Abstract

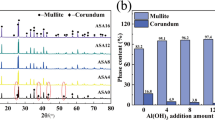

The effects of the precursor pH and sintering temperature on the synthesizing behavior and morphology of mullite were studied using a stoichiometric mullite (3Al2O3 · 2SiO2) precursor sol. The mullite precursor sol was prepared by the dissolution of aluminum nitrate enneahydrate [Al(NO3)3 · 9H2O] into the mixture of silica sol. The precursor pH of the sols was controlled to the acidic (pH ≈ 1.5 to 2), intermediate (pH ≈ 4.5 to 5) and basic (pH ≈ 8.5 to 9) conditions. The gels dried from the synthesized aluminosilicate sols were formed into a disk shape under 20 MPa pressure; then the green bodies were sintered for 3 h in the temperature range of 1100–1600 °C. The synthesizing temperature of mullite phase was found to be above 1200 °C for pH ≈ 1.5 to 2, and above 1300 °C for pH ≈ 4.5 to 5 and pH ≈ 8.5 to 9. The grain morphology of the synthesized mullite was changed to a rod shape for pH ≈ 1.5 to 2, and granulate shape for pH ≈ 4.5 to 5 and pH ≈ 8.5 to 9 with increasing sintering temperature. It was found that the morphology of mullite particle was predominantly governed by precursor pH and sintering temperature. However, at higher pH, the precursor pH and sintering temperature did not affect the synthesis behavior and grain morphology.

Similar content being viewed by others

References

P.C. Dokko, J.A. Pask, and K.S. Nazdiyasni, J. Am. Ceram. Soc. 60, 150 (1997).

Y. Hirata, S. Matsushita, Y. Ishihara, and H. Katsuki, J. Am. Ceram. Soc. 74, 2438 (1991).

I.A. Aksay, D.M. Dabbs, and M. Sarikaya, J. Am. Ceram. Soc. 74, 2343 (1991).

J. Klug and S. Prochaka, J. Am. Ceram. Soc. 70, 750 (1987).

K. Okada, N. Otsuka, and S. Somiya, Am. Ceram. Soc. Bull. 70, 1633 (1991).

T.I. Mah and K.S. Mazdiyashi, J. Am. Ceram. Soc. 66, 699 (1983).

Y.G. Choi, J. Kor. Ceram. Soc. 7, 773 (1999).

Y. Hirata, K. Sakeda, Y. Matsuchma, K. Shimada, and Y. Ishihara, J. Am. Ceram. Soc. 72, 995 (1989).

D.W. Hoffman, R. Roy, and S. Komarneni, J. Am. Ceram. Soc. 67, 468 (1984).

I. Jaymes, A. Douy, D. Massiot, and J.P. Coutures, J. Mater. Sci. 31, 4581 (1996).

S. Rajendran, H.J. Rossell, and J.V. Sanders, J. Mater. Sci. 25, 4462 (1990).

A.K. Chakraborty and D.K. Ghosh, J. Mater. Sci. 29, 6131 (1994).

G.M. Anilkumar, P. Mukundan, A.D. Damodaran, and K.G.W. Warrier, Mater. Lett. 33, 117 (1997).

K. Okada and N. Otuska, J. Am. Ceram. Soc. 74, 2414 (1991).

J.S. Hong, X.X. Huang, and J.K. Guo, Mater. Lett. 24, 327 (1995).

K.C. Song, Mater. Lett. 35, 290 (1998).

B.L. Metcalfe and J.H. Sant, Trans. J. Br. Ceram. Soc. 74(6), 193 (1995).

C.G. Ha, Y.G. Jung, J.W. Kim, C.Y. Jo, and U. Paik, Mater. Sci. & Eng. A 337, 212 (2002).

H. Schneider, K. Okada, and J.A. Pask, Mullite and Mullite Ceramics (John Wiley & Sons, New York, 1994).

J. Temunjin, K. Okada, and K.J.D. Mackenzie, Ceram. Inter. 25, 85 (1999).

M.D. Sacks, H.W. Lee, and J.A. Pask, in Mullite and Mullite Matrix Composites: A Review of Powder Preparation Methods and Densification Procedures for Fabricating High Density Mullite, edited by S. Somiya, R.F. Davis, and J.A. Pask (Am. Ceram. Soc. Ceram. Trans. 61, Westerville, OH, 1990), pp. 167–207.

H. Schneider, D. Voll, L. Merwin, and A. Sebald, J. Eur. Ceram. Soc. 11, 87 (1993).

K. Okada and N. Otsuka, in Mullite and Mullite Matrix Composites: Formation Process of Mullite, edited by S. Somiya, R.F. Davis, and J.A. Pask (Am. Ceram. Soc. Ceram. Trans. 61, Westerville, OH, 1990), pp. 87–375.

T.A. Ring, Fundamentals of Ceramic Powder Processing and Synthesis (Academic Press, New York, 1996), pp. 340–347.

A. Chakravorty and D.K. Ghosh, J. Am. Ceram. Soc. 71, 978 (1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JW., Lee, JE., Jung, YG. et al. Synthesis behavior and grain morphology in mullite ceramics with precursor pH and sintering temperature. Journal of Materials Research 18, 81–87 (2003). https://doi.org/10.1557/JMR.2003.0012

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2003.0012