Abstract

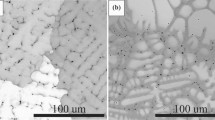

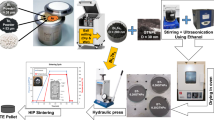

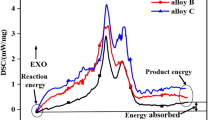

In the present study, various (Ag–Cu) nanoalloy particles are embedded in the Ni matrix and synthesized by rapid solidification, namely Ni–3.8 at.% (Ag77–Cu23), Ni–4 at.% (Ag60–Cu40), and Ni–4.8 at.% (Ag24–Cu76), to understand the effect of matrix on nanoparticles. The detailed TEM study reveals that Ni–3.8 at.% (Ag77–Cu23) and Ni–4 at.% (Ag60–Cu40) show a single phase of (Ag), while Ni–4.8 at.% (Ag24–Cu76) indicates the presence of bi-phasic (Cu)–(Ag) alloy nanoparticles. Furthermore, thermal cycling was carried out using DSC to study the influence of solid-solution properties. Unlike Ni–3.8 at.% (Ag77–Cu23) and Ni–4 at.% (Ag60–Cu40), Ni–4.8 at.% (Ag24–Cu76) shows no changes while melting and cooling. Further, in situ TEM investigation of Ni–4.8 at.% (Ag24–Cu76) nanoparticle reveals that the bi-phasic nanoparticles undergo fully solid-state transformation to single-phase (Ag) nanoparticles prior to melting while heating. Theoretical studies on the phase stability of Ag–Cu–Ni at the nanoscale were undertaken to validate the experimental results, offering insight into the phase change of these solid-solution nanoparticles in the Ni matrix.

Graphical abstract

Similar content being viewed by others

Data availability

The data will be available on reasonable request to the corresponding author.

References

F. Calvo, Thermodynamics of nanoalloys. Phys. Chem. Chem. Phys. 17, 27922–27939 (2015). https://doi.org/10.1039/C5CP00274E

F. Calvo, Nanoalloys: From Fundamentals to Emergent Applications (Elsevier, Amsterdam, 2013)

K. Tiwari, M. Manolata Devi, K. Biswas, K. Chattopadhyay, Phase transformation behavior in nanoalloys. Prog. Mater. Sci. 121, 100794 (2021). https://doi.org/10.1016/j.pmatsci.2021.100794

M.M. Devi, K. Tiwari, K. Biswas, Size-dependent melting behavior of Pb-17.5 At. Pct Sb-free biphasic alloy nanoparticles. Metall. Mater. Trans. A 50, 3959–3972 (2019). https://doi.org/10.1007/s11661-019-05275-0

Q.S. Mei, K. Lu, Melting and superheating of crystalline solids: from bulk to nanocrystals. Prog. Mater. Sci. 52, 1175–1262 (2007). https://doi.org/10.1016/j.pmatsci.2007.01.001

K. Chattopadhyay, R. Goswami, Melting and superheating of metals and alloys. Prog. Mater. Sci. 42, 287 (1997). https://doi.org/10.1016/S0079-6425(97)00030-3

J. Weissmuller, P. Bunzel, G. Wilde, Two-phase equilibrium in small alloy particles. Scr. Mater. 51, 813–818 (2004). https://doi.org/10.1016/j.scriptamat.2004.06.025

P. Bunzel, G. Wilde, H. Rösner, J. Weissmüller, Two-phase equilibrium in binary alloy nano particles, in Solidification and Crystallization, ed. by D.M. Herlach. 157–165 (2004). https://doi.org/10.1002/3527603506.ch18

P.Y. Khan, K. Biswas, Melting and solidification behaviour of Bi–Pb multiphase alloy nanoparticles embedded in aluminum matrix. J. Nanosci. Nanotechnol. 15, 309–316 (2015). https://doi.org/10.1166/jnn.2015.9221

K. Chattopadhyay, Behaviour of embedded metals and alloys at small sizes. Trans. Indian Inst. Met. 58, 1057–677 (2005)

V. Bhattacharya, K. Chattopadhyay, Phase transformation in nanoscale indium-tin alloy particles embedded in metallic matrices. J. Nanosci. Nanotechnol. 7, 1736–1743 (2007). https://doi.org/10.1166/jnn.2007.708

K. Tiwari, M. Paliwal, M. Verma, K. Biswas, Solidification behavior of nanoscaled triphasic bismuth-indium-tin alloy particles embedded in Al–Cu–Fe quasicrystalline matrix. J. Alloys Compd. 867, 159011 (2021). https://doi.org/10.1016/j.jallcom.2021.159011

K. Tiwari, K. Biswas, Precision in compositional determination of multiphase nanoscale structures using the aberration-corrected advance electron microscope: challenges and opportunities. Microsc. Microanal. 26, 988 (2020). https://doi.org/10.1017/S143192762001658X

D. Turnbull, Formation of crystal nuclei in liquid metals. J. Appl. Phys. 21, 1022–1028 (1950). https://doi.org/10.1063/1.1699435

D. Turnbull, R.E. Cech, Microscopic observation of the solidification of small metal droplets. J. Appl. Phys. 21, 804 (1950). https://doi.org/10.1063/1.1699763

K. Tiwari, K. Biswas, M. Palliwal, B. Majumdar, H.J. Fecht, Melting behaviour of triphasic Bi44In32Sn23 alloy nanoparticle embedded in icosahedral quasicrystalline matrix. J. Alloys Compd. 834, 155160 (2020). https://doi.org/10.1016/j.jallcom.2020.155160

P.Y. Khan, V. Bhattacharya, K. Biswas, K. Chattopadhyay, Melting and solidification behavior of Pb–Sn embedded alloy nanoparticles. J. Nanopart. Res. 15, 2049 (2013). https://doi.org/10.1007/s11051-013-2049-8

P.Y. Khan, K. Biswas, The effect of matrix on melting and solidification behaviours of embedded Pb–Sn alloy nanoparticles. Philos. Mag. 94, 2031–2045 (2014). https://doi.org/10.1080/14786435.2014.904966

M. Peterlechner, A. Moros, H. Rösner, S. Lazar, P. Ericus, G. Wilde, Melting and solidification of lead nanoparticles embedded in aluminium-gallium matrices. Acta Mater. 128, 284 (2017). https://doi.org/10.1016/j.actamat.2017.01.062

K. Biswas, G. Phanikumar, D. Holland-Moritz, D.M. Herlach, K. Chattopadhyay, Disorder trapping and grain refinement during solidification of undercooled Fe–18 at% Ge melts. Philos. Mag. 87, 3817 (2007). https://doi.org/10.1080/14786430701420549

R. Ferrando, J. Jellinek, R.L. Johnston, Nanoalloys: from theory to applications of alloy clusters and nanoparticles. Chem. Rev. 108, 845 (2008). https://doi.org/10.1021/cr040090g

A. Sharma, S. Yadav, K. Biswas, B. Basu, High-entropy alloys and metallic nanocomposites: processing challenges, microstructure development and property enhancement. Mater. Sci. Eng. R 131, 1–42 (2018). https://doi.org/10.1016/j.mser.2018.04.003

K.S. Moon, Y. Li, J. Xu, C. Wong, Lead-free interconnect technique by using variable frequency microwave. J. Electron. Mater. 34, 1081–1088 (2005). https://doi.org/10.1007/s11664-005-0099-0

T. Yamauchi, Y. Tsukahara, T. Sakata, H. Mori, T. Yanagida, T. Kawai, Y. Wada, Magnetic Cu–Ni (core–shell) nanoparticles in a one-pot reaction under microwave irradiation. Nanoscale 2, 515 (2010). https://doi.org/10.1039/b9nr00302a

Z. Zhang, T.M. Nenoff, K. Leung, S. Ferreira, J. Huang, D. Berry, P. Provencio, R. Stumpf, Room-temperature synthesis of Ag−Ni and Pd−Ni alloy nanoparticles. J. Phys. Chem. 114, 14309 (2010). https://doi.org/10.1021/jp911947v

S. Dev, P. Basak, I. Singh, R. Dubey, O. Mohanty, A copper-base brazing alloy for electronics industries. J. Mater. Sci. 27, 6646 (1992). https://doi.org/10.1007/BF01165949

H.T. Luo, S.-W. Chen, Phase equilibria of the ternary Ag–Cu–Ni system and the interfacial reactions in the Ag–Cu/Ni couples. J. Mater. Sci. 31, 5059 (1996). https://doi.org/10.1007/BF00355906

T. Massalski, Phase diagrams ASM metals handbook. ASM Met. Handb. 3, 206 (1992)

X.J. Liu, F. Gao, C.P. Wang, K. Ishida, Thermodynamic assessments of the Ag–Ni binary and Ag–Cu–Ni ternary systems. J. Electron. Mater. 37, 210–217 (2008). https://doi.org/10.1007/s11664-007-0315-1

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melançon, A.D. Pelton, S. Petersen, FactSage thermochemical software and databases. Calphad 26, 189 (2002). https://doi.org/10.1016/S0364-5916(02)00035-4

C.W. Bale, E. Bélisle, P. Chartrand, S. Decterov, G. Eriksson, A. Gheribi, K. Hack, I.H. Jung, Y.B. Kang, J. Melançon, FactSage thermochemical software and databases. Calphad 100, 35–53 (2009). https://doi.org/10.1016/j.calphad.2008.09.009

O. Redlich, A.T. Kister, Algebraic representation of thermodynamic properties and the classification of solutions. Ind. Eng. Chem. 40, 345–348 (1948). https://doi.org/10.1021/ie50458a036

A.T. Dinsdale, SGTE data for pure elements. Calphad 15, 317–425 (1991). https://doi.org/10.1016/0364-5916(91)90030-N

W.H. Qi, M.P. Wang, Q.H. Liu, Shape factor of nonspherical nanoparticles. J. Mater. Sci. 40, 2737 (2005). https://doi.org/10.1007/s10853-005-2119-0

J. Av Butler, J.P. Kendall, The thermodynamics of the surfaces of solutions. Proc. R. Soc. Lond. Ser. A 135, 348 (1932). https://doi.org/10.1098/rspa.1932.0040

A. Roshanghias, J. Vrestal, A. Yakymovych, K.W. Richter, H. Ipser, Sn–Ag–Cu nanosolders: melting behavior and phase diagram prediction in the Sn-rich corner of the ternary system. Calphad 49, 101–109 (2015). https://doi.org/10.1016/j.calphad.2015.04.003

A.S. Shirinyan, Two-phase equilibrium states in individual Cu–Ni nanoparticles: size, depletion and hysteresis effects. Beilstein J. Nanotechnol. 6, 1811 (2015). https://doi.org/10.3762/bjnano.6.185

J. Sopousek, J. Vrestal, J. Pinkas, P. Broz, J. Bursik, A. Styskalik, D. Skoda, O. Zobac, J. Lee, Cu–Ni nanoalloy phase diagram—prediction and experiment. Calphad 45, 33–39 (2014). https://doi.org/10.1016/j.calphad.2013.11.004

R. Sonkusare, P. Divya Janani, N.P. Gurao, S. Sarkar, S. Sen, K.G. Pradeep, K. Biswas, Phase equilibria in equiatomic CoCuFeMnNi high entropy alloy. Mater. Chem. Phys. 210, 269 (2018). https://doi.org/10.1016/j.matchemphys.2017.08.051

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest regarding the current research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 5184 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tiwari, K., Paliwal, M. & Biwas, K. Phase transformation of Ag–Cu alloy nanoparticle embedded in Ni matrix. Journal of Materials Research 37, 4124–4139 (2022). https://doi.org/10.1557/s43578-022-00777-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00777-x