Abstract

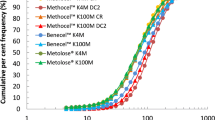

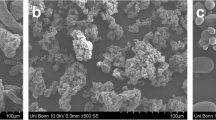

The purpose of this paper was to evaluate the compressional behavior of granules containing high load of a Phyllanthus niruri spray-dried extract in eccentric (ETM) and rotary (RTM) tablet presses. Tablets were constituted by spray-dried extract granules (SDEG, 92%), excipient granules (EXCG, 7.92%), and magnesium stearate (0.08%). SDEG was obtained by dry granulation and EXCG, composed of microcrystalline cellulose (62.9%) and sodium starch glycolate (37.1%), by wet granulation. Particle size distribution was fixed between 0.250 and 0.850 mm. Tablets did not evidence any mechanical failures, such as lamination or capping, or anomalous weight variation in either tablet machine types. Upper and lower tablet surface photomicrographs from ETM and RTM tablets showed differences in porosity and texture. Different RTM speeds suggested the visco-plastic behavior of the formulation, since, by slowing down rotation speeds, the tensile strength of the tablets increased significantly, but the porosity and disintegration time were not affected. Tablets produced in RTM showed lower friability and porosity than ETM tablets, which did not reflect on higher tensile strength. The EXCG distribution at upper and lower surfaces from ETM and RTM tablets was quantified by image analysis and evaluated through statistical methods. Spray-dried extract release was not influenced by the type of equipment or operational conditions to which the compacts were submitted. Construction and operation differences between both tablet presses influenced the final product, since tablets with similar tensile strength, made by distinct tablet machines, exhibited different quality parameters.

Similar content being viewed by others

References

Calixto JB, Santos ARS, Cechinel Filho V, Yunes RA. A review of the genus Phyllanthus: their chemistry, pharmacology and therapeutic potential. Med Res Rev. 1998;18:225–58.

Soares LAL. Padronização de extrato aquoso e desenvolvimento de produto seco por aspersão de Phyllanthus niruri L.—Euphorbiaceae (Quebra-Pedra). M.Sc. Dissertation on Pharmaceutical Sciences, Programa de Pós-Graduação em Ciências Farmacêuticas, UFRGS, Porto Alegre; 1997.

Couto AG. Desenvolvimento tecnológico de comprimidos a partir de granulados do produto seco por aspersão de Phyllanthus niruri e controle de qualidade da matéria-prima vegetal a partir do seu cultivo. Ph. D. Thesis on Pharmaceutical Sciences, Programa de Pós-Graduação em Ciências Farmacêuticas, UFRGS, Porto Alegre; 2005.

Souza TP, Martínez-Pacheco R, Gómez-Amoza JL, Petrovick PR. Eudragit E as excipient for production of granules and tablets from Phyllanthus niruri L. spray-dried extract. AAPS PharmScitech. 2007;8(2):E1–7.

Armstrong NA, Palfrey LP. The effect of machine speed on the consolidation of four directly compressible tablet diluents. J Pharm Pharmacol. 1989;41:149–51.

Vogel PJ, Schmidt PC. Force–time curves of a modern rotary tablet machine II. Influence of compression force and tabletting speed on the deformation mechanism of pharmaceutical substances. Drug Dev Ind Pharm. 1993;19:1917–30.

Konkel P, Mielck JB. Association of parameters characterizing the time course of the tabletting process on a reciprocating and on a rotary tabletting machine for high speed production. Eur J Pharm Biopharm. 1997;44:289–301.

Voigt R. Pharmazeutische Technologie, 10., vollst. überab. Aufl. Stuttgart: Deutscher Apotheker Verlag; 2005.

Aldeborn G. Comprimidos e compressão. In: Aulton M, editor. Delineamento de formas farmacêuticas. 2nd ed. Porto Alegre: Artmed; 2005. p. 402–43. Cap 27.

Souza TP. Desenvolvimento tecnológico e otimização de formas farmacêuticas sólidas contendo alto teor de produto seco por aspersão de Phyllanthus niruri L. (Euphorbiaceae). Ph.D. Thesis on Pharmaceutical Sciences, Programa de Pós-Graduação em Ciências Farmacêuticas, UFRGS, Porto Alegre; 2004.

Soares LAL, Ortega GG, Petrovick PR, Schmidt PC. Dry granulation and compression of spray-dried plant extracts. AAPS PharmSciTech. 2005;6(3):E359–66.

Carr RL. Evaluating flow properties of solids. Chem Eng. 1965;72:163–8.

Hausner HH. Friction conditions in a mass of metal powder. Int J Metall. 1967;3:7–13.

Fell JT, Newton JM. Determination of tablet strength by diametral compression test. J Pharm Sci. 1970;59:688–91.

Picker KM. Time dependence of elastic recovery for characterization of tableting materials. Pharm Dev Technol. 2001;6:61–70.

Lionço MI, Couto AG, Petrovick PR. Efeito de desintegrante na recuperação axial de comprimidos. In: SALÃO DE INICIAÇÃO CIENTÍFICA, 13, Programa e Resumos, Porto Alegre: UFRGS; 2002. p. 390. Res. 103.

Martin A, Bustamante P, Chun AH. Physical pharmacy. London: Lea & Febiger; 1993.

The United States Pharmacopoeia, 30. rev. ed. Unites States Pharmacopeial Convention, Rockville, Mack, Easton; 2007.

Wagner KG, Krumme M, Schmidt PC. Investigation of the pellet-distribution in single tablets via image analysis. Eur J Pharm Biopharm. 1999;47:79–85.

Rasband WS. ImageJ, U.S. National Institutes of Health, Bethesda, http://rsb.info.nih.gov/ij/ (accessed 6/22/07).

Venables HJ, Wells JI. Powder mixing. Drug Dev Ind Pharm. 2001;27:599–612.

Twichell A. Mistura. In: Aulton ME, editor. Delineamento de formas farmacêuticas. 2nd ed. Porto Alegre: Artmed; 2005. p. 192–207. Cap 13.

Kibbe AH. Handbook of pharmaceutical excipients. 3rd ed. Washington: American Pharmaceutical Association; 2000.

Hanus EJ, King LD. Thermodynamic effects in the compression of solids. J Pharm Sci. 1968;57:677–84.

Ketolainen J, Ilkka J, Paronen P. Temperature changes during tabletting measured using infrared thermoviewer. Int J Pharm. 1993;92:157–66.

Ritschel WA, Bauer A. Brandl. Die Tablette, 2. Aufl. Aulendorf: ECV; 2002.

Sinka IC, Schneider LCR, Cocks ACF. Measurement of the flow properties of powders with special reference to die fill. Int J Pharm. 2004;280:27–38.

Jackson S, Sinka IC, Cocks ACF. The effect of suction during die fill on a rotary tablet press. Eur J Pharm Biopharm. 2007;65:253–6.

Garr JSM, Rubinstein MH. An investigation into the capping of paracetamol at increasing speeds of compression. Int J Pharm. 1991;72:117–22.

Wray PE. The physics of tablet compactation revisited. Drug Dev Ind Pharm. 1992;18:627–58.

Katikaneni PR, Upadrashta SM, Rowlings CE, Neau SH, Hileman GA. Consolidation of ethylcellulose: effect of particle size, press speed and lubricants. Int J Pharm. 1995;117:13–21.

Souza TP, Gómez-Amoza JL, Martinez-Pacheco R, Petrovick PR. Compressional behavior of formulations from Phyllanthus niruri spray dried extract. Pharmazie. 2006;61:213–7.

Palmieri GF, Joiris E, Bonacucina G, Cespi M, Mercuri A. Differences between eccentric and rotary tablet machines in the evaluation of powder densification behavior. Int J Pharm. 2005;298:164–75.

Malkowska S, Khan KA. Effect of the re-compression on the properties of tablets prepared by dry granulation. Drug Dev Ind Pharm. 1983;9:331–47.

Shao Q, Rowe RC, York P. Comparison of neurofuzzy logic and decision trees in discovering knowledge from experimental data of an immediate release tablet formulation. Eur J Pharm Sci. 2007;31:129–36.

Sinka IC, Motazedian F, Cocks ACF, Pitt KG. The effect of processing parameters on pharmaceutical tablet properties. Powder Tech. 2009;189:276–84.

Souza TP, Spaniol B, Petrovick PR. Avaliação de comprimidos revestidos por película contendo alta concentração de produto seco por aspersão de Phyllanthus niruri. Acta Farm Bonaer. 2005;24:61–7.

Acknowledgments

The authors thank the Brazilian National Council for Scientific and Technological Development (CNPq) for financial support and Blanver-Colorcon/Brazil for providing the excipients Microcel MC 101 and Explosol.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spaniol, B., Bica, V.C., Ruppenthal, L.R. et al. Compressional Behavior of a Mixture of Granules Containing High Load of Phyllanthus niruri Spray-Dried Extract and Granules of Adjuvants: Comparison between Eccentric and Rotary Tablet Machines. AAPS PharmSciTech 10, 1013–1023 (2009). https://doi.org/10.1208/s12249-009-9297-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-009-9297-z