Abstract

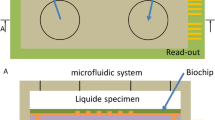

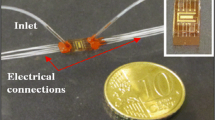

Low-cost and chemical resistant microfluidic devices based on thermoplastic elastomers have been fabricated by hot embossing technology. Commercial available thermoplastic elastomer foils based on polyurethane (PU) in a thickness range of 100-600 μm have been used. Prior to the fabrication of the microfluidic devices the chemical resistance of the material against a wide range of standard biological buffer solutions and solvents had been analysed. We created systems of channels, reservoirs and holes for the connections to external capillaries by double-sided hot embossing with an alignment accuracy of +/- 3 micrometer. Closed channel structures were produced by an additional chemical bonding process of the embossed devices with another thermoplastic elastomer foil. The total volume of the fluidic cell was 2 μl/sensor for the use with SAW (surface-acoustic wave) sensor chip and about 0.2 μ/sensor for the impedance sensors. A novel multi-chamber fluidic device was successfully tested for in-situ immobilization of thrombin antibodies and Bovin Serum Albumin (BSA) on different sensor elements of the same sensor chip.

Similar content being viewed by others

References

S-sens analytics (www.s-sens.com)

M. Schlensog, T.M.A. Gronewold, M. Tewes, M. Famulok, E. Quandt, Sensors and Actuators 101/3, 308–313 (2004).

M. Löhndorf, A. Malavé, S. Glass, I. Stoyanov, M. Tewes, Proc. of µ-TAS 2004, 2, 431– 433 (2004).

A. Malavé, T.M.A. Gronewold, M. Tewes, M. Löhndorf, Micromechanical Engineering (2005) in press.

M. Heckele and W.K. Schomburg, J. Micromech. Microeng. 14, R1–R14 (2004).

P. Gravesen, J. Branebjerg and O.S. Jensen, J. Micromech. Microeng. 3, 168–182 (2003).

H. Domininghaus, Die Kunsstoffe und ihre Eigenschaften, 5th ed. (Springer-Verlag Berlin Heidelberg, 1998) pp16–32.

R.J. Spontak, P.P Nikunj, J. Cur. Op. Col. & Int. Sc. 5, 334–341 (2000).

S. Hollande, J.L. Laurent and T. Lebey, Polymer 39, 5343 (1998).

H.J. Qi and M.C.Boyce, Mech. of mat., (2004) (in press)

G. Holden, N.R. Legge, R. Quirk and H.E. Schroeder, “Thermoplastic polyurethane elastomers,” Thermoplastic elastomers, 2nd ed., (Hanser/Gardner, 1996).

Epurex Films GmbH & Co. (www.epurex.de).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stoyanov, I., Tewes, M., Glass, S. et al. Low-cost and Chemical Resistant Microfluidic Devices Based on Thermoplastic Elastomers for a Novel Biosensor System. MRS Online Proceedings Library 872, 114 (2005). https://doi.org/10.1557/PROC-872-J11.4

Published:

DOI: https://doi.org/10.1557/PROC-872-J11.4