Abstract

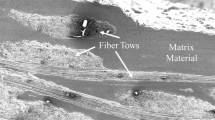

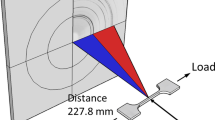

Here, we probed the local creep response of SiC/SiC ceramic matrix composites via high-temperature indentation to examine the contributions of heterogeneous microstructure to creep. Indentations were conducted up to 800 °C on single and polycrystalline Si and SiC, reaction-bonded SiC, and the SiC/SiC composite, which indicated higher creep strain rates of polycrystalline materials yet uncovered comparably lower strain rates of the SiC/SiC composite. Indentation creep rate was observed to be highly dependent on contact stresses. An analytical creep model was presented based on a rule of mixtures approach to incorporate material heterogeneity of the SiC/SiC composite. A finite element model was applied to predict the indentation deformation zone, in which the composite constituents would jointly influence the creep response. The analytical model was then solved for temperatures up to 800 °C and exhibited good agreement with experimental measurements.

Graphic abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

H.M. Yun, J.Z. Gyekenyesi, Y.L. Chen, D.R. Wheeler, J.A. Dicarlo, Tensile behavior of SiC/SiC composites reinforced by treated Sylramic SiC fibers. Ceram. Eng. Sci. Proc. 22(3), 521–531 (2001)

Y. Zhou, W. Zhou, F. Luo, D. Zhu, Effects of dip-coated BN interphase on mechanical properties of SiCf/SiC composites prepared by CVI process. Trans. Nonferrous Met. Soc. China 24(5), 1400 (2014)

Y. Gowayed, G. Ojard, R. Miller, U. Santhosh, J. Ahmad, and R. John: Mechanical Properties of MI SiC/SiC Composites and Their Constituents (2007).

T. Ishikawa, Recent developments of the SiC fiber Nicalon and its composites, including properties of the SiC fiber Hi-Nicalon for ultra-high temperature. Compos. Sci. Technol. 51(2), 135 (1994)

C. Droillard, J. Lamon, Fracture toughness of 2-D woven SiC/SiC CVI-composites with multilayered interphases. J. Am. Ceram. Soc. 79(4), 849 (1996)

G.N. Morscher, H.M. Yun, J.A. Dicarlo, In-plane cracking behavior and ultimate strength for 2D woven and braided melt-infiltrated SiC/SiC composites tensile loaded in off-axis fiber directions. J. Am. Ceram. Soc. 90(10), 3185 (2007)

B.F. Sorensen, J.W. Holmes, Effect of loading rate on the monotonic tensile behavior of a continuous-fiber-reinforced glass-ceramic matrix composite. J. Am. Ceram. Soc. 79(2), 313 (1996)

G.N. Morscher, Stress-dependent matrix cracking in 2D woven SiC-fiber reinforced melt-infiltrated SiC matrix composites. Compos. Sci. Technol. 64, 1311 (2004)

J.Z. Gyekenyesi, N.P. Bansal, High Temperature Tensile Properties of Unidirectional Hi-Nicalon/Celsian Composites in Air (2000)

D.J. Bertrand, V. Sabelkin, L. Zawada, S. Mall, Fatigue behavior of sylramic-iBN/BN/CVI SiC ceramic matrix composite in combustion environment. J. Mater. Sci. 50(22), 7437 (2015)

R.K. Mishra, C. Beura, Life consumption assessment of a large jet engine. J. Fail. Anal. Prev. 14(4), 519 (2014)

C. B. Meher-Homji, G. Gabriles, in Proc. 27th Turbomach. Symp. (1998), pp. 129–179.

W.D. Nix, H. Gao, Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids 46(3), 411 (1998)

J. Pelleg, Solid Mechanics and Its Applications: Creep in Ceramics (Springer, New York, 2017).

G.N. Morscher, G. Ojard, R. Miller, Y. Gowayed, U. Santhosh, J. Ahmad, R. John, Tensile creep and fatigue of Sylramic-iBN melt-infiltrated SiC matrix composites: retained properties, damage development, and failure mechanisms. Compos. Sci. Technol. 68, 3305 (2008)

S. Zhu, M. Mizuno, Y. Kagawa, Y. Mutoh, Monotonic tension, fatigue and creep behavior of SiC-fiber-reinforced SiC-matrix composites: a review. Compos. Sci. Technol. (6 SPEC. SEC) 59(6), 833 (1999)

G. Chollon, R. Pailler, R. Naslain, Correlation between microstructure and mechanical behaviour at high temperatures of a SiC fibre with a low oxygen content (Hi-Nicalon). J. Mater. Sci. 32, 1133 (1997)

E.G. Herbert, G.M. Pharr, W.C. Oliver, B.N. Lucas, J.L. Hay, On the measurement of stress–strain curves by spherical indentation. Thin Solid Films 398–399, 331 (2001)

B. Xu, X. Chen, Determining engineering stress-strain curve directly from the load-depth curve of spherical indentation test. J. Mater. Res. 25(12), 2297 (2010)

N.A. Sakharova, J.V. Fernandes, J.M. Antunes, M.C. Oliveira, Comparison between Berkovich, Vickers and conical indentation tests: a three-dimensional numerical simulation study. Int. J. Solids Struct. 46(5), 1095 (2009)

K. Komvopoulos, V. Do, E.S. Yamaguchi, P.R. Ryason, Nanomechanical and nanotribological properties of an antiwear tribofilm produced from phosphorus-containing additives on boundary-lubricated steel surfaces. J. Tribol. 126, 775 (2004)

N. Rohbeck, D. Tsivoulas, I.P. Shapiro, P. Xiao, S. Knol, J.M. Escleine, M. Perez, B. Liu, Comparison study of silicon carbide coatings produced at different deposition conditions with use of high temperature nanoindentation. J. Mater. Sci. 52(4), 1868 (2017)

H. Takagi, M. Dao, M. Fujiwara, Analysis on pseudo-steady indentation creep. Acta Mech. Solida Sin. 21(4), 283–288 (2008)

G.M. Pharr, E.G. Herbert, Y. Gao, The indentation size effect: a critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 40(1), 271 (2010)

W.D. Nix, H. Gao, Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids 46(3), 411 (1997)

X.L. Gao, X.N. Jing, G. Subhash, Two new expanding cavity models for indentation deformations of elastic strain-hardening materials. Int. J. Solids Struct. 43(7–8), 2193 (2006)

Y. Huang, F. Zhang, K.C. Hwang, W.D. Nix, G.M. Pharr, G. Feng, A model of size effects in nano-indentation. J. Mech. Phys. Solids 54, 1668 (2006)

Q. Ma, D.R. Clarke, Size dependent hardness of silver single crystals. J. Mater. Res. 10(4), 853 (1995)

K.W. McElhaney, J.J. Vlassak, W.D. Nix, Determination of indenter tip geometry and indentation contact area for depth-sensing indentation experiments. J. Mater. Res. 13(5), 1300 (1998)

Mech. APDL Command Ref. (2011).

Z. Xu, X. Li, Sample size effect on nanoindentation of micro-/nanostructures. Acta Mater. 54(6), 1699 (2006)

J.L. Daly, On Comparison of Indentation Models (University of South Florida, Tampa, 2007).

A.K. Swarnaker, O. Van der Biest, J. Vanhellemont, Determination of the Si Young’s modulus between room and melt temperature using the impulse excitation technique. Phys. Status Solidi C 11(1), 150 (2014)

C.H. Cho, Characterization of Young’s modulus of silicon versus temperature using a “beam deflection” method with a four-point bending fixture. Curr. Appl. Phys. 9(2), 538 (2009)

S. Goel, Nanoindentation of polysilicon and single crystal silicon: Molecular dynamics simulation and experimental validation. J Phys D 47(27), 275304 (2014)

J. Vanhellemont, A.K. Swarnakar, O. Van der Biest, Temperature dependent Young’s modulus of Si and Ge. ECS Trans. 64(11), 283 (2014)

A.A. Wereszczak, W.L. Daloz, K.T. Strong, O.M. Jadaan, Effect of indenter elastic modulus on Hertzian ring crack initiation in silicon carbide. Int. J. Appl. Ceram. Technol. 8(4), 885 (2011)

CoorsTek, Silicon Carbides-SiC-01024I (2017).

Y. Katoh, D.F. Wilson, C.W. Forsberg, Assessment of Silicon Carbide Composites for Advanced Salt- Cooled Reactors (Oak Ridge, TN, TN, 2007).

G.N. Morscher, V.V. Pujar, Creep and stress-strain behavior after creep for SiC fiber reinforced, melt-infiltrated SiC matrix composites. J. Am. Ceram. Soc. 89(5), 1652 (2006)

G. Morscher, J. Gyekenyesi, Room temperature tensile behavior and damage accumulation of Hi-Nicalon reinforced SiC matrix composites. 22nd Annu. Conf. Compos. Adv. Ceram. Mater. Struct. (2009).

J. Chen, Y. Shen, W. Liu, B.D. Beake, X. Shi, Z. Wang, Y. Zhang, X. Guo, Effects of loading rate on development of pile-up during indentation creep of polycrystalline copper. Mater. Sci. Eng. A 656, 216 (2016)

S. Yao, D. Xu, B. Xiong, Y. Wang, The plastic and creep characteristics of silicon microstructure at elevated temperature. Microsyst. Technol. 21(5), 1111 (2015)

T.A. Taylor, C.R. Barrett, Creep and recovery of silicon single crystals. Mater. Sci. Eng. 10(C), 93 (1972)

J. Pelleg: in Creep Ceram. (2017), pp. 357–393.

G.S. Corman, Creep of 6H α-silicon carbide single crystals. J. Am. Ceram. Soc. 75(12), 3421 (1992)

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, 1985).

C.S. Lynch, A.G. Evans, J. Am. Ceram. Soc. 79, 3113 (1996)

J.F. Smith, S. Zheng, High temperature nanoscale mechanical property measurements. Surf. Eng. 16(2), 143 (2000)

J.M. Wheeler, D.E.J. Armstrong, W. Heinz, R. Schwaiger, High temperature nanoindentation: the state of the art and future challenges. Curr. Opin. Solid State Mater. Sci. 19(6), 354 (2015)

W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564 (1992)

W.C. Oliver, G.M. Pharr, Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J. Mater. Res. 19(01), 3 (2004)

G. Feng, A. Ngan, Effects of creep and thermal drift on modulus measurement using depth-sensing indentation Effects of creep and thermal drift on modulus measurement using depth-sensing indentation. Cit. J. Mater. Res. 17(3), 660 (2002)

Acknowledgments

The authors would like to thank Rolls-Royce Corporation for providing funding for this research. Silicon carbide ceramic matrix composite specimens were provided by Rolls-Royce for the purposes of this study.

Funding

Co-authors Jason D. Baker and Andrew J. Ritchey are employees of Rolls-Royce Corporation, which provided funding and materials for this research. All work and analyses were conducted independently by the University of Virginia. Co-authors Baker and Ritchey contributed to the editing of this manuscript.

Author information

Authors and Affiliations

Contributions

CHB involved in formal analysis, methodology, investigation, and writing. JDB contributed to resources and reviewing/editing. AJR performed project administration, supervision, resources, funding acquisition, and reviewing/editing. XL did project administration, supervision, and reviewing/editing.

Corresponding author

Rights and permissions

About this article

Cite this article

Bumgardner, C.H., Baker, J.D., Ritchey, A.J. et al. Probing the local creep mechanisms of SiC/SiC ceramic matrix composites with high-temperature nanoindentation. Journal of Materials Research 36, 2420–2433 (2021). https://doi.org/10.1557/s43578-021-00128-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00128-2