Abstract

Degradation of triamcinolone acetonide (TCA) in an ointment was investigated. TCA appeared to be concentrated in propylene glycol (PG) which in turn is dispersed in a lanolin-petrolatum mixture. Two predominant degradation products were identified: a 21-aldehyde and a 17-carboxylic acid. The 21-aldehyde is formed after TCA is oxidized by O2, a reaction that is catalyzed by trace metals. Logically, the content of trace metals has a profound effect on the degradation rate. It was shown that trace metals are extracted from lanolin and petrolatum by PG, increasing the concentration in PG. In accordance with these findings, TCA degrades faster in PG that is present in the ointment formulation than in regular PG. The 21-aldehyde was confirmed to be a primary degradation product, while the 17-carboxylic acid was identified as a secondary degradation product. Based on the mechanism of degradation, the ointment can be stabilized by the addition of sodium metabisulfite which was shown to reside also in the PG phase within the ointment.

Similar content being viewed by others

INTRODUCTION

Corticosteroids are widely used in a broad range of products. A selection of these products is for dermal application, such as ointments. In the Netherlands, TCA ointment 0.1% FNA (Formulary of Dutch Pharmacists) was available until it was withdrawn from the market after license holders reported poor chemical stability (1). The ointment consists of 0.1% TCA, 10% propylene glycol (PG), 10% lanolin, and 79.9% petrolatum. Various similar products are used worldwide.

TCA and molecularly similar corticosteroids are prone to oxidative degradation. This particular degradation predominantly occurs at the 17-side chain of the corticosteroid molecules (2,3,4,5). Amongst other degradation products, two are the most often mentioned for corticosteroids with the same 17-side chain as TCA (Fig. 1); first, a 21-aldehyde degradation product which formation is described in aqueous and alcoholic solutions (Fig. 1, compound 2). This 21-aldehyde is formed by a reaction between TCA and molecular oxygen (O2) that is catalyzed by metal salts (4). Second, for hydrocortisone and flurandrenolide the formation of a 17-carboxylic acid in alkaline environment was demonstrated by using O2 and OH− as reagents (2,3). Other degradation products concern degradation of the A ring (6,7,8) or hydrolysis of the acetonide moiety (9). For a water-free environment such as the TCA ointment, it was shown that the 21-aldehyde and 17-carboxylic acid are the main degradation products (10). The mechanism by which these are formed remains unclear however.

The aim of this study was to investigate the degradation mechanism of TCA in TCA ointment 0.1% FNA.

MATERIAL AND METHODS

Chemicals and Reagents

The following chemicals and reagents were used (all materials complied with the quality requirements of the European Pharmacopoeia (Ph. Eur. 2016)): TCA (Newchem, Milan, Italy), PG (Brenntag, Dordrecht, the Netherlands), lanolin (Stella Lanolines, Mouscron, Belgium), petrolatum (Sonneborn, Amsterdam, the Netherlands), copper(II) acetate (Cu(Ac)2) (Alfa Aesar, Haverhill, MA, USA), tert-butyl peroxybenzoate (TBPB), sodium metabisulfite and 1,10-phenanthroline (Sigma-Aldrich, St Louis, MO, USA), hexane and acetonitrile (Avantor Performance Materials, Center Valley, PA, USA), and phosphoric and acetic acid (Boom, Meppel, the Netherlands). Distilled, deionized water was prepared by an Elga Centra R 60/120 system (Woodridge, IL, USA).

The Solubility of TCA in the Ointment Components and Microscopical Structure of TCA Ointment

One hundred grams of PG was added to an Erlenmeyer flask and heated to 60°C on a magnetic stirrer hot plate (IKA C-MAG HS4, Staufen, Germany). TCA was added in 0.25 g increments. One hundred grams of lanolin or petrolatum was added to stainless steel mortars that were heated to 60°C on a water bath (Ika Werke HB4 Basic, Strufen, Germany). TCA was added in 0.010 g increments. End point (solubility) was defined as the amount of TCA where solid dispersed particles were still observed after intensive stirring for 10 min.

Additionally, TCA ointment sample was analyzed for microscopic structure using a light microscope (Euromex ME-2880 microscope, Euromex, Arnhem, the Netherlands) with a magnification of × 40.

The Metal Content in the Excipients of the Ointment

PG was mixed with lanolin and petrolatum in a ratio of 1:1:8 (i.e., the ratio of the ointment formulation). This mixture was stored at 60°C for 1 month. At 60°C, the ointment is phase separated in a PG and a lanolin-petrolatum phase. The PG phase was separated from the lanolin-petrolatum phase by using a syringe. 0.5 g of this PG extract, normal PG, lanolin, and petrolatum were dispersed in 10 ml nitric acid and 2 ml of hydrogen peroxide in a Teflon tube in a MDS 2000 lab microwave (CEM Corporation, Matthews, NC, USA). After completing the microwave program (15 min 60% power and 80 psi; 15 min 80% power and 100 psi; and 30 min 90% power and 120 psi) the sample tubes were cooled, transferred to 50-ml sample tubes and diluted to 30 g with water. Samples were analyzed using an inductively coupled plasma optical emission spectrometry (ICP-OES) spectrometer Dual-View Prodigy 7 (Teledyne Leemanlabs, Hudson, NH, USA) for iron, nickel, and copper content.

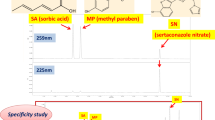

LC Settings

LC was conducted on a Shimadzu Prominence-i LC-2030C 3D liquid chromatograph with diode array detector (Kyoto, Japan) and an Altima C18 column (250 × 4.6 mm, with 5 μm particles) (Mandel Scientific Company, Ontario, Canada). The flow rate was 1.5 mL/min, the injection volume was 20 μL and UV detection was performed at 241 nm. The mobile phase consisted of acetonitrile and water with the addition of 20 mM phosphoric acid (acetic acid when subsequently analyzed with MS). A gradient program was used: 0% acetonitrile from start to 12 min, increased to 32% at 12 min, maintained at 32% until 30 min, increased to 65% at 40 min, decreased to 0% at 42 min, and maintained at 0% until 47 min. Chromatograms were obtained and analyzed with Shimadzu LabSolutions software version 5.5.7. This method is similar to a recently published analytical method for TCA ointment (10).

MS Settings

MS was conducted on an Agilent 1100 series ion-trap system equipped with an electrospray ionization (ESI) source and liquid chromatography sprayer (Agilent Technologies, Waldbronn, Germany) and operated in positive mode. Masses were scanned from m/z 50 to 600, nebulizer pressure was 70 psi, gas flow was 12 L/min, gas temperature was 350°C and capillary voltage was 1600 V. Data was analyzed with Agilent LC/MSD Trap 4.1 version 5.0 (build 65) software.

RESULTS AND DISCUSSION

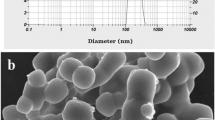

The Microscopical Structure of the TCA Ointment and the Solubility of TCA in Ointment Excipients

Using a light microscope, the physical structure of the ointment appeared to consist of two phases, a dispersed phase in a more voluminous continuous phase. Since PG is more polar than lanolin and petrolatum, it seems logical to state that the dispersed phase consists of PG and the continuous phase of lanolin and petrolatum. The latter two are mixable, while these compounds hardly mix with PG. To study in what phase TCA resides within the ointment, solubility tests in the separate ingredients were conducted. The solubilities of TCA in PG, lanolin, and petrolatum were 1.25, < 0.01, and < 0.01%, respectively. From this, it can be concluded that TCA is mainly present in the PG phase that is emulsified in a lanolin-petrolatum mixture. Therefore, degradation experiments in PG can be assumed to yield representative outcomes.

The Identity of the Major TCA Degradation Products in the Ointment

To elucidate the degradation mechanism of TCA, degradation products in the ointment were determined. Ointment was prepared and stored in closed glass containers at 60°C for 1 month. Samples were analyzed using LC-MS. The two major degradation products were identified to be the 21-aldehyde and the 17-carboxylic acid (Fig. 1, compounds 2 and 3, respectively) based on the m/z ratios of 451.2 and 421.2, respectively. The 17-carboxylic acid showed a shift in retention time in response to mobile phase pH confirming it to be an acidic compound. To confirm that testing at 60°C shows a realistic degradation pattern, an old ointment that was stored for 5 years at room temperature was tested; the same degradation products were formed.

The Degradation Mechanism of TCA

The two degradants, 21-aldehyde and 17-carboxylic acid, are oxidative degradation products of TCA. They have been described before as degradants of hydrocortisone and TCA in aqueous and ethanolic solution in the presence of O2 and metal salts (2,3,4). For a water-free environment, it is unclear what reactants are present to oxidize TCA. In the ointment, the excipient lanolin is known to contain peroxide impurities (European Pharmacopoeia monograph 0134). Furthermore, the presence of trace metals cannot be excluded since excipients of natural origin are generally known to contain low levels of these (11). Therefore, a stress study was conducted to investigate whether TCA is oxidized by peroxide residues and if its oxidation is catalyzed by trace metals in the non-aqueous ointment. TBPB was used as a model for organic peroxide residues (12). TCA was dissolved in PG and exposed to varying combinations of Cu(Ac)2, purging air, and TBPB (Table I). TCA content was determined after storage at 60°C for 7 days.

The results in Table I clearly show that without the presence of Cu(Ac)2, no clear degradation of TCA occurred. This indicates that the presence of air or peroxides alone does not initiate TCA degradation. However, when TCA was exposed to Cu(Ac)2, significant decomposition occurred. This is slightly increased by purging air in the presence of Cu(AC)2. Previously, it has been shown that TCA degradation is oxidative (2,3,4) and therefore, oxygen must be present in PG to react with TCA. To study whether sufficient oxygen is present in PG, it was purged for 1 hour with nitrogen in the presence of Cu(Ac)2 in preliminary experiments (90.3% TCA left for the purged and 85.9% for the untreated sample). Clearly, less degradation occurred in the purged PG compared to untreated PG. This clearly indicates that oxygen is indeed necessary for TCA to decompose and that in untreated PG sufficient oxygen is present to react with TCA.

Interestingly, the combination of Cu(Ac)2 and TBPB led to less degradation than Cu(Ac)2 alone (96.1 versus 80.3%). A similar amount of decomposition was expected since the same amount of Cu(Ac)2 was present in the sample. It therefore appears that the peroxide (TBPB) and Cu(Ac)2 interact. Such interaction can possibly be explained by the Fenton-type reaction that occurs when trace metals (M) react with peroxides (see Eqs. 1 and 2). Competition for Cu(Ac)2 between TBPB and TCA can explain the difference in degradation between the samples with Cu(Ac)2 alone and those with both Cu(Ac)2 and TBPB. Moreover, the hydroxyl radicals (HO•) that form during Fenton-type reactions are much more reactive than the natural oxidant (ROO•) (11,13). Even in this environment, TCA degraded less than in the presence of Cu(Ac)2 alone; affirming TCA oxidation is mediated by trace metals and oxygen rather than peroxides.

Influence of Storage Conditions

As is shown above, the presence of air enforces TCA degradation. Therefore, an in use stability study was performed on a 0.5% TCA in PG:lanolin (1:1) mixture stored in closed glass containers and in glass containers that were opened twice a week for 10 min. After 218 days at 60°C 96.8% (± 0.2) of TCA (± RSD) was left in the closed containers while in the opened containers 73.1% (± 0.9) was left (n = 3). Clearly, TCA decomposes significantly faster in opened containers. When containers are opened, the sample is exposed to fresh air, allowing the supply of oxygen. Since in general, oxygen is more soluble in fatty environment compared to polar environment (14), it seems likely that opening containers twice a week is enough to replenish the oxygen concentration in the sample. Therefore, more substrate (oxygen) is available to react with TCA which can explain the higher TCA degradation.

The Influence of Trace Metal Content on TCA Degradation Constant

Metal salts greatly influence TCA degradation (4). To determine the relation between trace metal content and TCA degradation, a 0.5% TCA solution in PG was exposed to varying amounts of Cu(Ac)2 and equilibrated with air. Cu(Ac)2 was used as a model for other metal salts which are likely to react in a similar way (2,4). TCA content was determined after 1 month. Figure 2 presents the results.

A clear concentration dependence of the degradation constant can be observed. TCA degraded completely in the 10-ppm copper sample. In this sample, TCA is present in a concentration which is 75 times higher than the copper molar concentration. This shows that significantly more TCA degraded than copper was present, indicating that copper catalyzed the reaction. Copper, or other trace metals, as oxidation catalysts is further supported by literature (2,11,13). This indicates that TCA oxidation can be catalyzed and hence, significantly increased even if only small traces of metal impurities are present.

The Trace Metal Content in the Excipients of the Ointment

Limits for trace metals in topical products are set in the European Pharmacopoeia (Ph. Eur. general text 5.20). Limits for copper and iron are 250 and 1300 ppm, respectively. Therefore, amounts < 250 ppm are allowed to be present in lanolin, PG, and petrolatum. Commonly suspected trace metals, copper, iron, and nickel (11,13) were determined using ICP-OES in the individual excipients. Additionally, lanolin and petrolatum were extracted with PG and analyzed as well. Table II shows the results.

Trace metal content differed between excipients. It is clear that lanolin and petrolatum contain more trace metals than PG. Interestingly, the saturated PG extract shows a higher level of trace metal content, showing that trace metals transfer to PG when exposed to lanolin and petrolatum. This extract was free from any undissolved lanolin and petrolatum since at 60°C the PG phase is phase separated from the lanolin-petrolatum mixture. Hence, it is to be expected that the metal content in the PG phase of the ointment increases when mixed with lanolin and petrolatum.

The Influence of Lanolin and Petrolatum Extracted with PG

As has been concluded above, TCA is predominantly present in the PG phase of the ointment. To check the influence of metals towards the TCA degradation, TCA was dissolved in PG and in lanolin and petrolatum extracted with PG. TCA content in this PG extract was determined after 16 days of storage at 60°C and compared to untreated PG. The remaining relative content was 85.2 ± 0.5% and 97.2 ± 0.04% for the PG extract and in the untreated PG, respectively. The faster degradation of TCA in the PG extract confirmed that the additional trace metals originating from the two excipients accelerate TCA degradation.

The Degradation Pathway

As described earlier, TCA degrades into the 21-aldehyde and the 17-carboxylic acid. To study how this degradation evolves, the ointment was stored at 60°C and samples were analyzed at various time points for TCA, 21-aldehyde and 17-carboxylic acid content. Figure 3 presents the results.

Formation of the two major degradation products of triamcinolone acetonide (TCA) in the ointment formulation. The predicted values are based on degradation kinetics models presented in (15). For the experimental data (n = 3), a 95% CI was calculated, error bars however were too small to be visible

Figure 3 shows that the 21-aldehyde content increases initially and subsequently levels and even slightly decreases after 3 days. The 17-carboxylic acid forms after a lag time of a few hours and the content increases subsequently. This points in the direction of a reaction from A (TCA) to B (21-aldehyde) to C (17-carboxylic acid) (Fig. 4). This phenomenon has been described earlier by Waterman et al. (15). The degradation constants k1 and k2 can be calculated using Eqs. 3 and 4.

Using these equations, a degradation constant for the formation of the 21-aldehyde (k1) was calculated to be 0.00576 ± 0.00048 day−1 and for the formation of the 17-caboxylic acid (k2) 0.456 ± 0.144 day−1. The fit for the equations was 0.946 further underlining the likelihood that the 17-carboxylic acid is formed from the 21-aldehyde in the ointment.

Since k2 ≫ k1, more of the 17-carboxylic acid is present than 21-aldehyde shortly after the start of TCA degradation.

Based on the previously shown influence of trace metals and oxygen on the degradation of TCA, the following degradation mechanism can be proposed (Fig. 5).

Figure 5 indicates that the suggested sequence of degradation as shown in Fig. 4 is likely to occur according to the mechanism shown. The transformation of TCA to a 21-aldehyde is likely to involve Cu2+ to form both the 21-aldehyde and Cu+, which subsequently forms Cu2+ using oxygen (16). The degradation of a 21-aldehyde to a 17-carboxylic acid has been reported for a corticosteroid with the same 17-side chain as TCA, betamethasone, using LC-MS isotope experiments using 18O2 as the oxidant (17). When the two described mechanisms are linked, a water-free transformation of TCA to a 21-aldehyde and a 17-carboxylic acid is proposed. Potentially corticosteroids containing the same C17-moiety as TCA may degrade likewise. This is further supported by literature on for example hydrocortisone showing similar degradation products formed (2).

The Prevention of TCA Degradation

Since the degradation of TCA depends on O2 and trace metal content, the addition of a sacrificing antioxidant and a chelating agent could prevent degradation. To investigate the influence of such compounds, 0.1% sodium metabisulfite (11) and 0.1% 1,10-phenantroline as a chelating agent in organic environment (18) were dissolved in PG in combination with TCA and added to the lanolin-petrolatum mixture which was then stored at 60°C for over 6 months in Erlenmeyer flasks. An ointment without additional ingredients was stored as well. Figure 6 presents the results.

Figure 6 clearly shows that sodium metabisulfite stabilizes TCA in the ointment showing that it can work as a sacrificing antioxidant in organic environment. The addition of 1,10-phenantroline shows an additional stabilizing effect. Logically, 1,10-phenantroline will sequester metals and thereby decrease the available amount of catalytic metals to react with TCA.

CONCLUSION

Oxidation of TCA takes place in the PG phase of the ointment. This oxidation is catalyzed by trace metals which are extracted from lanolin and petrolatum. An extensive degradation mechanism is proposed based on these findings. Sodium metabisulfite stabilized TCA in the ointment and 1,10-phenantroline shows an additional improvement when combined with sodium metabisulfite.

References

Scientific Institute for Dutch Pharmacists. Triamcinolonacetonidezalf 0,1%—commentaar. In: Formularium der Nederlandse Apothekers (FNA), 4th edition. 2009. p. 232–4.

Hansen J, Bundgaard H. Studies on the Stability of Corticosteroids V. The Degradation Pattern of Hydrocortisone in Aqueous Solution. Int J Pharm [Internet]. 1980 Sep [cited 2017 Mar 1];6(6):307–19. Available from: http://linkinghub.elsevier.com/retrieve/pii/0378517380901143

Pearlman R, Rutherford BS, Pozsgai KM, Hirsch CA. The isolation and identification of some degradation products of flurandrenolide in Cordran cream. Int J Pharm. 1984;18(1–2):53–65. https://doi.org/10.1016/0378-5173(84)90107-8.

Wu ZZ, Thatcher ML, Lundberg JK, Ogawa MK, Jacoby CB, Battiste JL, et al. Forced degradation studies of corticosteroids with an alumina-steroid-ethanol model for predicting chemical stability and degradation products of pressurized metered-dose inhaler formulations. J Pharm Sci [Internet]. Elsevier Masson SAS; 2012;101(6):2109–2122. Available from: https://doi.org/10.1002/jps.23111

Lewbart ML, Mattox VR. Conversion of Steroid-17-yl Glyoxals to Epimeric Glycolic Esters1. J Org Chem [Internet]. 1963;28(7):1779–86. Available from: https://doi.org/10.1021/jo01042a011.

Miolo G, Ricci A, Caffieri S, Levorato L, Fasani E, Albini A. In Vitro Phototoxic Properties of Triamcinolone 16,17-acetonide and Its Main Photoproducts. Photochem Photobiol [Internet]. Blackwell Publishing Ltd; 2003 1;78(5):425–30. Available from: https://doi.org/10.1562/0031-8655(2003)0780425IVPPOT2.0.CO2.

Ricci A, Fasani E, Mella M, Albini A. Noncommunicating photoreaction paths in some pregna-1,4-diene-3,20-diones. J Org Chem. 2001;66(24):8086–93. https://doi.org/10.1021/jo015884z.

Williams R, Moore IRH, Li R, Weekslc CM. Photochemistry of 11α- and 11β-hydroxy steroidal 1,4-Dien-3-ones and 11α- and 11β-hydroxy steroidal Bicyclo[3.1.0]hex-3-en-2-ones in neutral and acidic media. J Org Chem. 1980;45(12):2324–31. https://doi.org/10.1021/jo01300a012.

Timmins P, Gray EA. The degradation of triamcinolone acetonide in aqueous solution: influence of the cyclic ketal function. J Pharm Pharmacol [Internet]. Blackwell Publishing Ltd; 1983 1;35(3):175–7. Available from: https://doi.org/10.1111/j.2042-7158.1983.tb04300.x.

van Heugten AJP, de Boer W, de Vries WS, Markesteijn CMA, Vromans H. Development and validation of a stability-indicating HPLC-UV method for the determination of triamcinolone acetonide and its degradation products in an ointment formulation. J Pharm Biomed Anal [Internet]. Elsevier B.V.; 2018 149:265–70. Available from: https://doi.org/10.1016/j.jpba.2017.11.026.

Waterman KC, Adami RC, Alsante KM, Hong J, Landis MS, Lombardo F, et al. Stabilization of pharmaceuticals to oxidative degradation. Pharm Dev Technol. 2002;7(1):1–32. https://doi.org/10.1081/PDT-120002237.

Xu J, Gleason KK. Conformal polymeric thin films by low-temperature rapid initiated chemical vapor deposition (iCVD) using tert-butyl peroxybenzoate as an initiator. ACS Appl Mater Interfaces. 2011;3(7):2410–6. https://doi.org/10.1021/am200322k.

Boccardi G. Oxidative Susceptibility Testing. In: Pharmaceutical Stress Testing: Predicting Drug Degradation [Internet]. 2005 [cited 2017 May 23]. p. 205–34. Available from: http://www.crcnetbase.com/doi/abs/10.1201/9780849359194.ch7

Chaix E, Guillaume C, Guillard V. Oxygen and carbon dioxide solubility and diffusivity in solid food matrices: a review of past and current knowledge. Compr Rev Food Sci Food Saf. 2014;13(3):261–86. https://doi.org/10.1111/1541-4337.12058.

Waterman KC, Swanson JT, Lippold BL. A scientific and statistical analysis of accelerated aging for pharmaceuticals. Part 1: accuracy of fitting methods. J Pharm Sci. 2014;103(10):3000–6. https://doi.org/10.1002/jps.24075.

Liang H, Liu H, Jiang X. Research on the conversion of alpha-hydroxy ketones into 1,2-diketones and subsequent transformations. Synlett. 2016;27(20):2774–82.

Li M, Chen B, Monteiro S, Rustum AM. Mechanism of base-catalyzed autooxidation of corticosteroids containing 20-keto-21-hydroxyl side chain. Tetrahedron Lett [Internet]. Elsevier Ltd; 2009;50(32):4575–81. Available from: https://doi.org/10.1016/j.tetlet.2009.05.074.

Sun C, Wu Y, Zhang W, Jiang N, Jiu T, Fang J. Improving efficiency by hybrid TiO2 nanorods with 1,10-phenanthroline as a cathode buffer layer for inverted organic solar cells. ACS Appl Mater Interfaces. 2014;6(2):739–44. https://doi.org/10.1021/am404423k.

Funding

This work was supported by the R&D tax credit of the Ministry of Economic Affairs, the Netherlands (grant number S016053527).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

van Heugten, A.J.P., de Vries, W.S., Markesteijn, M.M.A. et al. The Role of Excipients in the Stability of Triamcinolone Acetonide in Ointments. AAPS PharmSciTech 19, 1448–1453 (2018). https://doi.org/10.1208/s12249-018-0957-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-018-0957-8