses. J Texture Stud 29:43–55. https://doi.org/10.1111/j.1745-4603.1998.tb00152.x

Roussel N, Lanos C (2003) Plastic fluid flow parameters identification using a simple squeezing test. Appl Rheol 13:132–141. https://doi.org/10.1515/arh-2003-0009

Roussel N, Lanos C (2004) Particle fluid separation in shear flow of dense suspensions: experimental measurements on squeezed clay pastes. Appl Rheol 141410:256–26556. https://doi.org/10.1515/arh-2004-0015

Perrot A, Rangeard D, Courteille E (2018) 3D printing of earth-based materials: processing aspects. Constr Build Mater 172:670–676. https://doi.org/10.1016/j.conbuildmat.2018.04.017

Y Jacquet , Picandet V, Rangeard D (2020) Gravity driven tests to assess mechanical properties of printable cement-based materials at Fresh State. In: Second RILEM international conference on concrete and digital fabrication: digital concrete 280–289. https://doi.org/https://doi.org/10.1007/978-3-030-49916-7_29

Ducoulombier N, Carneau P, Mesnil R, et al (2020) The slug test: inline assessment of yield stress for extrusion-based additive manufacturing. In: Second RILEM international conference on concrete and digital fabrication: digital concrete, Spinger, Cham, 216–224. https://doi.org/https://doi.org/10.1007/978-3-030-49916-7_22

Carrière SR, Jongmans D, Chambon G et al (2018) Rheological properties of clayey soils originating from flow-like landslides. Landslides 15:1615–1630. https://doi.org/10.1007/s10346-018-0972-6

Khaldoun A, Moller P, Fall A et al (2009) Quick clay and landslides of clayey soils. Phys Rev Lett 103:1–4. https://doi.org/10.1103/PhysRevLett.103.188301

Coussot P, Meunier M (1996) Recognition, classification and mechanical description of debris flows. Earth-Science Rev 40:209–227. https://doi.org/10.1016/0012-8252(95)00065-8

NF EN ISO 17892–12:2018 Reconnaissance et essais géotechniques — Essais de laboratoire sur les sols — Partie 12: Détermination des limites de liquidité et de plasticité

Fitton T, Seddon K (2012) Relating Atterberg limits to rheology. In: Proceedings of the 15th International Seminar on Paste and Thickened Tailings. pp 273–284

Gutiérrez A (2006) Determination of atterberg limits: uncertainty and implications. J Geotech Geoenviron Eng 132:420–424. https://doi.org/10.1061/(ASCE)1090-0241(2006)132:3(420)

Day JH, Everett KR (1972) Classification of organic soils. Arct Alp Res 4:283. https://doi.org/10.2307/1550232

Andrade FA, Al-Qureshi HA, Hotza D (2011) Measuring the plasticity of clays: a review. Appl Clay Sci 51:1–7. https://doi.org/10.1016/j.clay.2010.10.028

Roussel N (2007) The LCPC BOX: a cheap and simple technique for yield stress measurements of SCC. Mater Struct Constr 40:889–896. https://doi.org/10.1617/s11527-007-9230-4

Roussel N, Stefani C, Leroy R (2005) From mini-cone test to Abrams cone test: measurement of cement-based materials yield stress using slump tests. Cem Concr Res 35:817–822. https://doi.org/10.1016/j.cemconres.2004.07.032

Roussel N, Coussot P (2005) “Fifty-cent rheometer” for yield stress measurements: from slump to spreading flow. J Rheol 49:705–718. https://doi.org/10.1122/1.1879041

Tan Z, Bernal SA, Provis JL (2017) Reproducible mini-slump test procedure for measuring the yield stress of cementitious pastes. Mater Struct 50:1–12. https://doi.org/10.1617/s11527-017-1103-x

NF EN 413–2:2017 Ciment à maçonner - Partie 2: Méthodes d’essai

Khelifi H, Perrot A, Lecompte T, Ausias G (2013) Design of clay/cement mixtures for extruded building products. Mater Struct Constr 46:999–1010. https://doi.org/10.1617/s11527-012-9949-4

Landrou G, Brumaud C, Winnefeld F et al (2016) Lime as an anti-plasticizer for self-compacting clay concrete. Materials (Basel). https://doi.org/10.3390/ma9050330

Landrou G, Brumaud C, Plötze ML et al (2018) A fresh look at dense clay paste: deflocculation and thixotropy mechanisms. Colloids Surfaces A Physicochem Eng Asp 539:252–260. https://doi.org/10.1016/j.colsurfa.2017.12.029

Achenza M, Fenu L (2007) On earth stabilization with natural polymers for earth masonry construction. Mater Struct 39:21–27. https://doi.org/10.1617/s11527-005-9000-0

Hamard E, Cammas C, Lemercier B et al (2019) Micromorphological description of vernacular cob process and comparison with rammed earth. Front Archit Res. https://doi.org/10.1016/j.foar.2019.06.007

Dubor A, Cabay E, Chronis A (2018) Energy efficient design for 3D printed earth architecture. In: De Rycke K, Gengnagel C, Baverel O et al (eds) Humanizing digital reality: design modelling symposium Paris 2017. Springer Singapore, Singapore, pp 383–393

Ibrahim A (2019) 3D printing clay facade walls | integrating ventilation systems into printing process. Delft University of Technology, Netherlands

Rael R, Fratello VS (2017) Clay bodies: crafting the future with 3D printing. Archit Des 87:92–97. https://doi.org/10.1002/ad.2243

Ma C, Zhao B, Long G et al (2018) Quantitative study on strength development of earth-based construction prepared by organic clay and high-efficiency soil stabilizer. Constr Build Mater 174:520–528. https://doi.org/10.1016/j.conbuildmat.2018.04.119

Tiwari B, Ajmera B (2011) A new correlation relating the shear strength of reconstituted soil to the proportions of clay minerals and plasticity characteristics. Appl Clay Sci 53:48–57. https://doi.org/10.1016/j.clay.2011.04.021

Luzu B, Duc M, Djerbi A, Gautron L (2020) high performance illitic clay-based geopolymer: influence of the mechanochemical activation duration on the strength development. Calcined Clays Sustain Concr. https://doi.org/10.1007/978-981-15-2806-4_43

ISO 17892–12 (2018) Geotechnical investigation and testing — Laboratory testing of soil — Part 12: Determination of liquid and plastic limits

Bourgès A, Vergès-Belmin V (2011) Application of fresh mortar tests to poultices used for the desalination of historical masonry. Mater Struct Constr 44:1233–1240. https://doi.org/10.1617/s11527-010-9695-4

Lootens D, Jousset P, Martinie L et al (2009) Yield stress during setting of cement pastes from penetration tests. Cem Concr Res 39:401–408. https://doi.org/10.1016/j.cemconres.2009.01.012

Uhlherr PHT, Guo J, Fang T, Tiu C (2002) Static measurement of yield stress using a cylindrical penetrometer. Korea-Aust Rhology J 14:17–23

Boujlel J, Coussot P (2012) Measuring yield stress: a new, practical, and precise technique derived from detailed penetrometry analysis. Rheol Acta 51:867–882. https://doi.org/10.1007/s00397-012-0643-9

Beris AN, Tsamopoulos JA, Armstrong RC, Brown RA (1985) Creeping motion of a sphere through a Bingham plastic. J Fluid Mech 158:219–244. https://doi.org/10.1017/S0022112085002622

Mitsoulis E (1998) Effect of rheological properties on the drag coefficient for creeping motion around a sphere falling in a tightly-fitting tube. J Nonnewton Fluid Mech 74:263–283. https://doi.org/10.1016/S0377-0257(97)00059-1

Vinceslas T (2019) Caractérisation d’éco-matériaux terre-chanvre en prenant en compte la variabilité des ressources disponibles localement. Université Bretagne Sud

Dekking FM, Kraaikamp C, Lopuhaä HP, Meester LE (2005) A modern introduction to probability and statistics. Springer, London

Acknowledegments

This work has been carried out within the frame of the project Alluvium. Initiated in 2018, Alluvium is part of I-SITE FUTURE, a French initiative to answer the challenges of sustainable city. We acknowledge the help of Loren Masson for the Atterberg limits measurements and Patrick Belin for his help on the implementation of the squeeze test. The authors thank Nicolas Roussel for enlightening discussions and Richard Buswell for useful comments.

Funding

This study was funded by I-SITE FUTURE from the French Research Agency (project name: Alluvium).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tourtelot, J., Ghattassi, I., Le Roy, R. et al. Yield stress measurement for earth-based building materials: the weighted plunger test. Mater Struct 54, 6 (2021). https://doi.org/10.1617/s11527-020-01588-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01588-4