Abstract

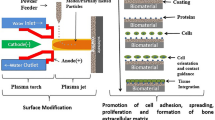

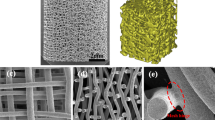

Titanium alloys are widely used for biomedical applications as porous lattice structures whose abilities can be altered via unit cell designs, pore size, and topology. In this study, Ti6Al4V octahedron, star, and dodecahedron cubic and plate lattice structures were designed as 0.20-mm strut diameter with different porosity values (83.06% for octahedron, 53.46% for star, and 63.29% for dodecahedron) and manufactured by laser powder bed fusion. Compression tests were conducted by ISO 13314. The elastic modulus for octahedron, star, and dodecahedron lattices were found 1.7 GPa, 8.6 GPa, and 6.7 GPa, respectively, and results were promising in terms of reducing stress shielding. Relation between relative density and mechanical response was investigated. Chitosan-substituted hydroxyapatite composite coating successfully deposited by electrophoretic deposition on surfaces for biological assessment. Coating increased bioactivity and reduced cell death, especially around implant samples. Chitosan addition ensured an antibacterial effect. Results revealed that mechanical properties and biological responses of structures were affected by the lattice design and pore size.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

All data and materials as well as a software application or custom code support their published claims and comply with field standards.

References

V.S. Muthaiah, S. Indrakumar, S. Suwas, K. Chatterjee, Bioprinting. (2022). https://doi.org/10.1016/j.bprint.2021.e00180

A.N. Aufa, M.Z. Hassan, Z.B. Ismail, J. Miner. Met. Mater. Eng. (2021). https://doi.org/10.31437/2414-2115.2021.07.5

C. Yan, L. Hao, A. Hussein, Q. Wei, Y. Shi, Mater. Sci. Eng. C (2017). https://doi.org/10.1016/j.msec.2017.03.066

A. Jam, A. du Plessis, C. Lora, S. Raghavendra, M. Pellizzari, M. Benedetti, Addit. Manuf. (2022). https://doi.org/10.1016/j.addma.2021.102556

T. Maconachie, M. Leary, B. Lozanovski, X. Zhang, M. Qian, O. Faruque, M. Brandt, Mater. Des. (2019). https://doi.org/10.1016/j.matdes.2019.108137

S.M. Ahmadi, G. Campoli, S.A. Yavari, S.B. Sajadi, R. Wauthlé, J. Schrooten, H. Weinans, A.A. Zadpoor, J. Mech. Behav. Biomed. Mater. (2014). https://doi.org/10.1016/j.jmbbm.2014.02.003

E. Alabort, D. Barba, R.C. Reed, Scripta Mater. (2019). https://doi.org/10.1016/j.scriptamat.2019.01.022

L. Riva, P.S. Ginestra, E. Ceretti, Int. J. Adv. Manuf. Technol. (2021). https://doi.org/10.1007/s00170-021-06631-4

Z. Xiao, Y. Yang, R. Xiao, Y. Bai, C. Song, D. Wang, Mater. Des. (2018). https://doi.org/10.1016/j.matdes.2018.01.023

Z. Jihong, Z. Han, W. Chuang, Z. Lu, Y. Shangqin, W. Zhang, Chin. J. Aeronaut. (2021). https://doi.org/10.1016/j.cja.2020.09.020

M. Leary, M. Mazur, H. Williams, E. Yang, A. Alghamdi, B. Lozanovski, X. Zhang, D. Shidid, L. Farahbod-Sternahl, G. Witt et al., Mater. Des. (2018). https://doi.org/10.1016/j.matdes.2018.06.010

S. Li, S. Yuan, J. Zhu, W. Zhang, Y. Tang, C. Wang, J. Li, Struct. Multidiscip. Optim. (2022). https://doi.org/10.1007/s00158-021-03153-1

S. Drücker, M. Schulze, H. Ipsen, L. Bandegani, H. Hoch, M. Kluge, B. Fiedler, Int. J. Mech. Sci. (2021). https://doi.org/10.1016/j.ijmecsci.2020.105986

B. Zhang, X. Pei, C. Zhou, Y. Fan, Q. Jiang, A. Ronca, U. D’Amora, Y. Chen, H. Li, Y. Sun et al., Mater. Des. (2018). https://doi.org/10.1016/j.matdes.2018.04.065

H.D. Zheng, L.L. Liu, C.L. Deng, Z.F. Shi, C.Y. Ning, Rare Met. (2019). https://doi.org/10.1007/s12598-019-01231-4

N. Wang, G.K. Meenashisundaram, D. Kandilya, J.Y.H. Fuh, S.T. Dheen, A.S.A. Kumar, Biomater. Adv. (2022). https://doi.org/10.1016/j.bioadv.2022.212829

L.J. Gibson, M.F. Ashby, Cellular Solids Structures and Properties (Cambridge University Press, Cambridge, 1999)

N. Li, Y. Zhang, Q. Tang, H. Wang, D. He, Y. Yao, Y. Fan, Comput. Methods Biomech. Biomed. Eng. (2022). https://doi.org/10.1080/10255842.2022.2081505

A. Fukuda, M. Takemoto, T. Saito, S. Fujibayashi, M. Neo, D.K. Pattanayak, T. Matsushita, K. Sasaki, N. Nishida, T. Kokubo et al., Acta Biomater. (2011). https://doi.org/10.1016/j.actbio.2011.01.037

N. Taniguchi, S. Fujibayashi, M. Takemoto, K. Sasaki, B. Otsuki, T. Nakamura, T. Matsushita, T. Kokubo, S. Matsuda, Mater. Sci. Eng. C (2016). https://doi.org/10.1016/j.msec.2015.10.069

F. Benazzo, L. Botta, M.F. Scaffino, L. Caliogna, M. Marullo, S. Fusi, G. Gastaldi, J. Biomed. Mater. Res. Part A (2014). https://doi.org/10.1002/jbm.a.34875

D. Hara, Y. Nakashima, T. Sato, M. Hirata, M. Kanazawa, Y. Kohno, K. Yoshimoto, Y. Yoshihara, A. Nakamura, Y. Nakao et al., Mater. Sci. Eng. C (2016). https://doi.org/10.1016/j.msec.2015.11.025

S. Colen, R. Harake, J. De Haan, M.A. Mulier, Acta Orthop. Belg. 79(1), 71–75 (2013)

A.A. Zadpoor, J. Mater. Chem. B (2019). https://doi.org/10.1039/C9TB00420C

X.P. Tan, Y.J. Tan, C.S.L. Chow, S.B. Tor, W.Y. Yeong, Mater. Sci. Eng. C (2017). https://doi.org/10.1016/j.msec.2017.02.094

J.P. Luo, Y.J. Huang, J.Y. Xu, J.F. Sun, M.S. Dargusch, C.H. Hou, L. Ren, R.Z. Wang, T. Ebel, M. Yan, Mater. Sci. Eng. C (2020). https://doi.org/10.1016/j.msec.2020.110903

M. de Wild, R. Schumacher, K. Mayer, E. Schkommodau, D. Thoma, M. Bredell, A.K. Gujer, K.W. Grätz, F.E. Weber, Tissue Eng. Part A (2013). https://doi.org/10.1089/ten.tea.2012.0753

S.L. Sing, J. An, W.Y. Yeong, F.E. Wiria, J. Orthop. Res. (2016). https://doi.org/10.1002/jor.23075

L.W. Hunter, D. Brackett, N. Brierley, J. Yang, M.M. Attallah, Int. J. Adv. Manuf. Technol. (2020). https://doi.org/10.1007/s00170-020-04930-w

J. Li, P. Zhou, S. Attarilar, H. Shi, Coatings (2021). https://doi.org/10.3390/coatings11060647

A.R. Boyd, L. Rutledge, L.D. Randolph, B.J. Meenan, Mater. Sci. Eng. C (2015). https://doi.org/10.1016/j.msec.2014.10.046

R.A. Ilyas, H.A. Aisyah, A.H. Nordin, N. Ngadi, M.Y.M. Zuhri, M.R.M. Asyraf, S.M. Sapuan, E.S. Zainudin, S. Sharma, H. Abral et al., Polymers (2022). https://doi.org/10.3390/polym14050874

L. Kong, Y. Gao, W. Cao, Y. Gong, N. Zhao, X. Zhang, J. Biomed. Mater. Res. Part A (2005). https://doi.org/10.1002/jbm.a.30414

J. Singh, S.S. Chatha, H. Singh, Prog. Biomater. (2022). https://doi.org/10.1007/s40204-022-00183-w

E. Avcu, F.E. Baştan, H.Z. Abdullah, M.A.U. Rehman, Y.Y. Avcu, A.R. Boccaccini, Prog. Mater. Sci. (2019). https://doi.org/10.1016/j.pmatsci.2019.01.001

D. Yu, J. Feng, H. You, S. Zhou, Y. Bai, J. He, H. Cao, Q. Che, J. Guo, Z. Su, Mar. Drugs (2022). https://doi.org/10.3390/md20010069

E. Lokeshkumar, A. Saikiran, B. Ravisankar, L.V. Parfenova, E.V. Parfenov, R.Z. Valiev, N. Rameshbabu, Surf. Topogr. Metrol. Prop. (2022). https://doi.org/10.1088/2051-672X/ac5234

K. Iwanami-Kadowaki, T. Uchikoshi, M. Uezono, M. Kikuchi, K. Moriyama, J. Biomed. Mater. Res. Part A (2021). https://doi.org/10.1002/jbm.a.37182

A. Pawlik, M.A.U. Rehman, Q. Nawaz, F.E. Bastan, G.D. Sulka, A.R. Boccaccini, Electrochim. Acta (2019). https://doi.org/10.1016/j.electacta.2019.03.195

B. Sağbaş, D. Gürkan, Int. J. 3D Print. Technol. Digital Ind. (2021). https://doi.org/10.46519/ij3dptdi.953315

B. Sağbaş, D. Gürkan, J. Addit. Manuf. Technol. (2021). https://doi.org/10.18416/JAMTECH.2111594

L.J. Gibson, MRS Bull. (1997). https://doi.org/10.1557/mrs2003.79

W.C. Oliver, G.M. Pharr, J. Mater. Res. (1992). https://doi.org/10.1557/JMR.1992.1564

K.M. Nsiempba, M. Wang, M. Vlasea, Appl. Sci. (2021). https://doi.org/10.3390/app11093845

U.A. Dar, H.H. Mian, M. Abid, M.B. Nutkani, A. Jamil, M.Z. Sheikh, J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-021-06419-3

Z. Alomar, F.A. Concli, Adv. Eng. Mater. (2020). https://doi.org/10.1002/adem.202000611

M.F. Ashby, Cellular Ceramics: Structure, Manufacturing, Properties and Applications (Wiley, New York, 2006)

G. Yu, Z. Li, S. Li, Q. Zhang, Y. Hua, H. Liu, X. Zhao, D.T. Dhaidhai, W. Li, X. Wang, Mater. Des. (2020). https://doi.org/10.1016/j.matdes.2020.108754

X. Yan, Q. Li, S. Yin, Z. Chen, R. Jenkins, C. Chen, J. Wang, W. Ma, R. Bolot, R. Lupoi et al., J. Alloy Compd. (2019). https://doi.org/10.1016/j.jallcom.2018.12.220

L. Bai, X. Zhou, X. Chen, L. Xin, J. Zhang, J. Yang, L. Kun, Y. Sun, Mech. Adv. Mater. Struct. (2021). https://doi.org/10.1080/15376494.2021.2009600

N. Wang, G.K. Meenashisundaram, S. Chang, J.Y.H. Fuh, S.T. Dheen, A.S. Kumar, J. Mech. Behav. Biomed. Mater. (2022). https://doi.org/10.1016/j.jmbbm.2022.105151

G. Campoli, M.S. Borleffs, S.A. Yavari, R. Wauthle, H. Weinans, A.A. Zadpoor, Mater. Des. (2013). https://doi.org/10.1016/j.matdes.2013.01.071

C. Yan, L. Hao, A. Hussein, D. Raymont, Int. J. Mach. Tools Manuf (2012). https://doi.org/10.1016/j.ijmachtools.2012.06.002

H.C. Hamaker, Trans. Farad. Soc. 35, 279–287 (1940)

D. Juliadmi, D.H. Tjong, M. Manjas, IOP Conf. Ser. (2019). https://doi.org/10.1088/1757-899X/547/1/012005

Y. Castro, B. Ferrari, R. Moreno, A. Duran, J. Sol-Gel. Sci. Technol. (2003). https://doi.org/10.1023/A:1020750222322

E.G. Kalinina, D.S. Rusakova, E.Y. Pikalova, Chimica Techno Acta. (2022). https://doi.org/10.15826/chimtech.2022.9.2.07

L. Besra, M. Liu, Prog. Mater Sci. (2007). https://doi.org/10.1016/j.pmatsci.2006.07.001

R. Kumari, K.B. Yadav, S. Barole, K. Archana, L.D. Besra, Adv. Mater. Process. Technol. (2021). https://doi.org/10.1080/2374068X.2021.1959106

Y. Huang, X. Zhang, H. Mao, T. Li, R. Zhao, Y. Yan, X. Pang, RSC Adv. (2015). https://doi.org/10.1039/C4RA12118J

F.B. Coulter, R.E. Levey, S.T. Robinson, E.B. Dolan, S. Deotti, M. Monaghan, P. Dockery, B.S. Coulter, L.P. Burke, A.J. Lowery et al., Adv. Healthc. Mater. (2021). https://doi.org/10.1002/adhm.202100229

H. Sorg, D.J. Tilkorn, J. Hauser, A. Ring, Bioengineering (2022). https://doi.org/10.3390/bioengineering9070298

Z.-Y. Qiu, Y. Cui, X.-M. Wang, Natural bone tissue and its biomimetic. in: Mineralized Collagen Bone Graft Substitutes (Woodhead Publishing Series in Biomaterials, Woodhead Publishing, 2019), pp. 1–22

A.A. Al-Munajjed, M. Hien, R. Kujat, J.P. Gleeson, J. Hammer, J. Mater. Sci. (2008). https://doi.org/10.1007/s10856-008-3422-5

S.T. Chen, H.W. Chien, C.Y. Cheng, H.M. Huang, T.Y. Song, Y.C. Chen, C.H. Wu, Y.H. Hsueh, Y.H. Wang, S.F. Ou, Prog. Org. Coat. (2021). https://doi.org/10.1016/j.porgcoat.2021.106385

L.V. Oliveira, G.R. da Silva, G.L. Souza, T.E.A. Magalhães, G.L.R. Barbosa, A.P. Turrioni, C.C.G. Moura, Int. Endod. J. (2020). https://doi.org/10.1111/iej.13308

International Organization for Standardization, ISO 13314 Mechanical testing of metals, ductility testing, compression test for porous and cellular metals. (2011)

EOS Gmb, EOS Titanium Ti64 data sheet. http://www.eos.info/. Accessed 7 July 2022

Acknowledgments

The authors would like to thank Assoc. Prof. Dr. Cem Bülent Üstündağ for his support of HA synthesis and Prof. Dr. Elif Damla Arısan for her support of cell culture tests.

Funding

This work was supported by Yildiz Technical University Scientific Research Projects Coordination Unit. Project Number: FDK-2021-4135.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical approval

Not Related.

Consent for publication

By submitting the manuscript, the authors understand that the material presented in this manuscript has not been published before, nor has it been submitted for publication to another journal. The corresponding author attests that this study has been approved by all the co-authors concerned.

Research involving human participants and/or animals

The authors confirmed that there are no human participants or animals in the present work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gürkan, D., Sagbas, B. & Dalbayrak, B. Investigating mechanical and biological properties of additive manufactured Ti6Al4V lattice structures for orthopedic implants. Journal of Materials Research 38, 507–518 (2023). https://doi.org/10.1557/s43578-022-00837-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00837-2