Abstract

In this article, finite element methods and molecular dynamics method were employed to simulate covalent bonds between carbon atoms in nanotubes with a linear beam element. Single-walled carbon nanotubes with different structures, and a wide diameter and longitudinal range were analyzed. The effect of geometric parameters of CNTs including diameter, length, and chirality on the Young's and shear modulus of the nanotubes was independently investigated. Also, the decrease in Young's modulus of CNTs was determined due to the presence of a vacancy defect and an increase in the number and location of the defect. The results showed in all three types of defective nanotubes (armchair, zigzag, and chiral) with a small-diameter, Young's, and shear moduli increased with incrementing the nanotube diameter. Also, in all three types of structures with a diameter greater than 20 \(\AA \), the effect of the diameter of the nanotube is significantly reduced, and the Young's and shear modulus approached those of a graphene sheet. For nanotubes with a diameter greater than 20 \(\AA \) and a length greater than 240 \(\AA \), the effect of nanotube dimensions on Young's and shear moduli was negligible and the only factor affecting the mechanical properties of these nanotubes was the chirality or structure of the nanotube, and among the studied nanotubes, the vacancy defect had the greatest impact on Young's modulus of chiral nanotubes, with a chiral angle of 15.49\(^\circ \). Also the results demonstrated that the diameter of the nanotube has a greater effect on the elastic properties than the length of the nanotube. Comparing the results obtained for armchair, zigzag, and chiral nanotubes, the vacancy defect had the greatest impact on Young's modulus of chiral nanotubes. The present theoretical study highlights the important role played by vacancy defected CNTs in determining their mechanical behaviors as reinforcements in multifunctional nanocomposites.

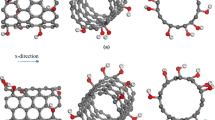

Graphical abstract

Similar content being viewed by others

Abbreviations

- a c-c :

-

Carbon–carbon bond lengths equal (0.142 nm)

- E s :

-

Elastic potential energy

- E b :

-

Bending energy

- E t :

-

Torsional potential energy

- E l :

-

Off-plane potential energy

- E vdw :

-

Van der Waals bonds forces

- E es :

-

Electrostatic bonds forces

- E hb :

-

Hydrogen bonds forces

- k r :

-

Force constants of bond tension

- k θ :

-

Force constants of bond bending

- k φ :

-

Force constants of bond torsion

- Δr :

-

Show the changes in bond length

- Δθ :

-

Show the changes in-plane angle of the bond

- Δφ :

-

Show the changes in out-of-plane torsion of the bond

- \(L0_{NT}\) :

-

Initial length of the nanotube

- \(\Delta L_{NT}\) :

-

Changes in the length of the nanotube

- \(A_{NT}\) :

-

Cross-sectional area of the nanotube

- D :

-

Diameter of CNTs

- t :

-

Walled thickness of CNTs

- v CNT :

-

Poisson's ratio of CNT

- G CNT :

-

Shear modulus of CNT

- \(\rho\) :

-

Density modulus of CNT

References

H. Sbiaai, A. Hader, S. Boufass et al., The effect of the substitution on the failure process in heterogeneous materials: fiber bundle model study. Eur. Phys. J. Plus. 134, 148 (2019). https://doi.org/10.1140/epjp/i2019-12475-7

A.G. Arani, A. Farazin, M. Mohammadimehr, The effect of nanoparticles on enhancement of the specific mechanical properties of the composite structures: a review research. Adv. Nano Res. 10, 327 (2021)

M. Naheed, M. Faryad, Excitation of surface plasmon–polariton waves at the interface of a metal and an isotropic chiral material in the prism-coupled configurations. Eur. Phys. J. Plus 135, 724 (2020). https://doi.org/10.1140/epjp/s13360-020-00757-2

Iijima S (1998) Graphite filaments having tubular structure and method of forming the same

J.-C. Sublet, I.P. Bondarenko, G. Bonny et al., Neutron-induced damage simulations: beyond defect production cross-section, displacement per atom and iron-based metrics. Eur. Phys. J. Plus 134, 350 (2019). https://doi.org/10.1140/epjp/i2019-12758-y

J. Hristov, Linear viscoelastic responses and constitutive equations in terms of fractional operators with non-singular kernels. Eur. Phys. J. Plus 134, 283 (2019). https://doi.org/10.1140/epjp/i2019-12697-7

C.-L. Zhang, H.-S. Shen, Buckling and postbuckling analysis of single-walled carbon nanotubes in thermal environments via molecular dynamics simulation. Carbon N. Y. 44, 2608–2616 (2006). https://doi.org/10.1016/j.carbon.2006.04.037

A. Ghasemi, M. Dardel, M.H. Ghasemi, M.M. Barzegari, Analytical analysis of buckling and post-buckling of fluid conveying multi-walled carbon nanotubes. Appl. Math. Model 37, 4972–4992 (2013). https://doi.org/10.1016/j.apm.2012.09.061

A. Ghasemi, M. Dardel, M.H. Ghasemi, Control of the non-linear static deflection experienced by a fluid-carrying double-walled carbon nanotube using an external distributed load. Proc. Inst. Mech. Eng. Part N. J. Nanoeng. Nanosyst. 226, 181–190 (2012). https://doi.org/10.1177/1740349912451387

J. Yang, H.-S. Shen, Free vibration and parametric resonance of shear deformable functionally graded cylindrical panels. J. Sound Vib. 261, 871–893 (2003). https://doi.org/10.1016/S0022-460X(02)01015-5

A. Ghasemi, M. Dardel, M.H. Ghasemi, Collective effect of fluid’s coriolis force and nanoscale’s parameter on instability pattern and vibration characteristic of fluid-conveying carbon nanotubes. J. Press. Vessel Technol. (2015). https://doi.org/10.1115/1.4029522

Z. Shah, K.P. Ikramullah et al., Impact of nanoparticles shape and radiation on the behavior of nanofluid under the Lorentz forces. Case Stud. Therm. Eng. 26, 101161 (2021). https://doi.org/10.1016/j.csite.2021.101161

M. Shoaib, M.A.Z. Raja, M.T. Sabir et al., A stochastic numerical analysis based on hybrid NAR-RBFs networks nonlinear SITR model for novel COVID-19 dynamics. Comput. Methods Programs Biomed. 202, 105973 (2021). https://doi.org/10.1016/j.cmpb.2021.105973

M. Bilal, H. Arshad, M. Ramzan et al., Unsteady hybrid-nanofluid flow comprising ferrousoxide and CNTs through porous horizontal channel with dilating/squeezing walls. Sci. Rep. 11, 12637 (2021). https://doi.org/10.1038/s41598-021-91188-1

Z. Shah, M.R. Hajizadeh, Ikramullah et al., Entropy optimization and heat transfer modeling for Lorentz forces effect on solidification of NEPCM. Int. Commun. Heat Mass Transf. 117, 104715 (2020). https://doi.org/10.1016/j.icheatmasstransfer.2020.104715

M.M.J. Treacy, T.W. Ebbesen, J.M. Gibson, Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 381, 678–680 (1996)

A. Krishnan, E. Dujardin, T.W. Ebbesen et al., Young’s modulus of single-walled nanotubes. Phys. Rev. B 58, 14013 (1998)

G.L. Burkholder, Y.W. Kwon, R.D. Pollak, Effect of carbon nanotube reinforcement on fracture strength of composite adhesive joints. J. Mater. Sci. 46, 3370–3377 (2011)

P. Jojibabu, Y.X. Zhang, A.N. Rider, J. Wang, Mechanical performance of adhesive joints using high-performance nanocomposite adhesive material with carbon nanotube and triblock copolymer hybrids. Compos Part B Eng 186, 107813 (2020)

A. Farazin, M. Mohammadimehr, Effect of different parameters on the tensile properties of printed Polylactic acid samples by FDM: experimental design tested with MDs simulation. Int. J. Adv. Manuf. Technol. (2021). https://doi.org/10.1007/s00170-021-07330-w

A. Farazin, M. Mohammadimehr, Computer modeling to forecast accurate of efficiency parameters of different size of graphene platelet, carbon, and boron nitride nanotubes: a molecular dynamics simulation. Comput. Concr. 27, 111 (2021)

M. Kuwar, S. Kamal, Molecular dynamics simulation study of novel properties of defect full single walled carbon nanotubes. Int. J. Appl. or Innov. Eng. Manag. 2, 77–81 (2013)

A. Kumar, K. Sharma, P.K. Singh, V.K. Dwivedi, Mechanical characterization of vacancy defective single-walled carbon nanotube/epoxy composites. Mater. Today Proc. 4, 4013–4021 (2017). https://doi.org/10.1016/j.matpr.2017.02.303

M. Sammalkorpi, A. Krasheninnikov, A. Kuronen et al., Mechanical properties of carbon nanotubes with vacancies and related defects. Phys. Rev. B 70, 245416 (2004). https://doi.org/10.1103/PhysRevB.70.245416

A. Farazin, M. Mohammadimehr, Nano research for investigating the effect of SWCNTs dimensions on the properties of the simulated nanocomposites: a molecular dynamics simulation. Adv. Nano Res. 9, 83–90 (2020)

J. Blumberger, M.-P. Gaigeot, M. Sulpizi, R. Vuilleumier, Frontiers in molecular simulation of solvated ions, molecules and interfaces. Phys. Chem. Chem. Phys. 22, 10393–10396 (2020). https://doi.org/10.1039/D0CP90091E

O. Barrera, D. Bombac, Y. Chen et al., Correction to: Understanding and mitigating hydrogen embrittlement of steels: a review of experimental, modelling and design progress from atomistic to continuum. J. Mater. Sci. 53, 10593–10594 (2018). https://doi.org/10.1007/s10853-018-2291-7

J.F. Castillo-Lara, E.A. Flores-Johnson, A. Valadez-Gonzalez et al., Mechanical properties of natural fiber reinforced foamed concrete. Materials (Basel) 13, 3060 (2020). https://doi.org/10.3390/ma13143060

M. Mohammadimehr, B. Rousta Navi, A. Ghorbanpour Arani, Free vibration of viscoelastic double-bonded polymeric nanocomposite plates reinforced by FG-SWCNTs using MSGT, sinusoidal shear deformation theory and meshless method. Compos. Struct. 131, 654–671 (2015). https://doi.org/10.1016/j.compstruct.2015.05.077

M. Mazaheri, J. Payandehpeyman, M. Khamehchi, A developed theoretical model for effective electrical conductivity and percolation behavior of polymer-graphene nanocomposites with various exfoliated filleted nanoplatelets. Carbon N. Y. (2020). https://doi.org/10.1016/j.carbon.2020.07.059

A.F. Ávila, G.S.R. Lacerda, Molecular mechanics applied to single-walled carbon nanotubes. Mater. Res. 11, 325–333 (2008). https://doi.org/10.1590/S1516-14392008000300016

T. Belin, F. Epron, Characterization methods of carbon nanotubes: a review. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 119, 105–118 (2005). https://doi.org/10.1016/j.mseb.2005.02.046

Y. Gogotsi, Nanomaterials Handbook (CRC Press, Boca Raton, 2006)

S.Y. Mensah, F.K.A. Allotey, N.G. Mensah, G. Nkrumah, Differential thermopower of a CNT chiral carbon nanotube. J. Phys. Condens. Matter. 13, 5653–5662 (2001). https://doi.org/10.1088/0953-8984/13/24/310

Z. Shah, E. Bonyah, S. Islam, T. Gul, Impact of thermal radiation on electrical MHD rotating flow of Carbon nanotubes over a stretching sheet. AIP Adv. 9, 015115 (2019). https://doi.org/10.1063/1.5048078

N. Feroz, Z. Shah, S. Islam et al., Entropy generation of carbon nanotubes flow in a rotating channel with hall and ion-slip effect using effective thermal conductivity model. Entropy 21, 52 (2019). https://doi.org/10.3390/e21010052

A. Saeed, Z. Shah, A. Dawar et al., Entropy generation in MHD flow of carbon nanotubes in a rotating channel with four different types of molecular liquids. Int. J. Heat Technol. 37, 509–519 (2019). https://doi.org/10.18280/ijht.370218

Z. Shah, M. Sheikholeslami, K.P. Ikramullah, Influence of nanoparticles inclusion into water on convective magneto hydrodynamic flow with heat transfer and entropy generation through permeable domain. Case Stud. Therm. Eng. 21, 100732 (2020). https://doi.org/10.1016/j.csite.2020.100732

L.G. Do, C.Z. Wang, E. Yoon et al., Diffusion, coalescence, and reconstruction of vacancy defects in graphene layers. Phys. Rev. Lett. 95, 1–4 (2005). https://doi.org/10.1103/PhysRevLett.95.205501

Z. Huang, S. Yi, H. Chen, X. He, Parameter analysis of damaged region for laminates with matrix defects. J. Sandw. Struct. Mater. 23, 580–620 (2021). https://doi.org/10.1177/1099636219842290

L. Cao, Changing port governance model: port spatial structure and trade efficiency. J. Coast. Res. 95, 963 (2020). https://doi.org/10.2112/SI95-187.1

B. Mou, F. Zhao, Q. Qiao et al., Flexural behavior of beam to column joints with or without an overlying concrete slab. Eng. Struct. 199, 109616 (2019). https://doi.org/10.1016/j.engstruct.2019.109616

Z. Yang, P. Xu, W. Wei et al., Influence of the crosswind on the pantograph arcing dynamics. IEEE Trans. Plasma Sci. 48, 2822–2830 (2020). https://doi.org/10.1109/TPS.2020.3010553

C. Zuo, J. Sun, J. Li et al., High-resolution transport-of-intensity quantitative phase microscopy with annular illumination. Sci. Rep. 7, 7654 (2017). https://doi.org/10.1038/s41598-017-06837-1

C.Q. Ru, Effective bending stiffness of carbon nanotubes. Phys. Rev. B 62, 9973–9976 (2000). https://doi.org/10.1103/PhysRevB.62.9973

K.T. Lau, C. Gu, D. Hui, A critical review on nanotube and nanotube/nanoclay related polymer composite materials. Compos. Part. B Eng. 37, 425–436 (2006). https://doi.org/10.1016/j.compositesb.2006.02.020

M. Meo, M. Rossi, Prediction of Young’s modulus of single wall carbon nanotubes by molecular-mechanics based finite element modelling. Compos. Sci. Technol. 66, 1597–1605 (2006). https://doi.org/10.1016/j.compscitech.2005.11.015

J. Zhang, Q. Chen, J. Sun et al., On a universal solution to the transport-of-intensity equation. Opt. Lett. 45, 3649 (2020). https://doi.org/10.1364/OL.391823

Y. Hu, Q. Chen, S. Feng, C. Zuo, Microscopic fringe projection profilometry: a review. Opt. Lasers Eng. 135, 106192 (2020). https://doi.org/10.1016/j.optlaseng.2020.106192

Q. Dong, L. Cui, Reliability analysis of a system with two-stage degradation using Wiener processes with piecewise linear drift. IMA J. Manag. Math. 32, 3–29 (2021). https://doi.org/10.1093/imaman/dpaa009

C. Zhang, H. Wang, Swing vibration control of suspended structures using the active rotary inertia driver system: theoretical modeling and experimental verification. Struct. Control Heal. Monit. (2020). https://doi.org/10.1002/stc.2543

L. Zhu, L. Kong, C. Zhang, Numerical study on hysteretic behaviour of horizontal-connection and energy-dissipation structures developed for prefabricated shear walls. Appl. Sci. 10, 1240 (2020). https://doi.org/10.3390/app10041240

J.M. Wernik, S.A. Meguid, Multiscale modeling of the nonlinear response of nano-reinforced polymers. Acta Mech. 217, 1–16 (2011). https://doi.org/10.1007/s00707-010-0377-7

K.I. Tserpes, P. Papanikos, Finite element modeling of single-walled carbon nanotubes. Compos. Part B Eng. 36, 468–477 (2005). https://doi.org/10.1016/j.compositesb.2004.10.003

C. Li, T.-W. Chou, A structural mechanics approach for the analysis of carbon nanotubes. Int. J. Solids Struct. 40, 2487–2499 (2003). https://doi.org/10.1016/S0020-7683(03)00056-8

Y. Xiang, H.-S. Shen, Shear buckling of rippled graphene by molecular dynamics simulation. Mater. Today Commun. 3, 149–155 (2015). https://doi.org/10.1016/j.mtcomm.2015.01.001

I. Benedetti, H. Nguyen, R.A. Soler-Crespo et al., Formulation and validation of a reduced order model of 2D materials exhibiting a two-phase microstructure as applied to graphene oxide. J. Mech. Phys. Solids 112, 66–88 (2018). https://doi.org/10.1016/j.jmps.2017.11.012

J.P. Lu, Elastic properties of carbon nanotubes and nanoropes. Phys. Rev. Lett. 79, 1297–1300 (1997). https://doi.org/10.1103/PhysRevLett.79.1297

E. Hernández, C. Goze, P. Bernier, A. Rubio, Elastic properties of single-wall nanotubes. Appl. Phys. A Mater. Sci. Process 68, 287–292 (1999). https://doi.org/10.1007/s003390050890

B.K. Sharma, Graphene—an exotic condensed matter and its impact on technology. Emerg. Mater. Res. 9, 1–49 (2020). https://doi.org/10.1680/jemmr.16.00147

L. Chen, Q. Zhao, Z. Gong, H. Zhang, The effects of different defects on the elastic constants of single-walled carbon nanotubes. in 2010 IEEE 5th International Conference on Nano/Micro Engineered and Molecular Systems. IEEE, pp 777–780 (2010)

X. Lu, Z. Hu, Mechanical property evaluation of single-walled carbon nanotubes by finite element modeling. Compos. Part B Eng. 43, 1902–1913 (2012). https://doi.org/10.1016/j.compositesb.2012.02.002

J.R. Xiao, J. Staniszewski, J.W. Gillespie, Tensile behaviors of graphene sheets and carbon nanotubes with multiple Stone-Wales defects. Mater. Sci. Eng. A 527, 715–723 (2010). https://doi.org/10.1016/j.msea.2009.10.052

Acknowledgements

The authors would like to thank the referees for their valuable comments. This research is financially supported by the Ministry of Science and Technology of China (Grant No. 2019YFE0112400), National Science Foundation of China (Grant No. 51678322), the Taishan Scholar Priority Discipline Talent Group program funded by the Shan Dong Province, and the first-class discipline project funded by the Education Department of Shandong Province.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this article, and the article was approved by all the authors.

Consent to participate

Not applicable.

Consent for publication

The article is approved by all authors for publication.

Rights and permissions

About this article

Cite this article

Eyvazian, A., Zhang, C., Musharavati, F. et al. Effects of appearance characteristics on the mechanical properties of defective SWCNTs: using finite element methods and molecular dynamics simulation. Eur. Phys. J. Plus 136, 946 (2021). https://doi.org/10.1140/epjp/s13360-021-01840-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-01840-y