Abstract

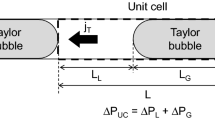

The process of convection and diffusion in a Taylor regime of gas–liquid flow through microchannels is modeled based on a three-layer mass transfer model in the axisymmetric formulation. The circulation circuit of Taylor vortices is described in the form of outer and inner layers surrounded by a thin film that does not participate in circulation. Due to the assumption about the predominance of convection over radial diffusion in the inner layer (the Peclet number order of magnitude is nearly 105) and a uniform concentration distribution over the cross sections of each layer, the problem is confined to a quasi-one-dimensional problem with boundary conditions of special type. The obtained numerical solutions allow us to determine the kinetics of mass transfer from a liquid to a channel wall in detail, calculate the average mass-transfer coefficient, and reveal optima in the dependences of the mass-transfer coefficient on the two-phase flow velocity and the capillary diameter; furthermore, there is also an optimum for the length of a liquid slug. The obtained results allow us to understand the pattern of Taylor convection and diffusion fluxes and to reveal the reasons for a decrease in mass fluxes under nonoptimal conditions. This enables the correction of selected geometric and process parameters during the design of microreactor equipment.

Similar content being viewed by others

References

Dolinskiy, A.A. and Ivanitskii, G.K., Principles for the development of new energy-resources-saving technologies and equipment on the based on methods of discrete pulse energy input, Ind. Heat Eng., 1997, vol. 19, nos. 4-5, p. 13.

Abiev, R.Sh., Teoreticheskie osnovy energo-i resursosberezheniya v khimicheskoi tekhnologii (Theoretical Foundations of Energy and Resource Saving in Chemical Engineering), St. Petersburg: VVM, 2006.

Abiev, R.Sh., Bubbles velocity, Taylor circulation rate and mass transfer model for slug flow in milli and micro channels, Chem. Eng. J., 2013, vol. 229, p. 285.

Kolb, W.B. and Cerro, R.L., Coating the inside of a capillary of square cross section, Chem. Eng. Sci., 1991, vol. 46, p. 2181.

Tsoligkas, A.N., Simmons, M.I.H., Wood, I., and Frost, C.G., Kinetic and selectivity studies of gas–liquid reaction under Taylor flow in a circular capillary, Catal. Today, 2007, vol. 128, p. 36.

Ghaini, A., Mescher, A., and Agar, D.W., Hydrodynamic studies of liquid–liquid slug flows in circular microchannels, Chem. Eng. Sci., 2011, vol. 66, p. 1168.

Thulasidas, T.C., Abraham, M.A., and Cerro, R.L., Flow patterns in liquid slugs during bubble-train flow inside capillaries, Chem. Eng. Sci., 1997, vol. 52, p. 2947.

Burns, I.R. and Ramshaw, C., The intensification of rapid reactions in multiphase systems using slug flow in capillaries, Lab. on a Chip, 2001, vol. 1, p. 10.

Kashid, M.N., Agar, D.W., and Turek, S., CFD modeling of mass transfer with and without chemical reaction in the liquid - liquid slug flow microreactor, Chem. Eng. Sci., 2007, vol. 62, p. 5102.

Harries, N., Burns, I.R., Barrow, D.A., and Ramshaw, C., A numerical model for segmented flow in a microreactor, Int. J. Heat Mass Transfer, 2003, vol. 46, p. 3313.

Thulasidas, T.C., Abraham, M.A., and Cerro, R.L., Bubble-train flow in capillaries of circular and square cross section, Chem. Eng. Sci., 1995, vol. 50, p. 183.

Patankar, S., Numerical Heat Transfer and Fluid Flow, Carlsbad, Calif.: Hemisphere, 1980.

Abiev, R.Sh., Vychislitel’naya gidrodinamika i teplomassoobmen: Vvedenie v metod konechnykh raznostei (Computational Fluid Dynamics and Heat and Mass Transfer: Introduction to the Finite Difference Method), St. Petersburg: NIIKhimii SPBGU, 2002.

Lavretsov, I.V., Abiev, R.Sh., and Krashanina, O.S., Mass transfer from a microchannel wall to a moving liquid or gas–liquid mixture, Izv. S.-Peterburg. Gos. Tekhnol. Inst., 2010, no. 8, p. 64.

Abiev, R.Sh. and Ostrovskii, G.M., Modeling of matter extraction from a capillary porous particle with a bidisperse capillary structure, Theor. Found. Chem. Eng., 2001, vol. 35, p. 254.

Abiev, R.Sh., Simulation of extraction from a capillaryporous particle with bidisperse structure, Russ. J. Appl Chem., 2001, vol. 74, p. 777.

Lykov, A.V., Teplomassoobmen: Spravochnik (Heat and Mass Transfer: A Handbook), Moscow: Energiya, 1972.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.D. Svetlov, R.Sh. Abiev, 2016, published in Teoreticheskie Osnovy Khimicheskoi Tekhnologii, 2016, Vol. 50, No. 6, pp. 694–708.

Rights and permissions

About this article

Cite this article

Svetlov, S.D., Abiev, R.S. Modeling mass transfer in a Taylor flow regime through microchannels using a three-layer model. Theor Found Chem Eng 50, 975–989 (2016). https://doi.org/10.1134/S0040579516060166

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579516060166