Abstract

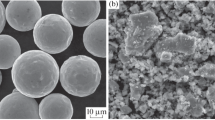

Ni-based composites with in situ formed Al2O3 and TiC ceramic phases were fabricated by hot pressing technology and that with directly added Al2O3 and TiC particles (ex situ) were also fabricated for comparison. The antioxygenic property and tribological properties of the composites were comparatively studied. The results show that the high-temperature oxidation resistance of the composite with in situ formed Al2O3 and TiC ceramic is superior to that of ex situ composite, and the friction coefficient of in situ composite is lower than that of ex situ composite in the wide temperature range from 400 °C to 1000 °C. The lowest friction coefficient was about 0.19 at 1000 °C and the wear rate of the composites are in the order of magnitude of 10−6 mm3/(N m) at high temperatures. The differences in tribological properties of in situ/ex situ composites are attributed to the formation of the glaze layer composed of MoO3, TiO2, Al2TiO5, NiAl2O4, and NiO on the worn surfaces and the difference of the distribution of the ceramics in the matrix.

Similar content being viewed by others

References

H. Spikes: Tribology research in the twenty-first century. Tribol. Int. 34 (12), 789 (2001).

S.Y. Zhu, Q.L. Bi, J. Yang, and W.M. Liu: Effect of fluoride content on friction and wear performance of Ni3Al matrix high-temperature self-lubricating composites. Tribol. Lett. 43 (3), 341 (2011).

Z.S. Xu, X.L. Shi, M. Wang, W.Z. Zhai, J. Yao, S.Y. Song, and Q.X. Zhang: Effect of Ag and Ti3SiC2 on tribological properties of TiAl matrix self-lubricating composites at room and increased temperatures. Tribol. Lett. 53 (3), 617 (2014).

A.D. Moghadam, E. Omrani, P.L. Menezes, and P.K. Rohatgi: Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Composites, Part B 77, 402 (2015).

C.H. Ding, P.L. Li, G. Ran, Y.W. Tian, and J.N. Zhou: Tribological property of self-lubricating PM304 composite. Wear 262 (5), 575 (2007).

J.L. Li and D.X. Xiong: Tribological properties of nickel-based self-lubricating composite at elevated temperature and counterface material selection. Wear 265 (3), 533 (2008).

C. DellaCorte and B.J. Edmonds: Nasa PS400: A new high temperature solid lubricant coating for high temperature wear applications. NASA TM-215678 (2009).

Q.L. Bi, W.M. Liu, J. Yang, J.Q. Ma, and Q.J. Xue: Tribological properties of Ni–17.5Si–29.3Cr alloy at room and elevated temperatures. Tribol. Int. 43 (1–2), 136 (2010).

I.A. Inman and P.S. Datta: Studies of high temperature sliding wear of metallic dissimilar interfaces. IV: Nimonic 80A versus Incoloy 800HT. Tribol. Int. 44 (12), 1903 (2011).

C. Rynio, H. Hattendorf, J. Klöwer, and G. Eggeler: The evolution of tribolayers during high temperature sliding wear. Wear 315 (1–2), 1 (2014).

J.X. Deng: Friction and wear behaviour of Al2O3/TiB2/SiCw ceramic composites at temperatures up to 800 °C. Ceram. Int. 27 (2), 135 (2001).

J.X. Deng, T.K. Cao, and L.L. Liu: Self-lubricating behaviors of Al2O3/TiB2 ceramic tools in dry high-speed machining of hardened steel. J. Eur. Ceram. Soc. 25 (7), 1073 (2005).

H. Gül, F. Kılıç, S. Aslan, A. Alp, and H. Akbulut: Characteristics of electro-co-deposited Ni–Al2O3 nano-particle reinforced metal matrix composite (MMC) coatings. Wear 267 (5–8), 976 (2009).

Z.B. Yin, J.T. Yuan, C.Z. Huang, Z.H. Wang, L. Huang, and Y. Cheng: Friction and wear behaviors of Al2O3/TiC micro-nano-composite ceramic sliding against metals and hard materials. Ceram. Int. 42, 1983 (2016).

R. Kumar, A. Chaubey, S. Bathula, B. Jha, and A. Dha: Synthesis and characterization of Al2O3–TiC nano-composite by spark plasma sintering. Int. J. Refract. Met. Hard. Mater. 54, 304 (2016).

H.Y. Tian, D. Zhu, N.S. Qu, and Z.W. Zhu: Wear resistance of Ni–Al2O3 nano-composite coatings prepared by electrophoretic-electroplating deposition. Mater. Mech. Eng. 33 (3), 65 (2009). (In Chinese).

J.J. Lu, J. Shang, J.H. Meng, and T. Wang: Friction and wear of Al2O3-based composites with dispersed and agglomerated nanoparticles. In Tribology of Nanocom-posites, Part of the series Materials Forming, Machining and Tribology, J. Paulo Davim ed.; Springer-Verlag: Berlin, Heidelberg, 2013; p. 61.

F. Liu and J.H. Jia: Tribological properties and wear mechanisms of NiCr–Al2O3–SrSO4–Ag self-lubricating composites at elevated temperatures. Tribol. Lett. 49 (1), 281 (2013).

F. Liu, J.H. Jia, G.W. Yi, W.Z. Wang, and Y. Shan: Mechanical and tribological properties of NiCr–Al2O3 composites at elevated temperatures. Tribol. Int. 84, 1 (2015).

C. Bartuli and R. Smith: Comparison between Ni–Cr–40 vol% TiC wear-resistant plasma sprayed coatings produced from self-propagating high-temperature synthesis and plasma densified powders. J. Therm. Spray Technol. 5 (3), 335 (1996).

Y. Choi, N.I. Baik, J.S. Lee, S.I. Hong, and Y.D. Hahn: Corrosion and wear properties of TiC/Ni–Mo composites produced by direct consolidation during a self-propagating high-temperature reaction. Compos. Sci. Technol. 61 (7), 981 (2001).

H.E. Sliney, C. Dellacorte, and V. Lukaszewicz: The tribology of PS212 coatings and PM212 composites for the lubrication of titanium 6A1–4V components of a Stirling engine space power system. Tribol. Trans. 38 (3), 497 (1995).

C. DellaCorte and J. Laskowski: Tribological evaluation of PS300: A new chrome oxide-based solid lubricant coating sliding against Al2O3 from 25 to 650 °C. Tribol. Trans. 40 (1), 163 (1997).

T.A. Blanchet, J.H. Kim, S.J. Calabrese, and C. DellaCorte: Thrust-washer evaluation of self-lubricating PS304 composite coatings in high temperature sliding contact. Tribol. Trans. 45 (4), 491 (2002).

J.C. Zhao: Ultrahigh-temperature materials for jet engines. MRS Bull. 28 (9), 620 (2003).

S.C. Tjong and Z.Y. Ma: Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng., R 29 (3–4), 51 (2000).

S. Yang, W.J. Liu, and M.L. Zhong: In-situ TiC reinforced composite coating produced by powder feeding laser cladding. J. Mater. Sci. Technol. 22, 519 (2006).

S. Zohari, Z. Sadeghian, B. Lotfi, and C. Broeckmann: Application of spark plasma sintering (SPS) for the fabrication of in situ Ni–TiC nanocomposite clad layer. J. Alloys Compd. 633, 479 (2015).

X.H. Wang, M. Zhang, and B.S. Du: Fabrication in situ TiB2–TiC–Al2O3 multiple ceramic particles reinforced Fe-based composite coatings by gas tungsten arc welding. Tribol. Lett. 41 (1), 171 (2011).

E.Y. Liu, Y.M. Gao, J.H. Jia, Y.P. Bai, and W.Z. Wang: Microstructure and mechanical properties of in situ NiAl–Mo2C nanocomposites prepared by hot-pressing sintering. Mater. Sci. Eng., A 592, 201 (2015).

J.Y. Wang, Y. Shan, H.J. Guo, W.Z. Wang, G.W. Yi, and J.H. Jia: The tribological properties of NiCr–Al2O3–TiO2 composites at elevated temperatures. Tribol. Lett. 58, 2 (2015).

E.Y. Liu, Y.M. Gao, J.H. Jia, and Y.P. Bai: Friction and wear behaviors of Ni-based composites containing graphite/Ag2MoO4 lubricants. Tribol. Lett. 50 (3), 313 (2013).

L.Y. Sheng, F. Yang, T.F. Xi, and J.T. Guo: Investigation on microstructure and wear behavior of the NiAl–TiC–Al2O3 composite fabricated by self-propagation high-temperature synthesis with extrusion. J. Alloys Compd. 554 (2), 182 (2013).

G.L. Hou, Y.L. An, X.Q. Zhao, H.D. Zhou, and J.M. Chen: Effect of alumina dispersion on oxidation behavior as well as friction and wear behavior of HVOF-sprayed CoCrAlYTaCSi coating at elevated temperature up to 1000 °C. Acta Mater. 95, 164 (2015).

E.Y. Liu, Y.M. Gao, Y.P. Bai, G.W. Yi, W.Z. Wang, Z.X. Zeng, and J.H. Jia: Tribological properties of self-lubricating NiAl/Mo-based composites containing AgVO3 nanowires. Mater. Charact. 97, 116 (2014).

ACKNOWLEDGMENTS

The authors acknowledge the financial support of the National Natural Science Foundation of China (Grant Nos. 51471181, 51575505, and 51675508).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Wang, W. & Jia, J. The oxidation resistance and tribological properties of Ni-based composites with in situ/ex situ Al2O3 and TiC ceramic phases at high temperatures. Journal of Materials Research 31, 3262–3271 (2016). https://doi.org/10.1557/jmr.2016.350

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.350