Abstract

Grid-scale energy storage systems are of interest as the world increases reliance on renewable energy sources. Redox flow batteries are a type of grid-scale energy storage technology that shows exceptional promise for accommodating the dynamic output of wind and solar power sources. The research community employs dozens of diagnostic techniques to investigate nearly all facets of these devices. Material properties, operational losses, transport, and integrated system properties are studied through the lens of electrochemical, physical, and chemical phenomena that ultimately dictate cost by influencing efficiency, durability, power, and capacity. These diagnostic techniques can, if applied correctly, elucidate not only the types of losses in redox flow batteries, but also tie those losses to fundamental driving forces in such systems so that next generation systems and models can be designed. This review details various diagnostic techniques used in flow battery analysis. The benefits, unique insights, and limitations of these techniques are discussed. Recommendations are also made to assist researchers in identifying the diagnostics that can advance their particular investigations. The review concludes with a summary of opportunities for new diagnostics that are needed to enable solution of persistent issues in redox flow battery research and development.

Export citation and abstract BibTeX RIS

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/), which permits unrestricted reuse of the work in any medium, provided the original work is properly cited.

The successful implementation of renewable energy sources to the electric grid requires robust energy storage systems. Grid scale energy storage systems are being developed at a higher rate than ever before and are available in multiple technological formats. There, is of yet, no superior energy storage option for all types of applications since technologies vary in terms of performance characteristics, capital requirements, maturity level, lifetime, safety, reliability and the level of environmental and human risks. A comprehensive analysis of different storage technologies is available in a recent report from Sandia National Laboratory.1 There are several electrochemical-energy-based storage technologies including redox flow batteries (RFBs), non-flowing secondary batteries, regenerative fuel cells (RFCs), rechargeable metal-air batteries, supercapacitors and many others. Several review papers have discussed these technologies in greater detail (e.g.).2–5

Among the available storage technologies, RFBs have been a recent focus of interest. RFBs belong to the family of secondary batteries and have two broad categories: all-liquid and hybrid phase batteries. The hybrid phase RFBs has three main categories including gas/liquid, solid/liquid and semi-solid phases. For semi-solid hybrid RFBs, energy-dense solid particles are suspended within the liquid electrolyte. In terms of operation, all-liquid RFBs differ from conventional batteries since the electrodes themselves typically do not undergo any faradaic reaction. In hybrid RFBs, faradaic reactions can occur at solid electrodes which are typically paired with liquid- or gas-phase electrodes.

All-liquid RFBs boast the advantage of decoupling energy storage capacity from power capacity, because the electroactive redox couples are stored in external reservoirs and brought together in the reactor during operation. The storage of solutions in reservoirs separated from the reactor provides RFBs with unique benefits compared to other secondary batteries: safety is improved by minimizing the potential to short circuit; state of charge (SoC) monitoring can be done directly on the solution reservoirs, improving system control; and crossover can be significantly curtailed. Some other properties of RFBs include relatively long cycle life and the possibility of rapid mechanical charging.3,6,7 RFBs do have relatively low energy density, largely preventing their use in mobile applications.

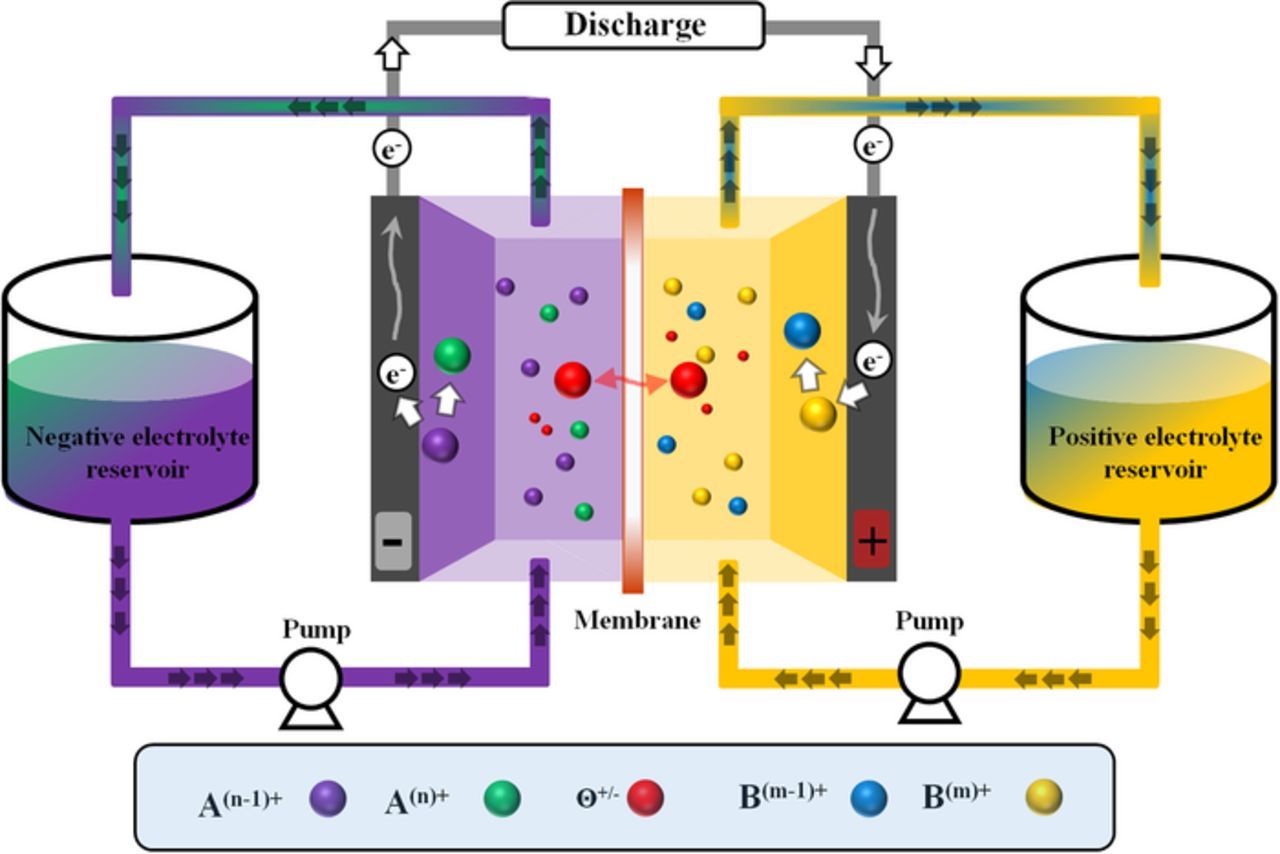

Like some other secondary batteries, RFBs utilize reversible anodic and cathodic redox reactions of soluble species within the electrolyte. The negative and positive electrolytes are pumped inside the reactor where the half-cell electrochemical reactions occur. The generic half-cell reactions can be formulated as follows, assuming an n electron transfer process for the redox reactions.

![Equation ([1])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0001.gif)

![Equation ([2])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0002.gif)

![Equation ([3])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0003.gif)

Equation 1 is the negative half-cell reaction and Eq. 2 demonstrates the positive half-cell reaction; together they compose the overall cell reaction (Eq. 3) with the maximum theoretical cell potential of E0cell at standard conditions.

Myriad chemistries have been proposed and investigated for RFBs, with the primary differences being which compounds, organic or inorganic, carry charge in aqueous or non-aqueous solutions. Table I includes many of the predominant types of RFBs under development. The choice of electro-active redox couple depends on the particular application but ultimately is determined based on many factors, overall cost of the redox flow battery system being one of the strongest. The Department of Energy (DOE) has set a target cost of $250/kWh for short-term grid storage system capital cost; $150/kWh is the long-term goal.8 Moreover, the Advanced Research Projects Agency-Energy (ARPA-E) Grid-Scale Rampable Intermittent Dispatchable Storage (GRIDS) program has proposed the more aggressive cost target of $100/kWh.9 One methodology for determining the total energy storage cost in the system level has been discussed using a performance-based cost model developed at Pacific National Laboratory (PNNL).10,11 It has been shown via model prediction that the overall system level cost is not only a function of the electroactive material selection, but also the stack design, performance, and operating conditions. In order to achieve the aggressive cost targets determined by DOE for widespread commercialization of RFBs, decreasing the system material costs and increasing the cell performance are the logical pathways.7,12 Recently, a hybrid aqueous sulfur/sodium/air RFB has been demonstrated in the laboratory scale with the chemical cost of only $1/kWh opening a door toward achieving the cost target assigned by DOE.13 In addition, a zinc-iron (Zn-Fe) RFB with double-membrane triple-electrolyte design has been demonstrated with an estimated system capital cost of under $100/kWh.14

Table I. Different Varieties of RFBs.

| Negative electrolyte | Positive electrolyte | OCV (V) | Ref. | ||||

|---|---|---|---|---|---|---|---|

| All-liquid RFB | Aqueous solvent | Inorganic solutes | All-Vanadium | V(II)/V(III) | V(IV)/V(V) | 1.26 | 15–18 |

| Iron-Chromium | Cr(II)/Cr(III) | Fe(II)/Fe(III) | 1.18 | 19–22 | |||

| Polysulfide-Bromine | Sodium Polysulfide | Sodium Bromide | 1.36 | 3,19 | |||

| Vanadium-Bromine | V(II)/V(III) | Br2/Br− | 1.3 | 23,24 | |||

| Organic solutes | Quinone–Bromide | Quinone/Hydroquinone | Br2/Br− | 0.92 (at SoC = 90%) | 25 | ||

| Anthraquinone - Benzoquinone | AQS/H2AQS | BQDS/H2BQDS | 1.0 | 26 | |||

| Non-aqueous solvent | Inorganic solutes | Zinc-Cerium | Zn | Ce(III)/Ce(IV) | 2.5 | 27 | |

| Ruthenium Complexes | [Ru(bpy)3]2+/[Ru(bpy)3]3+ | [Ru(bpy)3]+/[Ru(bpy)3]2+ | 2.6 | 28 | |||

| Chromium - Acetylacetonate | Cr(I)/Cr(II) |Cr(II)/Cr(III) | Cr(III)/Cr(IV) |Cr(IV)/Cr(V) | 3.4 | 29–31 | |||

| Organic solutes | Anthraquinone | Li metal | Anthraquinone | 2.6 | 32 | ||

| Lithium-based | Li-PAHA | PAHB | 3.0 | 33 | |||

| Quinoxalines | N/A | N/A | N/A | 34,35 | |||

| Hybrid RFB | Solid-Liquid | Zinc-Bromine | Zn/Zn2+ | Br2/Br−/Br3− | 1.67 | 17 | |

| Zinc-Cerium | Zn/Zn2+ | Ce3+/ Ce4+ | 2.4 | 36,37 | |||

| All-Iron | Fe/Fe(II) | Fe(II)/Fe(III) | 1.2 | 38,39 | |||

| All-Lead | Pb(II)/Pb | Pb(II)/PbO2 | 1.78 | 40,41 | |||

| All-Copper | CuCl32−/Cu(s) | CuCl42−/CuCl32− | 0.773 | 42 | |||

| Semi-solid | Lithium-based | Li4Ti5O12 | LiCoO2 | 4.5 | 43 | ||

| Gas-Liquid | Hydrogen-Bromine | H2/H+ | Br2/Br− | 1.09 | 44,45 | ||

| Vanadium-Oxygen | V(II)/V(III) | H2O/O2 | 1.49 | 46–48 | |||

| Hydrogen-Vanadium | H2/H+ | V(IV)/V(V) | 0.99 | 49,50 | |||

| Sulfur-Sodium-Air | Polysulfide | Air | 1.5 | 13 | |||

The main objective of this review is to discuss the available experimental techniques to diagnose cell behavior, identify limitations of the existing diagnostics, and provide perspectives of the future needs of the field so that high performance systems meeting DOE cost and performance goals can be achieved. These diagnostic techniques can largely be applied to any material (chemistry) of interest, though some may carry increased complications in some systems.

The all-liquid RFBs are types in which the electroactive species are dissolved in a solvent to constitute the anolyte and catholyte solutions. The most common solvent is water; usually, some supporting electrolyte is added to adjust pH and increase conductivity and solubility. Aqueous solvents are typically limited by the water electrolysis potential window (The recorded onset potential for water splitting is 1.26 V and 1.48 V, depending on the presence of liquid and/or vapor water phase at the electrocatalyst-electrolyte interface)51 and the low solubility and stability of the electroactive species within the electrolyte. Non-aqueous solvents are also available for all-liquid RFBs. In general, non-aqueous electrolytes enable a wider operational potential window but at the cost of increased solvent cost, viscosity and ionic resistivity. More details regarding non-aqueous solvents are available through a relatively recent review paper in which comparisons are provided with reference to aqueous solvents.52 The electroactive species in all-liquid RFBs can be inorganic (mostly metals) or organic materials. The application of organic electroactive species is favorable because of generally lower cost and increased solubility.25,53–60 Recent developments in organic redox flow batteries have been reviewed in Ref. 61 focusing on the chemistry, redox potentials, solubility, stability and materials perspectives.

Hybrid batteries can be split into three main categories: solid/liquid, semisolid, and gas/liquid forms. For solid/liquid hybrid batteries, the solid species deposits on an electrode. Dendrite formation at high current and surface passivation are usually limiting factors, especially for system lifetime. In order to overcome this issue, semisolid RFBs show promise. The semisolid RFBs, demonstrated by Chiang et al.,43 utilize conductive materials that are suspended in solution and pumped inside the reactor.43,62,63 Gas/liquid hybrid batteries utilize a half-cell reaction involving gaseous species.

As summarized in Table I, there are many types of RFBs under development, with new chemistries frequently introduced and a rising interest in organic and/or non-aqueous solvents. Here, we included the most-investigated types of RFBs; we refer readers to other review papers that discuss the different types summarized in Table I in greater detail (e.g.).3,6,7,52,64–70

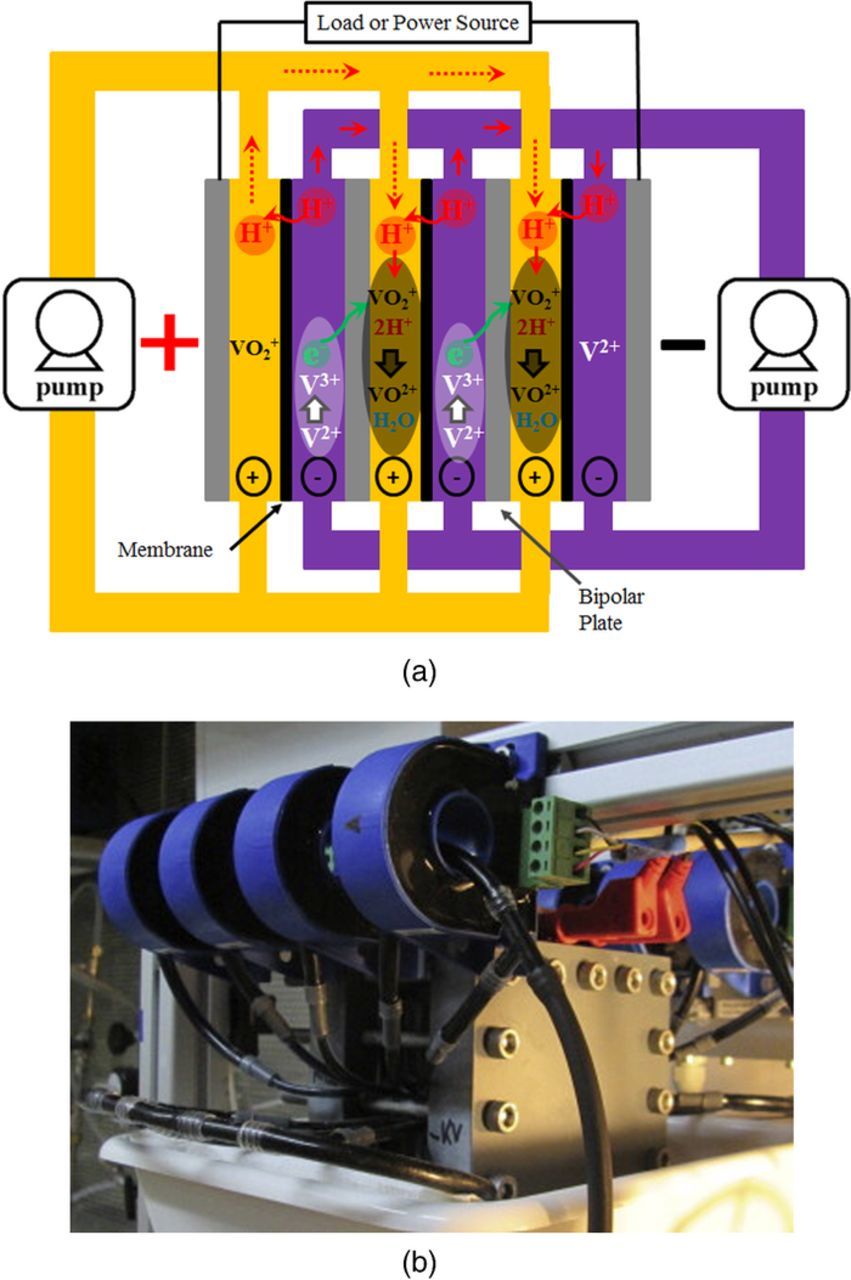

Performance improvements have been demonstrated recently for all-vanadium71–73 and hydrogen-bromine cells74–79 with these chemistries still requiring optimization in order to approach the DOE cost target goal. RFB optimization is usually performed at the component level for any established chemistry. Figure 1 is a schematic of a generic RFB. In general, a redox flow battery system includes the storage reservoirs (gas and/or liquid), electrochemical reactor, pumping system, temperature control system, and power control unit.

Figure 1. Schematic representation of a single-cell RFB.

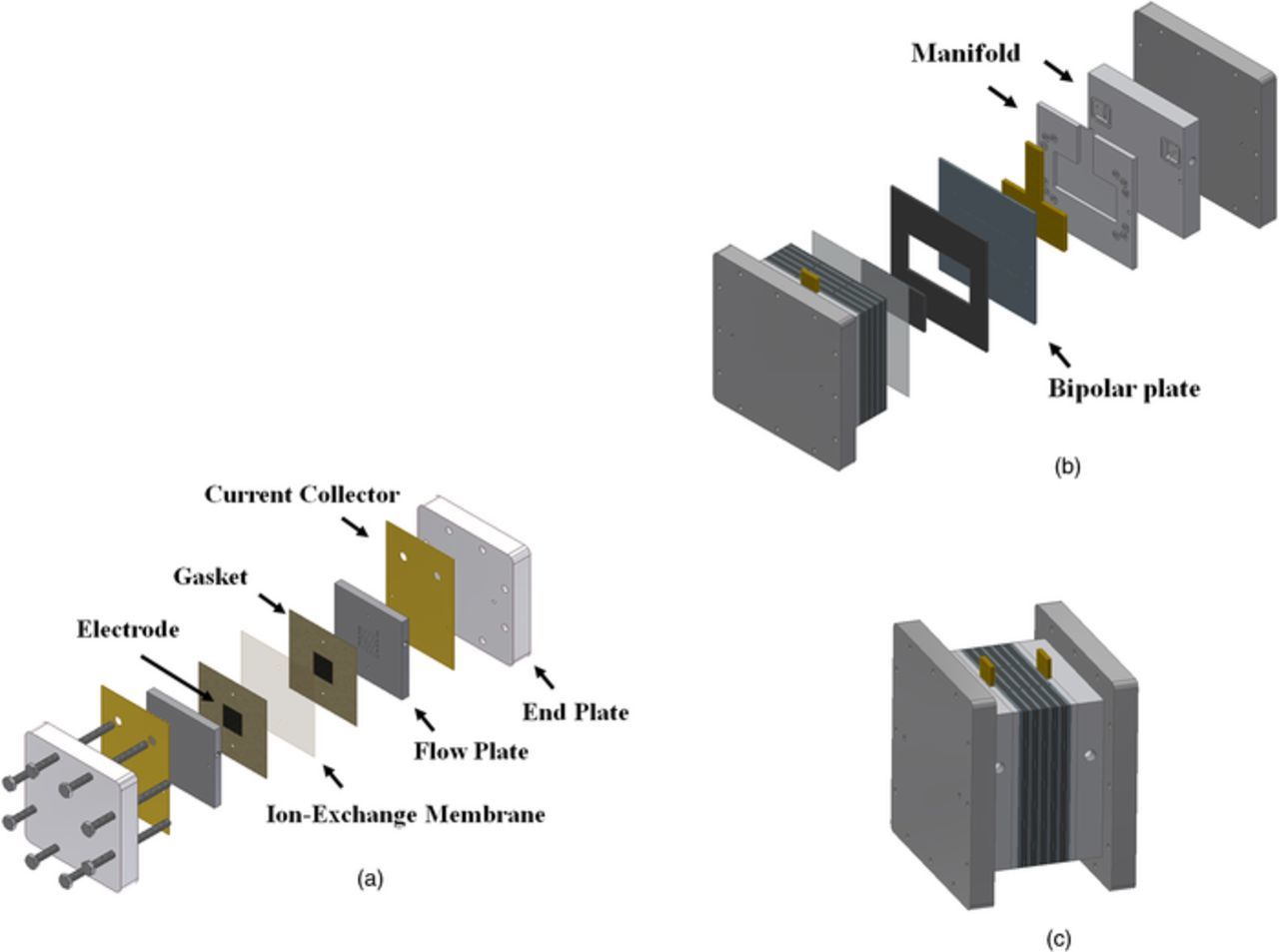

The reactor depicted in Fig. 1 is the most important part of the RFB system where energy conversion (between chemical and electrical) occurs. In general, the reactor includes the separator (with the exception of membrane-less RFBs),80 porous electrodes, gaskets, flow plates, current collectors and endplates. In practical applications, an arrangement of parallel stacks of multiple reactors is used to achieve the desired power/voltage of the system. Figure 2 includes exploded views of a single cell as well as of a stack.

Figure 2. Schematic representation of single-cell and stacked RFBs (a) Exploded view of a single cell, (b) Exploded view of stack of multiple cells, (c) schematic of the assembled stack of multiple cells).

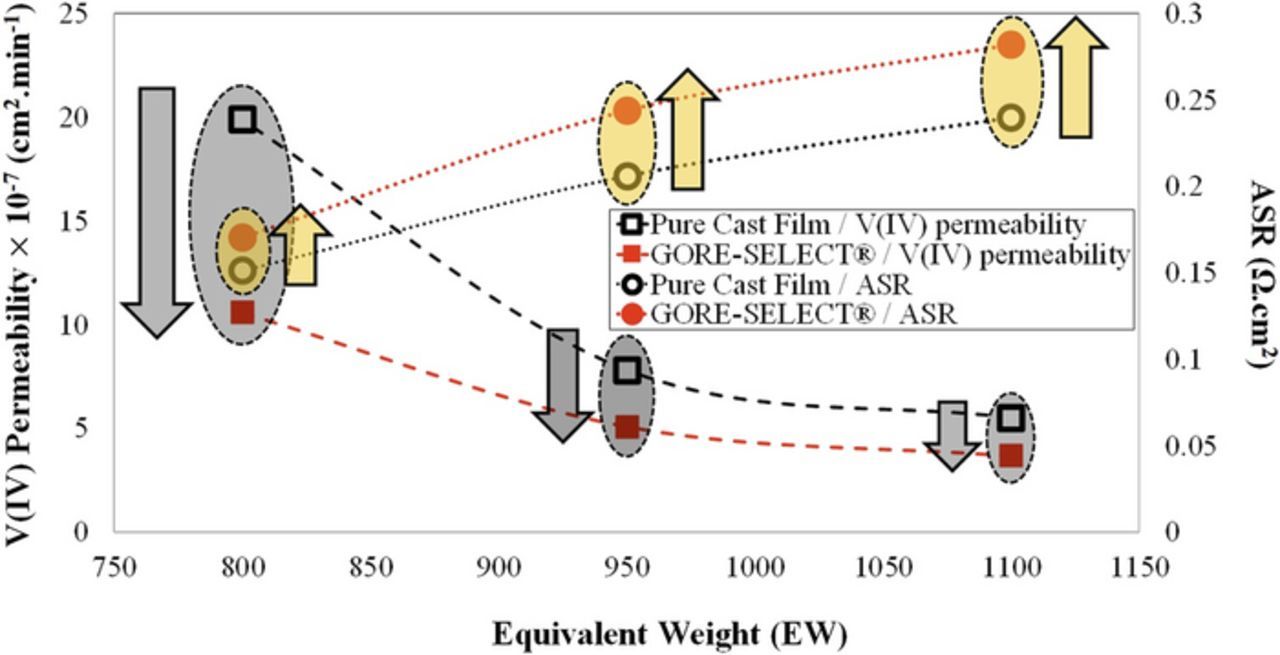

The ion-exchange membrane (separator) in the reactor separates the anode and cathode sides; an ideal separator must have high ionic conductivity, very low permeability for the electroactive species, chemical and thermo-mechanical stability, and low cost. For many RFB systems, the separator is the most expensive single component, comprising 30–40% of the reactor's cost.10 Nafion is a widely-used separator for aqueous RFBs and polymer electrolyte fuel cell systems (PEFC). More detailed information about Nafion membranes is available elsewhere (e.g.).81 Recent progress on separator development for vanadium RFBs has been summarized.82,83 Although Nafion has successfully been used for aqueous RFBs, its application for non-aqueous RFBs faces considerable challenges. Shin et al. has recently reviewed the application of different separators for non-aqueous RFBs.84

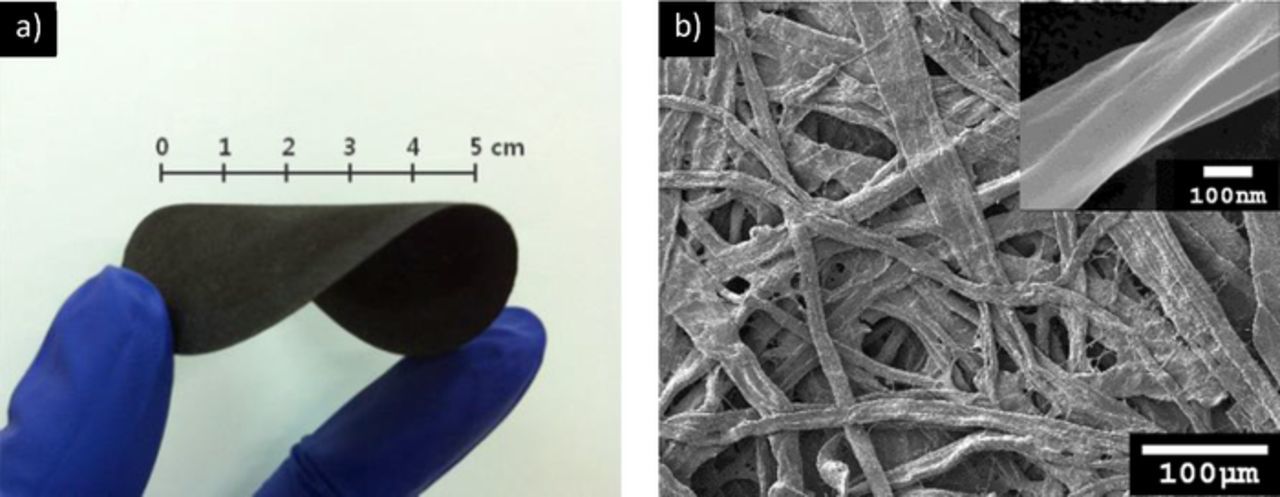

Porous electrodes are used to provide high surface area for electroactive species redox reactions. The electrodes must also have high electrical conductivity and electrochemical stability. Electrode morphology directly affects transport of electroactive species and the surface chemistry of the electrodes can provide catalytic support for redox reactions on one or both sides of a RFB. The application of disparate electrode materials for each half of a particular RFB has been discussed in multiple review papers.64,85 The most common electrode materials are partially or fully-graphitized carbon in the form of paper or felt.

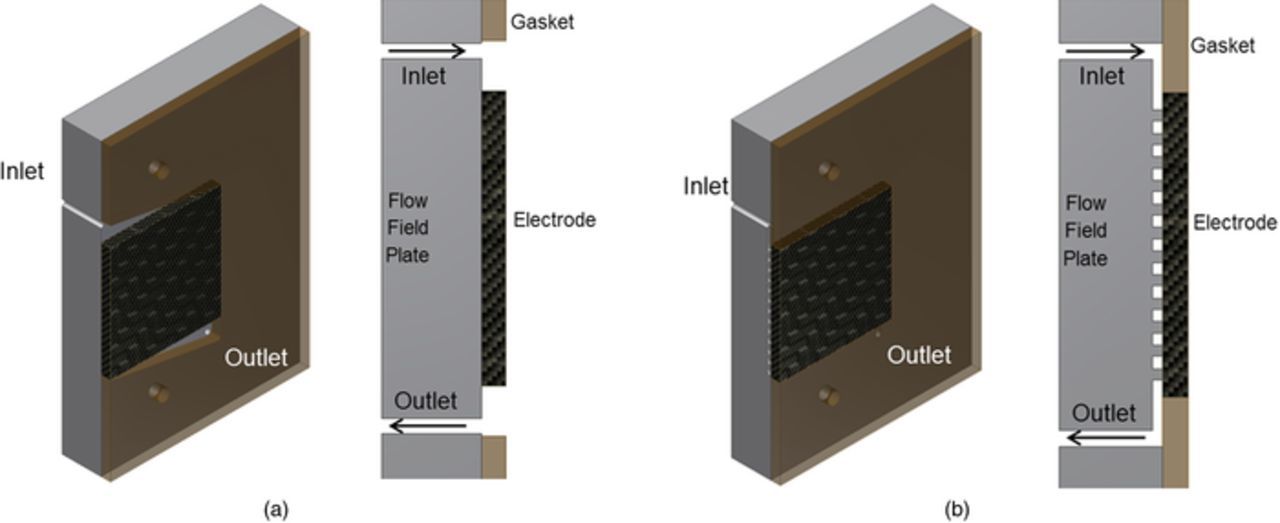

Flow plates in RFBs serve to distribute the electrolyte across the electrodes in each single cell while also functioning as bipolar plates in stacks. The flow plates should have high electrical conductivity and electrochemical stability and, at the same time, effectively-zero fluid permeability. Flow plates are often modified forms of graphite; many forms of graphite are porous; thus some sealing treatment is typically done to prevent electrolyte leakage through the flow plates. In general, there are two types of common configurations adopted for the flow plates (Fig. 3). In the first configuration (flow-frame architecture), the flow plates include electrolyte inlet and outlet ports with an optional gap in the top and bottom sections leading into and out of the electrode.86 In the second configuration (flow-channel architecture), porous electrodes are pressed against flow plates that have a channel pattern and geometry. A review of different flow plate architectures is available in the review paper of X. Li et al.87

Figure 3. Flow plate configurations. (a) flow-frame architecture, (b) flow-channel architecture).

The selection of gasket materials for any specific RFB is based on compressibility and material compatibility with regard to electrolytes. Teflon PTFE (DuPont Corporation) and Viton (DuPont Corporation) are among the common choices for gasket materials.

The current collectors are only at the end of a stack of cells; they are typically manufactured from very conductive materials (Au or Cu), plated onto aluminum (usually for lab-scale cells), and are electronically isolated from the endplates.

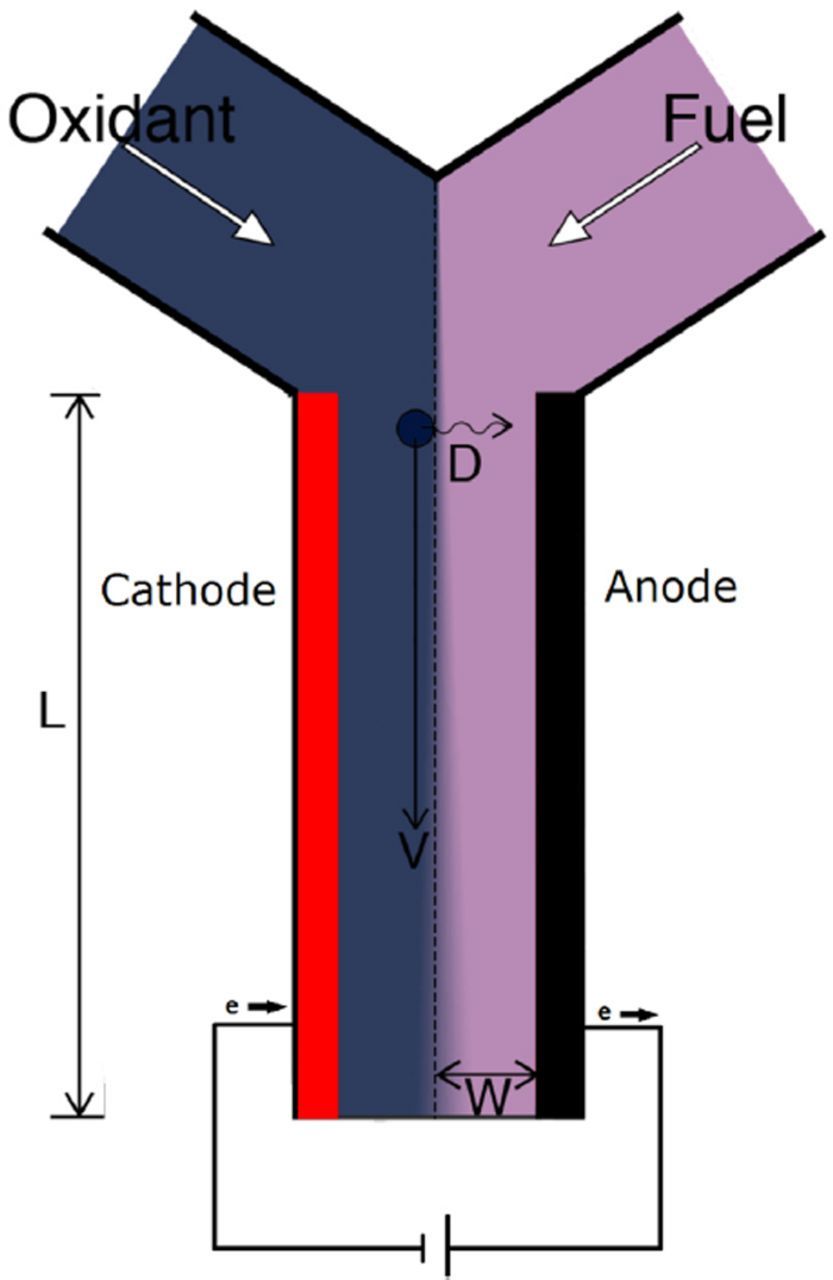

Figures 2 and 3 are only the most common reactor configurations for RFB systems. Membrane-less RFBs have attracted attention and are the focus of some research.80,88–90 Membrane-less RFBs avoid the high cost of a separator, but have only been demonstrated at low Reynolds numbers (Re < 10) which reduces mixing of electrolytes. In membrane-less RFBs, two laminar electrolyte streams flow in a co-flow configuration, side-by-side (Fig. 4), through the reactor. The membrane-less RFB variant is reviewed in Ref. 80. The most popular chemistries for membrane-less flow batteries are all-vanadium,91 hydrogen-bromine,90 zinc-bromine,92 and Au based systems.93 The concept of membrane-less RFBs is similar to the membrane-less microfluidic fuel cells introduced years earlier.94,95

Figure 4. Schematic of membrane-less RFB (picture is taken from Ref. 80).

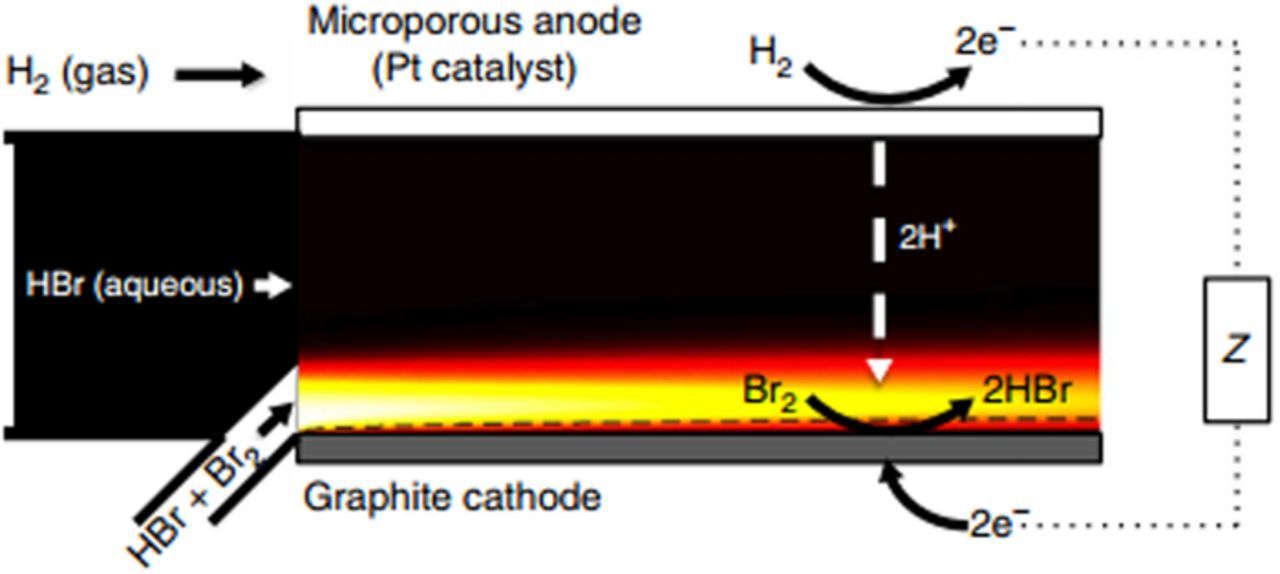

Although membrane-less RFBs can significantly decrease the cost of RFBs by eliminating the ion-exchange membranes, their application is mostly limited to low-power. Scale-up issues need to be solved before a transition to medium- or high-power can occur. Recently, Braff et al. demonstrated a promising hydrogen-bromine membrane-less flow battery that maintained voltage efficiency above 80% as high as ∼350 mW/cm2 (Fig. 5).90

Figure 5. Schematic of HBr membrane-less RFB (picture is taken from Ref. 90).

As the variety of chemistries continues to grow, the process of designing a high-performance RFB system becomes increasingly complex. Recently, online material databases and computational screening techniques have been the focus of attention for electrolyte material discovery and selection.96,97 One of the successful implementations of these techniques is the Electrolyte Genome project.98 The Electrolyte Genome project has been designed to aid in the selection of battery electrolyte materials based on calculations of molecular properties.98 It is also important to note that the investigation of appropriate materials for optimum electrolyte must be followed by a further analysis for improved electroactive ions solubility and stability (chemical and thermal) for long-term cycling. An example of such an analysis is provided recently in a review paper focused for the various types of electrolytes to be used for VRFBs.99

Upon finalizing the configuration along with the desired chemistry, performance improvement using multiple diagnostic techniques can be achieved through detailed understanding of localized inefficiencies. Further details are available regarding engineering aspects of the design and performance of RFBs in a recent review paper as described in Ref. 100.

Mathematical models are also being developed alongside diagnostic techniques to enhance the optimization process and provide deeper insights. Mathematical models have been developed for different RFB systems with varying levels of complexity. The focus of this review is on experimental diagnostics, thus modeling efforts are not emphasized here. A focused review of RFBs including modeling efforts and can be found elsewhere.101

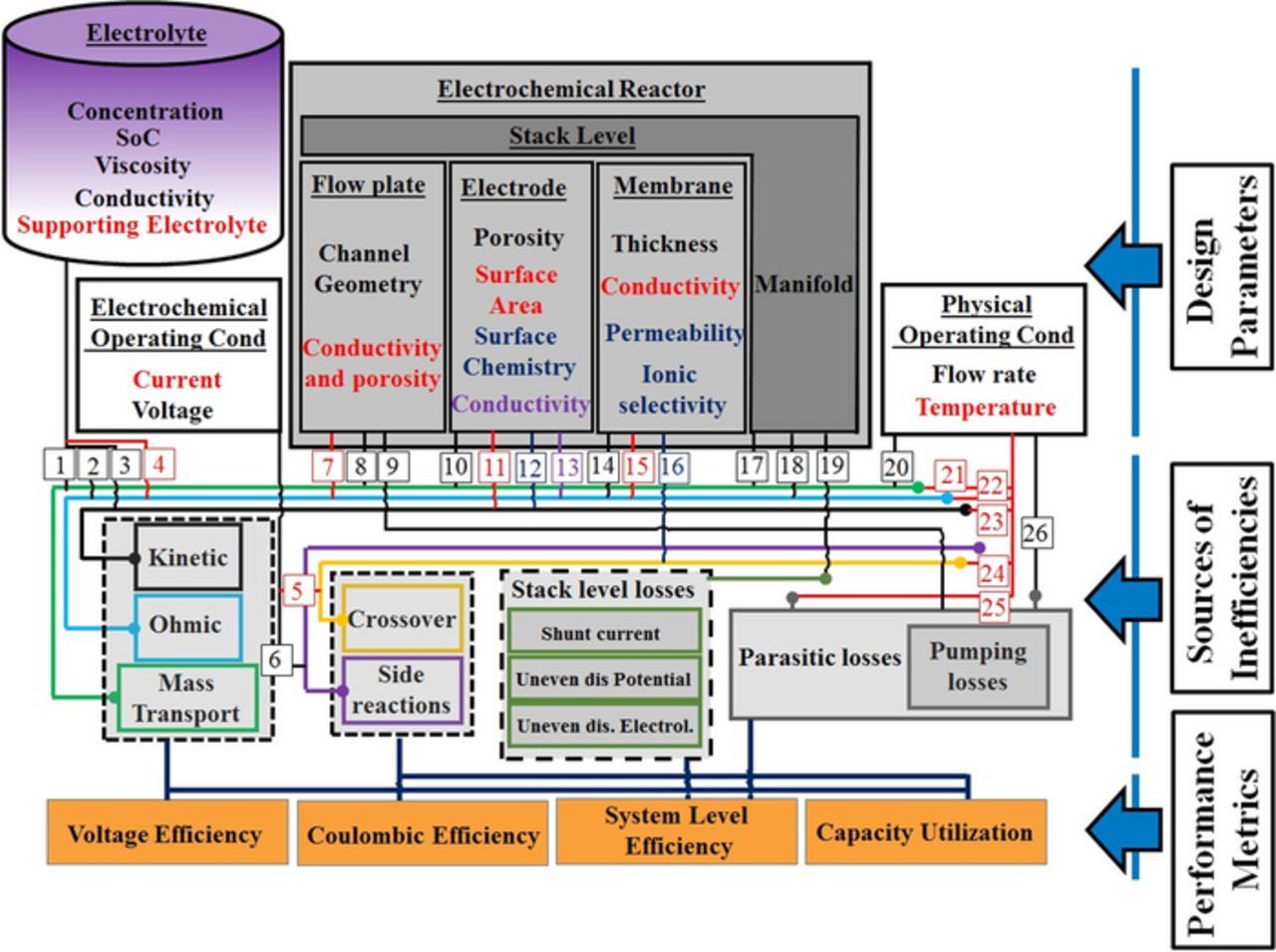

Performance metrics or figures of merit provide quantitative values to judge RFB performance from multiple perspectives. The most frequently-used figures of merit include voltage efficiency, coulombic efficiency, system level energy efficiency, theoretical capacity utilization and discharge capacity fade over long-term cycling.

Voltage efficiency

The ratio of cell voltage during discharge and charge processes is defined as the voltage efficiency, shown in Equation 4.3

![Equation ([4])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0004.gif)

Where the VcellDchg and VcellChg represent the average cell voltage during discharging and charging, respectively, at a certain time or desired SoC. For these measurements, current density is typically held constant. At any particular current density, there are multiple sources of overvoltage including kinetic, ohmic, and mass transport losses which result in decreased voltage efficiency. All three sources of loss increase with current density, though not with the same dependence.

Coulombic efficiency

The ratio of total electrical charge withdrawn during discharge versus the charge stored after charging is defined as coulombic efficiency, as shown in Equation 5.3

![Equation ([5])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0005.gif)

where the QtotalDchg and QtotalChg represent the total electrical charge (in C or A-hr) during discharge and charge processes, respectively, and IDchg and IChg represent the discharge and charge currents (A). There are multiple contributors to coulombic losses including crossover of electroactive species and side reactions. The coulombic losses can be reversible or irreversible depending on the reaction and nature of the electroactive species.

System level energy efficiency

The voltage and coulombic efficiencies represent composite losses at the single cell level and include kinetic, ohmic, mass transport, crossover, and side reaction losses. However, there are other sources of losses when considering the overall RFB system shown in Fig. 1. Parasitic losses (temperature control, pumping losses, and other auxiliary equipment) are generally the most important in terms of loss magnitude and added expense. In addition to single cell losses, stacks of multiple cells introduce new losses including shunt currents, uneven voltage distribution, and uneven electrolyte distribution among cells. System level energy efficiency is defined to account for these sources of losses that are beyond a single cell level.

Theoretical capacity utilization

The maximum theoretical capacity of a RFB system is based on the amount of total electroactive material within the electrolyte. In aqueous systems, this capacity is determined by electroactive species solubility limits. Ideally, a RFB system would be capable of using all the available capacity. However, voltage limits and the various losses (especially mass transport losses at the system SoC limits) cause the practical utilization to be well below 100%. Capacity utilization strongly influences system cost, especially in the case of RFBs that depend on expensive charge carriers.

Discharge capacity fade over long-term cycling

One of the major drawbacks about different types of RFBs is the relatively rapid discharge capacity fade during long-term cycling. The major reasons for discharge capacity fade during long-term cycling include the undesired crossover of solvent and electroactive species through the ion-exchange membrane, degradation of various cell components, undesired side reactions and precipitation of electroactive species. Discharge capacity fade is an important metric in evaluating the stability and robustness of a particular RFB system in delivering the desired output current density.102

In this review, diagnostic techniques are most broadly categorized as in-situ versus ex-situ. Subdivision to electrochemical, physical, or spectroscopic characterizations is further used. This categorization is shown in Table II with a full description of different techniques provided in the following section.

Table II. Major diagnostic techniques utilized for RFBs.

| Electrochemical | in-situ | Discharge Curves and Cycling |

| Polarization Curves | ||

| Cyclic Voltammetry (CV) | ||

| Current Interruption (CI) | ||

| Electrochemical Impedance Spectroscopy (EIS) | ||

| ex-situ | Cyclic Voltammetry (CV) | |

| Conductivity Measurement | ||

| Rotating Disk Electrode (RDE) | ||

| Physical and Spectroscopic | in-situ | Ultraviolet–visible (UV-Vis) spectroscopy |

| Potential Distribution | ||

| Neutron Radiography (NR) | ||

| Pressure Drop and Energy Analysis | ||

| Current Distribution | ||

| Shunt Current Measurement | ||

| ex-situ | Nuclear Magnetic Resonance (NMR) Spectroscopy | |

| Electron Spin Resonance (EPR) Spectroscopy | ||

| Optical Visualization of Flow Distribution | ||

| Thermal Visualization of Flow Distribution | ||

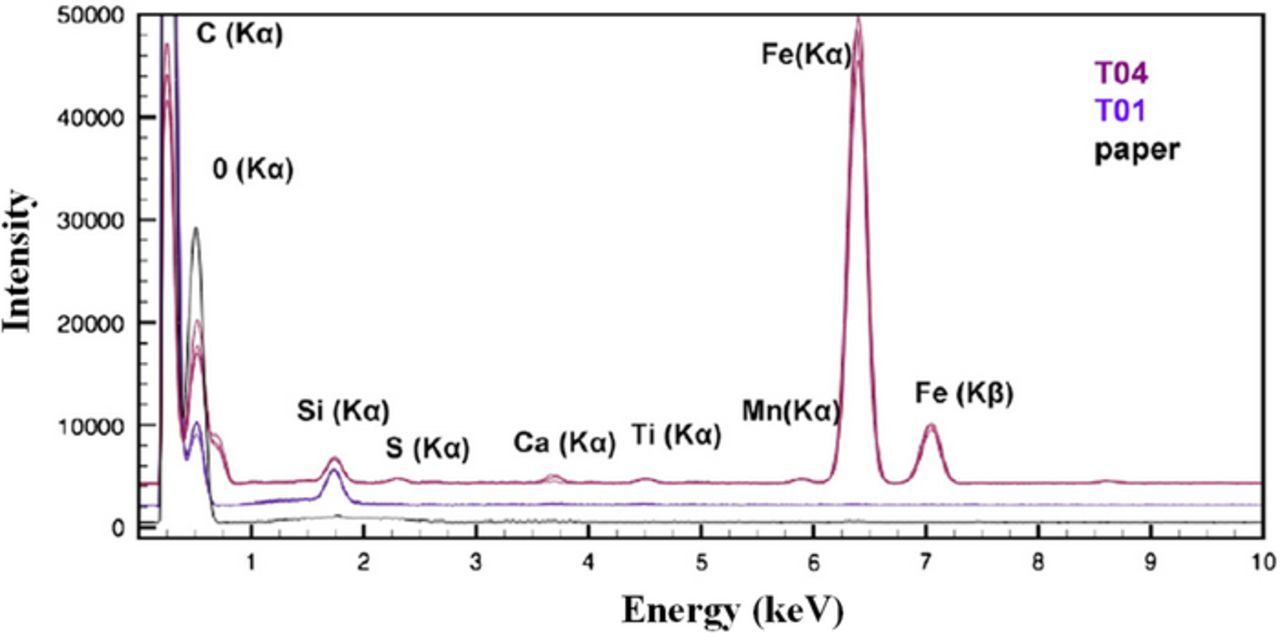

| Scanning Electron Microscope (SEM) | ||

| Energy Dispersive X-ray Spectroscopy (EDS) | ||

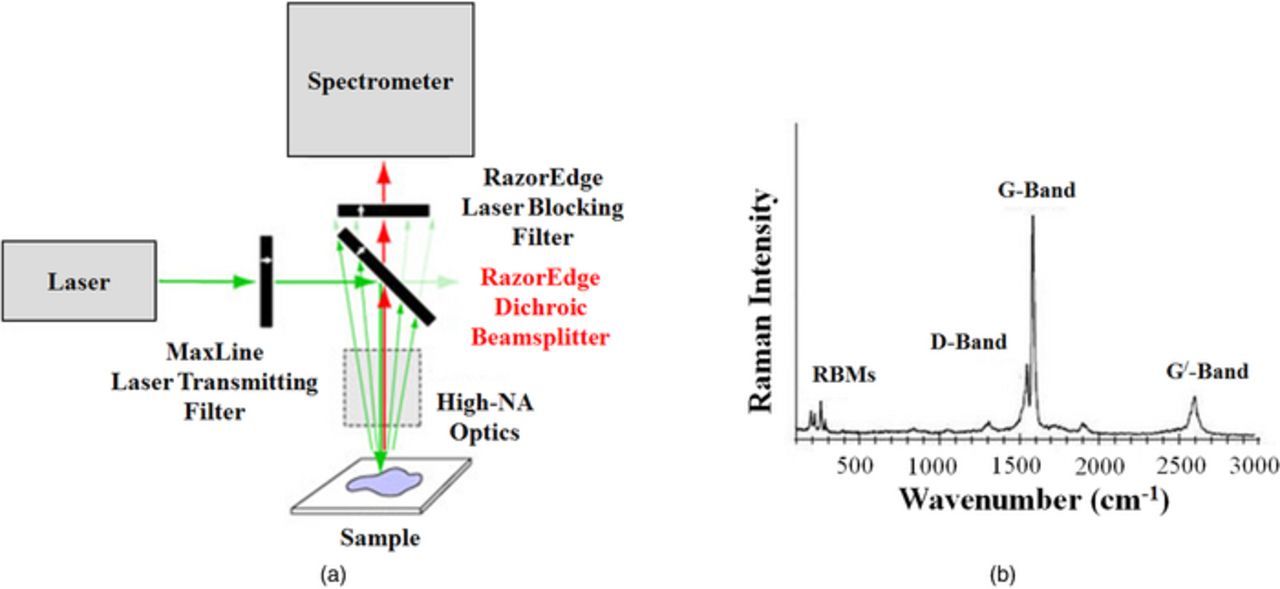

| Raman Spectroscopy | ||

| Brunauer-Emmett-Teller (BET) Method | ||

| X-ray photoelectron spectroscopy (XPS) | ||

| Mass Spectroscopy | ||

| X-ray Tomographic Microscopy (XTM) | ||

| Fourier Transform Infrared Spectroscopy (FTIR) |

Diagnostic Techniques

Discharge curves and cycling

Perhaps the most widely-used method for basic characterization of flow battery performance is constant-current discharge and/or charge curves. When charging and discharging curves are executed in series, cycling performance can be assessed. Ultimately, constant current cycling provides the evidence of improvement resulting from materials, design, and operational innovations. Equations 4 and 5 define voltage and coulombic efficiencies, both of which depend on operating current and are drawn from cycling experiments. The energy efficiency is simply the product of the voltage and coulombic efficiencies, also called round-trip energy efficiency in a battery system (often excluding system losses, e.g. pumps, electronics, etc.). A survey of the specifications provided by the companies active in RFBs shows that commercial flow battery systems operate in the 70–80% round-trip efficiency regime (sometimes including the losses from auxiliary systems), though battery systems can be considered competitive even in the 60–70% energy efficiency range, depending on cost.103 Since voltage efficiency strictly decreases with current while coulombic efficiency generally increases with current (prior to the onset of side reactions), there is often a range of current over which acceptable efficiency can be reached – this range is potentially a design consideration, as evidenced by the redox flow battery cost model developed by the team at Pacific Northwest National Laboratory.10

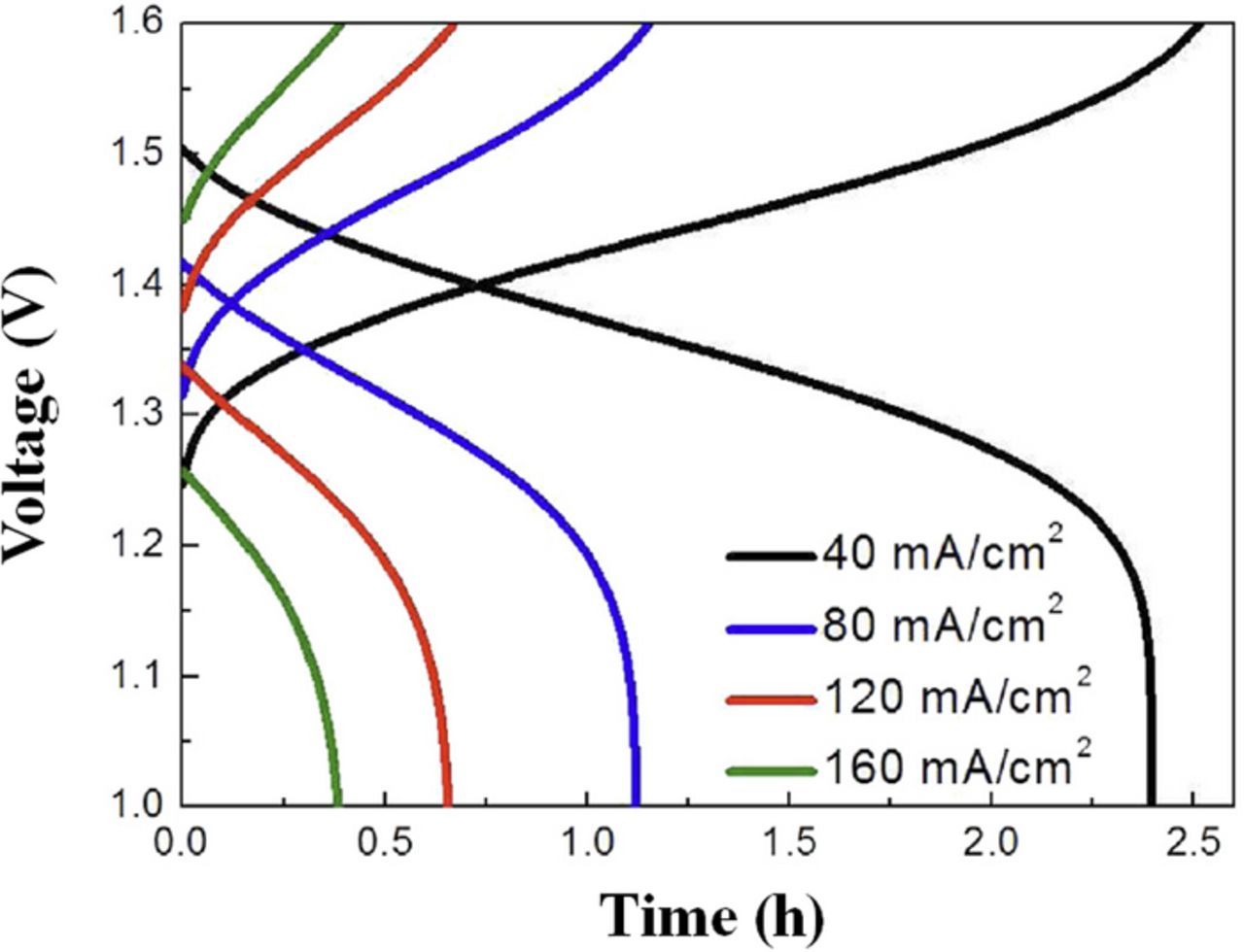

Another metric that can be determined via cycling is the actual charge capacity relative to a theoretical amount that is based on the amount of electroactive species present in a system, often called capacity utilization.104 Capacity utilization is possibly a critical driver of system cost – lower utilization incurs the cost of greater quantities of electroactive species and requires higher storage volume – driving cost up significantly if the electroactive materials strongly influence cost, as in the case of VRFBs.105 Capacity utilization is affected both by current density and by the inherent losses in a cell. Generally, utilization decreases with increasing current density since relatively higher current cannot be supported at the relevant SoC limits.106 An example of the capacity dependence on current density is shown in Fig. 6; here, the greater charge and discharge times correspond to greater capacity utilization at low current density. While voltage efficiency and capacity utilization both decrease with increasing current, achieving the highest current density possible while maintaining acceptable efficiency is the most likely pathway to achieving cost targets for any particular flow battery chemistry.107–112

Cycling is among the simplest diagnostics that can be performed on a flow battery. The cell is alternately charged and discharged at constant current while recording voltage. Assuming the charging and discharging processes are symmetric and that both half-cells are coulombically balanced, the midpoint of each charging or discharging step should be near 50% SoC. This midpoint voltage for both steps is used to calculate the voltage efficiency. The total time for each step is multiplied by the current to obtain the total coulombs passed during a step and then to calculate the coulombic efficiency. Finally, the product of average voltage and coulombs yields the total energy transferred during a step.3

While charge-discharge cycling is practically straightforward, there are numerous behaviors that can be observed, as well as some gaps in what can be learned. In addition to the insights described previously (efficiencies and capacity), the sensitivity of cycling behavior to current density can provide some indirect insight into limiting behaviors in the battery, e.g. slow reaction kinetics, high ohmic loss, and poor mass transport. Since the concentration of reactant species (in VRFB systems, V(IV) and V(III) during charging, V(V) and V(II) during discharging) decreases during a charge or discharge process, consideration of the current and concentration can give additional indirect information on limiting behavior (e.g. kinetics or transport-limited current). Such observations are possible in Fig. 6: at low current, long-duration voltage stability indicates that mass transport is not strongly limiting for most of the step and the polarization behavior of the cell can be predicted using mathematical models (e.g. Butler-Volmer equation); however, at the highest current, the absence of a stable voltage indicates combined ohmic and mass transport losses in addition to the voltage drop expected via the Butler-Volmer equation.113–118 Cycling experiments do offer the most accessible means to induce and study the degradation of novel RFB components in-situ, though this process is relatively slow except for when an experimental set-up is designed to accelerate degradation under realistic conditions.119 One area required to be explored in details in the literature is longer-range cycling experiments to verify durability of components. However, for the majority of RFB chemistries and configurations, such extensive cycling is difficult to justify due to the high cost in terms of materials, equipment, and time.

A drawback to cycling is that it does not readily provide much direct evidence of how specific changes to battery materials or operation affect loss mechanisms, as cycling provides only a composite assessment of performance. In order to quantitatively understand how various improvements (e.g. modified electrodes, new membranes, alternative flow fields, etc.) affect performance beyond the high-level efficiencies and capacity utilization, most investigations include numerous accompanying diagnostics that yield more focused assessment of in-situ phenomena. The merits and limitations of those diagnostics are described in greater detail as follows.

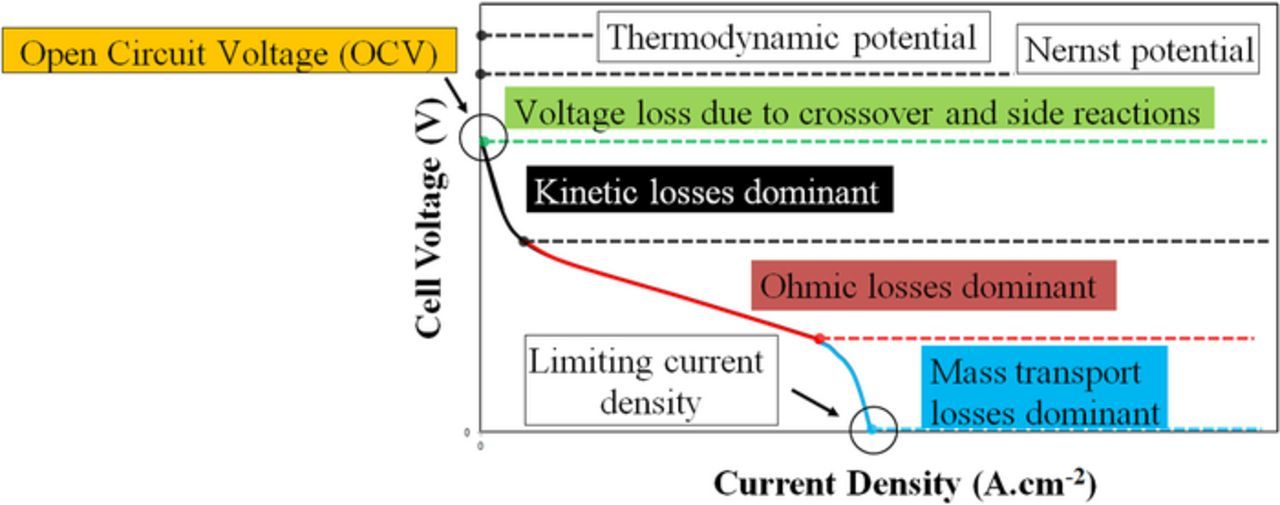

Polarization curves

Polarization curves illustrate the relationship between cell voltage and charging or discharging current. A generalized polarization curve is shown in Fig. 7; its shape is a composite of kinetic losses usually described by the Butler-Volmer model, ohmic losses obeying Ohm's Law, and mass transport losses (also known as concentration polarization) described by local concentration limitation effect on reaction.120–123 At relatively low current, the losses in the cell are primarily attributed to high kinetic overpotential corresponding to sluggish electrochemical reactions. The steep drop in cell voltage at low current before a cell begins to behave as a series ohmic resistor is usually described with kinetics, most typically involving a Butler-Volmer approximation assuming charge-transport rate limited kinetics. This steep drop is tied to overcoming electrochemical activation energy for both electrode reactions. Simple polarization curve measurements have been used to investigate reaction kinetics in VRFBs and yield similar insights as those gleaned through other in-situ methods.124–127 Additionally, it has been shown in several studies that kinetically-controlled behavior can be largely alleviated in VRFBs via addition of catalysts, treating the electrodes (via thermal or chemical treatment) or by increasing the electrode surface area.128–131

Figure 7. Generalized polarization curve for an electrochemical power conversion device with multiple sources of overpotential.

At intermediate current density, the polarization curve illustrates a linear relationship between current and voltage. The slope of this straight line is proportional to the sum of all internal resistances in the cell. While these resistances include electrical conductivities of external wires, current collectors, flow fields, electrodes, all contacts between those components, and ionic resistance of the electrolyte within the electrodes, ohmic loss is generally dominated by the ionic resistance of the membrane, particularly for thicker membranes that inhibit electroactive materials' crossover.132–134 Strategies to improve contact resistance, which can contribute appreciably to internal resistance when thin membranes are used, generally focus on improved bipolar plate-electrode contact, especially in the case of carbon felt electrodes.135

At the highest currents, concentration polarization may ultimately limit the operation.136 Under these conditions, the cell current is high enough that the electroactive species' diffusion to and from the surface of the electrodes limits cell operation, preventing current from increasing despite increasing overpotential in the cell. It is noted that concentration polarization, as a dominating overpotential, may not be reached for cells with poor kinetics or ohmic losses great enough to drive a cell to the voltage limits before reaching a mass transport-limited current.59 While a polarization curve can be roughly divided into "controlling overpotentials" that are described by fundamental equations, all three components are present at all currents. This behavior prevents polarization curves from definitively correlating an RFB modification to, for example, improved kinetics at the expense of poorer mass transport. Electrochemical impedance spectroscopy (EIS) has been widely used to investigate these contributions based on impedance responses rather than simple, DC voltage-current behavior, providing more confident insight into how controlling overpotentials respond to changes in cell materials or operation;125,130,137,138 these studies and their implications are addressed more fully in the following sections.

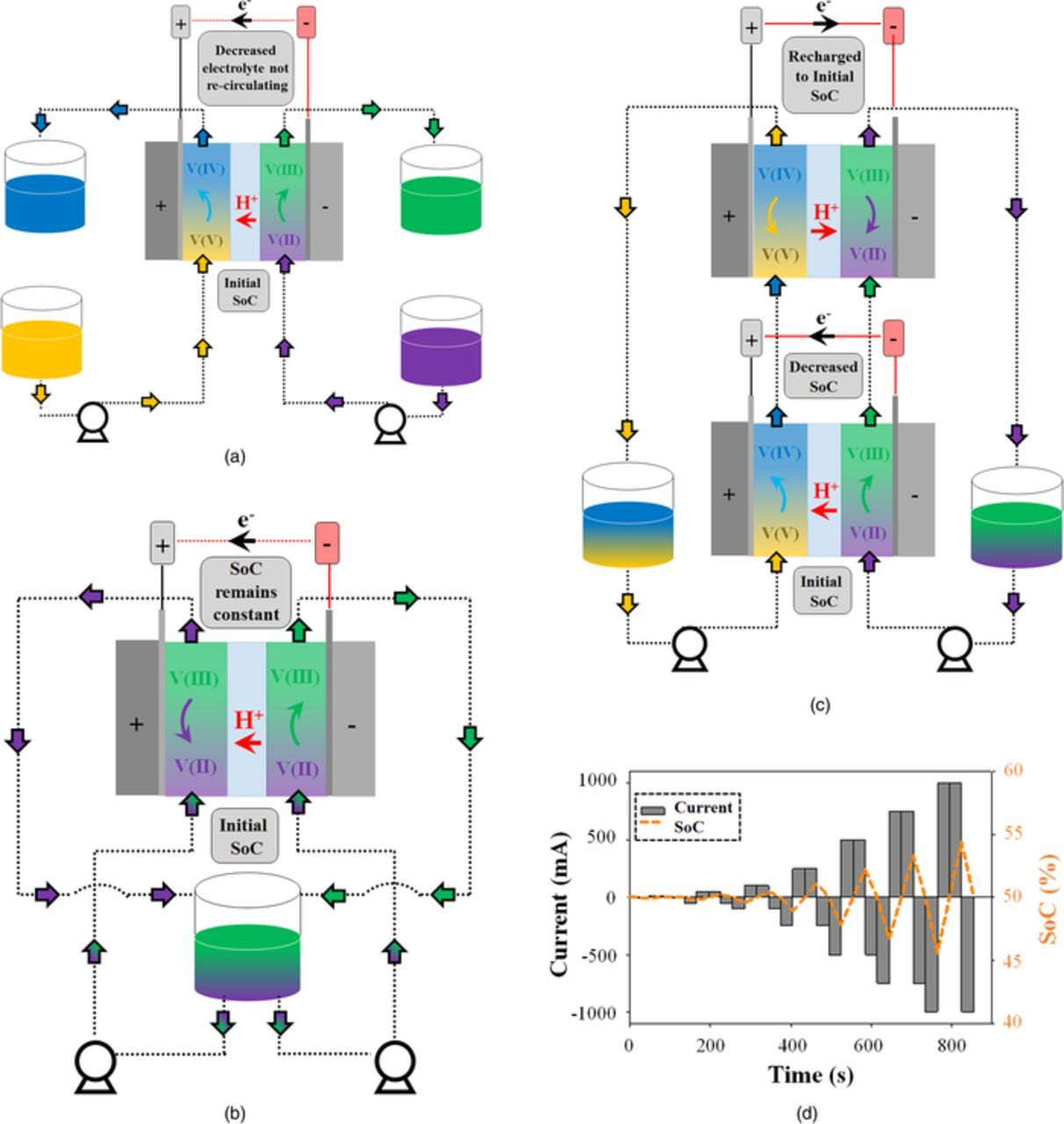

Another consideration for polarization curve analysis is that the measurement assumes a constant SoC in the RFB; having been widely used in fuel cells, this assumption was inherently met in those studies. However, assumption of constant SoC may not be appropriate for an RFB in which the electrolyte circulates from and then back to a reservoir for each half cell. Experimental modifications (as shown schematically in Fig. 8) have been described that allow SoC to remain constant in laboratory scale testing, including the cell-in-series method,114,119 symmetric cell operation,114,139 single-pass polarization curves (in which the electrolyte is not recirculated to a single reservoir)106 and alternating charge/discharge currents.

Figure 8. Schematic of the techniques used for operating RFBs under constant state of charge (SoC) condition (a) Single-pass technique, (b) Symmetric cell operation, (c) Cell-in-series method, (d) Alternating charge/discharge current method.

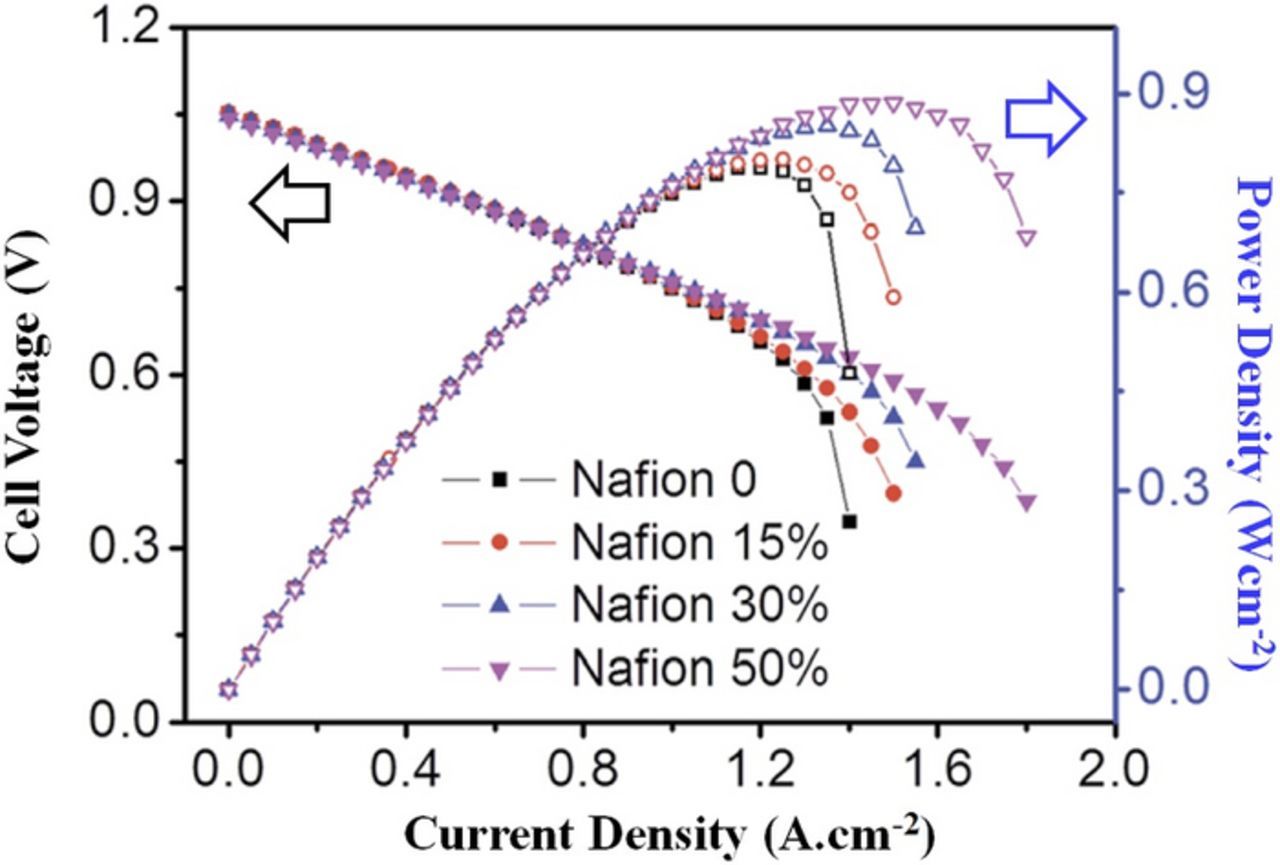

Finally, polarization curves provide no insight regarding coulombic efficiency for a battery.140 Conversely, charge-discharge cycling does not provide the same depth of insight regarding how a cell modification influences operation (via improved kinetics, internal resistance, or mass transport) that polarization curve analysis does. An example of this can be found in an H2/Br flow battery investigation and is shown in Fig. 9.130 Here, BP2000 carbon black was used as a catalyst in an H2/Br flow battery; however, rather than improved kinetics, the catalyst loading more strongly impacted mass transport behavior. In fact, the kinetic performance was impacted more strongly by the type of binder used for the catalyst than by the catalyst itself. Cycling experiments would yield a possible change in voltage efficiency, depending on the cycling current (assuming coulombic efficiency was unchanged). That change would presumably be due to kinetics responding to catalyst loading. The contribution of the polarization curve in this analysis, then, is the insight that mass transport, not kinetics, was most impacted by the catalyst loading. This being the case, polarization curves can be used as an enhancing companion to more common cycling characterization rather than as a replacement to cycling.

Figure 9. Polarization and power density curves showing the effect of BP2000 loading on H2/Br flow battery (adopted from Ref. 130).

Cyclic voltammetry (CV)

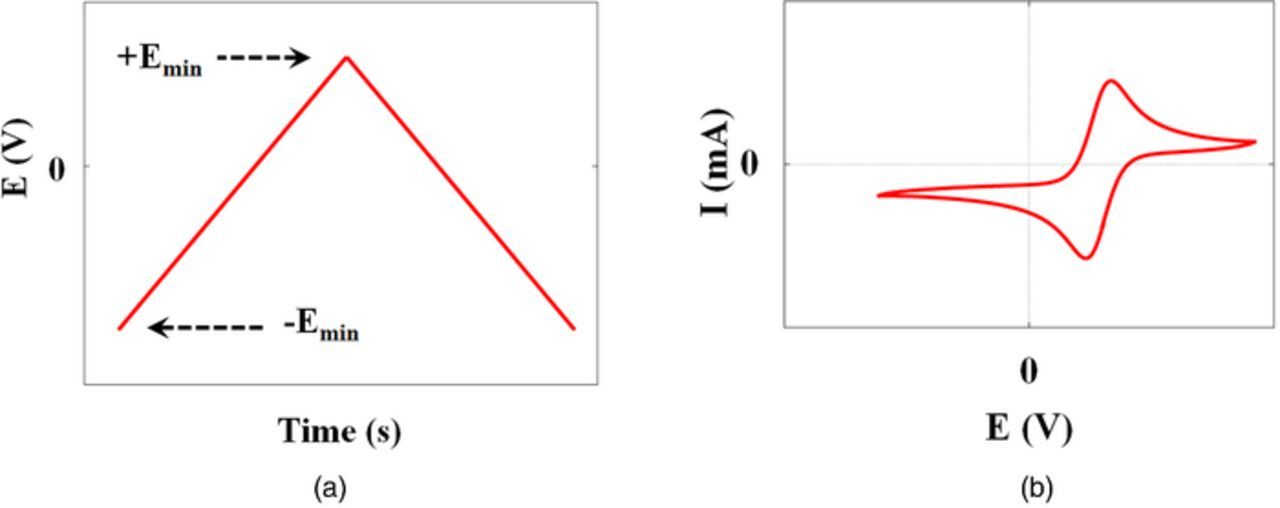

Cyclic Voltammetry (CV) is (typically) an ex-situ electrochemical experiment used to evaluate the current response to a linear voltage sweep. The experiment involves a three electrode set-up (working, counter and reference electrodes), where the working electrode's potential is ramped linearly with respect to time between a relatively negative vertex value and a more positive vertex value multiple times.141,142 The current response is then plotted as a function of the applied voltage sweep in a figure known as a voltammogram. An example of a voltammogram is shown in Fig. 10. This experimental method is commonly used in initial studies of new electrochemical systems.143

Figure 10. Typical cyclic voltammetry experiment in which (a) working electrode voltage is swept between two vertex potentials over time and (b) the measured current plotted against the control voltage.

An important experimental parameter in CV is voltage scan rate v (V/s). The response of peak current and peak potential separation to scan rate can be indicative of the reversibility of a process. Reversible and quasi-reversible processes have peak currents that are proportional to the square root of scan rate as indicated by the Randles-Sevcik equation.143

![Equation ([6])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0006.gif)

Where ip denotes peak current density, n is the number of electrons transferred in the limiting charge transfer step, A is the electrode area, C0 is the concentration of the reacting species, and D0 is the diffusivity.

While the distinction of being reversible or quasi-reversible can be suggestive of how efficiently electrochemical processes can occur, the primary benefit of this distinction is that there is an abundance of theory that has been developed to diagnose properties of these systems. If a process is reversible or quasi-reversible, a diffusion coefficient and rate constant can be determined. The diffusion coefficient can be determined directly from the Randles-Sevcik equation while a rate constant can be determined from peak current analysis by the Laviron method: a plot of ln(ip) vs. (Ep − E0') has a slope of − αf and an intercept proportional to k0.143

![Equation ([7])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0007.gif)

Where Ep refers to working electrode potential at peak current. k0 is the reaction rate constant and C*o is the concentration of reactive species within the bulk solution.

CV is most frequently used to study electrodes and to compare treatments (catalysts, additive particles)144–148 or other electrode preparation processes (electrochemical).149–152 CV is also commonly used to assess the viability of new electrolyte chemistries31,72,153–159 and has been utilized extensively to assess the performance of various porous electrodes for capacitive deionization.160–162 However, CV is not solely limited to use in studies of kinetics; Small et al.163 used CV to detect chemical species in a membrane crossover study. Common benchmark electrodes utilized in CV include glassy carbon, Pt, and graphite; novel electrode structures and materials are frequently compared to these benchmarks.

Although CV is a very common electrochemical technique, it has several important limitations. First, it can readily portray information about reversibility, but a more in-depth analysis is needed to determine long term stability of products. Another limitation of CV is that the information it provides is often the convolution of multiple experimental components (overpotential including iR loss; faradaic and capacitive current, etc.), this often necessitates very careful analysis or supplementary experiments to obtain accurate, quantitative results.146,149,150 Also, when performing ex-situ experiments, it is important to note the limitations and differences when using electrodes that differ in morphology from those to be used in-situ and how they can behave differently, particularly with respect to surface area and 3D morphology. Indeed, one of the most difficult aspects in obtaining meaningful CV results is replicating realistic cell conditions in an ex-situ setting.

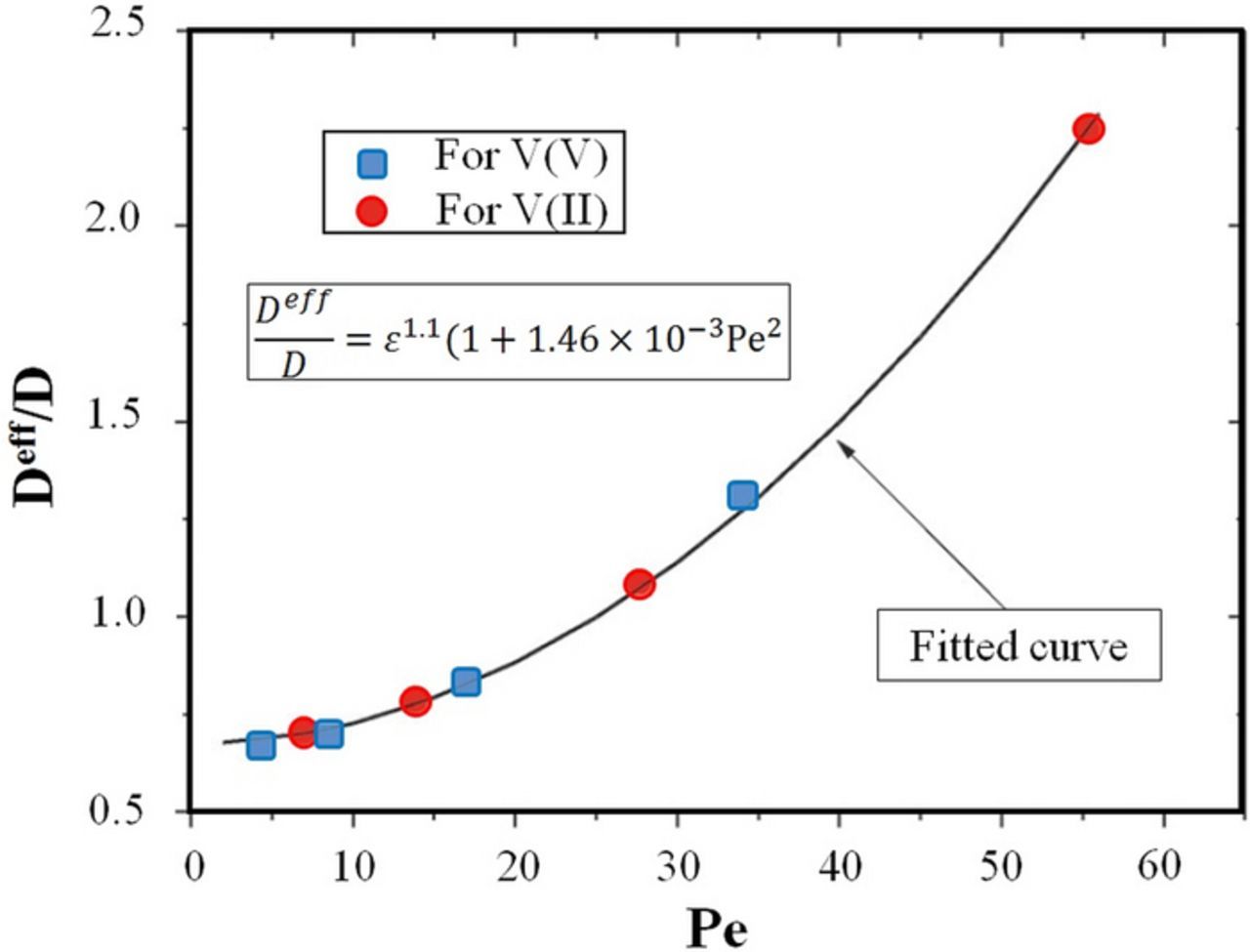

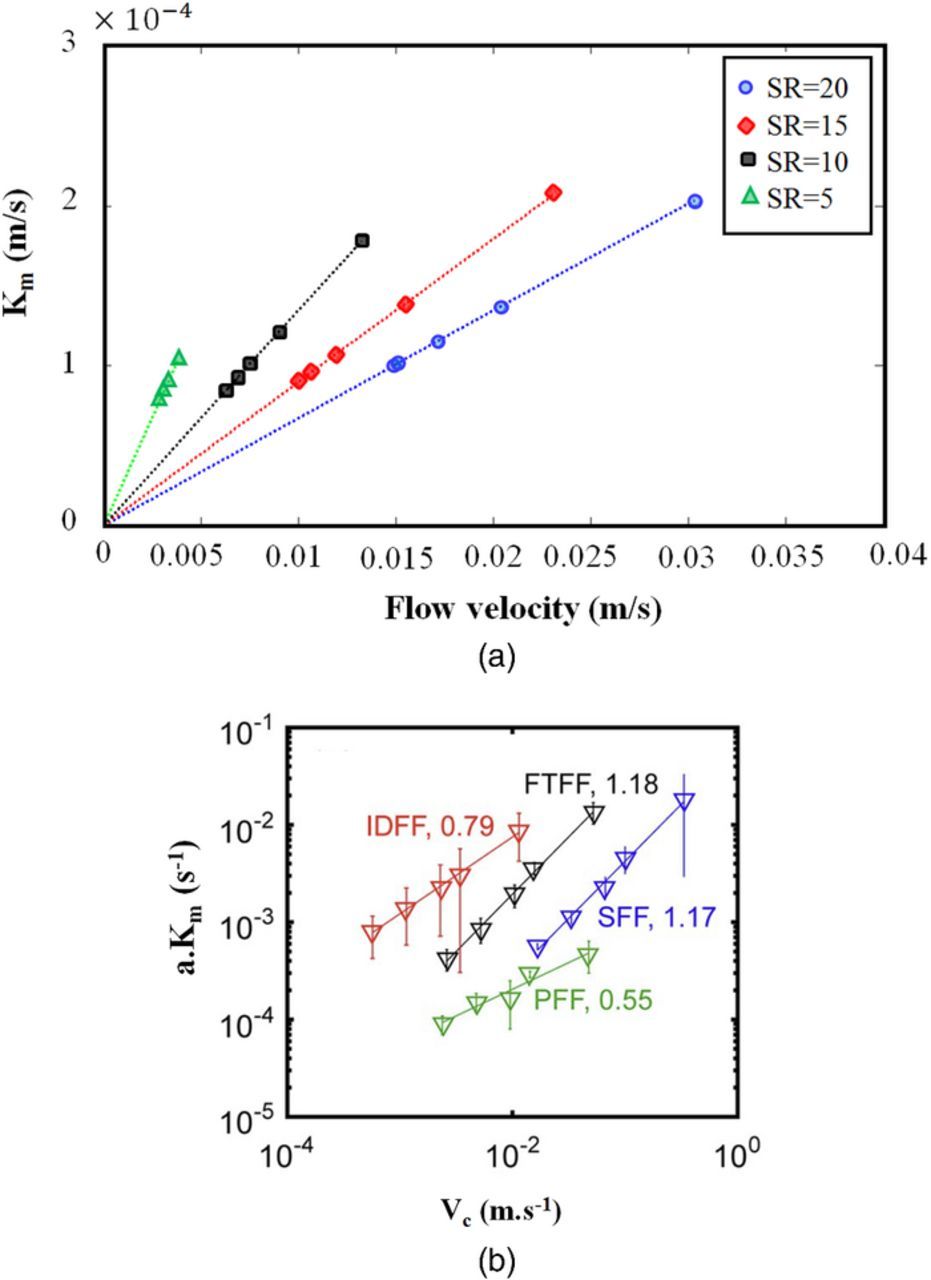

Rotating disk electrode (RDE) voltammetry

Rotating disk electrode (RDE) voltammetry is a common technique used to study reaction mechanism behavior and mass transport characteristics, similar to stationary cyclic voltammetry. However, in RDE, the working electrode spins in the electrolyte and a laminar flow is established above the surface of the RDE. As a result, a steady-state current develops as fresh electrolyte flows to the working electrode. The peak current, as in the case of stationary CV, is limited by mass transport of reactant to and product away from the electrode.

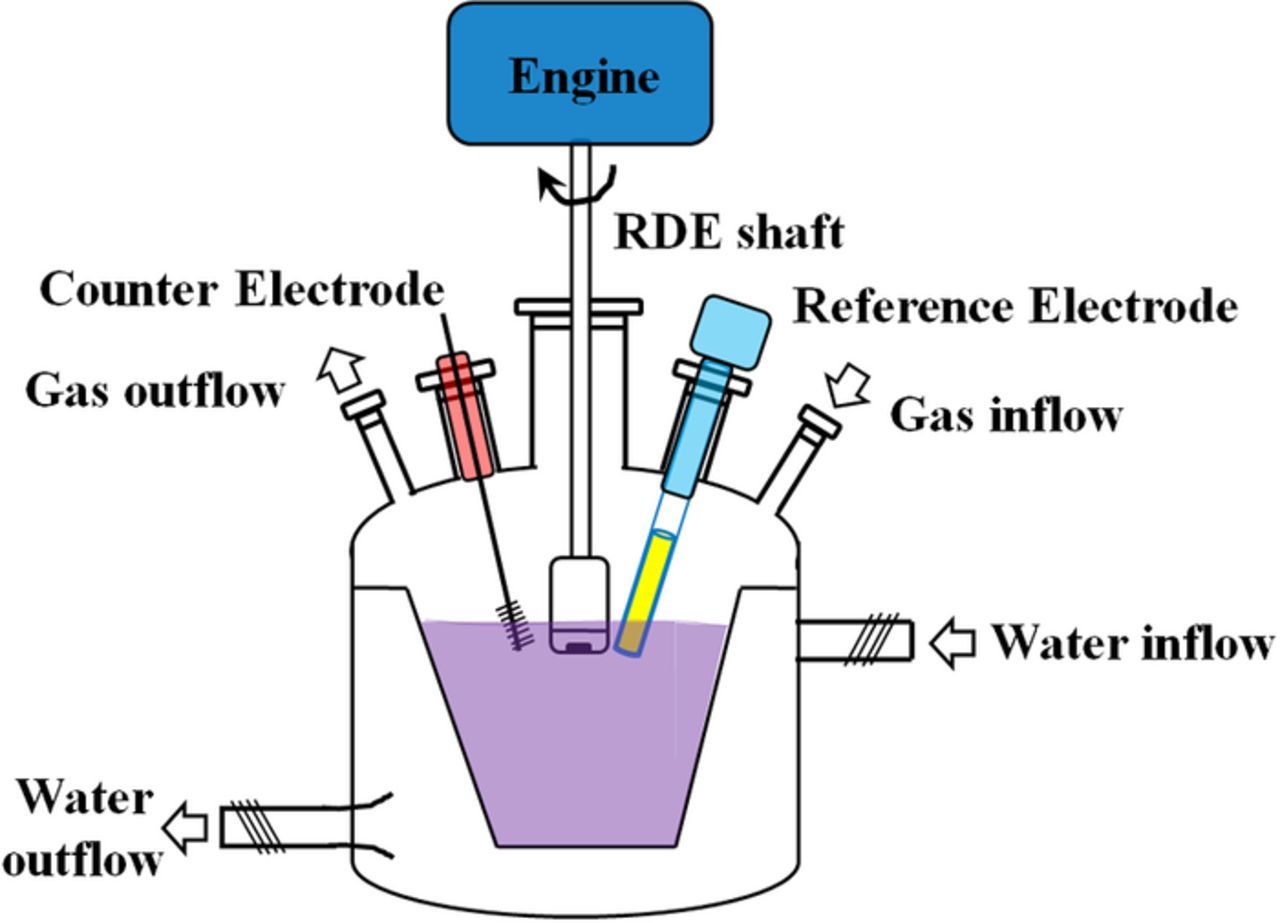

An RDE setup is inherently ex-situ and primarily uses electrode materials that are not directly useable in an operating RFB. Figure 11 is a schematic of a water-jacketed RDE cell. Water can flow through the external jacket (outside the yellow, inner reservoir) to maintain a steady temperature in the cell. Gas sparging lines are common to remove any dissolved oxygen and to prevent oxygen infiltration, especially when easily-oxidized compounds (e.g. V2+) may be present. Three other ports must be present for working, counter, and reference electrodes. The working electrode is physically connected to a motor that enables rotation at controlled rates. The physical shape of the reservoir (indicated by the yellow solution) causes the viscous flow of electrolyte, resulting from the working electrode rotation, to flow in a jet at the surface of the working electrode.

Figure 11. Schematic of a typical water-jacketed RDE cell.

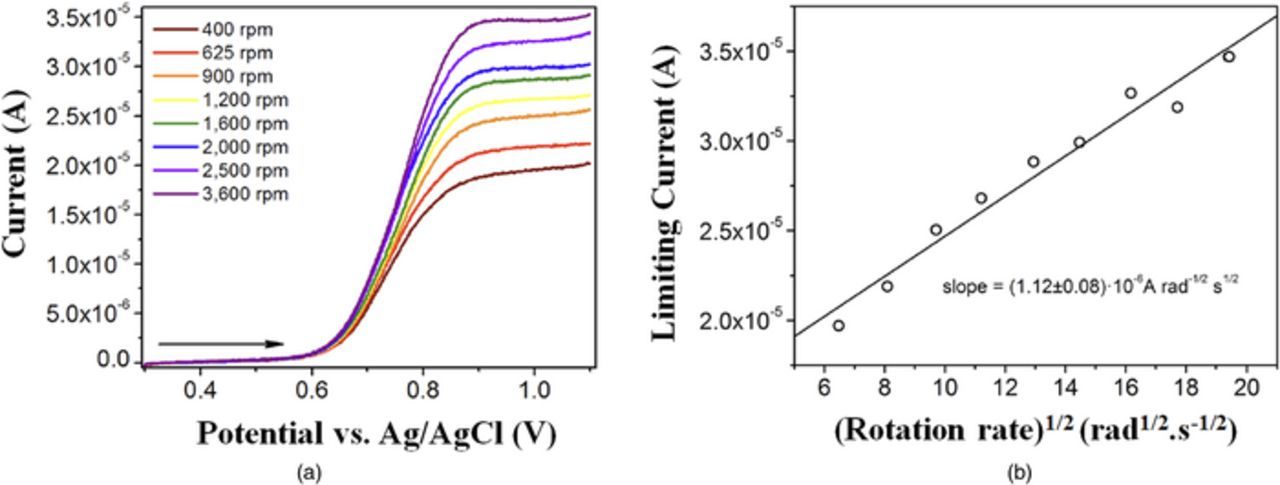

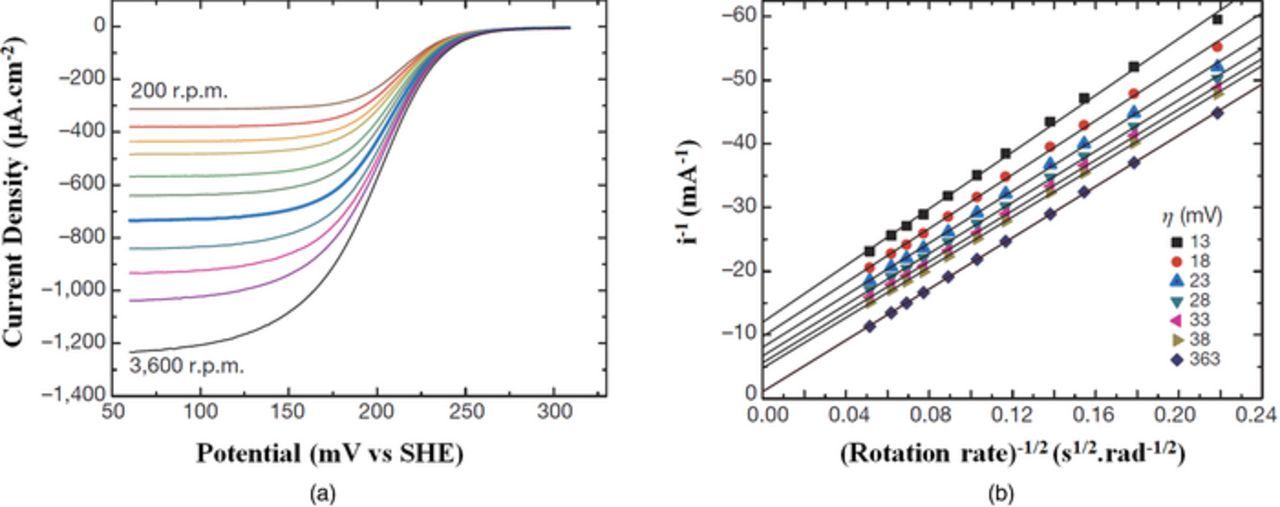

The typical result from an RDE experiment is a linear sweep voltammogram, shown in Figure 12a. Note that there is no peak current, as in CV, but a steady-state, limiting current. The Levich equation relates this limiting current at a RDE to rotation speed and the physical properties of the system, as shown in Eq. 8:

![Equation ([8])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0008.gif)

where n is the number of electrons transferred, D0 is reactant species diffusivity, ω is rotation rate, v* is kinematic viscosity, and Co is the reactant species at the surface, depending on electrode polarity.143 The limiting current obtained via RDE is typically much larger than the peak current found in stationary electrode CV due to the convective flux to the RDE surface. Additionally, reversing the polarity of the RDE will not result in a comparable reverse current because redox products are continually swept away from the surface. Figure 12b is an example set of data resultant from a Levich analysis for a system with facile kinetics and exhibiting convection-controlled current:

Figure 12. Levich analysis of kinetic behavior for a polymer-based RFB (a) linear voltammograms at varying RDE rotation rates and (b) Levich plot showing linear dependence of limiting current on square root of rotation rate.164

When the Levich plot is linear over a large range of rotation rates (e.g. 50–10000 rpm), the reaction can be assumed as a single, rapid transfer of n electrons with a relatively large rate constant. Assuming one knows two of the variables in the Levich equation, the third property can be found (e.g., knowing n and v* allows one to determine D0 from the slope). With this formulation, RDE is frequently paired with stationary CV since they can provide complementary results.

There are systems that will exhibit sluggish kinetics and mass transport limitation in a RDE setup. Because mass transport is facilitated in an RDE, these instances arise when electrode properties may not support fast kinetics or the reaction itself may not be kinetically fast, bringing the kinetic rate down to one that is comparable to that of mass transport (as opposed to the scenario that is described by the Levich equation, above). When this is the case, a modification to the Levich equation is employed; in its most-used form, the reciprocal of measured current is comprised of a reciprocal kinetic current and a mass-transport-dominated component to the current. This behavior is described by the Koutecky-Levich equation, shown in Eq. 9.143

![Equation ([9])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0009.gif)

In this analysis, similar linear sweeps are performed for a RDE with varying rotation rates, as shown in Fig. 13a below. The reciprocal steady-state currents at particular overpotentials are plotted against ω− 1/2, shown in Fig. 13b. A major benefit to this style of analysis is that one can calculate the kinetic current (and a resultant kinetic rate constant) from the y-intercept of a Koutecky-Levich plot while also verifying or identifying n or D0, based on the slope of the figure.

Figure 13. Koutecky-Levich analysis of kinetic current for an organic molecule-based RFB (a) linear voltammogram and (b) resultant Koutecky-Levich plot with y-intercept equal to reciprocal kinetic current at varying electrode overpotential.25

One complication that arises from RDE analysis is that the kinetic information extracted with this method is highly dependent on the preparation and form of the electrode.165 Indeed, the kinetic rate constant can vary tremendously, not only based on an electrode's native morphology and behavior, but also as a result of preparing or modifying the electrode for RDE analysis.17,150 Glassy carbon is commonly the base electrode material employed in RDE analysis, but electrochemical behavior on glassy carbon isn't necessarily representative of in-situ kinetic behavior of a 3D electrode surface. Attempts are made to circumvent this by preparing RDE electrodes that incorporate RFB electrode material, but this must be pulverized and mixed with a binder, changing material properties. In whatever form, the electrode must be capable of withstanding a high rotational speed (e.g. up to 3000 rpm). Inherent in a Koutecky-Levich assessment of any transport-related property (number of electrons, diffusivity, or viscosity) is that all other parameters are constant with rotation rate and overpotential, as well as homogenous over the entire RDE surface. Without all other parameters being constant, calculation of that parameter will be erroneous, leading to significant over- or underprediction of a property.135

Current interruption (CI)

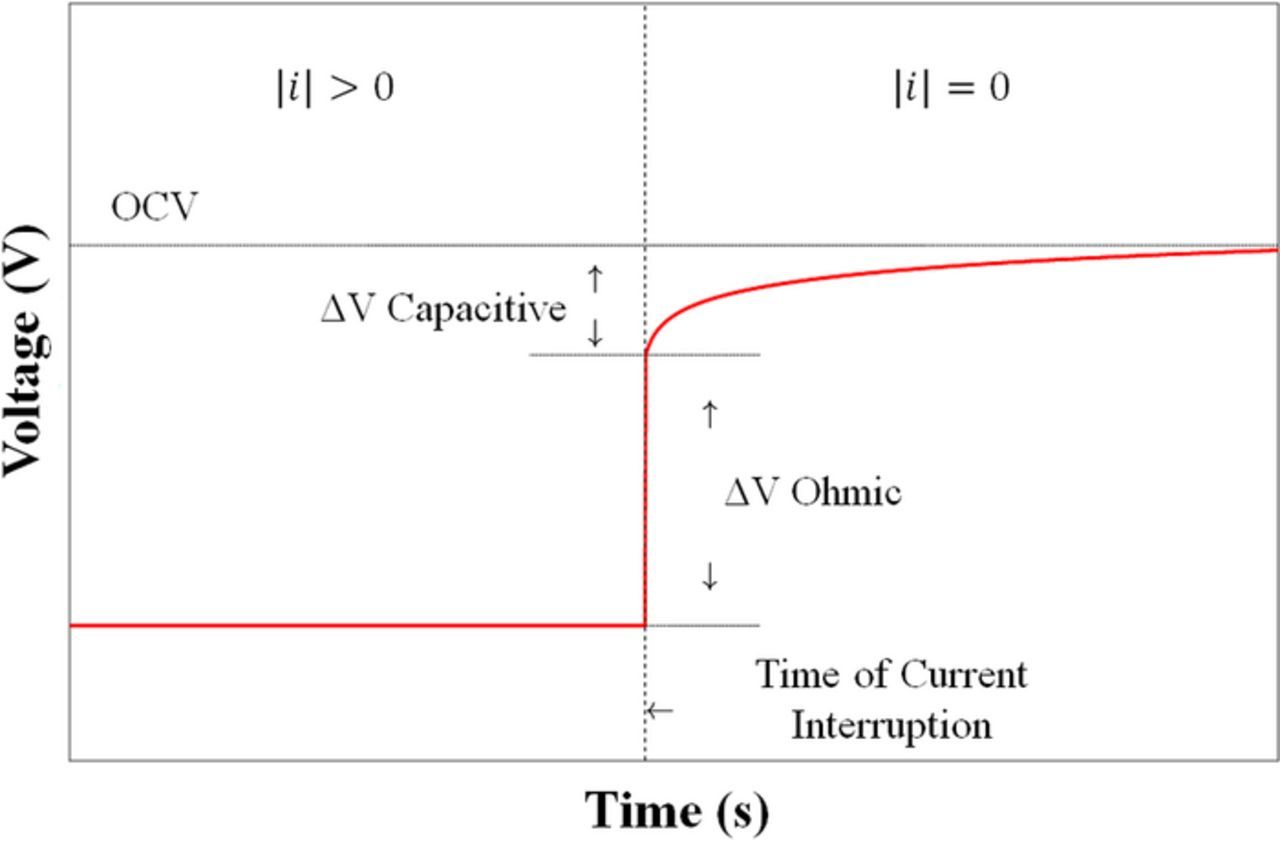

Current interruption (CI) is an in-situ technique used to relate the transient voltage response from a current interruption event to cell parameters, most commonly ohmic resistance.166 The ratio of the change in voltage to the current that was applied before the interruption event yields the ohmic resistance ( ).167 A curve showing the voltage response to a current interruption event is show in Fig. 14. CI is more commonly applied in fuel cell literature,168,169 but can in theory be used for flow battery measurements as well.

).167 A curve showing the voltage response to a current interruption event is show in Fig. 14. CI is more commonly applied in fuel cell literature,168,169 but can in theory be used for flow battery measurements as well.

Figure 14. Current Interruption technique.

While most studies use CI to measure total internal resistance, analysis of the voltage transient has also been used to study kinetics. This method was used in conjunction with electrochemical impedance spectroscopy (EIS) in PEM fuel cells research170,171 for model validation. Here Tafel slopes were determined from voltage transient data to calculate exchange current.

Current interruption has several stipulations to consider when used. As Lagergen et al.172 discussed, accurate iR measurements are contingent upon delay time. The voltage response is governed by the imposed current as well as the capacitive current that is built up at the electrode surface. The ohmic drop occurs almost instantaneously while the capacitive current discharges more slowly. Hence, getting an accurate ohmic resistance measurement with this method depends on having an understanding of the time scale for the voltage relaxation (typically on the order of 10−6 s167,170 or 10−9 s).168 Srivanasan et al.173 reported a mathematical model which demonstrates the effect of incorporating exchange current (i0) and double layer capacitance (CDL) into estimating voltage relaxation time constant. CI has also been used on the stack level for fuel cell research as Mennola et al.174 reported. Here, an improved approach was used to determine the iR drop, which helped to compensate for error in the voltage transient sampling. In practice, the ease of interpreting internal resistance from EIS renders CI absent from most flow battery literature and as a result, this technique is not commonly used in the study of redox flow batteries.

Electrochemical impedance spectroscopy (EIS)

The application of EIS requires a small voltage/current perturbation signal of known amplitude and frequency to the cell, forcing the cell to deviate from equilibrium by a very small magnitude. Over a spectrum of frequency, the amplitude and phase of the resultant, measured signal is recorded.

In practice, there are two common experimental techniques used for conducting an EIS experiment, depending on whether current (galvao-EIS or GEIS) or voltage (potentiostatic EIS or PEIS) is controlled. In PEIS, the full bandwidth supplied by the frequency response analyzer of the potentiostat is often utilized. GEIS is predominantly utilized for linear systems (systems with facile kinetics and negligible capacitive current); as a result, for RFBs, PEIS technique is more common. A detailed review of AC impedance technique is available in another review paper.175

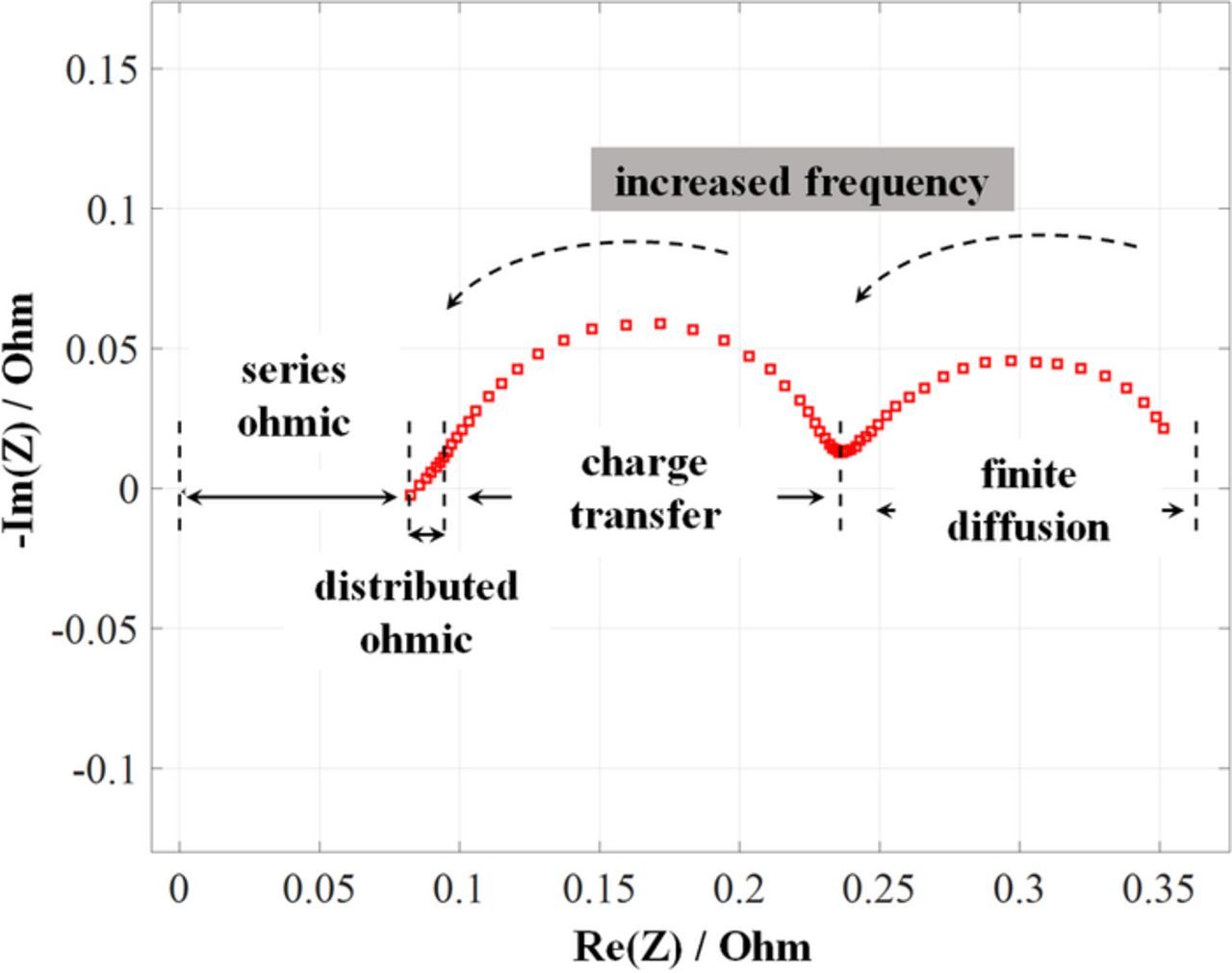

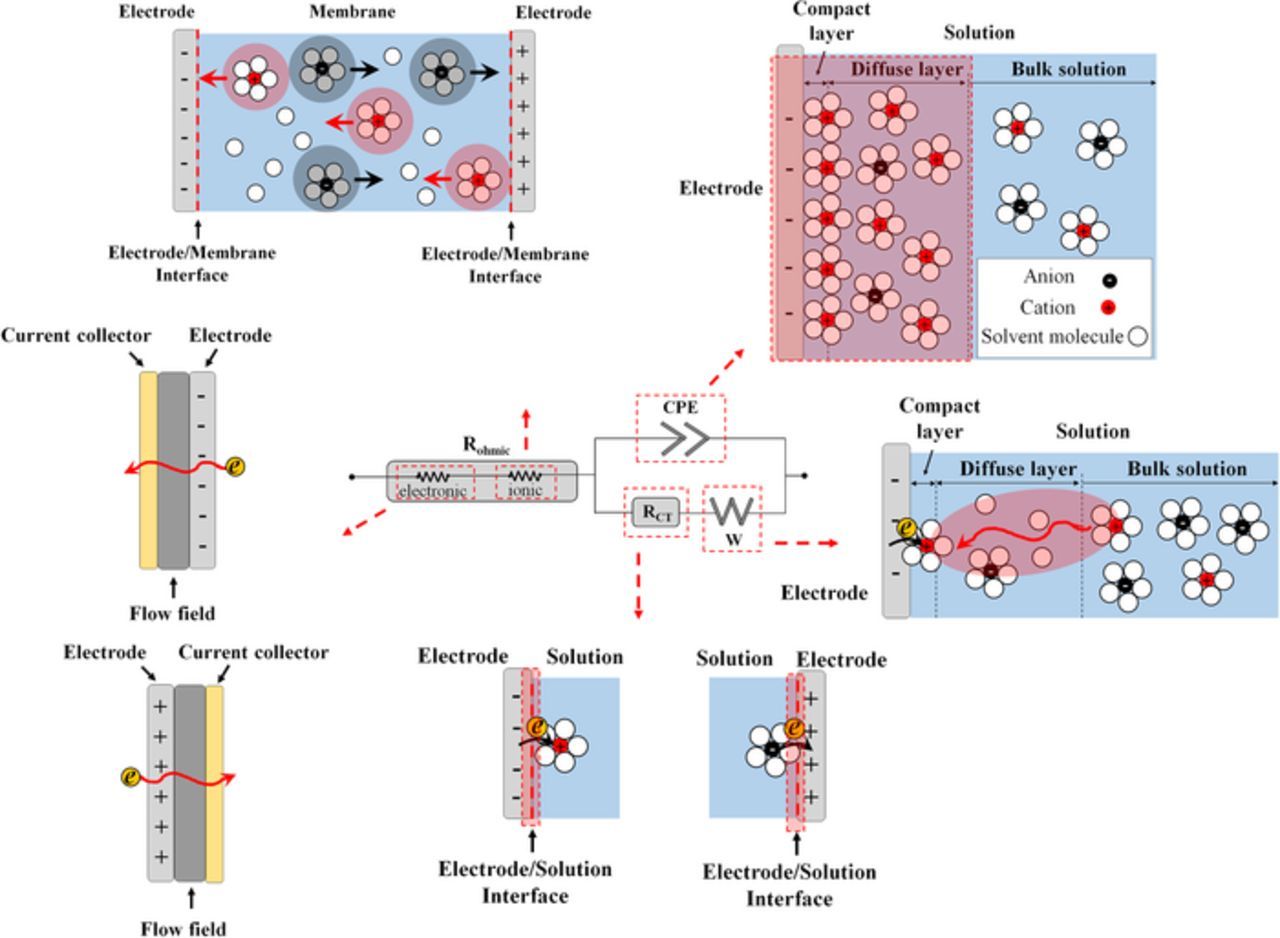

Impedance spectra can be plotted in the form of a Bode diagram (impedance magnitude and phase angle as a function of frequency) and/or the more common Nyquist diagram (the imaginary component of impedance versus the real part at each frequency). A typical Nyquist plot for an RFB is shown in Fig. 15, with the ohmic (series and distributed), charge-transfer, and finite diffusion resistances (overpotentials) denoted.

Figure 15. Typical impedance spectrum.

To obtain quantitative values from a Nyquist plot, the impedance results can be fitted by an equivalent circuit, often the Randles circuit or a close variant.176 It is common to replace the capacitor element in the Randles circuit with a constant phase element (CPE) in order to account for non-ideal capacitive behavior of the electrodes.176

In Fig. 16, Rsol represents ohmic impedance (comprised of ion-exchange membrane resistance, contact resistances, solution resistance and electrode resistance), Rct represents charge transfer resistance across the electrode-electrolyte interface, and W represents the Warburg element for finite diffusion. Rsol typically occurs at very high frequency (5–30 kHz) while the Warburg element manifests itself in a Nyquist plot by a 45-degree line in the low frequency region. It is also important to note that the value of the constant phase element can be converted to the value of double layer capacitance across the electrode-electrolyte interface.137 Thus, if applied correctly, EIS can yield quantitative insight into all overpotentials observed in a RFB.125

Figure 16. Schematic of Randles equivalent circuit model and elements.

The main advantage of the EIS technique is to resolve various sources of polarization for an operating cell under different conditions. If one obtains impedance spectra at several currents, these resistances can be integrated as a function of current to obtain the total overpotential due to each process within the system, allowing for identification of the most rate-limiting process/component for a particular cell design and electrolyte composition. For example, charge transfer resistance is defined by the following equation.177

![Equation ([10])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0010.gif)

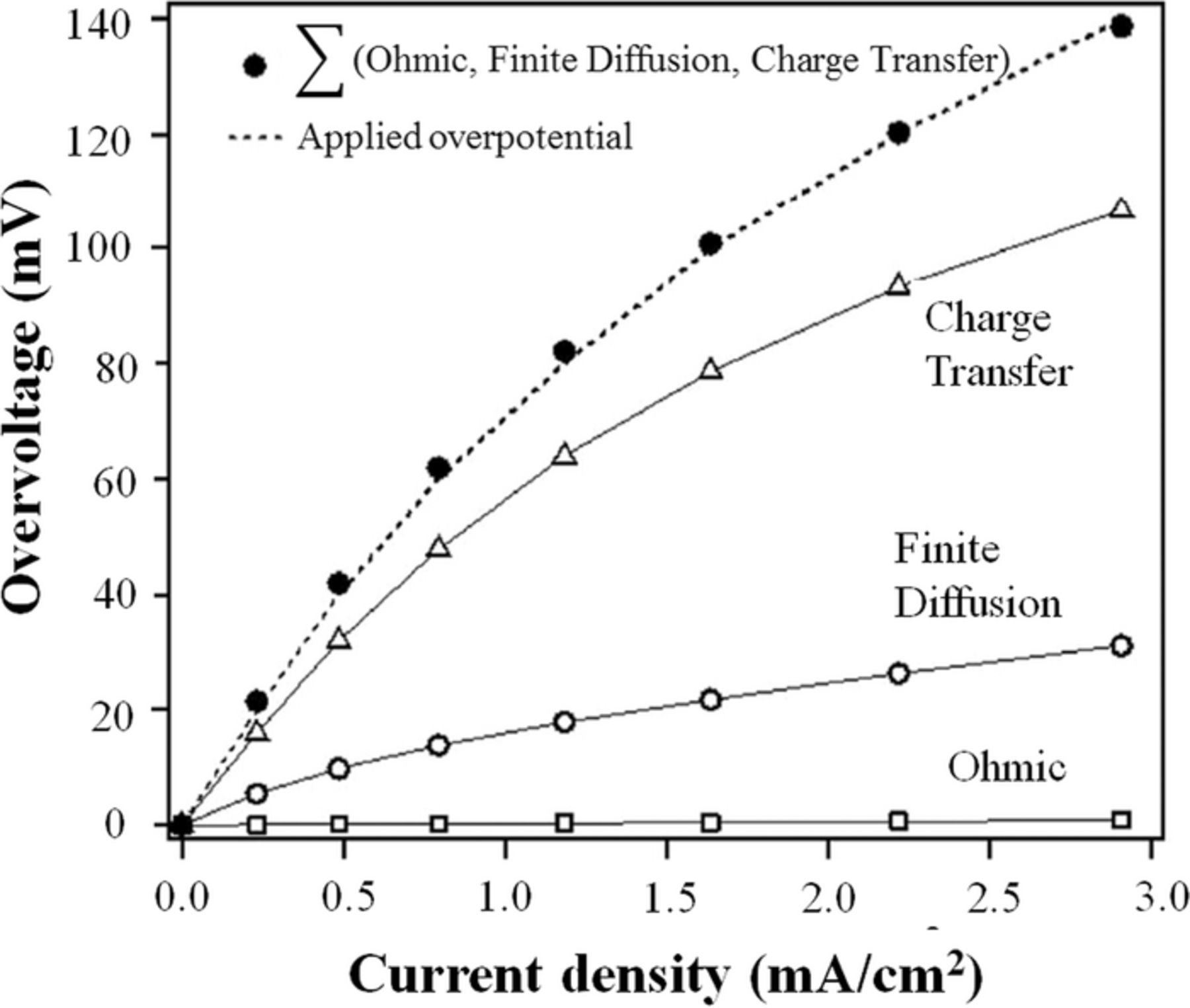

As is clear from Eq. 10, integrating the charge transfer resistance as a function of current will result in the charge-transfer overpotential. A similar approach can be applied for ohmic and mass transport impedance to obtain the overpotentials associated with each category. Further details regarding theoretical modeling of an EIS spectrum are available elsewhere.137,178 An impedance-resolved polarization curve is shown in Fig. 17.

Figure 17. Overpotentials associated with the ohmic, charge transfer and finite diffusion process for an RFB (Ref. 137).

While EIS provides relatively detailed information, it has major limitations. First, the impedance spectrum can be distorted for high concentration systems (as in RFBs) in the low frequency regimes by commonly-used pumps (e.g. peristaltic, diaphragm). The pulsing nature of these pumps necessitates extra equipment to stabilize impedance responses at low frequency.179 Resolving this issue can be done with constant flow syringe pumps or having a pressurized intermediate reservoir in which pump pulses are dampened by a gas headspace. Alternatively, relatively low concentration of electroactive species (ca. 0.1–0.5 M) can alleviate low frequency distortion.

Due to the previously-mentioned distortion at low frequency, EIS is frequently used to study ohmic and charge-transfer kinetics overpotentials.125,137,180,181 Even at frequencies avoiding pump-based distortion, some obstacles must be overcome to obtain reliable EIS results. Investigators must find a suitable reference electrode that is physically compatible with the electrochemical cell, while also being electrochemically stable. Interpretation of impedance spectra requires knowledge of active species concentrations, which may change as a result of crossover in full-cell measurements. Furthermore, interpretation of impedance spectra is not always straightforward, which can lead to incorrect conclusions regarding data.137 EIS is also a cell-averaged method, thus distributions in current and potential are not easily quantified. EIS has been applied to a variety of chemistries, including all-vanadium,125,137 aqueous organic,26 hybrid air-vanadium,138 non-aqueous vanadium,182 and iron slurry,183 among others. Reference 184 is a comprehensive text for more detailed information about EIS.

UV-Vis spectroscopy

Ultraviolet–visible spectroscopy (UV-Vis) is utilized to obtain quantitative information regarding the concentration of the ionic species within an electrolyte if the electrolyte has discernable signal variation between dissolved ions. UV-Vis is a type of absorption spectroscopy in the ultraviolet-visible spectral region. This technique requires a light source in the visible and adjacent ranges (near ultraviolet-visible) and a spectrometer. UV-Vis operates based on the principle that non-bonding electrons can absorb energy in the form of ultraviolet (10–380 nm) or visible (380–780 nm) light; such absorption excites these electrons to higher anti-bonding molecular orbitals and is correlated to the absorbing wavelength (easily-excited electrons are related to longer wavelength).

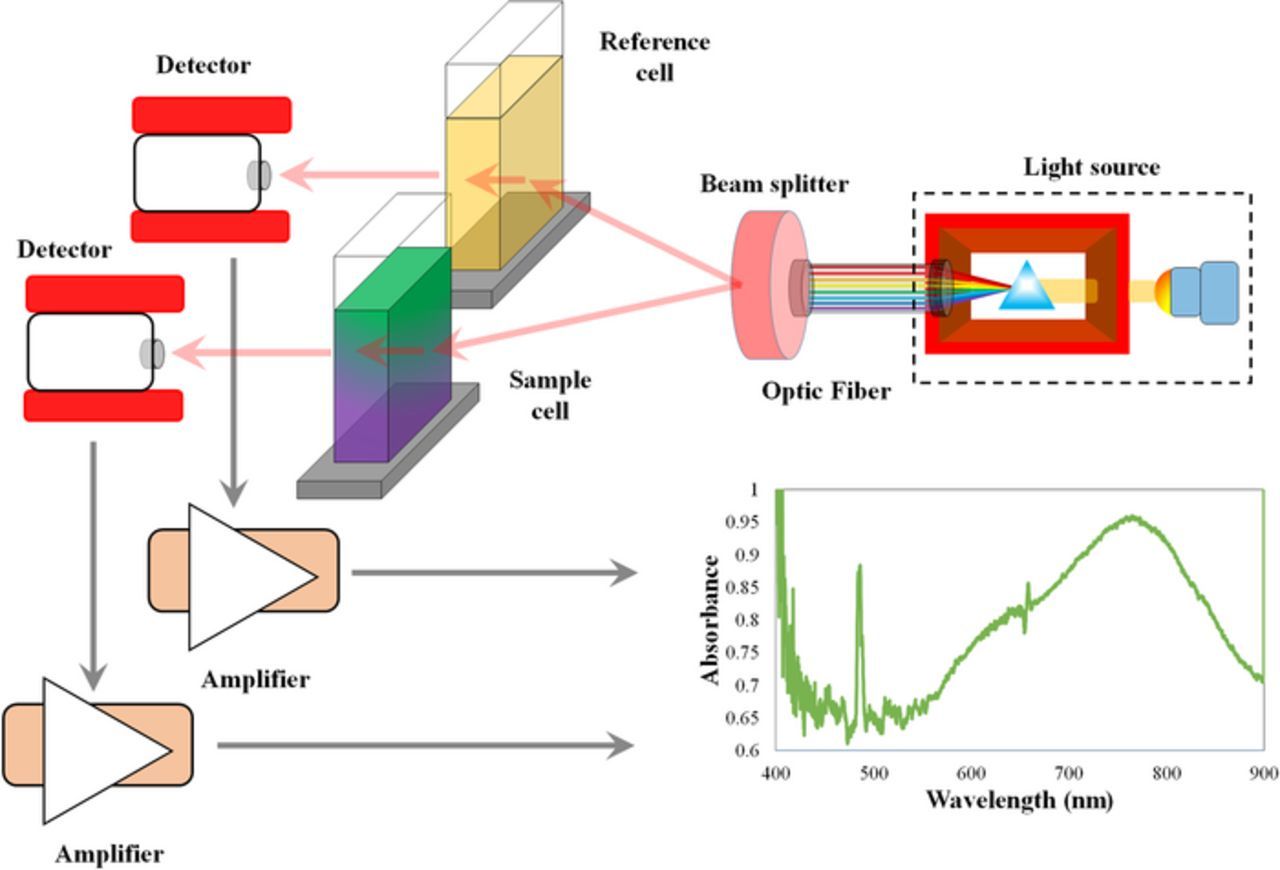

The light source and spectrometer can be integrated into a single device or can be separate devices based on the particular application of interest. Figure 18 is a schematic of a system where the detector (spectrometer) and light sources are separate devices, usually separated by a fiber optic light guide; integrated source-spectrometer devices are typically built as a single unit where the sample is inserted into the light path. An advantage of the separate source-spectrometer arrangement in Fig. 18 is that the sample chamber can be constructed to allow for liquid flow through it, enabling real-time UV-vis spectroscopy on a RFB electrolyte.

Figure 18. Schematic of UV-Vis setup.

UV-Vis spectroscopy can be used to quantitatively determine concentrations in a solution or electrolyte. This technique requires samples to be vividly colored in order to guarantee strong absorbance spectra. As a result, transition metal ions and highly conjugated organic compounds in solution are detectable using this technique. To determine the concentration of a particular species within the solution, the intensity of light transmitted through a solution can be measured relative to a clear medium (e.g. measuring light intensity for a solution of vanadium relative to the intensity through the supporting electrolyte without vanadium), as described in Eq. 11.

![Equation ([11])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0011.gif)

In Eq. 11, I is the measured light intensity of the solute-bearing solution, I0 is the baseline intensity of a solution without the solute of interest, l is the path length, ς is the cross-section area, N is the number density of the absorbing molecules. The absorbance ( ) is defined as:

) is defined as:

![Equation ([12])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/A970equ1.jpeg)

Beer's law is utilized in terms of molar concentration (cm) and molar absorptivity (am) in order to obtain the absorbance (A*) in Eq. 13.

![Equation ([13])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/A970equ2.jpeg)

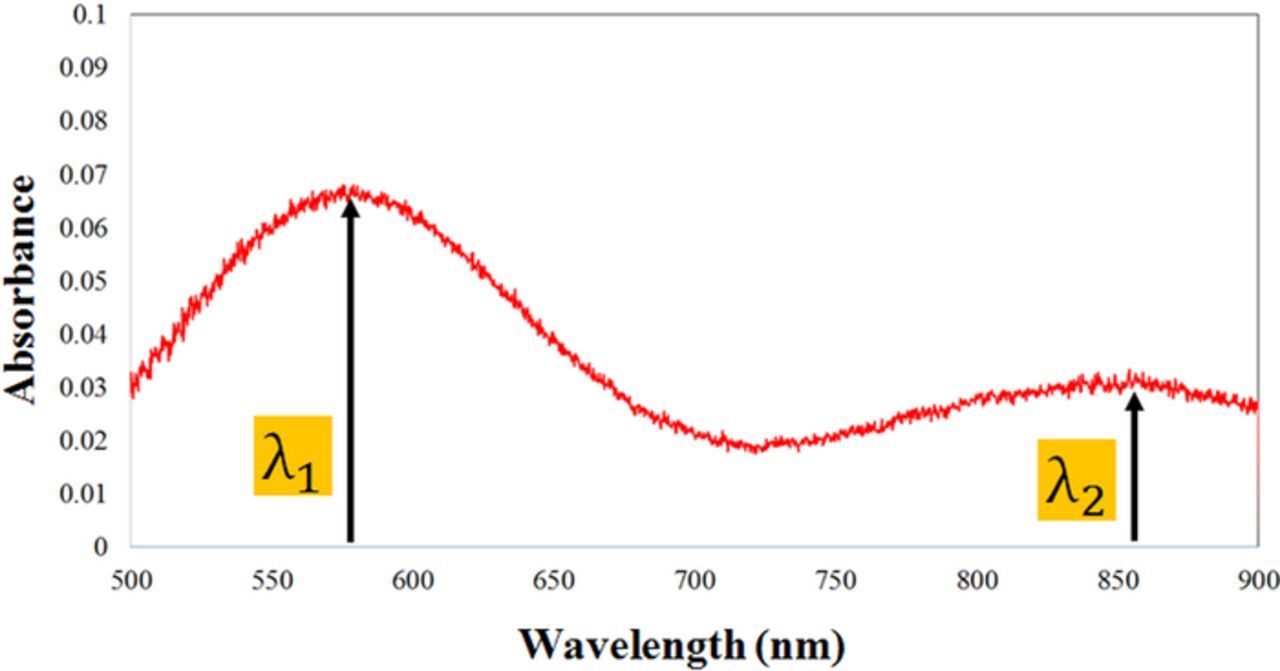

If multiple absorbing solutes exist within the solution, it is assumed that the total absorbance is the linear combination of them. As a result, in practical applications, usually the absorbance of spectra at two different wavelengths (i.e. λ1 and λ2) is obtained and the following set of equations is solved simultaneously in order to obtain the concentrations (cα and cβ).

![Equation ([14])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/A970equ3.jpeg)

![Equation ([15])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/A970equ4.jpeg)

A typical absorbance spectrum used for the calculations of Eqs. 14 and 15 has been shown in Fig. 19. In this case, absorbance maxima occurred at both ∼560 nm and ∼855 nm, corresponding to λ1 and λ2, respectively.

Figure 19. The absorbance for the solution of two solutes.

The UV-Vis technique provides a simple, robust, quantitative method for determining concentrations. The absorbance spectrum shown in Fig. 19 can be measured ex-situ or in-situ. For VRFBs, this technique was originally used to determine the electrolyte SoC since all four oxidation states of vanadium absorb at separate wavelengths.185 More recently, comprehensive mathematical models have been developed based on absorbance spectra in order to determine the SoC for VRFBs.186–188

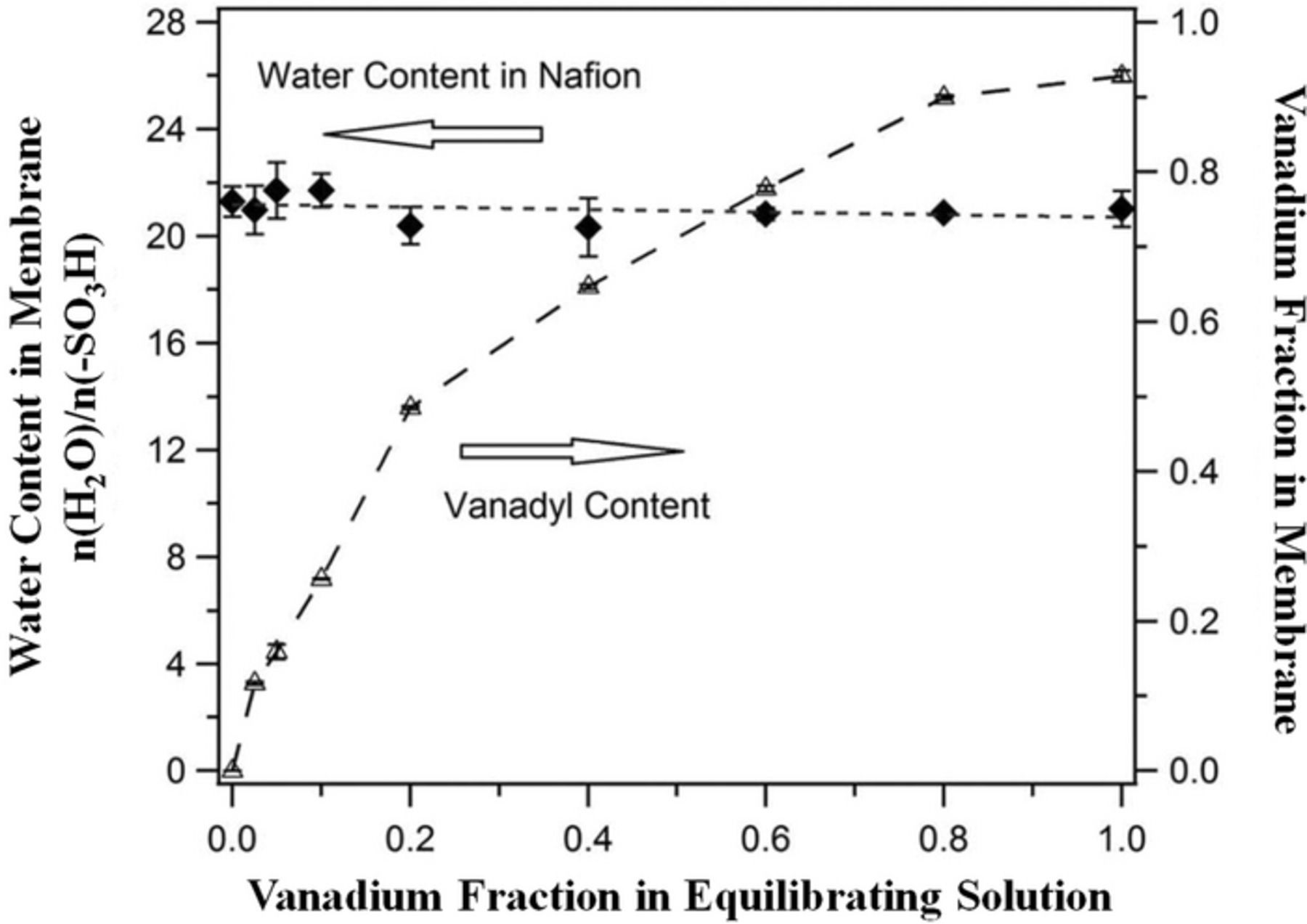

The UV-Vis spectroscopic method can also be used to measure crossover by coupling with a permeability cell.102,114,189 This approach targets concentration-gradient induced crossover in which a solution containing electroactive species (enriched side) is circulated on one side of a membrane while the other side is deficient of electroactive species. This technique to assess crossover has been successfully applied for all-vanadium RFBs and vanadium-air hybrid RFBs as summarized in Table III. The permeability cell has also widely been used to quantify the water transport through various types of nano-porous membranes for membrane-based water desalination.190–193

Table III. Crossover research summary in the literature.

| RFB Type | Species type | Ref. |

|---|---|---|

| All-Vanadium | V(II) | E. Wiedemann et al.194 |

| V(III) | ||

| V(IV) | ||

| V(V) | ||

| All-Vanadium | V(III) | X. Luo et al.195 |

| V(IV) | ||

| V(V) | ||

| All-Vanadium | V(II) | C. Sun et al.196 |

| V(III) | ||

| V(IV) | ||

| V(V) | ||

| All-Vanadium | V(II) | Q. Luo et al.197 |

| V(III) | ||

| V(IV) | ||

| V(V) | ||

| All-Vanadium | V(IV) | J. S. Lawton et al.198,199 |

| All-Vanadium | V(IV) | W. Xie et al.200 |

| Vanadium-Air | V(II) | J. G. Austing et al.201 |

| V(III) | ||

| All-Vanadium | V(II) | Y. Ashraf Gandomi et al.102,114 |

| V(III) | ||

| V(IV) | ||

| V(V) |

Although UV-Vis spectroscopy is a robust technique, it requires a customized set-up if the required measurements are to be done in-situ. Also, the major requirement for determining concentrations using this technique is a linear dependence of absorption on concentration. This requirement is not guaranteed for all solutions and RFB electrolytes, thus calibrations for all compositions are necessary.

Potential distribution

Potential distribution is a distributed diagnostic technique that can be applied to obtain the potential of half-cells and bipolar plates in a multi-cell stack. This technique can also be applied to obtain in-plane and through-plane solid-phase and liquid-phase potential distributions. This technique requires the installation of a stable reference electrode.

Previous studies on polymer electrolyte membrane fuel cells (PEFC) have discussed the installation of a reference electrode that is stable, yet fits within the tightly-layered structure of a PEFC or RFB.202,203 The most common reference electrode configurations are sandwich-type and edge-type. In the sandwich-type, a thin conductive wire is inserted between two membranes.115,204,205 In the edge-type configuration, the reference electrode is attached to a region of the ion-exchange membrane outside the active area between the two electrodes.206,207 It is important to minimize the distance between the reference electrode and the working electrode when placing the reference electrode in order to minimize iR overpotential. The simplest measurement afforded by reference electrode inclusion is measurement of each half-cell potential during RFB operation; an insight that cannot be obtained without a reference electrode. If the more complex potential distribution measurement is needed, special cell design and configuration are required.

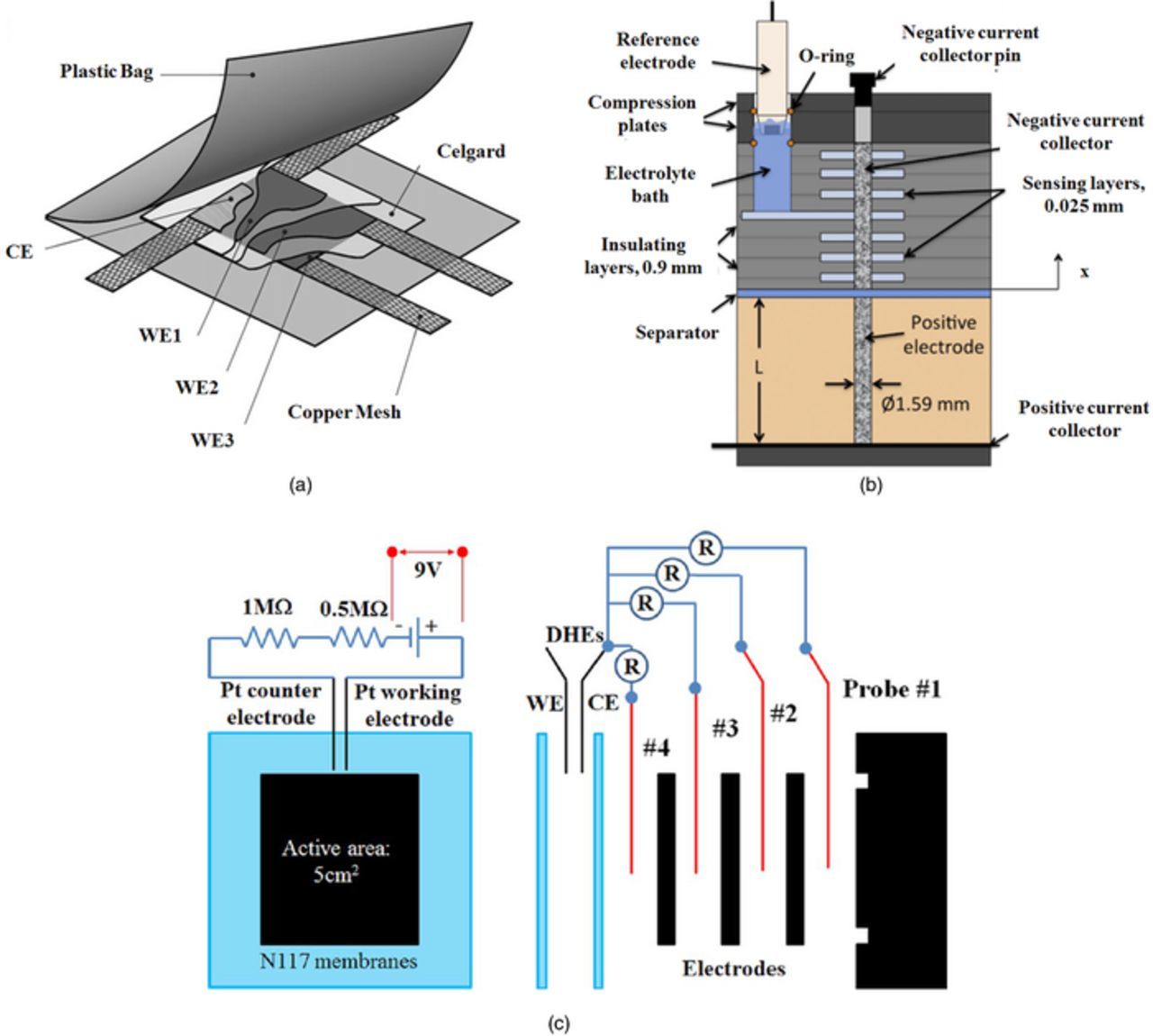

Ng et al. designed a cell with multiple working electrodes using a copper mesh (Fig. 20a) which was implemented in the in-plane configuration across the electrode thickness of an operating lithium-ion battery.208 Hess et al. measured the electrolyte potential distribution through the thickness of a PEFC electrode.209 The same group measured the electrode and electrolyte potential distribution (Fig. 20b) through the negative electrode of an electrochemical double layer capacitance for an aqueous sodium hybrid battery during charge and discharge.210,211 Potential distribution diagnostics have also been implemented for microfluidic fuel cell architecture,212 a PEFC equipped with a non-precious catalyst,213 and flowable electrodes.214 Recently, the potential distribution technique was applied to an all-vanadium redox flow battery.115,215 Ashraf Gandomi et al. inserted micro-probes into the layers of a multi-layer electrode (Fig. 20c) in an operating all-vanadium redox flow battery to measure the solid-phase, through-plane potential distribution between the flow fields and the membrane.115

Figure 20. Different potential distribution setups, (a) in-plane potential distribution diagnostics using copper mesh implemented to a lithium-ion battery,208 (b) Through-plane solid- and liquid-phase potential distribtion diagnostics applied to an aqueous sodium hybrid battery,211 (c) Through-plane solid-phase potential distribution diagnostics applied to the multiple layers of electrode stack for a VRFB.115

Potential distribution allows in-situ assessment of both the solid-phase and electrolyte-phase potential distribution. Information can be gained regarding electroactive species consumption between the flow fields and the membrane (related to electrode utilization), as well as between the inlet and the outlet, regardless of flow field geometry. In all of these, incorporating a stable reference electrode can be challenging with many RFB systems because sometimes-significant modifications to the design must be made. Particular care must be paid to ensuring there is no leakage around where probes or wires cross gaskets, the environment around the reference electrode is compositionally stable, and distinction between solid- and liquid-phase potential is accurately made. With these precautions addressed, potential distribution measurement can provide tremendous insight suitable for inclusion in multi-dimensional models.

Nuclear magnetic resonance (NMR)

Nuclear magnetic resonance (NMR) spectroscopy is primarily used to observe the migration of cations or anions. NMR spectroscopy exploits the magnetic properties of atomic nuclei and is applicable to a wide range of samples, including solutions and solids. For this spectroscopic measurement, a sample is placed in a magnetic field and NMR-active nuclei absorb electromagnetic radiation at a frequency characteristic of the isotope. The strength of the magnetic field affects the resonant frequency, energy of absorption, and the intensity of the signal. A commonly-applied magnetic field is 21 Tesla (900 MHz). A more comprehensive description regarding NMR spectroscopy is available in Refs. 216,217.

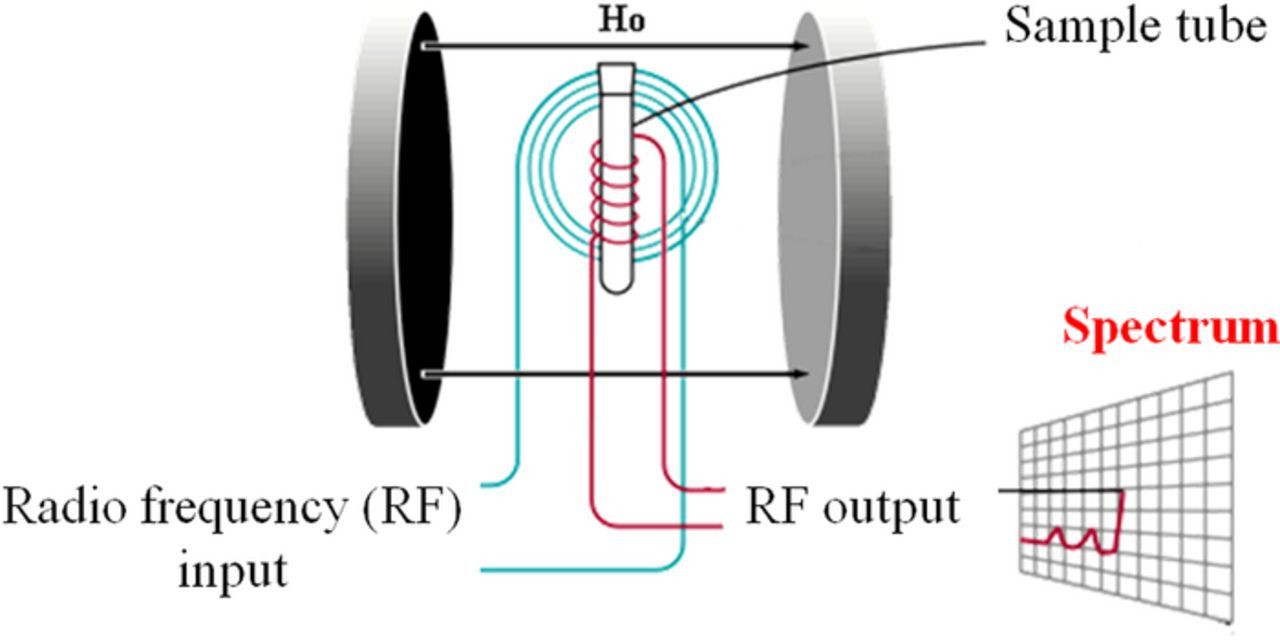

Upon excitation of the sample with a radio frequency pulse, a nuclear magnetic resonance response (time-domain) is obtained followed by a Fourier transform to extract the frequency-domain spectrum. A schematic of an NMR spectroscopic setup is shown in Fig. 21.

Figure 21. NMR setup (Figure adopted from the Ref. 218).

An NMR spectrum is a plot of the radio frequency applied against absorption. The frequency of a signal is known as its chemical shift. Chemical shift is defined in Eq. 16.

![Equation ([16])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0016.gif)

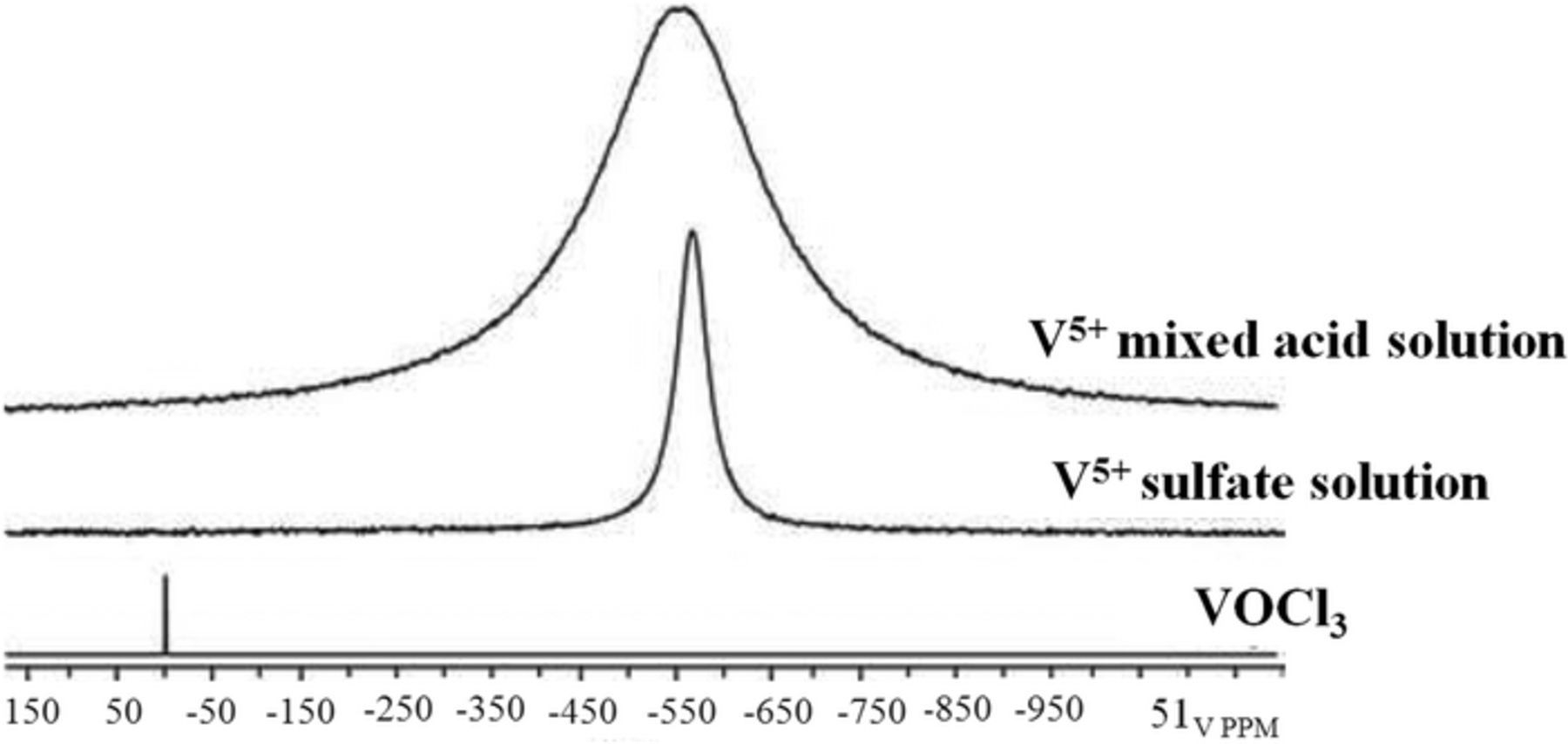

In Eq. 16, fs is the frequency of the signal, fref is the frequency of the reference signal and fsp is the spectrometer frequency. The reference frequency is defined at 0 ppm of the material of interest. A typical NMR spectrum is shown in Fig. 22.

Figure 22. Typical NMR spectra (from Ref. 72).

NMR spectroscopy has been widely used in RFBs and PEFCs for studies on solution and separators to identify and quantify the species of interest.219–221 NMR has also been applied to obtain the ionic diffusivities in other fuel cell types (i.e. methanol diffusion in PEFCs has been studied with NMR).221 The effect of supporting electrolytes for aqueous solutions has also been studied with NMR.222 NMR spectroscopy has also been used to study solubility in aqueous solutions.72,223 Also, assessment of species diffusion within the bulk portion of an ion-exchange membranes has been conducted using NMR.224 Although very useful, NMR is a relatively expensive technique, thus it is not widely reported in the RFB literature. The main limitation of NMR spectroscopy is relatively less sensitivity compared to mass spectroscopy diagnostics.225 This limitation necessitates much larger samples to be used for analysis. Also, among the various types of nuclides detectable by NMR, proton (1H) is the most widely used one in the literature due to exhibiting high sensitivity.225 Also, as a result of relatively low sensitivity, signal averaging is required for almost all measurements in order to achieve an acceptable signal-to-noise level and this, complicates the analysis of NMR data for most cases.225

Ionic and electronic conductivity measurement

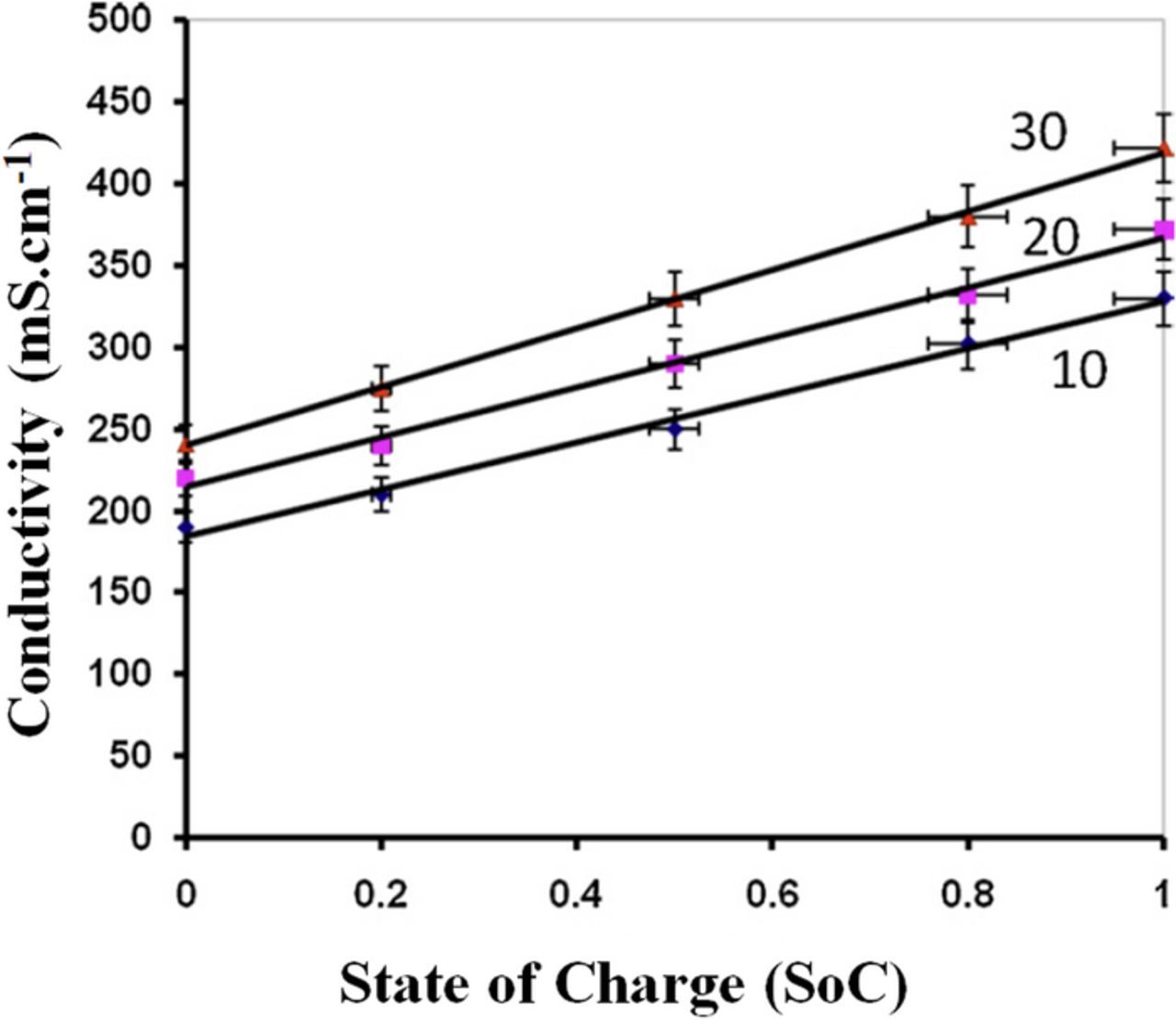

Conductivity measurements can be performed in-situ or ex-situ. Usually, in-situ conductivity measurements include combined effects of both ionic and electronic conductivity of the series-connected components in the cell. As a result, ex-situ conductivity measurements are of great importance because they enable the study of conductivity at the individual component level. Additionally, ex-situ conductivity measurement can be done on relatively small samples and with greater rapidity than those done in-situ. Conductivity measurements can be done to assess electronic, thermal, and ionic conductivity. Electronic conductivity measurement is usually straight forward and operates on the principle of Ohm's law for a conductor. The ionic conductivity is usually measured to assess the conductivity of the solution (electrolyte) as well as the conductivity of the ion-exchange membrane (separator). In order to measure the conductivity of a liquid electrolyte, an external conductivity meter is usually used. Skyllas-Kazacos et al. measured the conductivity of vanadium electrolyte as a function of state of charge (SoC) and of supersaturated vanadium solutions.222,226 The ionic conductivity of these solutions is of interest since it comprises a significant share of the total internal resistance in most RFBs. However, little optimization of solution conductivity has been done to date.

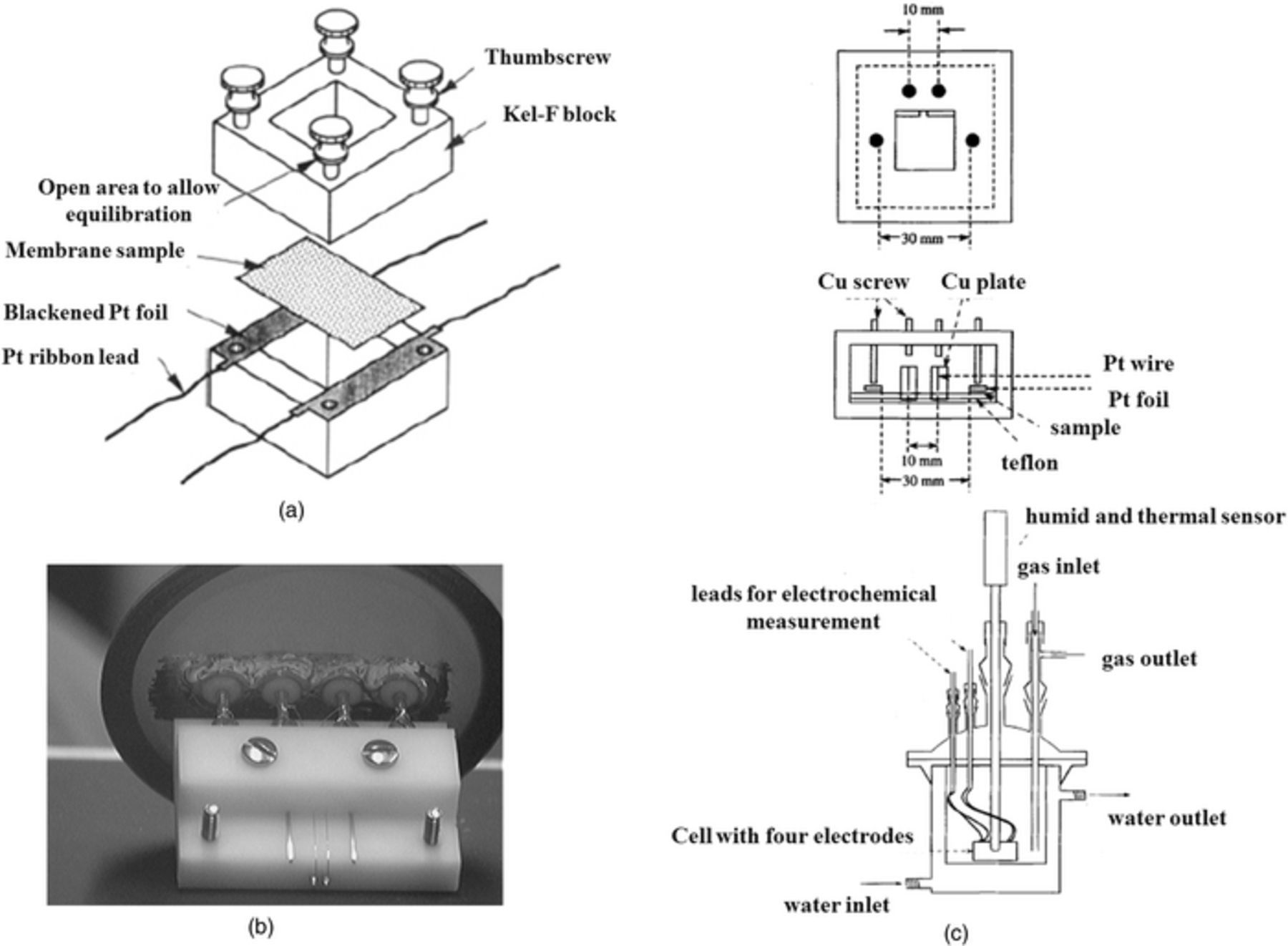

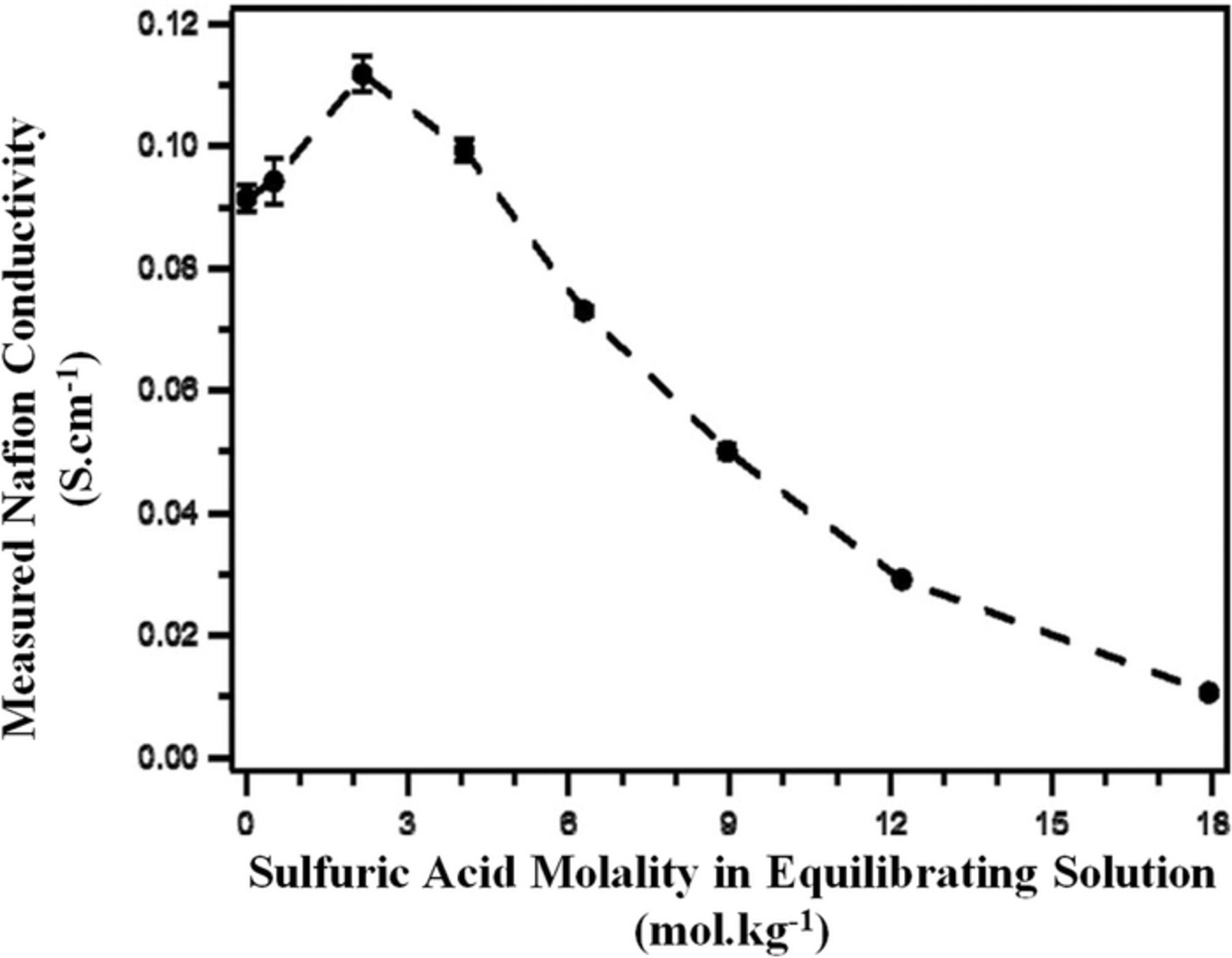

The ionic conductivity of separators is usually measured using the four-electrode AC impedance technique. T. A. Zawodzinski et al.219 measured the conductivity of partially-hydrated Nafion membranes using such a conductivity cell, as shown in Fig. 23a. M. Doyle et al.227 measured the conductivity of perfluorinated ionomers as a function of non-aqueous solvent properties using the conductivity cell shown in Fig. 23b. Y. Sone et al.228 measured the proton conductivity of Nafion 117 using a four-electrode cell (Fig. 23c). In this measurement, two platinum foil electrodes (3 cm apart) were used to conduct current and two platinum needles (1 cm apart) were used to measure the potential drop.228 In all of these four-point cell measurements, similar principles are employed. Calculating the conductivity (σ) is performed according to Eq. 17.

![Equation ([17])](https://content.cld.iop.org/journals/1945-7111/165/5/A970/revision1/d0017.gif)

where Ls is the distance between voltage probes, Rs is the resistance of the medium (e.g. a membrane), and Ss is the cross-sectional area of the medium. The resistance, Rs, is typically obtained by measuring the high frequency resistance between the voltage probes.

The conductivity cell has also widely been used to study the ionic conductivity of different types of ion-exchange membranes exposed to various bathing electrolytes (aqueous and non-aqueous)229–234 and has been implemented to assess the degradation of membranes during long-term cycling.235 The ionic conductivity measurement using a four-electrode cell, although facile and rapid, requires care since this test is conducted ex-situ under conditions likely very dissimilar from those experienced in the cell. It is critical to guarantee the species uptake states are similar to the in-situ operational conditions. The in-plane conductivity of the ion-exchange membrane is typically obtained over a range of operating conditions in order to quantify the optimum conditions to achieve the highest ionic conductivity.233,236 Figures 24 and 25 show examples of measuring in-plane ionic conductivity for an ion-exchange membrane using a conductivity cell and ionic conductivity of solution using an external conductivity meter.

Figure 24. Measured membrane conductivity as a function of sulfuric acid concentration in the electrolyte (Ref. 233).

Figure 25. Measured conductivity of negative electrolyte (V(II)/V(III)) as a function of SoC at various temperatures (10, 20, and 30°C) for all-vanadium redox flow batteries using external conductivity meter (Ref. 226).

It is important to note that the conductivity measured using a conductivity cell enables the measurement of in-plane conductivity for the membranes. Depending on the morphology of the membranes and the degree of reinforcement, the properties of the membranes might exhibit inhomogeneity and therefore, the through-plane conductivity is not the same as in-plane conductivity. The through-plane conductivity is usually measured using electrochemical impedance spectroscopy. Also, it is important to note that in comparison of in-plane and through-plane conductivity assessment, the electrolyte in contact with the membrane is also critical. The in-plane conductivity measurement usually is performed in ambient environment; however, the through-plane measurement is conducted in real cell conditions in which the electrolyte-electrode-membrane boundary is the boundary conditions for the membrane for equilibrium and non-equilibrium conditions.

In addition, it is important to mention that according to Fig. 23, it is critical to precisely measure the thickness and the width of the samples being used in conductivity cell. This measurement is cumbersome since the ionic uptake, elongation and stress-strain characteristics of the samples are strongly being affected by the soaking solution. Additionally, the applied pressure within the conductivity cells are not necessarily accurately controlled, which can also affect the measurement if not taken into account.

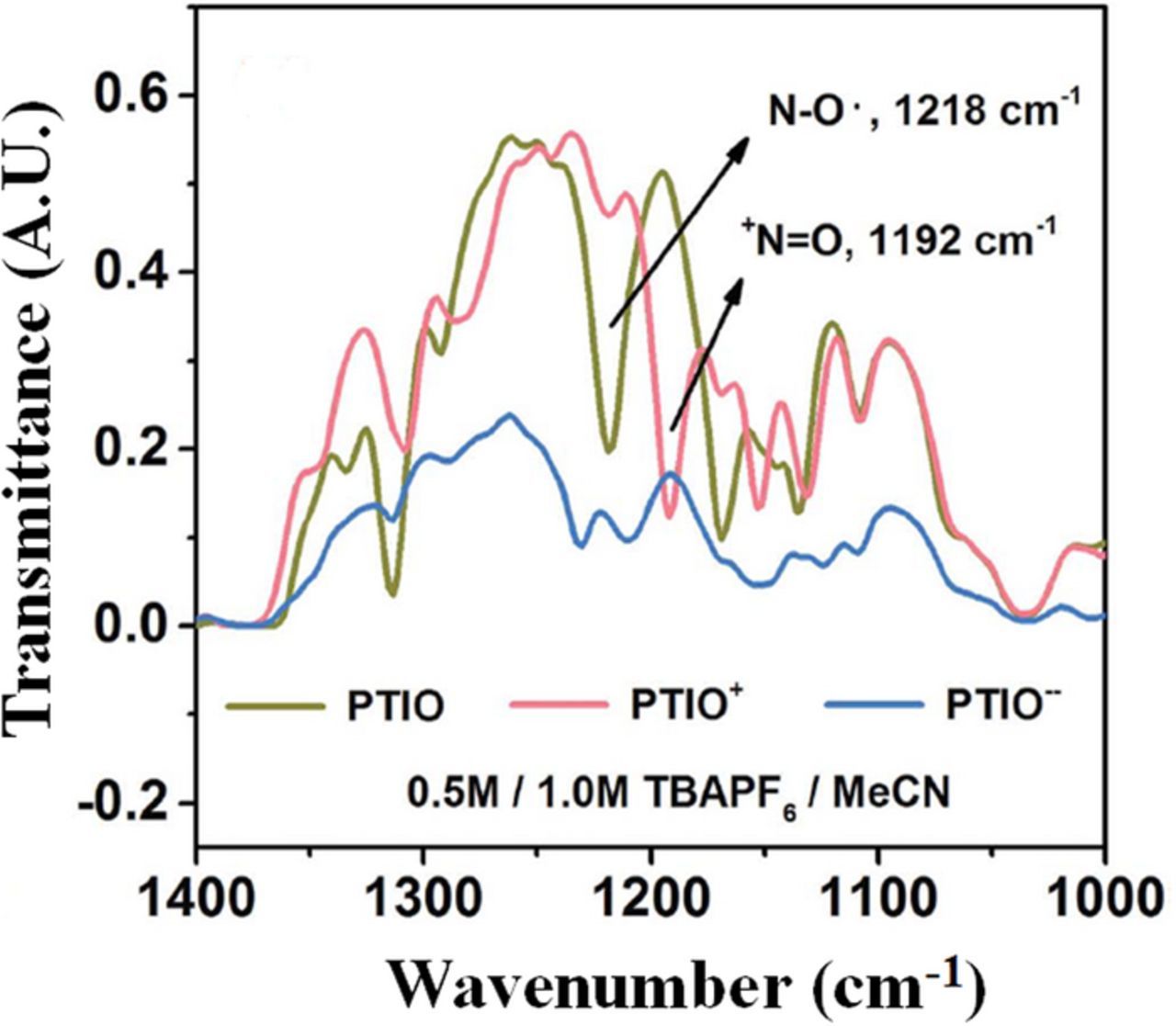

Electron spin resonance (EPR) spectroscopy

Undesired transport of ionic species and water (crossover) is a behavior of interest in redox flow batteries, thus multiple techniques are employed to understand this phenomenon. For VRFBs, crossover is merely a form of self-discharge. However, it is of greater concern for Fe/Cr and H2/Br flow batteries, as crossover may result in irreversible losses. Another tool employed to characterize membrane behavior is electron spin resonance spectroscopy, also called electron paramagnetic resonance (EPR) spectroscopy.237 This technique measures rotational diffusion for several materials, including organic free radicals and transition metals. When applied to VRFBs, EPR is limited, in that it only directly detects VO2+ and V2+. However, these two species have been shown to infiltrate and accumulate in Nafion unlike VO2+ and V3+.224 Thus, the directly-detectable species are most relevant for uptake and crossover studies. EPR also frequently includes the addition of spin probes – small molecules with stable free radicals that can elucidate fine features related to solvent motion and viscosity in the pores of a hydrated membrane. Such observations aid in understanding the environment inside ion exchange membranes. The presence of the probes can be used to report on the potential transport of species not directly detectable with EPR, including V3+ and VO2+.238 Consequently, EPR is used to quantify the uptake and transport of vanadium in VRFBs. This insight informs better understanding of water, proton, and vanadium crossover since all of these species interact in bulk solution as well as in most cation exchange membranes.239 It is noted here that EPR studies are not limited to Nafion; recent work has shown that EPR has been used in assessing the vanadium uptake in sulfonated Diels-Alder poly(phenylene) membranes-a hydrocarbon-based alternative to Nafion in VRFBs.199 Via EPR experiments, VO2+ uptake has been quantified and the results agree with studies that did not utilize EPR.240

Membrane properties of interest, including permeability and partitioning coefficient, have been investigated with EPR, as well. These experiments are accomplished typically by soaking membranes in an electrolyte representative of conditions in a VRFB and then placing the samples in an EPR spectrometer, similar to four-point conductivity probe measurements. In addition to observations of the environment inside ion exchange membranes, modified EPR experiments have been executed to measure vanadium crossover in permeation cells.198 In this work, the spectrometer was modified to measure VO2+ concentration in real time for the permeate side of the permeation cell, akin to the more common UV-Vis spectroscopy experiments described in UV-Vis spectroscopy section.

The insights gained by EPR appear relatively infrequently in the literature since the equipment required to do this measurement is expensive and the technique cannot directly detect all species. However, detailed studies of motion in membranes can be accomplished via EPR, thus it is useful and complimentary to the more common NMR.

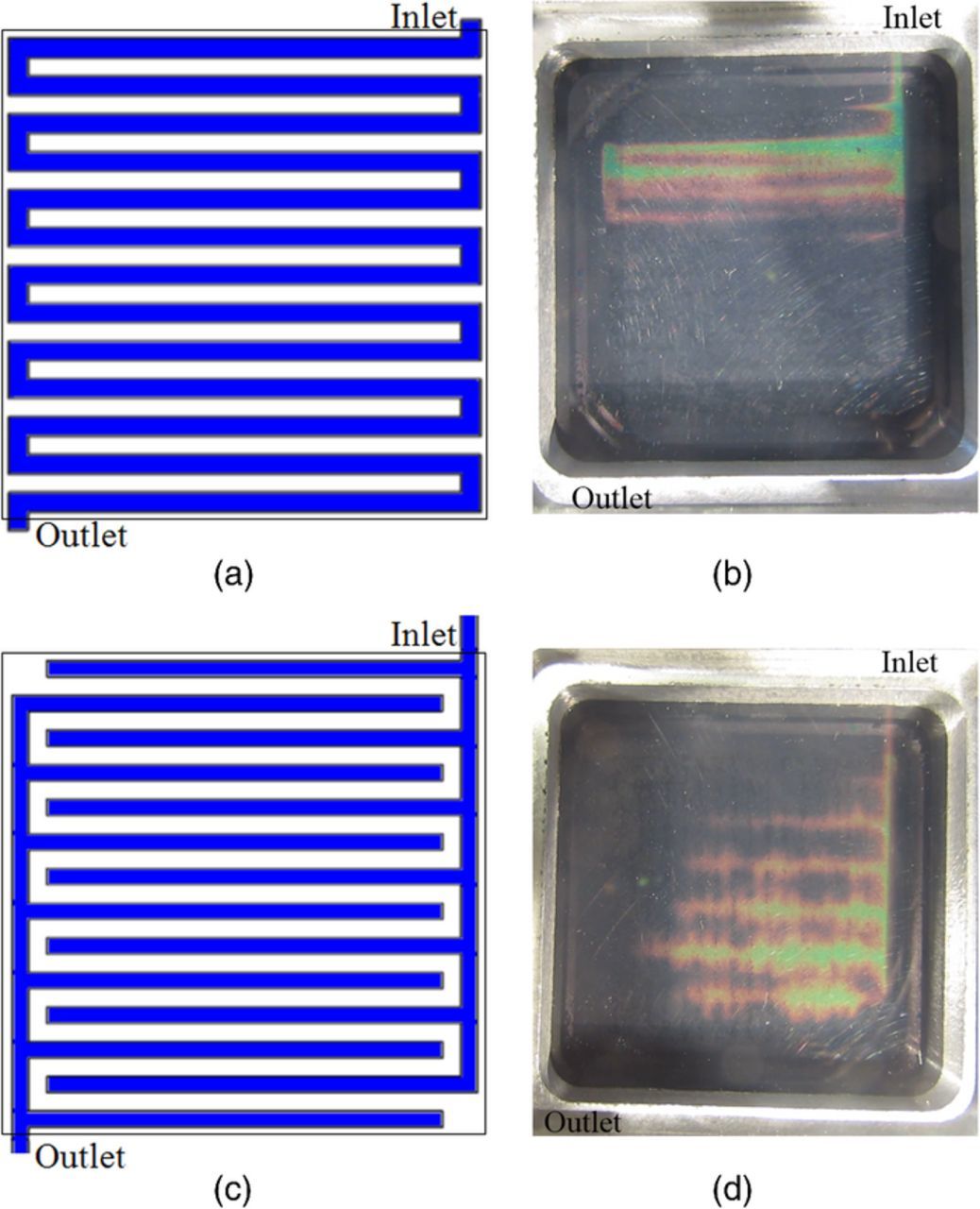

Flow visualization techniques

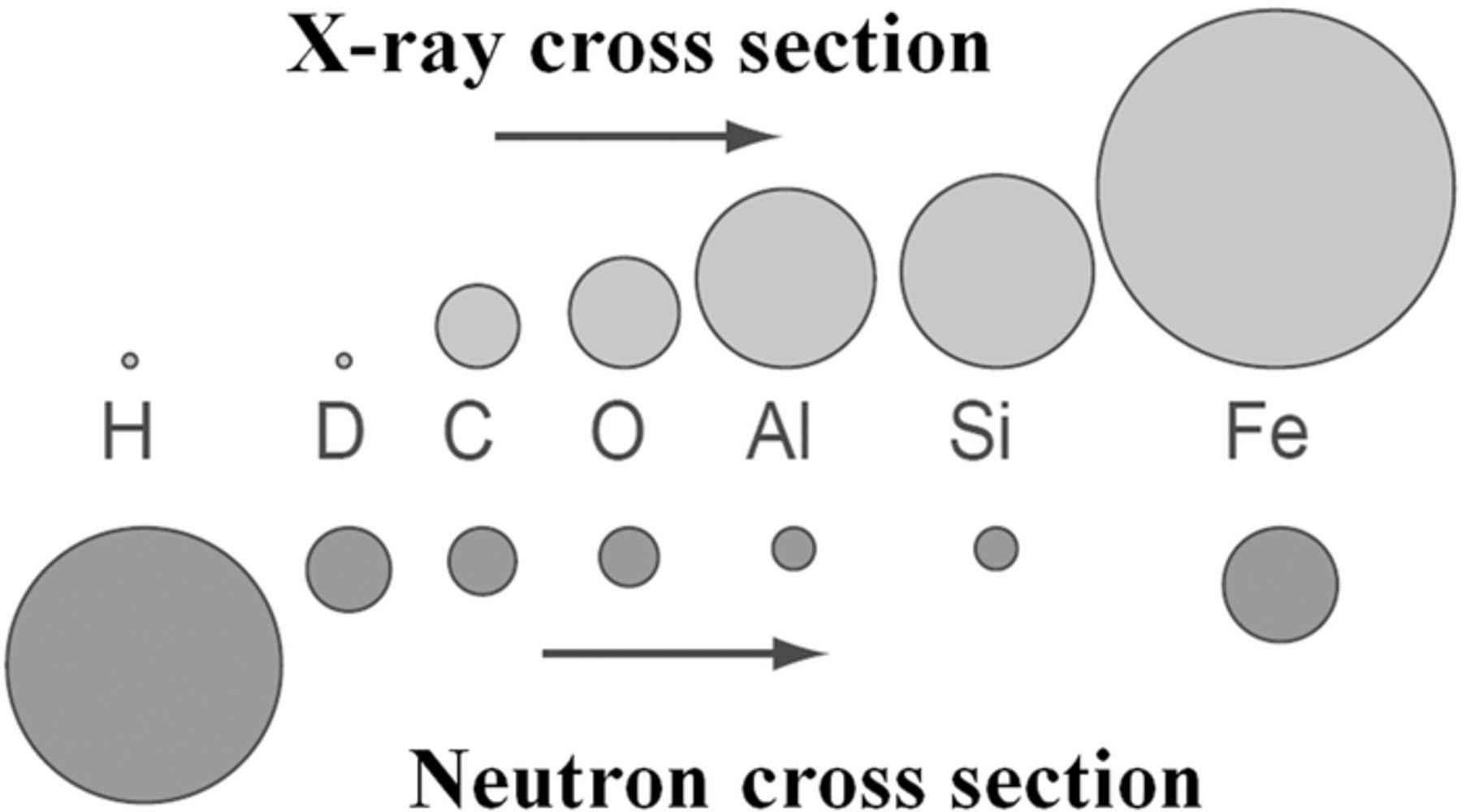

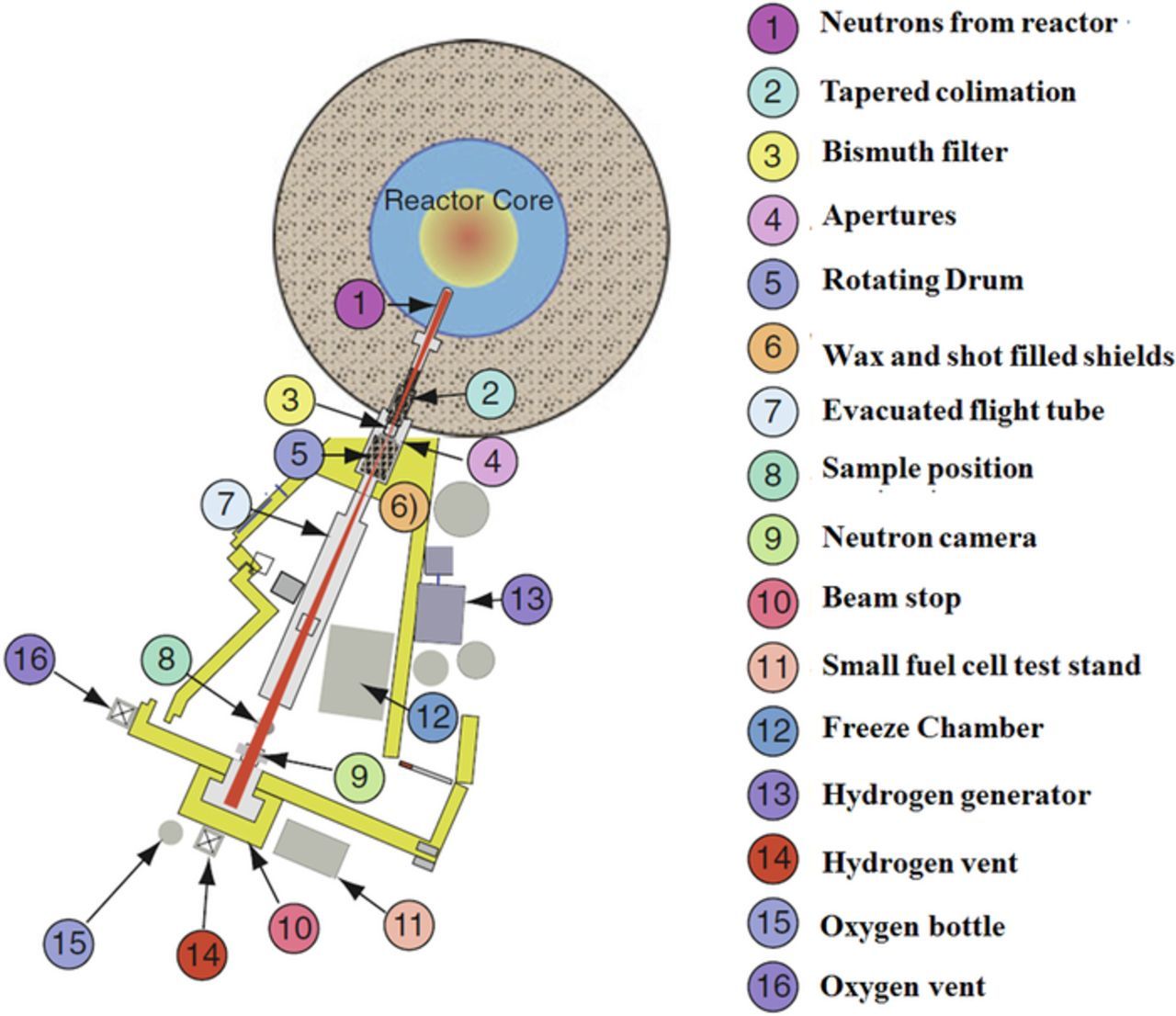

Visualization techniques in RFBs identify electrolyte flow distribution and have been conducted via optical and thermal methods. Optical visualization of RFB flow distributions is an area that has been scarcely explored due to system and component limitations. Further details regarding the optically transparent cells for flow visualization is available in another reference.241 The primary obstacle is the opacity of the porous electrode and structural materials. This opacity, combined with the three dimensional and porous nature of the electrode, hinders attempts to use standard light-based methods such as shadowgraphs, schlieren photography, and interferometry, all of which require light to penetrate throughout the entire flow domain. Additionally, fluorescent techniques involving the addition of dyes to measure concentrations can merely give a two-dimensional result on the electrode surface. While various particle tracing methods such as Positron Emission Tomography (PET) may eventually become a solution, light-based tracing techniques suffer from the same issues as most optical methods. Those involving X-ray or computed tomography do not yet have the necessary spatial or temporal resolution for such a task within the electrode, and may not be even suitable for characterizing channel and manifold flow depending on the geometry. Some of the most recent studies have reported the spatial and temporal resolution of 200 microns and 1 millisecond respectively.242

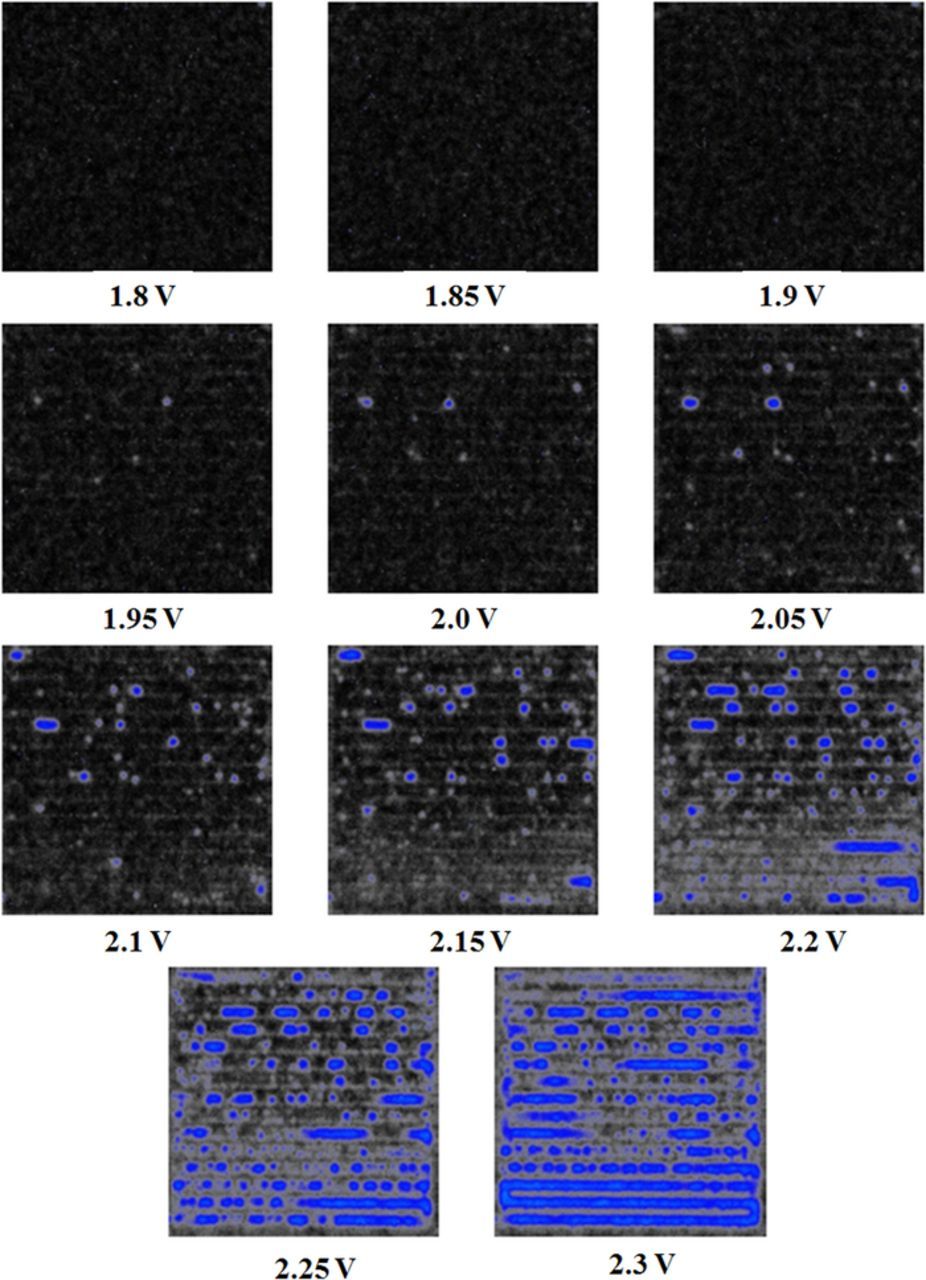

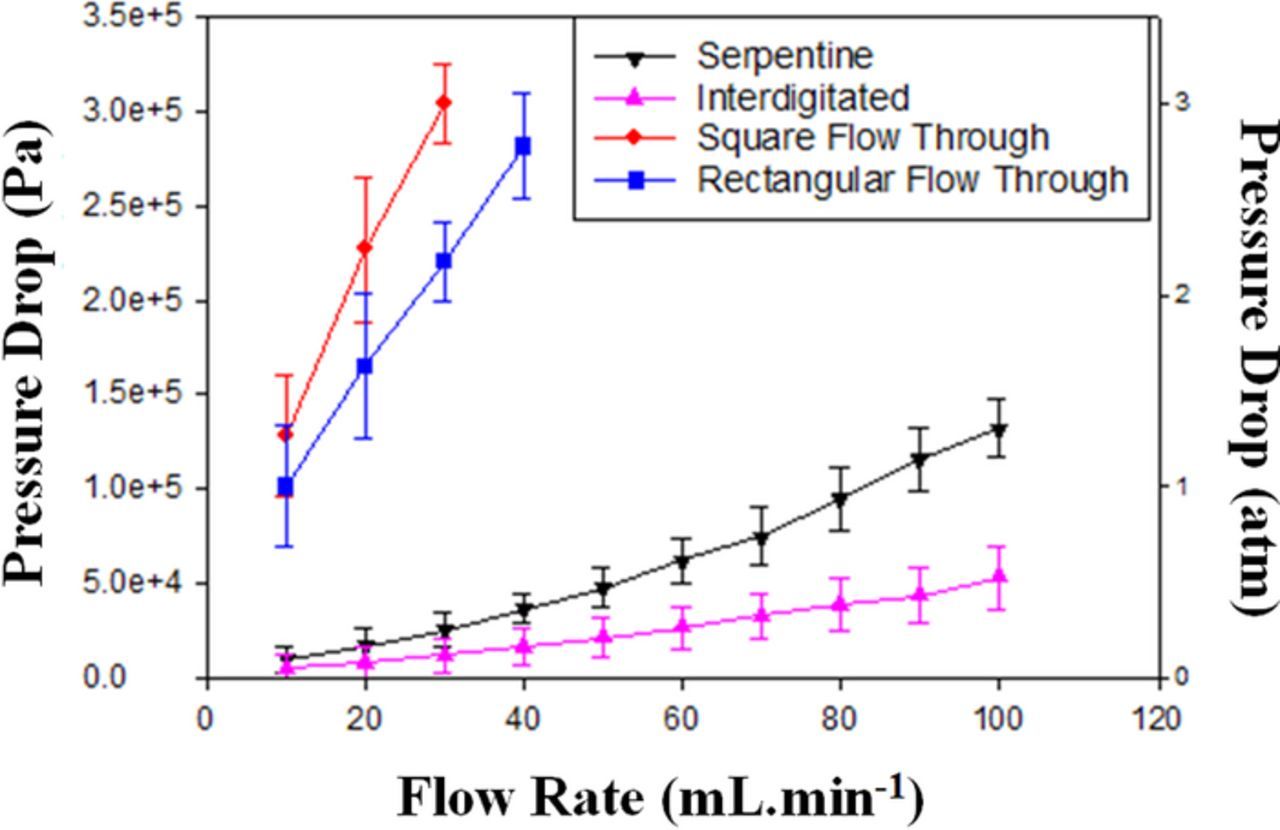

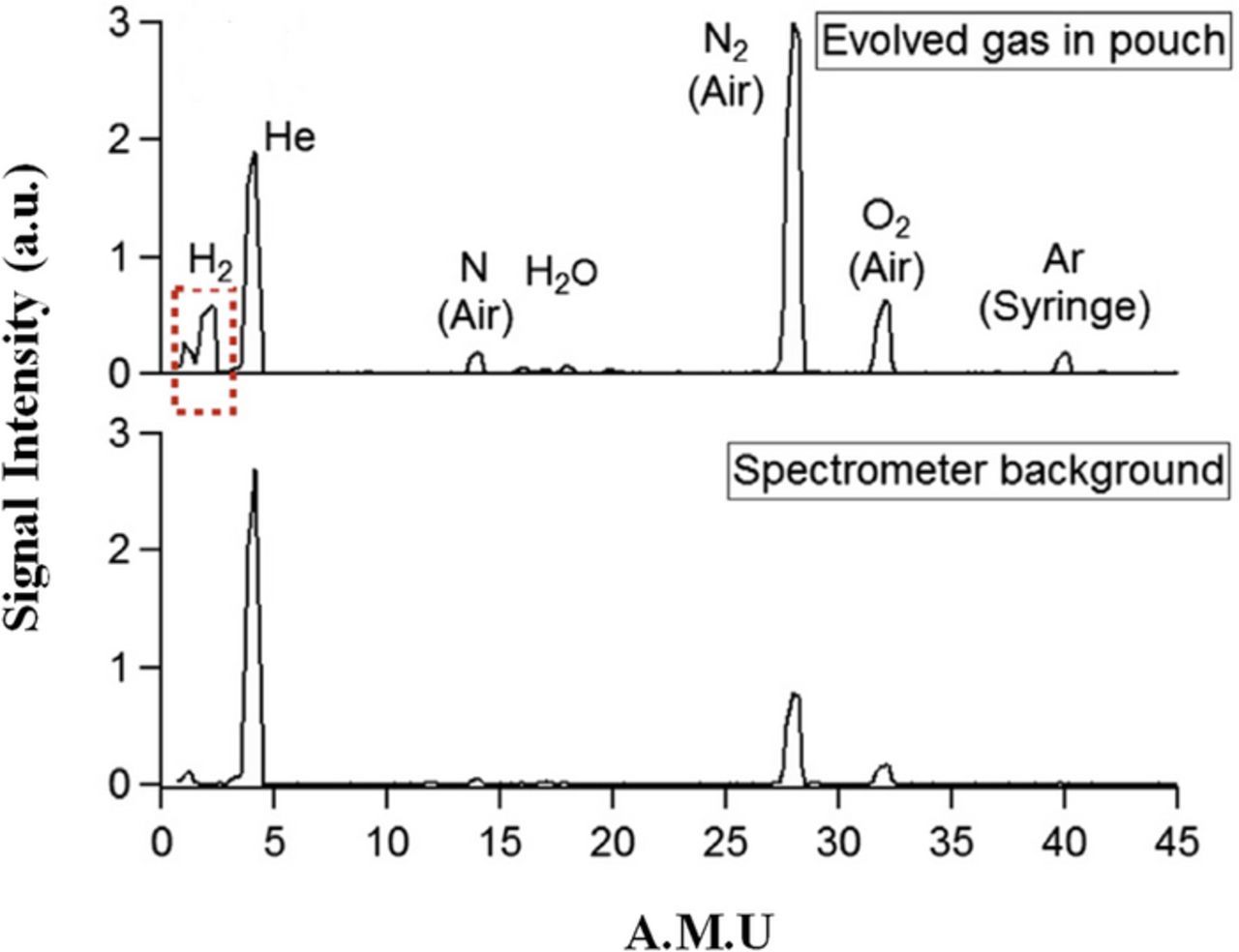

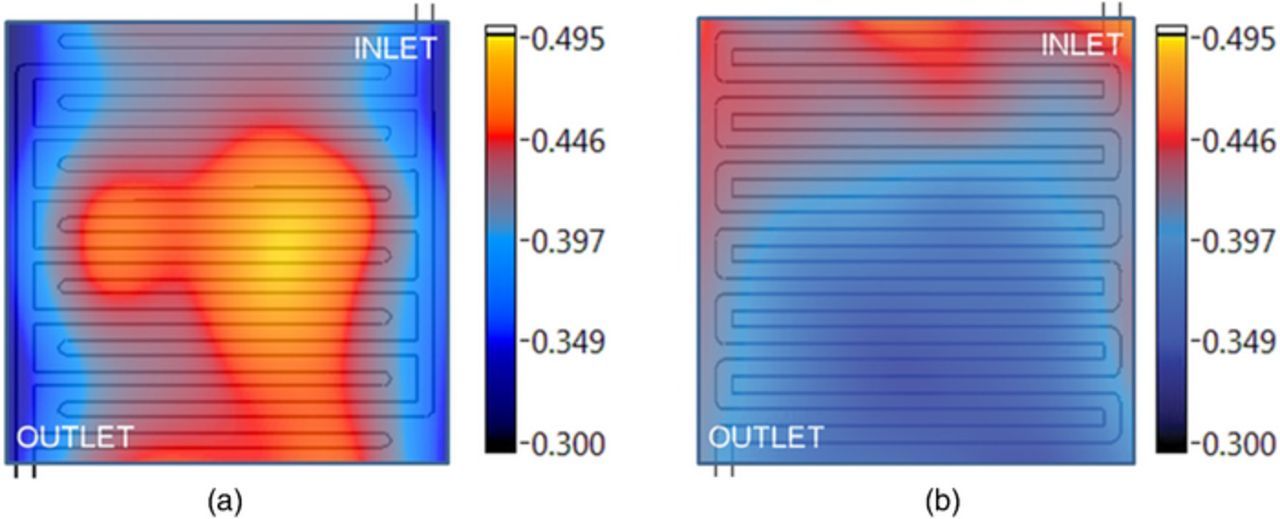

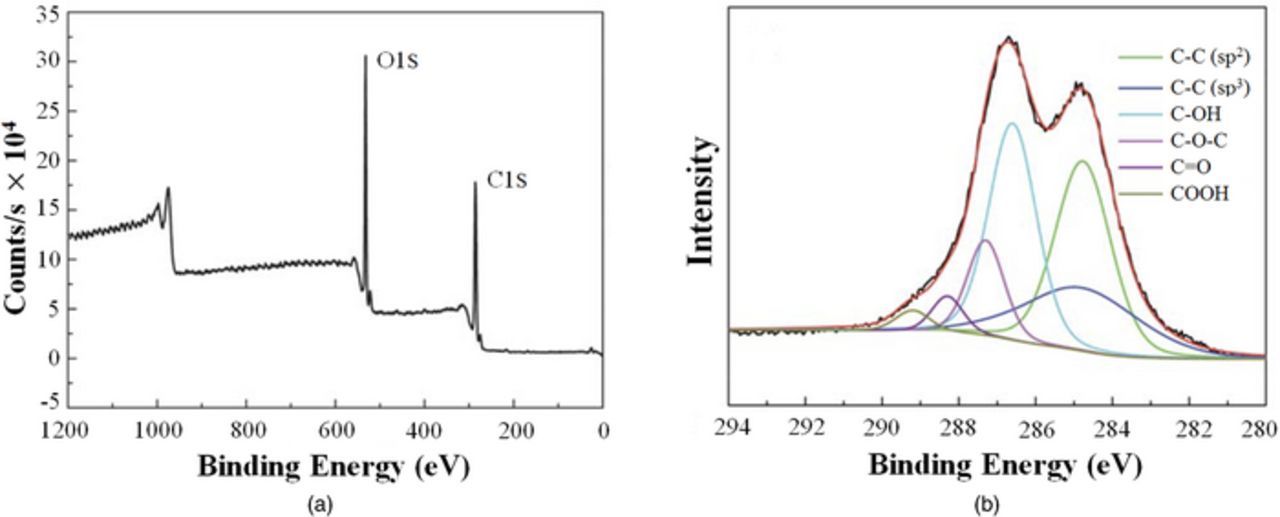

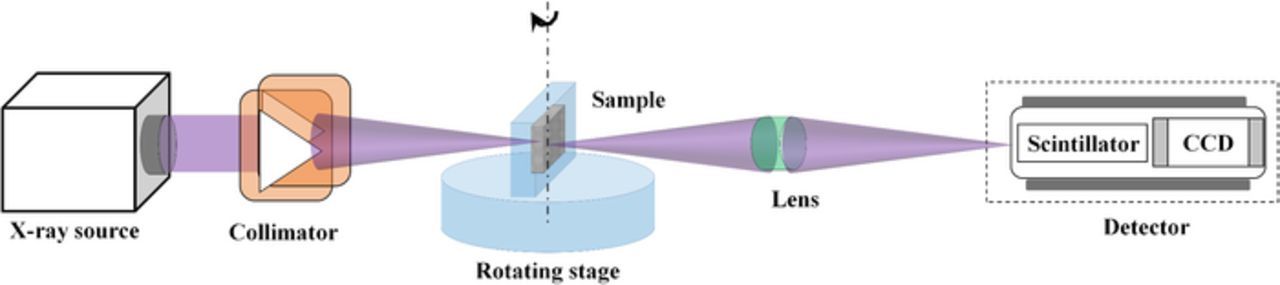

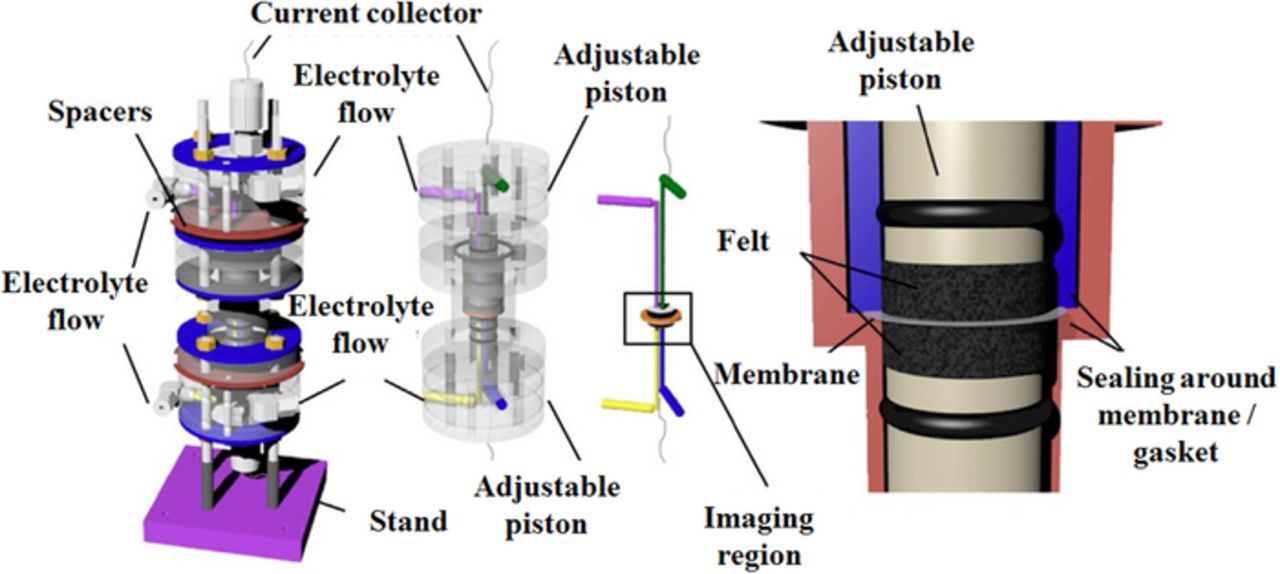

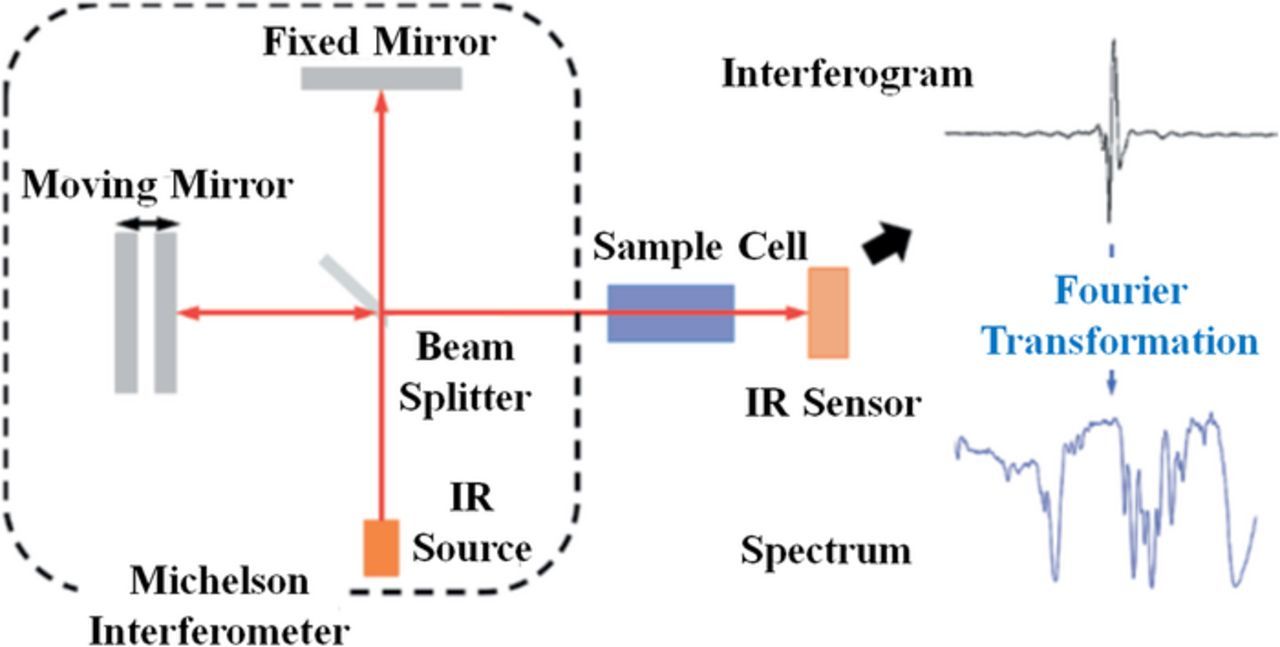

Therefore, this technique, although valuable, cannot give a complete picture of fluid transport. This lack of a suitable technique to address flow visualization in RFBs is a clear opportunity for future advancements to be made within the field.