Abstract

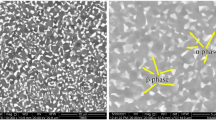

A novel NiTi/AlNi2Ti ternary intermetallic alloy were prepared by arc melting. Tribocorrosion behaviors of the NiTi/AlNi2Ti alloy were investigated by tribocorrosion tests. The results showed that NiTi/AlNi2Ti alloy had an excellent tribocorrosion resistance in NaCl solution and is more suitable as a tribocorrosion resistant material than 1Cr18Ni9Ti stainless steel. With the onset of sliding, the OCP of NiTi/AlNi2Ti alloy decreases and the corrosion current density increases during tribocorrosion test, and the decrease of the OCP is proportional to the increase of the frictional force, showing a strong corrosion-wear synergy effect. The corrosion current density and wear loss volume of the NiTi/AlNi2Ti alloy increase with the increase of applied potentials.

Similar content being viewed by others

REFERENCES

J. Liu, J. Zhang, L. J. Deng, et al., Surf. Eng. 35, 59 (2019).

L. Yuan and H. M. Wang, Electrochim. Acta 54, 421 (2008).

X. D. Du, J. Q. Wang, G. D. Sun, et al., Mater. Sci. Eng. A 477, 277 (2008).

E. Huttunen-Saarivirta, L. Kilpi, T. J. Hakala, et al., Tribol. Int. 95, 358 (2016).

D. D. Liang, X. S. Wei, T. C. Ma, et al., J. Non-Cryst. Solids 510, 62 (2019).

B. Sefer and S. Virtanen, Corros. Sci. 154, 287 (2019).

G. Song, Z. Q. Sun, J. D. Poplawsky, et al., Acta Mater. 127, 1 (2017).

L. J. Zheng, F. X. Zhang, R. G. Ding, et al., Mater. Des. 110, 494 (2016).

A. Dębski, W. Gąsior, A. Sypień, et al., Intermetallics 42, 92 (2013).

Y. Koizumi, Y. Ro, S. Nakazawa, et al., Mater. Sci. Eng. A 223, 36 (1997).

M. Farvizi, T. Ebadzadeh, M. R. Vaezi, et al., Wear 334–335, 35 (2015).

H. R. Sichani, M. Salehi, H. Edris, et al., Surf. Coat. Technol. 309, 959 (2017).

J. C. Schuster, Z. Pan, S. H. Liu, et al., Intermetallics 15, 1257 (2007).

T. Shao, F. F. Ge, Y. Dong, et al., Wear 416–417, 44 (2018).

P. Nash and W. W. Liang, Metall. Trans. A 16, 319 (1985).

F. Pougoum, J. C. Qian, L. Martinu, et al., Surf. Coat. Technol. 357, 774 (2019).

Y. Sun and E. Haruman, Surf. Coat. Technol. 205, 4280 (2011).

Y. Wang, S. L. Jiang, Y. G. Zheng, et al., Corros. Sci. 63, 159 (2012).

L. Liu, Y. Li, and F. H. Wang, J. Mater. Sci. Technol. 26 (1), 1 (2010).

H. H. Hassan, Electrochim. Acta 51, 526 (2005).

L. Liu, Y. Li, and F. H. Wang, Electrochim. Acta 53, 2453 (2008).

M. Fazel, H. R. Salimijazi, and M. Shamanian, ACS Appl. Mater. Interfaces 10, 15281 (2018).

J. Xu, L. L. Liu, P. Munroe, et al., J. Mater. Chem. A 1, 10281 (2013).

L. Yuan and H. M. Wang, Intermetallics 16, 1149 (2008).

Q. Chen, Z. W. Xie, T. Chen, et al., Materials 9, 963 (2016).

P. Močnik, T. Kosec, J. Kovač, et al., Mater. Sci. Eng. C 78, 682 (2017).

ACKNOWLEDGMENTS

This research was supported by the Funded by the “Qizhi” Talent Cultivation Project of Lanzhou Institute of Technology (grant no. 2020QZ-02), Higher Education Innovation Fund Project of Gansu Province of China (grant no. 2021B-314). The authors acknowledge Lei Huang for their assistance on experiments of arc melting.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Zhang, J.X., Liang, B.N. & Guo, X.R. Tribocorrosion Behaviors of NiTi/AlNi2Ti Intermetallic Alloy in NaCl Solution. Russ. J. Phys. Chem. 96, 2894–2899 (2022). https://doi.org/10.1134/S0036024422130271

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024422130271