Abstract

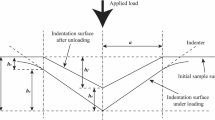

We have begun to explore the use of continuous stiffness techniques for studying the mechanical properties of coated systems using nanoindentation and thus to critically assess the differing types of sample information available from simple load-displacement (P-δ) curves, P-δ2 analyses and P-S2 (i.e. load-vs-(contact stiffness)2) data. We have also examined whether the small superposed AC signal used to continuously measure contact stiffness has had any marked effect on the sample load-displacement response. A range of fully calibrated Nano Indenter II and Nano Indenter XP instruments have been used for data acquisition, while transmission electron microscopy (TEM) and high resolution scanning electron microscopy (HRSEM) have both been employed to characterise the resultant indentation appearances and deformation structures. Samples have spanned a number of monolithic and coated materials systems including fused silica, 6H-SiC, 3C-SiC on Si and TiN on both M2 and 304 steels. Plots of P-δ and P-δ2recorded with and without the additional AC signal were found to be indistinguishable. Further, apart from some small statistical variation in the loads at which crack initiation was observed in a SiC-on-Si coated system, TEM and HRSEM studies showed no detectable differences in deformation substructures between nominally identical indentations made with and without the AC signal.

While the parameter P/S2 is independent of detailed tip shape and is a constant with displacement for monolithic systems, it was found to display unexpected variations with displacement for the coated systems. In order to explore the origins of these variations, we have examined plots of system elastic modulus (Es) and system hardness (Hs) as a function of indenter displacement which have shown that the effective contact elastic modulus decreases more rapidly with increasing contact scale than does the effective system hardness P/S2 can also be related to the plasticity index (ψ) widely used to describe the balance between the elastic and plastic responses of materials subjected to contact damage. Thus, the observations of maxima in plots of P/S2 with displacement, for at least some coated systems, suggests that there may be an optimum contact scale for maximising the elastic contribution to the contact response of such systems

Similar content being viewed by others

Reference

D S Rickerby & S J Bull, Surf Coat. Tech., 39/40, 1989, 315–328.

T F Page and S V Hainsworth, Surf Coat. Tech. 61, 1993, 201–208.

T F Page in Solid-SolidInteractions, 1996, (Eds M.J. Adams, B.J. Briscoe & S.K. Biswas) (Imperial College Press & World Scientific Pub. Co. UK & USA), pp 93–116.

S V Hainsworth, T Bartlettand T F Page, Thin Solid Films, 236, 1993, 214–218.

S V Hainsworth, M R McGurk & T F Page, Surf Coat. Tech., 102, 1998, 97–107

M R McGurk & T F Page, submitted to J. Mater. Res., (1998)

A M Korsunsky, M R McGurk, S J Bull & T F Page, Surf Coat. Tech., 99, 1998, 171–183.

M R McGurk, H W Chandler, P C Twigg & T F Page, Surf. Coat. Tech., 68/69, 1994, 576–581

M R McGurk, & T F Page, Surf. Coat. Tech., 92, 1997, 87–95

S V Hainsworth, H W Chandler, & T F Page, J. Mater. Res., 11, 1995, 1987–1995.

S V Hainsworthand T F Page, Symp. Proc. Mats. Res. Society, 436, 1997, 171–176.

W C Oliver & G M Pharr, J. Mater. Res., 7, 1992, 1564–1583.

J-L Loubet, J M Georges & J Meille in Microindentation Techniques in Materials Science & Engineering, 1986, (Eds P J Blau & B R Lawn)(ASTM, Philadelphia), 72–89.

K L Johnson, Contact Mechanics, 1985, p 62 (Cambridge University Press, UK)

S V Hainsworth, S J Bulland T F Page, Symp. Proc. Mats. Res. Society, 522, 1998.

S J Bull, and A M Korsunsky, Tribol. Int., 1998, (in press)

D L Joslin and W C Oliver, J. Mater. Res., 5, 1990, 123–126.

I N Sneddon, Int. J. Eng. Sci., 3, 1965, 47–57.

M F Ashby, Materials Selection in Mechanical design, 1992, (Pergamon Press).

B N Lucas, W C Oliver, G M Pharr, and J-L Loubet, Symp. Proc. Mats. Res. Society, 436, 1997, 233–238.

T.F. Page, L. Riester & S. V. Hainsworth, Symp. Proc. Mats. Res. Society, 522, 1998.

T F Page, W C Oliverand C J McHargue, J. Mater. Res., 7, 1992, 450–473

J A Greenwoodand J B P Williamson, Proc. Roy. Soc. London, A295, 1966, 300–330

Y-T Cheng & C-M Cheng, Appl. Phys. Letts., 73, 1998, 614–616.

R B King, Int. J. Solids Structures, 23, 1987, 1657–1664

D S Stone, M F Tambwe, H Kung, & M Nastasi, Symp. Proc. Mats. Res. Soc., 522, 1998.

J L Hay, W C Oliver, A Bolshakov & G M Pharr, Symp. Proc. Mats. Res. Soc., 522, 1998.

B Taljat, T Zacharia, and G M Pharr, Symp. Proc. Mats. Res. Society, 522, 1998.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Page, T.F., Pharr, G.M., Hay, J.C. et al. Nanoindentation Characterisation of Coated Systems: P:S2 - A New Approach Using the Continuous Stiffness Technique. MRS Online Proceedings Library 522, 53–64 (1998). https://doi.org/10.1557/PROC-522-53

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-522-53