Abstract

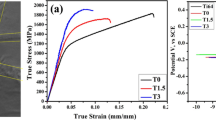

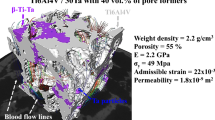

The aim of this work was to study tribological behavior and biological response of selective laser-melted Ti6Al7Nb-based TiB-reinforced composites. The synergistic properties achieved by different content of the in situ TiB phase (1.5 and 3.0 wt%) enhanced the wear resistance of Ti6Al7Nb. Abrasion and microplastic deformations were the predominant wear mechanisms observed in these composites. The contact angle of simulated body fluid on TiB-reinforced sample surfaces revealed that the surfaces were moderately hydrophilic. In vitro cell studies with pre-osteoblasts confirmed the non-toxic nature of all the three samples (matrix—Ti6Al7Nb, 1.5, and 3.0 wt% TiB composites) studied here. The enhanced wear resistance coupled with its non-toxic nature and good cell proliferation demonstrated that the Ti6Al7Nb–TiB composites are promising candidates for the fabrication of biomedical implants. In addition, the results demonstrate that Ti6Al7Nb composites can be easily fabricated by solidification-based additive manufacturing processes.

Graphical abstract

Similar content being viewed by others

Data availability

The authors will provide the data, if needed.

References

D. Herzog, V. Seyda, E. Wycisk, C. Emmelmann, Additive manufacturing of metals. Acta Mater. 117, 371 (2016)

N. Singh, P. Hameed, R. Ummethala, G. Manivasagam, K.G. Prashanth, J. Eckert, Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects. Mater. Today Adv. 8, 100097 (2020)

P. Wang, J. Eckert, K.G. Prashanth, M. Wei Wu, I. Kaban, L. Xi, S. Scudino, A review of particulate-reinforced aluminum matrix composites fabricated by selective laser melting. Trans. Nonferrous Metals Soc. China 30(8), 2001 (2020)

S. Ford, M. Despeisse, Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 137, 1573 (2016)

M. Roudnicka, F. Bayer, A. Michalcova, J. Kubasek, E.G. Hamed Alzubi, D. Vojtech, Biomedical titanium alloy prepared by additive manufacturing: Effect of processing on tribology. Manuf. Technol. 20(6), 809 (2020)

M. Benedetti, E. Torresani, M. Leoni, V. Fontanari, M. Bandini, C. Pederzolli, C. Potrich, The effect of post-sintering treatments on the fatigue and biological behavior of Ti-6Al-4V ELI parts made by selective laser melting. J. Mech. Behav. Biomed. Mater. 71, 295 (2017)

K.S. Suresh, M. Geetha, C. Richard, J. Landoulsi, H. Ramasawmy, S. Suwas, R. Asokamani, Effect of equal channel angular extrusion on wear and corrosion behavior of the orthopedic Ti-13Nb-13Zr alloy in simulated body fluid. Mater. Sci. Eng. C 32(4), 763 (2012)

S. Bose, D. Ke, H. Sahasrabudhe, A. Bandyopadhyay, Prog. Mater Sci. 93, 45 (2018)

E.D. Sheha, S.D. Gandhi, M.W. Colman, 3D printing in spine surgery. Ann. Transl. Med. 7(S5), S164 (2019)

N. Xu, F. Wei, X. Liu, L. Jiang, H. Cai, Z. Li, M. Yu, F. Wu, Z. Liu, Reconstruction of the upper cervical spine using a personalized 3D-printed vertebral body in an adolescent with ewing sarcoma. Spine 41(1), 50 (2016)

K. Phan, A. Sgro, M.M. Maharaj, P. D’Urso, R.J. Mobbs, Application of a 3D custom printed patient specific spinal implant for C1/2 arthrodesis. J. Spine Surg. 2(4), 314 (2016)

K. Prashanth, L. Löber, H.-J. Klauss, U. Kühn, J. Eckert, Characterization of 316L steel cellular dodecahedron structures produced by selective laser melting. Technologies (Basel) 4(4), 34 (2016)

J. Lv, Z. Jia, J. Li, Y. Wang, J. Yang, P. Xiu, K. Zhang, H. Cai, Z. Liu, Electron beam melting fabrication of porous Ti6Al4V scaffolds: Cytocompatibility and osteogenesis. Adv. Eng. Mater. 17(9), 1391 (2015)

Q. Chen, G.A. Thouas, Metallic implant biomaterials. Mater. Sci. Eng. R. Rep. 87, 1 (2015)

B.P. Kumar, V. Venkatesh, K.A.J. Kumar, B.Y. Yadav, S.R. Mohan, J. Maxillofac. Oral Surg. 15, 425 (2016)

L.C. Zhang, H. Attar, Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: A review. Adv. Eng. Mater. 18(4), 463 (2016)

H. Attar, K.G. Prashanth, A.K. Chaubey, M. Calin, L.C. Zhang, S. Scudino, J. Eckert, Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 142, 38 (2015)

S. Ehtemam-Haghighi, K.G. Prashanth, H. Attar, A.K. Chaubey, G.H. Cao, L.C. Zhang, Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 111, 592 (2016)

L. Gaviria, J.P. Salcido, T. Guda, J.L. Ong, Current trends in dental implants. J. Korean Assoc. Oral Maxillofac. Surg. 40(2), 50 (2014)

T. Ghassemi, A. Shahroodi, M.H. Ebrahimzadeh, A. Mousavian, J. Movaffagh, A. Moradi, Arch. Bone Joint Surg. 6, 90 (2018)

S. Gorsse, C. Hutchinson, M. Gouné, R. Banerjee, Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 18(1), 584 (2017)

M. Motyka, A. Baran-Sadleja, J. Sieniawski, M. Wierzbinska, K. Gancarczyk, Decomposition of deformed α′(α″) martensitic phase in Ti–6Al–4V alloy. Mater. Sci. Technol. (United Kingdom) 35(3), 260 (2019)

M. Long, H.J. Rack, Friction and surface behaviour of selected titanium alloys during reciprocating-sliding motion. Wear 249(1–2), 157 (2001)

K.G. Prashanth, J. Eckert, Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloy. Compd. 707, 27 (2017)

M. Fousová, D. Vojtěch, J. Kubásek, E. Jablonská, J. Fojt, Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process. J. Mech. Behav. Biomed. Mater. 69, 368 (2017)

H.Y. Jung, S.J. Choi, K.G. Prashanth, M. Stoica, S. Scudino, S. Yi, U. Kühn, D.H. Kim, K.B. Kim, J. Eckert, Fabrication of Fe-based bulk metallic glass by selective laser melting: A parameter study. Mater. Des. 86, 703 (2015)

T.H. Becker, P. Kumar, U. Ramamurty, Fracture and fatigue in additively manufactured metals. Acta Mater. 219, 117240 (2021)

C. Zhao, Z. Wang, D. Li, L. Kollo, Z. Luo, W. Zhang, K. Gokuldoss, K.G. Prashanth, Selective laser melting of Cu–Ni–Sn: A comprehensive study on the microstructure, mechanical properties, and deformation behavior. Int. J. Plast. 138, 102–926 (2021)

K.G. Prashanth, S. Scudino, J. Eckert, Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 126, 25 (2017)

K.G. Prashanth, S. Scudino, H.J. Klauss, K.B. Surreddi, L. Löber, Z. Wang, A.K. Chaubey, U. Kühn, J. Eckert, Microstructure and mechanical properties of Al-12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng., A 590, 153 (2014)

Z. Wang, R. Ummethala, N. Singh, S. Tang, C. Suryanarayana, J. Eckert, K.G. Prashanth, Selective laser melting of aluminum and its alloys. Materials 13(20), 1 (2020)

S. Scudino, C. Unterdörfer, K.G. Prashanth, H. Attar, N. Ellendt, V. Uhlenwinkel, J. Eckert, Additive manufacturing of Cu-10Sn bronze. Mater. Lett. 156, 202 (2015)

T. Maity, N. Chawake, J.T. Kim, J. Eckert, K.G. Prashanth, Anisotropy in local microstructure: Does it affect the tensile properties of the SLM samples? Manuf. Lett. 15, 33 (2018)

D. Kuroda, M. Niinomi, M. Morinaga, Y. Kato, T. Yashiro, Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng. A 243(1–2), 244 (1998)

L.C. Zhang, L.Y. Chen, A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 21(4), 1 (2019)

J.W. Nicholson, Titanium alloys for dental implants: A review. Prosthesis 2(2), 100 (2020)

M. Geetha, A.K. Singh, R. Asokamani, A.K. Gogia, Ti based biomaterials, the ultimate choice for orthopaedic implants: A review. Prog. Mater Sci. 54(3), 397 (2009)

A.A. Raheem, P. Hameed, R. Whenish, R.S. Elsen, G. Aswin, A.K. Jaiswal, K.G. Prashanth, G. Manivasagam, Biomimetics 6, 65 (2021)

A. Bandyopadhyay, A. Shivaram, M. Isik, J.D. Avila, W.S. Dernell, S. Bose, Additively manufactured calcium phosphate reinforced CoCrMo alloy: Bio-tribological and biocompatibility evaluation for load-bearing implants. Addit. Manuf. 28, 312 (2019)

K. Zhuravleva, M. Bönisch, K.G. Prashanth, U. Hempel, A. Helth, T. Gemming, M. Calin, S. Scudino, L. Schultz, J. Eckert, A. Gebert, Production of porous β-type Ti-40Nb alloy for biomedical applications: Comparison of selective laser melting and hot pressing. Materials 6(12), 5700 (2013)

R. Ummethala, P.S. Karamched, S. Rathinavelu, N. Singh, A. Aggarwal, K. Sun, E. Ivanov, L. Kollo, I. Okulov, J. Eckert, K.G. Prashanth, Selective laser melting of high-strength, low-modulus Ti–35Nb–7Zr–5Ta alloy. Materialia 14, 100–941 (2020)

W. Kim, H. Kim, Microstructure and texture evolution of Ti-Nb-Si based alloys for biomedical applications. Rare Met. 25(6), 163 (2006)

A.T. Sidambe, Materials 7, 8168 (2014)

Y. Hu, F. Ning, H. Wang, W. Cong, B. Zhao, Laser engineered net shaping of quasi-continuous network microstructural TiB reinforced titanium matrix bulk composites: Microstructure and wear performance. Opt. Laser Technol. 99, 174 (2018)

S. Gorsse, Y. Le Petitcorps, S. Matar, F. Rebillat, Investigation of the Young’s modulus of TiB needles in situ produced in titanium matrix composite. Mater. Sci. Eng. A 340(1–2), 80 (2003)

A. Miklaszewski, M.M. Jurczyk, M. Kaczmarek, A. Paszel-Jaworska, A. Romaniuk, N. Lipińska, J. Żurawski, P. Urbaniak, M.M. Jurczyk, Nanoscale size effect in in situ titanium based composites with cell viability and cytocompatibility studies. Mater. Sci. Eng. C 73, 525 (2017)

H. Attar, L. Löber, A. Funk, M. Calin, L.C. Zhang, K.G. Prashanth, S. Scudino, Y.S. Zhang, J. Eckert, Mechanical behavior of porous commercially pure Ti and Ti-TiB composite materials manufactured by selective laser melting. Mater. Sci. Eng. A 625, 350 (2015)

H. Attar, K.G. Prashanth, L.C. Zhang, M. Calin, I.V. Okulov, S. Scudino, C. Yang, J. Eckert, Effect of powder particle shape on the properties of in situ Ti-TiB composite materials produced by selective laser melting. J. Mater. Sci. Technol. 31(10), 1001 (2015)

H. Attar, M. Bönisch, M. Calin, L.C. Zhang, S. Scudino, J. Eckert, Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 76, 13 (2014)

A. Miklaszewski, M.U. Jurczyk, M. Jurczyk, Microstructural development of Ti-B alloyed layer for hard tissue applications. J. Mater. Sci. Technol. 29(6), 565 (2013)

M. Kaczmarek, M.U. Jurczyk, A. Miklaszewski, A. Paszel-Jaworska, A. Romaniuk, N. Lipińska, J. Żurawski, P. Urbaniak, K. Jurczyk, In vitro biocompatibility of titanium after plasma surface alloying with boron. Mater. Sci. Eng. C 69, 1240 (2016)

C.N. Elias, J.H.C. Lima, R. Valiev, M.A. Meyers, JOM 60, 46 (2008)

P. Hameed, C.F. Liu, R. Ummethala, N. Singh, H.H. Huang, G. Manivasagam, K.G. Prashanth, Biomorphic porous Ti6Al4V gyroid scaffolds for bone implant applications fabricated by selective laser melting. Prog. Addit. Manuf. 6(3), 455 (2021)

T. Bhardwaj, M. Shukla, C.P. Paul, K.S. Bindra, Direct energy deposition: Laser additive manufacturing of titanium-molybdenum alloy: Parametric studies, microstructure and mechanical properties. J. Alloy. Compd. 787, 1238 (2019)

C. Shi, B. Yan, L. Xie, L. Zhang, J. Wang, A. Takahara, H. Zeng, Long-range hydrophilic attraction between water and polyelectrolyte surfaces in oil. Angew. Chem. 128(48), 15241 (2016)

V. Edachery, V. Swamybabu, A. Gurupatham, M. Paramasamy, and S. V. Kailas: The role of surface topography and normal load in the initiation of ratchetting-peak friction, seizure, scuffing, and elastic shakedown. Journal of Tribology 144(2) (2022).

N. Singh, S. Acharya, K.G. Prashanth, K. Chatterjee, S. Suwas, Ti6Al7Nb-based TiB-reinforced composites by selective laser melting. J. Mater. Res. 36(18), 3691 (2021)

N. Singh, S. Banerjee, O. Parkash, D. Kumar, Tribological and corrosion behavior of (100–x)(Fe70Ni30)-(x)ZrO2 composites synthesized by powder metallurgy. Mater. Chem. Phys. 205, 261 (2018)

H.C. Madhu, V. Edachery, K.P. Lijesh, C.S. Perugu, S.V. Kailas, Fabrication of wear-resistant Ti3AlC2/Al3Ti hybrid aluminum composites by friction stir processing. Metall. Mater. Trans. A 51(8), 4086 (2020)

L. Zhou, G. Liu, Z. Han, K. Lu, Grain size effect on wear resistance of a nanostructured AISI52100 steel. Scripta Mater. 58(6), 445 (2008)

R.B. Waterhouse, D.E. Taylor, Fretting debris and the delamination theory of wear. Wear 29(3), 337 (1974)

V. Edachery, A. John, A. Rajendran, V. Srinivasappa, S. Mathiyalagan, S. Kumar, S.V. Kailas, Enhancing tribological properties of Inconel X-750 superalloy through surface topography modification by shot blasting. Mater. Perform. Charact. 10(2), 20200172 (2021)

S. Bahl, S. Raj, S. Vanamali, S. Suwas, K. Chatterjee, Effect of boron addition and processing of Ti–6Al–4V on corrosion behaviour and biocompatibility. Mater. Technol. (2014). https://doi.org/10.1179/1753555713Y.0000000118

K. Das, A. Bandyopadhyay, S. Bose, Biocompatibility and in situ growth of TiO2 nanotubes on Ti using different electrolyte chemistry. J. Am. Ceram. Soc. 91(9), 2808 (2008)

M. Rajput, P. Mondal, P. Yadav, K. Chatterjee, Light-based 3D bioprinting of bone tissue scaffolds with tunable mechanical properties and architecture from photocurable silk fibroin. Int. J. Biol. Macromol. 202, 644 (2022)

Acknowledgments

N.S. would like to thank the financial support from C V Raman Fellowship funded by the Indian Institute of Science (IISc) Bangalore and the European Regional Development Fund through Project ASTRA6-6. This work was supported in part by funding from the Department of Science and Technology, Government of India (DST/NM/NB/2018/119(G)). The technical support provided by Tallinn University of Technology (Tallinn), Estonia, and Department of Mechanical Engineering, IISc is acknowledged. Further financial support from the High-end Foreign Experts Recruitment Program (G2021163004L) and the Guangdong International Science and Technology Cooperation Program (2021A0505050002) are appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflict of interest.

Rights and permissions

About this article

Cite this article

Singh, N., Edachery, V., Rajput, M. et al. Ti6Al7Nb–TiB nanocomposites for ortho-implant applications. Journal of Materials Research 37, 2525–2535 (2022). https://doi.org/10.1557/s43578-022-00578-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00578-2