Abstract

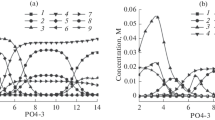

Highly permeable macroporous implants of various architectures for bone grafting have been fabricated by thermal extrusion 3D printing using highly filled β-Ca3(PO4)2/poly(D,L-lactide) (degree of filling up to 70 wt %) and β-Ca3(PO4)2/poly(ε-caprolactone) (degree of filling up to 70 wt %) composite filaments. To modify the surface of the composite macroporous implants with the aim of improving their wettability by saline solutions, we have proposed exposing them to a cathode discharge plasma (2.5 W, air as plasma gas) in combination with subsequent etching in a 0.5 M citric acid solution. It has been shown that the main contribution to changes in the wettability (contact angle) of the composites is made by the changes produced in their surface morphology by etching in a low-temperature plasma and citric acid. An alternative approach to surface modification of the composites is to produce a carbonate hydroxyapatite layer via precipitation from a simulated body fluid solution a factor of 5 supersaturated relative to its natural analog (5xSBF).

Similar content being viewed by others

References

Grover, L.M., Wright, A.J., Gbureck, U., Bolarinwa, A., Song, J., Liu, Y., Farrar, D.F., Howling, G., Rose, J., and Barralet, J.E., The effect of amorphous pyrophosphate on calcium phosphate cement resorption and bone generation, Biomaterials, 2013, vol. 34, no. 28, pp. 6631–6637.

Yang, Y., Yang, S., Wang, Y., Yu, Z., Ao, H., Zhang, H., Qin, L., Guillaume, O., Eglin, D., Richards, R.G., and Tang, T., Anti-infective efficacy, cytocompatibility and biocompatibility of a 3D-printed osteoconductive composite scaffold functionalized with quaternized chitosan, Acta Biomater., 2016, vol. 46, pp. 112–128.

Danilevicius, P., Georgiadi, L., Pateman, Ch.J., Claeyssens, F., Chatzinikolaidou, M., and Farsari, M., The effect of porosity on cell ingrowth into accurately defined, laser-made, polylactide-based 3D scaffolds, Appl. Surf. Sci., 2015, vol. 336, pp. 2–10.

Dhandayuthapani, B., Yoshida, Ya., Maekawa, T., and Kumar, S.D., Polymeric scaffolds in tissue engineering application: a review. Int. J. Polym. Sci., 2011, vol. 2011, pp. 1–19.

Shtil’man, M., Polimery mediko-biologicheskogo naznacheniya (Polymers for Biomedical Applications), Moscow: IKTs Akademkniga, 2006.

Woodruff, M.A. and Hutmacher, D.W., The return of a forgotten polymer—polycaprolactone in the 21st century, Prog. Polym. Sci., 2010, vol. 35, no. 10, pp. 1217–1256.

Pretula, J., Slomkowski, S., and Penczek, S., Polylactides— methods of synthesis and characterization, Adv. Drug Delivery Rev., 2016, vol. 107, pp. 3–16.

Russmueller, G., et al., Tricalcium phosphate-based biocomposites for mandibular bone regeneration—a histological study in sheep, J. Cranio-Maxillofacial Surg., 2015, vol. 43, no. 5, pp. 696–704.

Mayr, H.O., Suedkamp, N.P., Hammer, T., Hein, W., Hube, R., Roth, P.V., and Bernstein, A., β-Tricalcium phosphate for bone replacement: stability and integration in sheep, J. Biomech., 2015, vol. 48, no. 6, pp. 1023–1031.

Jordá-Vilaplana, A., Fombuena, V., García-García, D., Samper, M.D., and Sánchez-Nácher, L., Surface modification of polylactic acid (PLA) by air atmospheric plasma treatment, Eur. Polym. J., 2014, vol. 58, pp. 23–33.

Barrere, F., van Blitterswijk, C.A., de Groot, K., and Layrolle, P., Influence of ionic strength and carbonate on the Ca–P coating formation from SBFx5 solution, Biomaterials, 2002, vol. 23, pp. 1921–1930.

Hofmann, I., Müller, L., Greilc, P., and Müller, F.A., Precipitation of carbonated calcium phosphate powders from a highly supersaturated SBF solution, Key Eng. Mater., 2007, vols. 330–332, pp. 59–62.

Hirotsu, T., Nakayama, K., Tsujisaka, T., Mas, A., and Schue, F., Plasma surface treatments of melt-extruded sheets of poly(L-lactic acid), Polym. Eng. Sci., 2002, vol. 42, pp. 299–306.

Morent, R., De Geyter, N., Desmet, T., Dubruel, P., and Leys, Ch., Plasma surface modification of biodegradable polymers: a review, Plasma Process. Polym., 2011, no. 8, pp. 171–190.

Bolbasov, E.N., Rybachuk, M., Golovkin, A.S., Antonova, L.V., Shesterikov, E.V., Malchikhina, A.I., Novikov, V.A., Anissimov, Y.G., and Tverdokhlebov, S.I., Surface modification of poly(L-lactide) and polycaprolactone bioresorbable polymers using RF plasma discharge with sputter deposition of a hydroxyapatite target, Mater. Lett., 2014, vol. 132, pp. 281–284.

Siparsky, G.L., Degradation kinetics of poly(hydroxy) acids: PLA and PCL, Polymers from Renewable Resources: Biopolyesters and Biocatalysis, ACS Symposium Series, Washington, DC: American Chemical Society, 2000, chapter 16, pp. 230–253.

Evdokimov, P.V., Fadeeva, I.V., Fomin, A.S., Filippov, Ya.Yu., Koval’kov, V.K., Knotko, A.V., Putlyaev, V.I., and Barinov, S.M., Reinforcing a-TCP-based brushite cement with a polylactide scaffold, Materialovedenie, 2017, no. 8, pp. 30–33.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © D.M. Zuev, E.S. Klimashina, P.V. Evdokimov, Ya.Yu. Filippov, V.I. Putlyaev, 2018, published in Neorganicheskie Materialy, 2018, Vol. 54, No. 1, pp. 94–103.

Rights and permissions

About this article

Cite this article

Zuev, D.M., Klimashina, E.S., Evdokimov, P.V. et al. Preparation of β-Ca3(PO4)2/Poly(D,L-lactide) and β-Ca3(PO4)2/Poly(ε-caprolactone) Biocomposite Implants for Bone Substitution. Inorg Mater 54, 87–95 (2018). https://doi.org/10.1134/S002016851801017X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S002016851801017X