Abstract

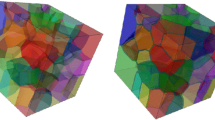

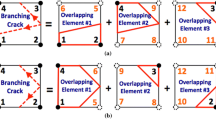

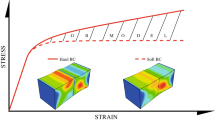

We investigated how coherent interfaces, between face centered cubic (fcc)/hexagonal close packed (hcp) systems, affect large strain deformation and fracture modes in hcp zircaloy aggregates with fcc hydrides. We derived 36 unique transformations related to coherent interfaces between fcc and hcp systems. We then used these orientation relations (ORs) with a dislocation-density crystalline plasticity formulation, a nonlinear finite-element, and a fracture approach that account for crack nucleation and propagation. We investigated how these ORs affect crack nucleation and propagation, dislocation density and inelastic slip evolution, stress accumulation, lattice rotation, and adiabatic heating. The predictions indicate that the physical representation of ORs affects local deformation and fracture behavior and are, therefore, essential for the accurate predictions of behavior at different physical scales in heterogeneous crystalline systems.

Similar content being viewed by others

References

J. Lévesque, K. Inal, K.W. Neale, and R.K. Mishra: Numerical modeling of formability of extruded magnesium alloy tubes. Int. J. Plast. 26 (1), 65 (2010).

S. Graff, W. Brocks, and D. Steglich: Yielding of magnesium: From single crystal to polycrystalline aggregates. Int. J. Plast. 23 (12), 1957 (2007).

K. Inal and R.K. Mishra: Crystal plasticity based numerical modelling of large strain deformation inhexagonal closed packed metals. Procedia IUTAM 3, 239 (2012).

F.F. Lavrentev and Y.A. Pokhil: Relation of dislocation density in different slip systems to work hardening parameters for magnesium crystals. Mater. Sci. Eng. 18 (2), 261 (1975).

S. Ziaei and M.A. Zikry: Modeling the effects of dislocation-density interaction, generation, and recovery on the behavior of H.C.P. materials. Metall. Mater. Trans. A1 (2014).

N. Gey and M. Humbert: Characterization of the variant selection occurring during the α→β→α phase transformations of a cold rolled titanium sheet. Acta Mater. 50 (2), 277 (2002).

S. Suwas, R.K. Ray, A.K. Singh, and S. Bhargava: Evolution of hot rolling textures in a two-phase (α2+β) Ti3Al base alloy. Acta Mater. 47 (18), 4585 (1999).

S. Suwas and R.K. Ray: Effect of rolling on textures of primary and secondary α2 produced by thermomechanical processing of the intermetallic alloy Ti-24Al-11Nb. Scr. Mater. 44 (2), 275 (2001).

J.C. Williams and G. Lutjering: Titanium (Springer, Berlin, Germany, 2003).

R.T. Webster: ASM Handbook. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, Vol. 2 (ASM, Novelty, OH, 1990); p. 1328.

J.H. Schemel: ASTM Manual on Zirconium and Hafnium (ASTM International, West Conshohocken, PA, 1977).

A. Sarkar, K. Boopathy, J. Eapen, and K.L. Murty: Creep behavior of hydrogenated zirconium alloys. J. Mater. Eng. Perform. 23 (10), 3649 (2014).

K.L. Murty and I. Charit: Texture development and anisotropic deformation of zircaloys. Prog. Nucl. Energy 48 (4), 325 (2006).

A.T. Motta, A. Yilmazbayhan, M.J. Gomes da Silva, R.J. Comstock, G.S. Was, J.T. Busby, E. Gartner, Q. Peng, Y.H. Jeong, and J.Y. Park: Zirconium alloys for supercritical water reactor applications: Challenges and possibilities. J. Nucl. Mater. 371 (1–3), 61 (2007).

A.M. Alam and C. Hellwig: Cladding tube deformation test for stress reorientation of hydrides. In Zirconium in the Nuclear Industry: 15th International Symposium, Vol. 1505, ASTM International, West Conshohocken, PA, 2009; p. 635.

C. Lemaignan and A.T. Motta: Zirconium Alloys in Nuclear Applications (Wiley-VCH Verlag GmbH & Co. KGaA, 2006).

J.J. Kearns: Terminal solubility and partitioning of hydrogen in the alpha phase of zirconium, zircaloy-2 and zircaloy-4. J. Nucl. Mater. 22 (3), 292 (1967).

J.J. Kearns: Dissolution kinetics of hydride platelets in zircaloy-4. J. Nucl. Mater. 27 (1), 64 (1968).

W. Qin, N.A.P. Kiran Kumar, J.A. Szpunar, and J. Kozinski: Intergranular δ-hydride nucleation and orientation in zirconium alloys. Acta Mater. 59 (18), 7010 (2011).

M.P. Puls: The effects of misfit and external stresses on terminal solid solubility in hydride-forming metals. Acta Metall. 29 (12), 1961 (1981).

M.P. Puls: Elastic and plastic accommodation effects on metal-hydride solubility. Acta Metall. 32 (8), 1259 (1984).

M.P. Puls: Review of the thermodynamic basis for models of delayed hydride cracking rate in zirconium alloys. J. Nucl. Mater. 393 (2), 350 (2009).

M. Veleva, S. Arsene, M. Record, J. Bechade, and J. Bai: Hydride embrittlement and irradiation effects on the hoop mechanical properties of pressurized water reactor (PWR) and boiling-water reactor (BWR) ZIRCALOY cladding tubes: Part II. Morphology of hydrides investigated at different magnifications and their interaction with the processes of plastic deformation. Metall. Mater. Trans. A 34 (3), 567 (2003).

S. Arsene, J.B. Bai, and P. Bompard: Hydride embrittlement and irradiation effects on the hoop mechanical properties of pressurized water reactor (PWR) and boiling-water reactor (BWR) ZIRCALOY cladding tubes: Part I. Hydride embrittlement in stress-relieved, annealed, and recrystallized ZIRCALOYs at 20 °C and 300 °C. Metall. Mater. Trans. A 34 (3), 553 (2003).

M. Puls: Fracture initiation at hydrides in zirconium. Metall. Trans. A 22 (10), 2327 (1991).

M. Puls, S. Shi, and J. Rabier: Experimental studies of mechanical properties of solid zirconium hydrides. J. Nucl. Mater. 336 (1), 73 (2005).

X-F. Gu and W-Z. Zhang: A simple method for calculating the possible habit planes containing one set of dislocations and its applications to fcc/bct and hcp/bcc systems. Metall. Mater. Trans. A 45A (4), 1855 (2014).

Z. Wang, U. Garbe, H. Li, A.J. Studer, R.P. Harrison, M.D. Callaghan, Y. Wang, and X. Liao: Hydrogen-induced microstructure, texture and mechanical property evolutions in a high-pressure torsion processed zirconium alloy. Scr. Mater. 67 (9), 752 (2012).

G. Pilania, B.J. Thijsse, R.G. Hoagland, I. Lazic, S.M. Valone, and X. Liu: Revisiting the Al/Al2O3 interface: Coherent interfaces and misfit accommodation. Sci. Rep. 4, 4485 (2014).

D.A. Porter, K.E. Easterling, and M. Sherif: Phase Transformations in Metals and Alloys (CRC Press, Boca Raton, FL, 2009); 520 pp.

H. Abdolvand, M.R. Daymond, and C. Mareau: Incorporation of twinning into a crystal plasticity finite element model: Evolution of lattice strains and texture in zircaloy-2. Int. J. Plast. 27 (11), 1721 (2011).

M.A. Zikry: An accurate and stable algorithm for high strain-rate finite strain plasticity. Comput. Struct. 50 (3), 337 (1994).

Q. Wu, P. Shanthraj, and M.A. Zikry: Modeling the heterogeneous effects of retained austenite on the behavior of martensitic high strength steels. Int. J. Fract. 184 (1–2), 241 (2013).

R.J. Asaro and J.R. Rice: Strain localization in ductile single-crystals. J. Mech. Phys. Solids 50, 337 (1977).

P. Franciosi, M. Berveiller, and A. Zaoui: Latent hardening in copper and aluminium single crystals. Acta Metall. 28 (3), 273 (1980).

B. Devincre, T. Hoc, and L. Kubin: Dislocation mean free paths and strain hardening of crystals. Science 320, 1745 (2008).

L. Kubin, B. Devincre, and T. Hoc: Towards a physical model for strain hardening in fcc crystals. Mater. Sci. Eng., A 19, 483–484 (2008).

L. Kubin, B. Devincre, and T. Hoc: Modeling dislocation storage rates and mean free paths in face-centered cubic crystals. Acta Mater. 56 (20), 6040 (2008).

M.A. Zikry and M. Kao: Inelastic microstructural failure mechanisms in crystalline materials with high angle grain boundaries. J. Mech. Phys. Solids 44 (11), 1765 (1996).

P. Shanthraj and M.A. Zikry: Dislocation density evolution and interactions in crystalline materials. Acta Mater. 59 (20), 7695 (2011).

M-X. Zhang, S-Q. Chen, H-P. Ren, and P.M. Kelly: Crystallography of the simple HCP/FCC system. Metall. Mater. Trans. A 39A (5), 1077 (2008).

M. Niewczas: Lattice correspondence during twinning in hexagonal close-packed crystals. Acta Mater. 58 (17), 5848 (2010).

A. Musienko and G. Cailletaud: Simulation of inter- and transgranular crack propagation in polycrystalline aggregates due to stress corrosion cracking. Acta Mater. 57 (13), 3840 (2009).

E. Pouillier, A. Gourgues, D. Tanguy, and E.P. Busso: A study of intergranular fracture in an aluminium alloy due to hydrogen embrittlement. Int. J. Plast. 34, 139 (2012).

Q. Wu and M.A. Zikry: Microstructural modeling of crack nucleation and propagation in high strength martensitic steels. Int. J. Solids Struct. 51 (25–26), 4345 (2014).

A. Hansbo and P. Hansbo: A finite element method for the simulation of strong and weak discontinuities in solid mechanics. Comput. Methods Appl. Mech. Eng. 193 (33–35), 3523 (2004).

J.W. Morris, Jr.: On the ductile-brittle transition in lath martensitic steel. ISIJ Int. 51 (10), 1569 (2011).

C. Wang, M. Wang, J. Shi, W. Hui, and H. Dong: Effect of microstructural refinement on the toughness of low carbon martensitic steel. Scr. Mater. 58 (6), 492 (2008).

C.Q. Chen, S.X. Li, H. Zheng, L.B. Wang, and K. Lu: An investigation on structure, deformation and fracture of hydrides in titanium with a large range of hydrogen contents. Acta Mater. 52 (12), 3697 (2004).

S. Arsene, J. Bai, and P. Bompard: Hydride embrittlement and irradiation effects on the hoop mechanical properties of pressurized water reactor (PWR) and boiling-water reactor (BWR) ZIRCALOY cladding tubes: Part III. Mechanical behavior of hydride in stress-relieved annealed and recrystallized ZIRCALOYs at 20 °C and 300 °C. Metall. Mater. Trans. A 34 (3), 579 (2003).

T. Kubo, Y. Kobayashi, and H. Uchikoshi: Determination of fracture strength of δ-zirconium hydrides embedded in zirconium matrix at high temperatures. J. Nucl. Mater. 435 (1–3), 222 (2013).

A. Rico, M.A. Martin-Rengel, J. Ruiz-Hervias, J. Rodriguez, and F.J. Gomez-Sanchez: Nanoindentation measurements of the mechanical properties of zirconium matrix and hydrides in unirradiated pre-hydrided nuclear fuel cladding. J. Nucl. Mater. 452 (1–3), 69 (2014).

M. Kuroda, K. Yoshioka, S. Yamanaka, H. Anada, F. Nagase, and H. Uetsuka: Influence of precipitated hydride on the fracture behavior of zircaloy fuel cladding tube. J. Nucl. Sci. Technol. 37 (8), 670 (2000).

C. Mareau and M.R. Daymond: Comparison of experimentally determined texture development in zircaloy-2 with predictions from a rate-dependent polycrystalline model. Mater. Sci. Eng., A 528 (29–30), 8676 (2011).

D.C. Hofman and V.A. Lubarda: New method for determining hexagonal direction indices and their relationship to crystallographic directions. J. Appl. Crystallogr. 36 (1), 23 (2003).

K. Une, K. Nogita, S. Ishimoto, and K. Ogata: Crystallography of zirconium hydrides in recrystallized zircaloy-2 fuel cladding lay electron backscatter diffraction. J. Nucl. Sci. Technol. 41 (7), 731 (2004).

V. Perovic and G.C. Weatherly: The β to α transformation in a Zr-2.5 wt% Nb alloy. Acta Metall. 37 (3), 813 (1989).

L. Tournadre, F. Onimus, J-L. Béchade, D. Gilbon, J-M. Cloué, J-P. Mardon, and X. Feaugas: Toward a better understanding of the hydrogen impact on the radiation induced growth of zirconium alloys. J. Nucl. Mater. 441 (1–3), 222 (2013).

M.H. Yoo, S.R. Agnew, J.R. Morris, and K.M. Ho: Non-basal slip systems in HCP metals and alloys: Source mechanisms. Mater. Sci. Eng., A 319–321, 87 (2001).

ACKNOWLEDGMENTS

A Support from the Consortium for Advanced Simulation of Light Water Reactors an Energy Innovation Hub for Modeling and Simulation of Nuclear Reactors under U.S. Department of Energy Contract No. DE-AC05-00OR227 and partial support from ARO grant W911NF-12-1-0329 are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ziaei, S., Wu, Q. & Zikry, M.A. Orientation relationships between coherent interfaces in hcp–fcc systems subjected to high strain-rate deformation and fracture modes. Journal of Materials Research 30, 2348–2359 (2015). https://doi.org/10.1557/jmr.2015.207

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.207