Abstract

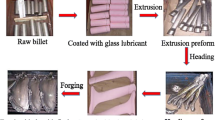

Balanced mechanical properties are needed for TiAl low pressure turbine blades envisaged for use in new generation aircraft engines. However, thermomechanical processing of γ-TiAl based alloys is a challenging task due to a small “processing window”. Isothermal forging, as state of the art process for this class of material, results in high productions costs and lower productivity. Due to these facts Bohler Schmiedetechnik GmbH & Co KG has developed a higher efficient “near conventional” thermomechanical processing technology. Lower die temperature and processing at standard atmosphere as well as the use of standard hydraulic presses with higher ram speed result in a highly economical process. Subsequent heat treatment strategies can be used to tailor microstructure and, therefore, mechanical properties according to customer needs. The paper summarizes our effort to establish a near conventional forging route for the fabrication of TiAl components for aerospace industry.

Similar content being viewed by others

References

S. Kremmer, H. F. Chladil, H. Clemens, A. Otto and V. Güther, in Ti-2007 Science and Technology, edited by M. Niinomi, S. Akiyama, M. Hagiwari, M. Ikeda and K. Maruyama (The Japan Institute of Metals, Sendai, 2007), pp. 989–992.

W. Wallgram, T. Schmölzer, L. Cha, G. Das, V. Güther, H. Clemens, Int. J. Mat. Res. 100, 1021 (2009).

M. Achtermann, V. Güther, J. Klose and H.-P. Nicolei, paper presented at the „4th International Workshop on Titanium Aluminides”, Nuremberg, Germany (September 14–16, 2011).

H. Clemens, W. Wallgram and M. Schloffer, U.S. Patent No. US 2011/0277891 A1 (17 November 2011).

M. Schloffer, F. Iqbal, H. Gabrisch, E. Schwaighofer, F. P. Schimansky, S. Mayer, A. Stark, T. Lippmann, M. Göken, F. Pyczak and H. Clemens, Intermetallics 22, 231 (2012).

H. Clemens and S. Mayer, Adv. Eng. Mater., DOI 10.1002/adem.201200231.

H. Clemens, W. Wallgram, S. Kremmer, V. Güther, A. Otto and A. Bartels, Adv. Eng. Mater. 10, 707, (2008).

F. Appel, H. Kestler and H. Clemens, Intermetallic compounds – principles and practice, Vol. 3, edited by J. H. Westbrook and R. L. Fleischer (WILEY-VCH, Chicester, UK, 2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Huber, D., Clemens, H. & Stockinger, M. Near Conventional Forging of an Advanced TiAl Alloy. MRS Online Proceedings Library 1516, 23–28 (2013). https://doi.org/10.1557/opl.2012.1665

Published:

Issue Date:

DOI: https://doi.org/10.1557/opl.2012.1665