Abstract

The stress-shielding effect can be minimized by using porous materials with pre-determined implant stiffness. This study aims to design interconnected porous metal implants that resemble the stiffness variations in a bone. Our design is intended to innovate mechanical loading conditions at the peri-implant bone, promoting a more robust implant–bone interface. The positional variations of stiffness in the scaffold are designed based on the Hounsfield Unit of computed tomography (CT) scan data of that location. Finite element (FE) analysis evaluates porous implants' performance compared to solid implants. Porous metal implants were additively manufactured with Ti6Al4V for compression test and reconstructed the 3D model from the micro-CT scan to validate the FE model. FE results revealed that porous implants generated a strain profile at peri-implant bone closer to normal bone irrespective of material property or anatomical location compared to solid implants.

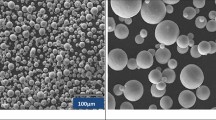

Graphic abstract

Similar content being viewed by others

References

H. Shegarfi, O. Reikeras, Bone transplantation and immune response. J. Orthopaedic Surg. 17(2), 206–211 (2009)

P. Lichte, H.C. Pape, T. Pufe, P. Kobbe, H. Fischer, Scaffolds for bone healing: concepts, materials, and evidence. Injury 42(6), 569–573 (2011)

N.E. Putra, M.J. Mirzaali, I. Apachitei, J. Zhou, A.A. Zadpoor, Multi-material additive manufacturing technologies for Ti-, Mg-, and Fe-based biomaterials for bone substitution. Acta Biomater. 109, 1–20 (2020)

M. Kaur, K. Singh, Review on titanium and titanium-based alloys as biomaterials for orthopedic applications. Mater. Sci. Eng. C 102, 844–862 (2019)

S. Chatterjee, S. Dey, S. Majumder, A. Roy Chowdhury, S. Datta, Computational intelligence based design of implant for varying bone conditions. Int. J. Numer. Methods Biomed. Eng. 35(6), e3191 (2019). https://doi.org/10.1002/cnm.3191

X.P. Tan, Y.J. Tan, C.S.L. Chow, Tor, SB, and Yeong, WY, Metallic powder-bed based 3D printing of cellular scaffolds for orthopedic implants: a state-of-the-art review on manufacturing, topological design, mechanical properties, and biocompatibility. Mater. Sci. Eng. C 76, 1328–1343 (2017)

B.V. Krishna, W. Xue, S. Bose, A. Bandyopadhyay, Engineered porous metals for implants. JOM 60(5), 45–48 (2008)

S. Gómez, M.D. Vlad, J. López, E. Fernández, Design and properties of 3D scaffolds for bone tissue engineering. Acta Biomater. 42, 341–350 (2016)

H. Montazerian, E. Davoodi, M. Asadi-Eydivand, J. Kadkhodapour, M. Solati-Hashjin, Porous scaffold internal architecture design based on minimal surfaces: a compromise between permeability and elastic properties. Mat. Des. 126, 98–114 (2017)

D. Ali, M. Ozalp, S.B. Blanquer, S. Onel, Permeability and fluid flow-induced wall shear stress in bone scaffolds with TPMS and lattice architectures: a CFD analysis. Eur. J. Mech. B-Fluids 79, 376–385 (2019)

S. Bose, D. Banerjee, A. Shivaram, S. Tarafder, A. Bandyopadhyay, Calcium phosphate coated 3D printed porous titanium with nanoscale surface modification for orthopedic and dental applications. Mater. Des. 151, 102–112 (2018)

S. Bose, M. Roy, A. Bandyopadhyay, Recent advances in bone tissue engineering scaffolds. Trends Biotechnol. 30(10), 546–554 (2012)

A. Ataee, Y. Li, D. Fraser, G. Song, C. Wen, Anisotropic Ti-6Al-4V gyroid scaffolds manufactured by electron beam melting (EBM) for bone implant applications. Mater. Des. 137, 345–354 (2018)

J. Markhoff, J. Wieding, V. Weissmann, J. Pasold, A. Jonitz-Heincke, R. Bader, Influence of different three-dimensional open porous titanium scaffold designs on human osteoblasts behavior in static and dynamic cell investigations. Materials 8(8), 5490–5507 (2015)

J.E. Biemond, R. Aquarius, N. Verdonschot, P. Buma, Frictional and bone ingrowth properties of engineered surface topographies produced by electron beam technology. Arch. Orthop. Trauma Surg. 131(5), 711–718 (2011)

S. Ghouse, N. Reznikov, O.R. Boughton, S. Babu, K.G. Ng, G. Blunn, J.P. Cobb, M.M. Stevens, J.R. Jeffers, The design and in vivo testing of a locally stiffness-matched porous scaffold. Appl. Mater. Today 15, 377–388 (2019)

M.J. Ciarelli, S.A. Goldstein, J.L. Kuhn, D.D. Cody, M.B. Brown, Evaluation of orthogonal mechanical properties and density of human trabecular bone from the major metaphyseal regions with materials testing and computed tomography. J. Orthop. Res. 9, 674–682 (1991)

Rho, J. Y., Hobatho, M. C., and Ashman, R. B., Anatomical variation of mechanical properties of human cortical bone. In: Hochmuth, R. M., Langrana, N. A., and Hefzy, M. S., Eds. Bioeng. Conf., ASME, Vol. BED-29. Beaver Creek, CO; 1995; 239–240.

M. Amling, S. Herden, M. Posl, M. Hahn, H. Ritzel, G. Delling, Heterogeneity of the skeleton: comparison of the trabecular microarchitecture of the spine, the iliac crest, the femur, and the calcaneus. J. Bone Miner. Res. 11, 36–45 (1996)

S. Roy, M. Das, P. Chakraborty, J.K. Biswas, S. Chatterjee, N. Khutia, S. Saha, A. RoyChowdhury, Optimal selection of dental implant for different bone conditions based on the mechanical response. Acta Bioeng Biomech 19(2), 11–20 (2017)

A. Berner, M.A. Woodruff, C.X.F. Lam, M.T. Arafat, S. Saifzadeh, R. Steck, J. Ren, M. Nerlich, A.K. Ekaputra, I. Gibson, D.W. Hutmacher, Effects of scaffold architecture on cranial bone healing. Int. J. Oral Maxillofac. Surg. 43(4), 506–513 (2014)

J. Kadkhodapour, H. Montazerian, A.C. Darabi, A.P. Anaraki, S.M. Ahmadi, A.A. Zadpoor, S. Schmauder, Failure mechanisms of additively manufactured porous biomaterials: effects of porosity and type of unit cell. J. Mech. Behav. Biomed. Mater. 50, 180–191 (2015)

S. Roy, S. Dey, N. Khutia, A.R. Chowdhury, S. Datta, Design of patient-specific dental implant using FE analysis and computational intelligence techniques. Appl. Soft Comput. 65, 272–279 (2018)

A. Entezari, Z. Zhang, A. Sue, G. Sun, X. Huo, C.C. Chang, S. Zhou, M.V. Swain, Q. Li, Nondestructive characterization of bone tissue scaffolds for clinical scenarios. J. Mech. Behav. Biomed. Mater. 89, 150–161 (2019)

R.L. Austman, J.S. Milner, D.W. Holdsworth, C.E. Dunning, The effect of the density–modulus relationship selected to apply material properties in a finite element model of long bone. J. Biomech. 41(15), 3171–3176 (2008)

J.K. Biswas, M. Rana, S. Majumder, S.K. Karmakar, A. Roychowdhury, Effect of two-level pedicle-screw fixation with different rod materials on lumbar spine: a finite element study. J. Orthop. Sci. 23(2), 258–265 (2018)

C.A. McCarty, J.J. Thomason, K.D. Gordon, T.A. Burkhart, J.S. Milner, D.W. Holdsworth, Finite-element analysis of bone stresses on primary impact in a large-animal model: the distal end of the equine third metacarpal. PLoS ONE 11(7), e0159541 (2016)

S. Roy, M. Das, P. Chakraborty, J.K. Biswas, S. Chatterjee, N. Khutia, S. Saha, A. RoyChowdhury, Optimal selection of dental implant for different bone conditions based on the mechanical response. Acta Bioeng. Biomech. 19(2), 11–20 (2017)

V. Filardi, R. Montanini, Measurement of local strains induced into the femur by trochanteric Gamma nail implants with one or two distal screws. Med. Eng. Phys. 29(1), 38–47 (2007)

B. Pal, S. Gupta, A.M. New, M. Browne, Strain and micromotion in intact and resurfaced composite femurs: experimental and numerical investigations. J. Biomech. 43(10), 1923–1930 (2010)

M. Marco, E. Giner, R. Larraínzar-Garijo, J.R. Caeiro, M.H. Miguélez, Modelling of femur fracture using finite element procedures. Eng. Fract. Mech. 196, 157–167 (2018)

Gibson, L., & Ashby, in Cellular Solids: Structure and Properties (Cambridge Solid State Science Series, 1999), pp. 175–234. https://doi.org/10.1017/CBO9781139878326.007

Heinl, P., Körner, C., and Singer, RF, Selective electron beam melting of cellular titanium: mechanical properties. Adv. Eng. Mater. 10(9), 882–888 (2008).

S. Roy, N. Khutia, D. Das, M. Das, V.K. Balla, A. Bandyopadhyay, A.R. Chowdhury, Understanding compressive deformation behavior of porous Ti using finite element analysis. Mater. Sci. Eng. C 64, 436–443 (2016)

L. Wang, J. Kang, C. Sun, D. Li, Y. Cao, Z. Jin, Mapping porous microstructures to yield desired mechanical properties for application in 3D printed bone scaffolds and orthopedic implants. Mater. Des. 133, 62–68 (2017)

J. Parthasarathy, B. Starly, S. Raman, A. Christensen, Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 3(3), 249–259 (2010)

J.K. Biswas, T.P. Sahu, M. Rana, S. Roy, S.K. Karmakar, S. Majumder, A. Roychowdhury, Design factors of lumbar pedicle screws under bending load: A finite element analysis. Biocybern. Biomed. Eng. 39(1), 52–62 (2019)

Y. Liu, K. Li, T. Luo, M. Song, H. Wu, J. Xiao, Y. Tan, M. Cheng, B. Chen, X. Niu, R. Hu, Powder metallurgical low-modulus Ti–Mg alloys for biomedical applications. Mater. Sci. Eng. C 56, 241–250 (2015)

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Amit Bandyopadhyay was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Supplementary Information

Below is the link to the electronic supplementary material.

43578_2021_307_MOESM2_ESM.jpg

Supplementary file 2 (JPG 615 kb) Fig. 11: von Mises stress (MPa) distribution on the peri-implant bone of greater trochanter for (a) natural model, (b) solid implant, (c) porous Ti6Al4V, (d) porous Ti-Mg, (e) reconstructed model

43578_2021_307_MOESM3_ESM.jpg

Supplementary file 3 (JPG 625 kb) Fig. 12: von Mises stress distribution (MPa) on the peri-implant bone of diaphysis for (a) natural model, (b) solid implant, (c) porous Ti6Al4V, (d) porous Ti-Mg, (e) reconstructed model

Rights and permissions

About this article

Cite this article

Rana, M., Karmakar, S.K., Pal, B. et al. Design and manufacturing of biomimetic porous metal implants. Journal of Materials Research 36, 3952–3962 (2021). https://doi.org/10.1557/s43578-021-00307-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00307-1